Академический Документы

Профессиональный Документы

Культура Документы

10-14. Welding Process

Загружено:

JithuJohnАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

10-14. Welding Process

Загружено:

JithuJohnАвторское право:

Доступные форматы

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

TWI

CSWIP 3.2

WIS 10

SENIOR WELDING INSPECTION

WELDING PROCESS

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

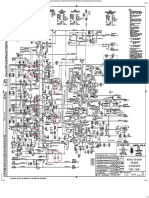

Welding process chart

Fusion welding

Pressure

welding

MMA TIG MIG/MAG

/FCAW

SAW

EBW LBW

Arc

welding

Power

beam

welding

Oxy fuel

welding

Electroslag

welding

Thermit

welding

Resistance

welding

Solid state

welding

PAW

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MMA - Principle of operation

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

ARC CHARACTERISTICS

Volts

Amps

OCV

Constant Current/Amperage Characteristic

Large change in voltage =

Smaller change in amperage

Welding Voltage

Large arc gap

Small arc

gap

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MMA welding

Shielding provided by decomposition of flux

covering

Electrode consumable

Manual process

Welder controls

Main features

Arc length

Angle of electrode

Speed of travel

Amperage settings

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MMA welding power source

Transformers AC only

Transformer/Rectifiers AC and DC

Petrol or Diesel driven Generators Site work DC

Inverters AC and DC

TYPES:-

Input 240v (single phase) or

415v ( 2 live phases of 3 phase supply)

Output AC (O.C.V. 80v) or DC (O.C.V. 50v) or both.

AC for Shop

DC for site work as it is SAFER (lower OCV). Also for

shop work..

Current adjustment control

POWER

SOURCE:-

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Equipment for MMA welding

Safety visor

(with dark lens)

Electrode oven

Power return

cable

Power source.

Transformer/

Rectifier

Heated quiver

Inverter

power source

Power cable

Power control

panel

Electrodes

Electrode

holder

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MMA electrodes - type of covering

Acid

covering

Cellulosic

covering

contains oxides and silicates high O

2

content low UTS weld

smooth profile with tendency to

concavity

slag easy to detach

limited usability

contains organic material no

backing/drying allowed

generates high level of fumes and H

2

cold cracking

thin slag layer, poor appearance

increased penetration

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MMA electrodes - type of covering

Rutile

covering

Basic

covering

contains TiO

2

stable, easy-to-use arc can operate in

both DC and AC

slag easy to detach, smooth profile

good strength weld metal

can be dried to lower H

2

content

contains CaF

2

and CaCO

3

requires backing to keep H

2

low

very good mechanical properties

difficult to detach slag

produce convex weld profile

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

3) Porosity

1) Slag inclusions

2) Arc strikes

4) Undercut

Most welding defects in MMA are caused by a lack

of welder skill (not an easily controlled process),

the incorrect settings of the equipment, or the

incorrect use, and treatment of electrodes

5) Shape defects (overlap, excessive root

penetration, etc.)

MMA welding typical defects

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Advantages:

1) Field or shop use

2) Range of consumables

3) All positional

4) Very portable

5) Simple equipment

Disadvantages:

1) High skill factor

2) Slag inclusions

3) Low operating factor

4) High level of fume

5) Hydrogen control

MMA advantages/disadvantages

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

TIG - Principle of operation

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Sizes/types vary depending on current/application TORCH

To deliver correct gas flow (velocity) depending on

welding position and joint configuration.

FLOWMETER

(graduated in ltr/min)

Correct type for application.(ar, he, ar/he mixture)

Argon/hydrogen for austenitic stainless steel

INERT GAS SUPPLY

(Cylinder & regulator)

Note that current actually flows from this lead RETURN LEAD

Flexible may carry current, gas, cooling water. TORCH HOSE

Transformers for AC aluminium alloys

Rectifiers for DC - steels

Transformer/rectifier for AC/DC

Inverters for AC/DC more portable - expensive

POWER SOURCE

440v 50Hz 3 phase or

240v single phase

input

TIG power source

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Inverter

power source

Power cable

Flow-meter

Power

control panel

Transformer

/ Rectifier

Power

control panel

Power return

cable

Torch

assemblies

Tungsten

electrodes

Equipment for TIG

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

TIG torch

Ceramic

shield cup

Gas lens

Torch body

Tungsten

electrodes

Spare ceramic

shielding cup

Gas diffuser

Split collet

Fitted ceramic

shielding cup

Tungsten

housing

On/Off switch

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Most welding defects with TIG are caused by a lack of

welder skill, or incorrect setting of the equipment. i.e.

current, torch manipulation, welding speed, gas flow

rate, etc.

1) Tungsten inclusions (low skill or wrong vertex angle)

2) Surface porosity (loss of gas shield mainly on site)

3) Crater pipes (bad weld finish technique i.e. slope out)

4) Oxidation of S/S weld bead, or root by poor gas cover

5) Root concavity (excess purge pressure in pipe)

6) Lack of penetration/fusion (widely on root runs)

TIG typical defects

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Advantages:

1) High quality

2) Good control

3) All positional

4) Lowest H

2

arc

process

5) No slag

Disadvantages:

1) Very high skill factor

2) Range of consumable

3) Loss of gas shield/site

4) Complex equipment

5) High ozone levels

TIG advantages/disadvantages

6) Low Output

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MIG/MAG - Principle of operation

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

ARC CHARACTERISTICS

Volts

Amps

OCV

Constant Voltage Characteristic

Small change in voltage =

large change in amperage

The self

adjusting arc.

Large arc gap

Small arc gap

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Power return

cable

Transformer

/ Rectifier

Power cable

& hose

assembly

Liner for wire

Welding gun

assembly

External wire

feed unit

Power control

panel

Internal wire

feed system

15kg wire spool

Equipment for MIG/MAG

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Plain top roller

Half grooved

bottom roller

Wire guide

Internal wire

drive system

MIG/MAG wire drive system

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Torch body

Contact tips

Spot welding

spacer

Gas diffuser

Nozzles or

shrouds

Torch head assembly

(less nozzle)

On/Off switch

Hose

port

MIG/MAG torch head assembly

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MIG/MAG-methods of metal transfer

Dip transfer

Transfer occur due to short circuits

between wire and weld pool, high

level of spatter, need inductance

control to limit current raise

Can use pure CO

2

or Ar- CO

2

mixtures as shielding gas

Metal transfer occur when arc is

extinguished

Requires low welding current/arc voltage, a low

heat input process. Resulting in low residual

stress and distortion

Used for thin materials and all position welds

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MIG/MAG-methods of metal transfer

Spray transfer

Transfer occur due to pinch effect

NO contact between wire and weld

pool!

Requires argon-rich shielding gas

Metal transfer occur in small

droplets, a large volume weld pool

Requires high welding current/arc voltage, a

high heat input process. Resulting in high

residual stress and distortion

Used for thick materials and flat/horizontal

position welds

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MIG/MAG-methods of metal transfer

Globular transfer

Transfer occur due to gravity or

short circuits between drops and

weld pool

Requires CO

2

shielding gas

Metal transfer occur in large drops

(diameter larger than that of

electrode) hence severe spatter

Requires high welding current/arc voltage, a

high heat input process. Resulting in high

residual stress and distortion

Non desired mode of transfer!

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

MIG/MAG-methods of metal transfer

Pulsed transfer

Controlled metal transfer, one

droplet per pulse, NO transfer

between droplet and weld pool!

Requires special power sources

Metal transfer occur in small

droplets (diameter equal to that

of electrode)

Requires moderate welding current/arc voltage, a

reduced heat input . Resulting in smaller residual

stress and distortion compared to spray transfer

Pulse frequency controls the volume of weld pool,

used for root runs and out of position welds

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

3) Porosity (from loss of gas shield on site etc)

1) Silica inclusions (in Fe steels) due to poor

inter-run cleaning

2) Lack of fusion (primarily with dip transfer)

Most welding imperfections in MIG/MAG are caused by lack of

welder skill, or incorrect settings of the equipment

The use of low quality wires will cause wire feed problems

Worn contact tips will cause poor power pick up, or transfer

Bad power connections will cause a loss of voltage in the arc

4) Solidification problems (cracking, centerline

pipes, crater pipes) especially on deep

narrow welds

MIG/MAG typical defects

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Disadvantages:

Advantages:

1) Lower skill required

2) Easily automated

3) All positional Dip &

Pulse

4) Thick/thin materials

5) Continuous electrode

1) Lack of sidewall fusion

2) Range of consumables

3) Loss of gas shield/site

4) Complex equipment

5) High ozone levels

MIG/MAG advantages/disadvantages

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Flux cored arc welding

FCAW

methods

With gas

shielding -

Outershield

Without gas

shielding -

Innershield

With metal

powder -

Metal core

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Outershield - principle of operation

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Innershield - principle of operation

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

FCAW - differences from MIG/MAG

usually operates

in DCEP but some

Innershield

wires operates in

DCEN

doesn't work in

dip transfer mode

require knurled

feed rolls

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Advantages:

1) Field or shop use

2) High productivity

3) All positional

4) Slag supports and

shapes the weld Bead

5) No need for shielding

gas

Disadvantages:

1) High skill factor

2) Slag inclusions

3) Cored wire is

Expensive

4) High level of fume

(Innershield)

5) Limited to steels and

nickel alloys

FCAW advantages/disadvantages

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW - Principle of operation

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Principles of operation

Factors that determine whether to use SAW

chemical composition and mechanical

properties required for the weld deposit

thickness of base metal to be welded

joint accessibility

position in which the weld is to be made

frequency or volume of welding to be

performed

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Principles of operation

SAW methods

semiautomatic - for relatively small

diameter electrodes and moderate travel

speed

mechanised - the majority of applications

automatic - for mass production (e.g.

pipes)

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Advantages of SAW

high current density, high deposition rates (up to 10 times

those for MMA), high productivity

deep penetration allowing the use of small welding grooves

fast travel speed, less distortion

deslagging is easier

uniform bead appearance with good surface finish and good

fatigue properties

can be easily performed mechanised, giving a higher duty cycle

and low skill level required

provide consistent quality when performed automatic or

mechanised

Virtually assured radiographically sound welds

arc is not visible

little smoke/fumes are developed

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Disadvantages of SAW

limited mainly to flat/horizontal position

limited to carbon, low alloy, creep resisting, stainless steels

and nickel alloys

due to the high heat input, impact strength of weld metal/HAZ

may be low; also high dilution

slag must be cleared away after welding due to the danger of

slag inclusions

need flux storage, handling and recirculation control

difficult to apply on-site due to complicated equipment

high capital costs

weld line must be regular (straight or circumferential seams

only) with accurate fit-up

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW filler material

Welding wires can be used to weld:

carbon steels

low alloy steels

creep resisting steels

stainless steels

nickel-base alloys

special alloys for surfacing applications

Welding wires can be:

solid wires

metal-cored wires

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW FLUXES

Fused:

Baked at high temperature, glossy,hard and

black in colour, cannot add ferro-manganese,

non moisture absorbent and tends to be of the

acidic type

Agglomerated:

Baked at a lower temperature, dull, irregularly

shaped, friable, (easily crushed) can easily add

alloying elements, moisture absorbent and tend

to be of the basic type

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW FLUXES

Agglomerated SAW Flux

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW FLUXES

Fused SAW Flux

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

SAW

Which settings do you think are incorrect

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

PAW - Principle of operation

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

PAW features

operates on DCEN

can be used for welding, spraying and

cutting

Modes of

operation

Microplasma Plasma Microplasma

Plasma arc

modes

Non-

transferred arc

Transferred arc

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Advantages:

1) High energy

concentration

2) High arc stability

3) Can cut stainless

steels & aluminum

PAW advantages/disadvantages

Disadvantages:

1) High skill factor

2) Little tolerance for

joint misalignment

4) High level of UV/IR

radiation, fumes

5) Torch is heavy and

bulky

3) Expensive equipment

4) Wide range of

materials/thickness

5) No danger of

tungsten inclusions

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

OAW - Principle of operation

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Welding flame types

Carburising flame

Neutral flame

Oxidising flame

welding of Al and

high C steels

hardfacing with

Cr and W carbide

welding of most

materials

brazing

welding of bronze

and brasses

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

OAW advantages/disadvantages

Advantages:

1) No need for power

supply

2) Low equipment cost

3) Can cut carbon and

low alloy steels

Disadvantages:

1) High skill factor

2) Wide HAZ

4) Slow process

5) Limited range of

consumables

3) Safety issues

4) Good on thin

materials

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

Choosing welding process

Application characteristics:

Other factors to be considered:

Availability and fitness for service

Skill requirements

Parent material(s) weldability

Availability of consumables

Joint design and welding position

Heat input requirements

Quality requirements

Productivity

Health and safety issues

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Painting Inspection Procedure PDFДокумент1 страницаPainting Inspection Procedure PDFPhạm Văn Đảng67% (3)

- ASTM E 165 - 2012 (Standard Practice For Liquid Penetrant Examination For General Industry) - 2012Документ18 страницASTM E 165 - 2012 (Standard Practice For Liquid Penetrant Examination For General Industry) - 2012omar quiñonesОценок пока нет

- Pressure Vessel Exm QuestionsДокумент4 страницыPressure Vessel Exm QuestionsJithuJohn100% (1)

- General Questions4Документ31 страницаGeneral Questions4JithuJohnОценок пока нет

- General Questions4Документ31 страницаGeneral Questions4JithuJohnОценок пока нет

- General Questions4Документ31 страницаGeneral Questions4JithuJohnОценок пока нет

- General Questions4Документ31 страницаGeneral Questions4JithuJohnОценок пока нет

- Heat Exchanger-Design and ConstructionДокумент46 страницHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Heat Exchanger-Design and ConstructionДокумент46 страницHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Aircraft Hangar Lighting Fixture ScheduleДокумент10 страницAircraft Hangar Lighting Fixture ScheduleWaleed Abd El-HamiedОценок пока нет

- Ageing Phenomena of CelluloseДокумент9 страницAgeing Phenomena of CellulosedchyОценок пока нет

- Polymer Additives and PlasticizersДокумент25 страницPolymer Additives and PlasticizersDeva Raj100% (1)

- Material With Electrode SelectionДокумент2 страницыMaterial With Electrode SelectionJithuJohn100% (3)

- 2011 Exam GeotechnicalДокумент9 страниц2011 Exam GeotechnicalAhmed AwadallaОценок пока нет

- Aramco vendor inspection for line pipe API standardsДокумент3 страницыAramco vendor inspection for line pipe API standardsJithuJohnОценок пока нет

- 21a1004 02Документ1 страница21a1004 02JithuJohnОценок пока нет

- 2015 Rev-Ect Feb 17 ListДокумент7 страниц2015 Rev-Ect Feb 17 ListJithuJohnОценок пока нет

- 2015 Rev-Ect Feb 17 ListДокумент7 страниц2015 Rev-Ect Feb 17 ListJithuJohnОценок пока нет

- Aramco QuestionДокумент72 страницыAramco QuestionZuberYousuf100% (1)

- Hy Are Jews So SmartДокумент2 страницыHy Are Jews So SmartJithuJohnОценок пока нет

- Resume Ofjithu John (API, CSWIP & ASNT)Документ6 страницResume Ofjithu John (API, CSWIP & ASNT)JithuJohnОценок пока нет

- Canada RN CCNДокумент1 страницаCanada RN CCNJithuJohnОценок пока нет

- Canada RN CCNДокумент1 страницаCanada RN CCNJithuJohnОценок пока нет

- Aramco QuestionДокумент72 страницыAramco QuestionZuberYousuf100% (1)

- Hy Are Jews So SmartДокумент2 страницыHy Are Jews So SmartJithuJohnОценок пока нет

- 1-3 Email Nurse - Role PlayДокумент2 страницы1-3 Email Nurse - Role PlayJithuJohnОценок пока нет

- Welding AnswersДокумент4 страницыWelding AnswersJithuJohnОценок пока нет

- RGUHS MSc Nursing Exam Fee Notification April 2016Документ7 страницRGUHS MSc Nursing Exam Fee Notification April 2016JithuJohnОценок пока нет

- OET Test 3 Listening Answers - Part A and BДокумент6 страницOET Test 3 Listening Answers - Part A and BJithuJohn100% (1)

- QAДокумент3 страницыQAJithuJohnОценок пока нет

- Pumps API 610Документ2 страницыPumps API 610JithuJohnОценок пока нет

- CopyДокумент2 страницыCopyJithuJohnОценок пока нет

- Ut Q 5Документ4 страницыUt Q 5JithuJohnОценок пока нет

- Resume Ofjithu John (API, CSWIP & ASNT)Документ6 страницResume Ofjithu John (API, CSWIP & ASNT)JithuJohnОценок пока нет

- Basic 4 QДокумент8 страницBasic 4 QJithuJohnОценок пока нет

- Mpi Q-2Документ3 страницыMpi Q-2JithuJohnОценок пока нет

- Rizvi New Unit Shed-3 - 68'X111'Документ7 страницRizvi New Unit Shed-3 - 68'X111'shohugОценок пока нет

- Cold Drink AnalysisДокумент20 страницCold Drink AnalysisthatkotlinkidОценок пока нет

- Monday 20 May 2019: ChemistryДокумент24 страницыMonday 20 May 2019: Chemistrymostafa barakat75% (4)

- Water Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaДокумент8 страницWater Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaVijay PanchalОценок пока нет

- Electric Water Heaters GuideДокумент36 страницElectric Water Heaters GuidearshadОценок пока нет

- Experimental Characterization of Al-Cu Thermal Contact ResistanceДокумент20 страницExperimental Characterization of Al-Cu Thermal Contact Resistancenozue.tatsuhiro nozueОценок пока нет

- Eng Chem Lecture NotesДокумент2 страницыEng Chem Lecture NotesJunell TadinaОценок пока нет

- Product Environmental Profile: 3 TH110 Wireless Thermal Sensor - Self Powered + 3 Energy Harvesting & Fixing KitsДокумент6 страницProduct Environmental Profile: 3 TH110 Wireless Thermal Sensor - Self Powered + 3 Energy Harvesting & Fixing KitsHà Huy TấnОценок пока нет

- Mud ArchitectureДокумент61 страницаMud ArchitectureAshok Nene100% (1)

- Whiting (CalciumCarbonate) MSDSДокумент6 страницWhiting (CalciumCarbonate) MSDSrinda_indaОценок пока нет

- Water Pitcher Filter EN: MODELS: Time, Agate, Amethyst, Orion, Jasper, Compact, Onyx Operating ManualДокумент2 страницыWater Pitcher Filter EN: MODELS: Time, Agate, Amethyst, Orion, Jasper, Compact, Onyx Operating ManualMstefОценок пока нет

- (VESBO) Catalog enДокумент62 страницы(VESBO) Catalog enGhembel Lord100% (1)

- P Block Elements DPP 07 Extra DPP Yakeen 20 2023 PW StarДокумент3 страницыP Block Elements DPP 07 Extra DPP Yakeen 20 2023 PW StarAgnibha MaitiОценок пока нет

- Cdit157x01ph5p2 Jee Advanced 040616Документ8 страницCdit157x01ph5p2 Jee Advanced 040616Fc HeroОценок пока нет

- Advanced Silicide Based Materials - MoSi2Документ13 страницAdvanced Silicide Based Materials - MoSi2chandravadiyaketanОценок пока нет

- Fire Retardant Spray ComparisonДокумент11 страницFire Retardant Spray Comparisonsteve4goshel100% (1)

- Thesis On Soap MakingДокумент7 страницThesis On Soap Makingdwrxjhgr100% (1)

- Beseva Group Product Listing for Bleaching, Dyeing, Finishing and Printing ChemicalsДокумент9 страницBeseva Group Product Listing for Bleaching, Dyeing, Finishing and Printing ChemicalsNoumanKhanОценок пока нет

- Bulletin ASTM C 920Документ1 страницаBulletin ASTM C 920carlosОценок пока нет

- Furadur Kittloesung 20120416 en SD 91070119 PDFДокумент9 страницFuradur Kittloesung 20120416 en SD 91070119 PDFBarbara Andreina Sanchez AmayaОценок пока нет

- Enhanced Oil Recovery (EOR) - Schlumberger GlossaryДокумент66 страницEnhanced Oil Recovery (EOR) - Schlumberger GlossaryDiana La CruzОценок пока нет

- Important MCQ on VLSI Design Logic Gates and CMOS TechnologyДокумент4 страницыImportant MCQ on VLSI Design Logic Gates and CMOS TechnologyAkanksha DixitОценок пока нет

- Refinery Presentation On 07th July 07Документ83 страницыRefinery Presentation On 07th July 07meenuОценок пока нет

- Heavy MetalsДокумент4 страницыHeavy MetalsGeorona KAОценок пока нет