Академический Документы

Профессиональный Документы

Культура Документы

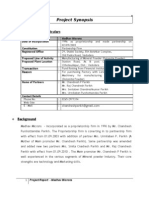

Capital and Manufacturing Cost Estimation

Загружено:

puracsintesesИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Capital and Manufacturing Cost Estimation

Загружено:

puracsintesesАвторское право:

Доступные форматы

Capital and Manufacturing

Cost Estimation

Jim Frederick

CHBE4505A

Summer, 2005

Capital Cost Estimation

Purchased vs. installed cost, etc.

Use simple estimation methods

Cost vs. capacity power law scale-up

Cost factors or equations from equipment

vendors

Cost charts from plant design textbooks, etc.

Cost estimates from web sites

Inflation factors

Cost Estimation Terminology

C

p

= Purchased cost

This is what you pay the vendor for the equipment

C

BM

= Bare module cost

Cost of the equipment plus installation

C

TM

= Total module cost

Cost of addition of equipment or minor expansion

Includes contingency and costs and other fees

C

GR

= total grass-roots cost

Cost of a new mill or major mill expansion

Includes a site development, auxiliary buildings, etc.

Cost vs. Capacity Power Law

Scale-up

Power law equation:

C

p,2

/C

p,1

= (Capacity

2

/Capacity

1

)

n

For process equipment, n is equipment

specific,

range from 0.41 (heat exchangers) to 1.15

(jaw crushers)

For an entire plant, use n = 0.6

C

GR,2

/C

GR,1

= (Capacity

2

/Capacity

1

)

0.6

Materials

Selection

Factors:

Temperature

Chemical

Environment

Pressure

Stress-temperature relationships for important metals and alloys. (Source:

Ulrich, 1984)

Temperature,

o

C

A

l

l

o

w

a

b

l

e

t

e

n

s

i

l

e

s

t

r

e

s

s

,

b

a

r

Cost Factors or Equations From

Equipment Vendors

Cost factors (apply for a narrow size range)

Installed cost for black liquor evaporators:

$60/ft

2

heat transfer area

Installed cost for kraft recovery boilers: $11 to

$13 per lb BL solids/day

Cost equations (apply over a wider size range)

Example of a Cost Equation (1/2)

A. Cost equations:

For effects in a multiple-effect evaporator operating with black

liquor above 30% solids content and/or at pressures above 1

atm,

C

BM

= $1,770 A

0.55

For evaporator effects operating with black liquor at or below

30% solids content and/or at pressures at or below 1 atm,

C

BM

= $830 A

0.55

Note: in both correlations, where A = heat transfer area, ft

2

Example of a Cost Equation (2/2)

B. Size limitations:

The largest dimple plate, falling film evaporator unit in the

world:

evaporates 2.2x10

6

pounds of water per hour,

contains 628,000 ft

2

of heat transfer area (~147,000 ft

2

per effect for the 6-effect train)

The 6

th

effect is 34 ft in diameter

Be aware of min and max equipment sizes in normal

design practice

Cost Estimation Charts

Based on data from many plants

Procedure

estimate C

p,cs

for equipment constructed from

carbon steel, and to operate at or only slightly

above one bar

Determine the factors for materials other than

carbon steel, pressure, etc.

Calculate C

BM

from C

p,cs

and these factors

Each chart has a specific equation for C

BM

= f(C

p,cs

)

Max

size

Min

size

From C

p

to C

TM

1. Account for inflation

Use the ratio of the Chemical Engineering Plan Cost

Index (CE Index) for the year of purchase and the year

on which the purchased cost estimation is based, i.e.

C

BM,2006

= C

BM,1978

(CE Index

2006

/CE Index

1978

)

Account for cost of installation, etc.

Add contingency + fee = 0.18 F

BM

Simplest: use Lang factor: f

Lang

= C

TM

/C

p

f

Lang

= 4.5 for chemical plants, 3.2 for solids processing

plants, and 2.5 for P&P mills

Вам также может понравиться

- Alumina Manufacturing ProcessesДокумент7 страницAlumina Manufacturing Processesm_hassanaliОценок пока нет

- Poly Lactic Acid Plant CostДокумент2 страницыPoly Lactic Acid Plant CostIntratec SolutionsОценок пока нет

- Environmental and Economic Analysis of Emerging Plastics Conversion TechnologiesДокумент70 страницEnvironmental and Economic Analysis of Emerging Plastics Conversion TechnologiesHenry JeyssonОценок пока нет

- Decanter TheoryДокумент20 страницDecanter Theorypuracsinteses100% (1)

- PRS - Biomass Energy Technology Experience in RuralДокумент78 страницPRS - Biomass Energy Technology Experience in RuralPrajwal Raj ShakyaОценок пока нет

- Nice EthanolДокумент187 страницNice Ethanolniyi206Оценок пока нет

- CH 13 Cost EstimationДокумент6 страницCH 13 Cost EstimationwetcoОценок пока нет

- CH-4 Plant Location & LayoutДокумент10 страницCH-4 Plant Location & LayoutShivam PanchalОценок пока нет

- Tk14 Revised Assignment1Документ74 страницыTk14 Revised Assignment1Grano PrabumuktiОценок пока нет

- Energy Conservation For Pulp and Paper IndustryДокумент13 страницEnergy Conservation For Pulp and Paper IndustryNicole PalomaresОценок пока нет

- Game Rules 2012Документ19 страницGame Rules 2012hiknikОценок пока нет

- Chapter One: 1 Bio-Oil Plant DesignДокумент55 страницChapter One: 1 Bio-Oil Plant DesignJomed Barallas100% (1)

- Mass BalanceДокумент9 страницMass Balancerr1819Оценок пока нет

- Foodwaste DigesterДокумент18 страницFoodwaste DigesterDhidik 近江 KiraОценок пока нет

- Fuel From FarmДокумент168 страницFuel From FarmKUKU100% (1)

- Design Hydrothermal Carbonization of Biomass Waste by Using A Stirred Reactor UndipДокумент6 страницDesign Hydrothermal Carbonization of Biomass Waste by Using A Stirred Reactor Undipraymond tambunanОценок пока нет

- Plant Design of Acetone ProductionДокумент20 страницPlant Design of Acetone ProductionMary Grace VelitarioОценок пока нет

- Material and Energy BalanceДокумент9 страницMaterial and Energy BalanceSana100% (1)

- Diborane: Click To Edit Master Subtitle StyleДокумент36 страницDiborane: Click To Edit Master Subtitle StyleSaumya GoelОценок пока нет

- Ethanol From Sugar Beets - A Process and Economic AnalysisДокумент143 страницыEthanol From Sugar Beets - A Process and Economic Analysisgigi7980Оценок пока нет

- Production of BioethanolДокумент27 страницProduction of BioethanolRavin KumarОценок пока нет

- Renewable Energy Planning GuidanceДокумент42 страницыRenewable Energy Planning GuidanceEdgar Velastegui GonzálezОценок пока нет

- Sulfuric 2520acid - Plant 2520Location&LayoutДокумент6 страницSulfuric 2520acid - Plant 2520Location&Layoutramnath-subramanian-1932Оценок пока нет

- Economics of ABS Production ProcessesДокумент4 страницыEconomics of ABS Production ProcessesfdfОценок пока нет

- Waste Water Treatment in Chemical IndustriesДокумент23 страницыWaste Water Treatment in Chemical IndustriesAzman Bin KadirОценок пока нет

- Thesis 6Документ48 страницThesis 6manoj100% (1)

- Feasibility Study of Lactic Acid ProductionДокумент4 страницыFeasibility Study of Lactic Acid ProductionIntratec SolutionsОценок пока нет

- Niir Manufacture Value Added Products From Rice Husk Hull Rice Husk Ash Rha 2nd Revised EditionДокумент7 страницNiir Manufacture Value Added Products From Rice Husk Hull Rice Husk Ash Rha 2nd Revised EditionShivam DangОценок пока нет

- Estimation of Offshore Brazilian Natural Gas Break-Even PricesДокумент10 страницEstimation of Offshore Brazilian Natural Gas Break-Even PricesMarcelo Varejão CasarinОценок пока нет

- Chapter 5 - Equipment Sizing and CostingДокумент21 страницаChapter 5 - Equipment Sizing and CostingHaiqal AzizОценок пока нет

- Advances in Biochemical Engineering Biotechnology 066 - Bioanalysis and Biosensors For Bioprocess MonitoringДокумент236 страницAdvances in Biochemical Engineering Biotechnology 066 - Bioanalysis and Biosensors For Bioprocess MonitoringGhaier KazmiОценок пока нет

- Site Selection and Plant LayoutДокумент12 страницSite Selection and Plant LayoutNaman SinhaОценок пока нет

- Direct-Thermochemical-Liquefaction Commercialization OverviewДокумент28 страницDirect-Thermochemical-Liquefaction Commercialization OverviewJairoVidalОценок пока нет

- Biomass - Power PlantДокумент16 страницBiomass - Power PlantVinay MishraОценок пока нет

- Bioreactors - Classification and TypesДокумент6 страницBioreactors - Classification and TypesKavisa Ghosh100% (1)

- Chapter 2.4 Facility LocationДокумент48 страницChapter 2.4 Facility LocationBetiglu WaghawОценок пока нет

- Bioethanol Production NotesДокумент42 страницыBioethanol Production NotesJhanvi SharmaОценок пока нет

- Economic Cost Analysis of Biodiesel Production: Case in Soybean OilДокумент8 страницEconomic Cost Analysis of Biodiesel Production: Case in Soybean OilshresthaanshuОценок пока нет

- Cement IndustryДокумент8 страницCement IndustryAnusha NeupaneОценок пока нет

- Hydrolysis of Lignocellulosic Materials For Ethanol ProductionДокумент56 страницHydrolysis of Lignocellulosic Materials For Ethanol Productionajali1957Оценок пока нет

- A Review: Biogas Production From Bakery WasteДокумент5 страницA Review: Biogas Production From Bakery WasteEditor IJTSRDОценок пока нет

- MBR OPEX - The Theory of Running CostsДокумент6 страницMBR OPEX - The Theory of Running CostsJeremy DudleyОценок пока нет

- Simulation Bio Ethanol Production - FinalДокумент10 страницSimulation Bio Ethanol Production - FinalJoseph McMullen100% (1)

- Methyl Alcohol Plant CostДокумент3 страницыMethyl Alcohol Plant CostIntratec SolutionsОценок пока нет

- Techno-Economic Modelling and Cost Functions of CO Capture ProcessesДокумент11 страницTechno-Economic Modelling and Cost Functions of CO Capture ProcessesAlex MarkОценок пока нет

- Chapter 3Документ14 страницChapter 3Larry Jampong100% (1)

- PNS BAFPS 22 2007 - Virgin Coconut OilДокумент8 страницPNS BAFPS 22 2007 - Virgin Coconut OilmaelizeОценок пока нет

- Power Generation Using Fast Pyrolysis Liquids From BiomassДокумент31 страницаPower Generation Using Fast Pyrolysis Liquids From BiomassPrakash SothivadivelОценок пока нет

- The Thermochemical Pathway: A Sustainable and Competitive Waste Diversion SolutionДокумент15 страницThe Thermochemical Pathway: A Sustainable and Competitive Waste Diversion SolutionDouGPhillips999100% (1)

- The Chemical IndustryДокумент45 страницThe Chemical IndustryYantiОценок пока нет

- Calorimetryand Coffee CupsДокумент8 страницCalorimetryand Coffee CupsDana Georgiana CrivoiОценок пока нет

- Optimization of Biogas Generation From Press Mud in Batch ReactorДокумент6 страницOptimization of Biogas Generation From Press Mud in Batch Reactorscm996Оценок пока нет

- Haldia Refinery Project Appraisal ReportДокумент43 страницыHaldia Refinery Project Appraisal Reportaravind_k104Оценок пока нет

- Techno-Economic Assessment About PropyleneДокумент6 страницTechno-Economic Assessment About PropyleneIntratec SolutionsОценок пока нет

- Butanol Production Using EthanolДокумент19 страницButanol Production Using EthanolmdmaznОценок пока нет

- Industrial Symbiosis LectureДокумент42 страницыIndustrial Symbiosis LectureTitanidesОценок пока нет

- Final Ip TolueneДокумент110 страницFinal Ip TolueneShazleen Sharfadeen100% (1)

- Global Bioethanol: Evolution, Risks, and UncertaintiesОт EverandGlobal Bioethanol: Evolution, Risks, and UncertaintiesSergio Luiz Monteiro Salles-FilhoОценок пока нет

- Pretreatment of Biomass: Processes and TechnologiesОт EverandPretreatment of Biomass: Processes and TechnologiesРейтинг: 5 из 5 звезд5/5 (1)

- Weighfeeders For Bulk Solids PDFДокумент9 страницWeighfeeders For Bulk Solids PDFpuracsintesesОценок пока нет

- Activated Sludge Microbiology Problems and Their ControlДокумент21 страницаActivated Sludge Microbiology Problems and Their ControlDaniel Pérez100% (1)

- Explosion Prevention in Grain Handling FacilitiesДокумент77 страницExplosion Prevention in Grain Handling FacilitiespuracsintesesОценок пока нет

- Class of Cost Estimates 10.1.6Документ17 страницClass of Cost Estimates 10.1.6mfcramerОценок пока нет

- Ejector Maintenance PDFДокумент18 страницEjector Maintenance PDFpuracsintesesОценок пока нет

- Improved Steam Condenser Gas Removal SystemДокумент7 страницImproved Steam Condenser Gas Removal Systemtfernandes.x18Оценок пока нет

- Sludge HandlingДокумент26 страницSludge HandlingpuracsintesesОценок пока нет

- Ejector PrincipleДокумент13 страницEjector Principlekhoshya7100% (1)

- Pressure Control For Vacuum SystemsДокумент4 страницыPressure Control For Vacuum SystemsnasirmuzaffarОценок пока нет

- Filtration of SuspensionsДокумент11 страницFiltration of SuspensionspuracsintesesОценок пока нет

- A Review of Lime SlakersДокумент18 страницA Review of Lime SlakerspuracsintesesОценок пока нет

- Selective Laser Sintering Technology For Customized Fabrication of Facial Prostheses Cristian.Документ8 страницSelective Laser Sintering Technology For Customized Fabrication of Facial Prostheses Cristian.Botoc BeatriceОценок пока нет

- Grid-Lign Fl4011 1209 WebДокумент2 страницыGrid-Lign Fl4011 1209 WebRenzo Jo LaurentОценок пока нет

- Webers Least Cost TheoryДокумент4 страницыWebers Least Cost Theoryapi-314084641Оценок пока нет

- ElectropolishingДокумент4 страницыElectropolishinggopinath_rgsОценок пока нет

- Supply Chain Strategies and PracticesДокумент37 страницSupply Chain Strategies and PracticesGreeshma100% (1)

- Posco WirerodДокумент17 страницPosco WirerodNina LazuardiОценок пока нет

- Reinforcement: Industrial Training Report Tudawe Brothers LimitedДокумент8 страницReinforcement: Industrial Training Report Tudawe Brothers Limitedymanfas100% (1)

- PT Semen Cibinong - Kiln Refractory LiningДокумент4 страницыPT Semen Cibinong - Kiln Refractory LiningAbdul SabirОценок пока нет

- Seting of CementДокумент11 страницSeting of CementSaloni Mishra77% (13)

- DS482Документ3 страницыDS482mariomatoОценок пока нет

- Logistics Driven Packaging Innovation AДокумент22 страницыLogistics Driven Packaging Innovation ASugaОценок пока нет

- K60-HSS Install GuideДокумент2 страницыK60-HSS Install GuidedakidofdaboomОценок пока нет

- Proposed Quality Control PlanДокумент3 страницыProposed Quality Control PlanMohamad Rafik50% (2)

- Metrode E2209 (B-60) ElectrodeДокумент6 страницMetrode E2209 (B-60) ElectrodeClaudia MmsОценок пока нет

- Project ReportДокумент14 страницProject Reportjignesh51100% (1)

- Airex C51: Industrial Processing FoamДокумент3 страницыAirex C51: Industrial Processing FoamCrizzti Nuara PbОценок пока нет

- Technology For Spiral Face Gears: MeasurementsДокумент60 страницTechnology For Spiral Face Gears: MeasurementsignaciomarinОценок пока нет

- ASTM A510 03-Astm-Standardspecivication-1 PDFДокумент7 страницASTM A510 03-Astm-Standardspecivication-1 PDFNina LazuardiОценок пока нет

- FMEA Preparation GuideДокумент0 страницFMEA Preparation GuidedrustagiОценок пока нет

- Material HandlingДокумент55 страницMaterial HandlingNishaThakuri100% (2)

- Cavi FlexДокумент11 страницCavi FlexCandace BlackburnОценок пока нет

- Primary Wastewater TreatmentДокумент12 страницPrimary Wastewater TreatmentJAY4029364Оценок пока нет

- Offshore StructuresДокумент50 страницOffshore StructuresSreeraja SreevilasanОценок пока нет

- Chapter 1 MPRДокумент14 страницChapter 1 MPRNeeraj DwivediОценок пока нет

- (RMD™) MIG Welding ProcessДокумент5 страниц(RMD™) MIG Welding ProcessPradip GoswamiОценок пока нет

- 06.6.1 Adcrete PDFДокумент1 страница06.6.1 Adcrete PDFkunalscribduomОценок пока нет

- Milling Machine SpecificationsДокумент17 страницMilling Machine SpecificationsParas GoelОценок пока нет

- Universiti Utara Malaysia College of BusinessДокумент5 страницUniversiti Utara Malaysia College of Businesspriyaa03Оценок пока нет

- Ruukki Splicing of Steel Piles by WeldingДокумент8 страницRuukki Splicing of Steel Piles by Weldingyanickdouce1206100% (1)