Академический Документы

Профессиональный Документы

Культура Документы

Temperature Measurement

Загружено:

Mahmoud Shaheen0 оценок0% нашли этот документ полезным (0 голосов)

108 просмотров42 страницыhow to measure temperature

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документhow to measure temperature

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

108 просмотров42 страницыTemperature Measurement

Загружено:

Mahmoud Shaheenhow to measure temperature

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 42

Petrofac Training

Training. Competence. Excellence.

Unit I-07

Temperature Measurement

Unit I-07: Temperature Measurement

Unit I-07: Temperature Measurement

Objectives

Given illustrations and drawings, the trainee will correctly:

Describe The Temperature Variable

Identify Temperature Measuring Devices

Explain Their Principles Of Operation

Unit I-07: Temperature Measurement

Introduction

In this unit, we will discuss the Temperature Variable and explain

how it can be measured.

Unit I-07: Temperature Measurement

Describe the Temperature Variable

Temperature is the degree of hotness or coldness, measured on a

definite scale. The motion of the molecule in a substance determines

how hot or cold it is.

Unit I-07: Temperature Measurement

Heat Transfer

When two substances of different temperatures come into contact

with each other, there is a flow of heat.

This flow is called heat transfer.

Heat transfer will always be from the hotter substance to the colder

substance.

Unit I-07: Temperature Measurement

Heat Transfer by CONVECTION

Unit I-07: Temperature Measurement

Heat Transfer through CONDUCTION

Unit I-07: Temperature Measurement

Heat Transfer by RADIATION

Unit I-07: Temperature Measurement

Temperature Scales

180 DIVISIONS

BOILING WATER

MELTING ICE

FAHRENHEIT (

O

F) CELSIUS (

O

C)

(491.67

0

R) (273.15 K)

100 212

0 32

180 DIVISIONS

BOILING WATER

MELTING ICE

Unit I-07: Temperature Measurement

The Absolute Scale

In instrumentation, many temperature measurements have to be

made from ABSOLUTE ZERO.

Absolute zero is the temperature at which no heat energy (atomic

movement) exists.

Unit I-07: Temperature Measurement

Expansion Type Thermometers

Most materials expand as they get hotter.

An expansion type thermometer uses the expansion of a material to

indicate temperature.

There are several different types.

Unit I-07: Temperature Measurement

Liquid in Glass Thermometer

SCALE

LIQUID FILLED BULB

LIQUID COLUMN

GLASS STEM

IMMERSION MARK

VACUUM

LIQUID

IMMERSION MARK

FRONT OF STEM SHAPED

AS LENS TO BROADEN

APPARENT SIZE OF COLUMN.

LIQUID COLUMN

WHITE VITREOUS ENAMEL

Unit I-07: Temperature Measurement

Filled System Thermometer

LIQUID FILLED

STEEL BULB

FILLED WITH

MERCURY

GAS FILLED

STEEL BULB

FILLED WITH

GAS

VAPORISING LIQUID FILLED

STEEL BULB

FILLED WITH

VAPORISING

LIQUID

Unit I-07: Temperature Measurement

Ambient Temperature Compensation for Filled System

BOURDON TUBES

POINTER

SCALE

Unit I-07: Temperature Measurement

SUPPLY

WATER TANK

WALL

ELECTRIC HEATER COIL

EXPANSION

INVAR ROD

BRASS TUBE

SWITCH

Solid Expansion Types - Thermostats

Unit I-07: Temperature Measurement

INVAR

BRASS

COLD

HOT

FIXED END

Bi-Metal Strips

Unit I-07: Temperature Measurement

NICKEL STEEL BI-METAL

HELICAL STRIP

5

0

1

0

0

20

0

FIXED END

SHAFT RIGIDLY FIXED

TO ROTATING END

CENTRE SHAFT SUPPORT

STEEL OR BRASS STEM

SOLID METAL BODY

POINTER

HEAVY GLASS PLATE

SCALE

Bi-Metal Strip Thermometers

Unit I-07: Temperature Measurement

TERMINAL BOX

CABLE TO

ELECTRONICS

STAINLESS STEEL

SHEATH

FIXING NUT INTO

THERMOWELL

Resistance Temperature Detector (RTD)

Unit I-07: Temperature Measurement

Resistance Temperature Detector (RTD)

THERMOWELL

CERAMIC SPACERS

STAINLESS STEEL

SHEATH

GLASS TO METAL SEALS

GLASS WOOL PACKING

GLASS COATING

LEAD WIRES

PLATINUM COIL

CERAMIC ROD

Unit I-07: Temperature Measurement

Temperature Resistance Value for a Pt100

Examples of Table use

The resistance at 200DegC

= 175.84

The resistance at -150DegC

= 39.73

The resistance at 560DegC

= 300.77

Unit I-07: Temperature Measurement

0

C

0 -10 -20 -30 -40 -50 -60 -70 -80 -90

-200 18.61

-100 60.24 56.18 52.10 48.00 43.88 39.73 35.54 31.33 27.10 22.85

0 100.00 96.08 92.15 88.21 84.26 80.29 76.31 72.32 68.31 64.28

0 +10 +20 +30 +40 +50 +60 +70 +80 +90

0 100.00 103.90 107.79 111.67 115.54 119.40 123.24 127.07 130.89 134.70

100 138.50 142.29 146.06 149.82 153.57 157.31 161.04 164.76 168.46 172.15

200 175.84 179.51 183.16 186.81 190.45 194.07 197.69 201.29 204.88 208.46

300 212.03 215.58 219.13 222.66 226.19 229.70 233.20 236.68 240.16 243.63

400 247.08 250.52 253.95 257.37 260.78 264.18 267.56 270.93 274.30 277.65

500 280.98 284.31 287.62 290.93 294.22 297.50 300.77 304.02 307.26 310.50

600 313.72 316.92 320.12 323.30 326.47 329.63 332.78 335.92 339.04 342.15

700 345.25 348.33 351.40 354.47 357.51 360.55

Temperature Resistance Valves for a Pt 100

Unit I-07: Temperature Measurement

Basic Circuit of a Simple RTD

SUPPLY

100R

R

1

RTD

100 at 0C

1

2

3

R

1

DISPLAY

UNIT

CONTROL ROOM

PLANT

Unit I-07: Temperature Measurement

4-Wire System RTD

BRIDGE

SUPPLY

100R

R

1

R

T

1

2

3

4

R

1

Unit I-07: Temperature Measurement

Thermocouple Seebeck Effect

IRON

CONSTANTAN

HOT JUNCTION COLD JUNCTION

I I I I

Unit I-07: Temperature Measurement

Thermocouple Thermometer

HOT

JUNCTION

COLD JUNCTION

COLD JUNCTION

COMPENSATION

CIRCUIT

INPUT

AMPLIFIER

OUTPUT AMPLIFIER

Unit I-07: Temperature Measurement

Thermocouple Thermometer

0

8

4

-8

12

16

0 -4

COLD JUNCTION AT 0

O

C

THERMOCOUPLE EMF mV

300

400

200

100

-200

-100

T

E

M

P

E

R

A

T

U

R

E

0

O

C

Unit I-07: Temperature Measurement

TYPE CONDUCTORS

(Positive conductor first)

ACCURACY OUTPUT FOR

INDICATED

TEMPERATURE

Cold Junction

At 0

0

C

SERVICE TEMPERATURE

B Platinum : 30% Rhodium

Platinum : 6 % Rhodium

0 to 1100

0

C + 3

0

C

1100 to 1550

0

C + 4

0

C

1.241 mV at 500

0

C 0 to 1500

0

C

Better life expectancy at

high temperature than

types R & S.

E Nickel: Chromium/

Constantan

(Chromel/Constantan)

0 to 400

0

C + 3

0

C 6.317 mV at 100

0

C -200 to 850

0

C

Resistant to oxidising

atmosphere.

J Iron /

Constantan

0 to 300

0

C + 3

0

C

300 to 850

0

C + 1%

5.268 mV at 100

0

C -200 to 850

0

C

Low cost,

suitable for general use.

K Nickel : Chromium /

Nickel : Aluminium

(Cromel/Alumel)

0 to 400

0

C + 3

0

C

400 to 1100

0

C + 0.75%

4.095 mV at 100

0

C -200 to 1100

0

C

Good general purpose,

best in oxidising

atmosphere.

N Nickel : Chromium : Silicon:/

Nickel Silicon

-230

0

C to 1230

0

C + 0.75% New high Tech.

replacement for Type K

Standard Thermocouples in Use

Unit I-07: Temperature Measurement

TYPE CONDUCTORS

(Positive conductor first)

ACCURACY OUTPUT FOR

INDICATED

TEMPERATURE

Cold Junction

At 0

0

C

SERVICE TEMPERATURE

R Platinum :

13% Rhodium / Platinum

0 to 1100 + 1

0

C

1100 to1400

0

C + 2

0

C

4.471 mV at 500

0

C 0 to 1500

0

C

High temperature

corrosion resistant.

S Platinum :

10% Rhodium/Platinum

1400

0

C + 3

0

C 4.234 mV at 500

0

C 0 to 1500

0

C

High temperature

corrosion resistant.

T Copper/Constantan:

(Cu/Con)

0 to 100

0

C + 1

0

C

100 to 400

0

C + 1%

4.277 mV at 100

0

C -250

o

C to 400

o

C

High resistance to

corrosion by water.

Standard Thermocouples in Use

Unit I-07: Temperature Measurement

TYPE

COMPOSITION

FOR USE WITH TYPE

AMBIENT TEMPERATURE RANGE

U Copper/ Copper- Nickel

R and S 0 - 50

0

C

V

X

Copper/ Constantan K and N 0 - 80

0

C

Compensating Leads

Unit I-07: Temperature Measurement

Practical Thermocouple

COMPENSATING CABLE

Cu

Cu

Cu:Ni Cu:Ni

PT: 10%Rh

PT

Unit I-07: Temperature Measurement

0

C

0 -10 -20 -30 -40 -50 -60 -70 -80 -90

-100 -3.378

0 0 -0.383 -0.757 -1.121 -1.475 -1.819 -2.152 -2.475 -2.788 -3.089

0 +10 +20 +30 +40 +50 +60 +70 +80 +90

0 0.000 0.391 0.789 1.196 1.611 2.035 2.467 2.908 3.357 3.813

100 4.277 4.749 5.227 5.712 6.204 6.702 7.207 7.718 8.235 8.757

200 9.286 9.820 10.360 10.905 11.456 12.011 12.572 13.137 13.707 14.281

300 14.860 15.443 16.030 16.621 17.217 17.816 18.420 19.027 19.638 20.252

400 20.869

mV verses Temperature Type T Thermocouple

Unit I-07: Temperature Measurement

Thermistor

Is a semiconductor made of metal oxides

Its resistance increases or decreases with temperature

Unit I-07: Temperature Measurement

Overall Length 52mm

Disk Diameter 10mm

Disc Thermistor

Unit I-07: Temperature Measurement

Thermistor Probe

CONNECTING

LEADS

ADJUSTABLE

LOCATING

NUT

THERMISTOR

STAINLESS

STEEL

SHEATH

Unit I-07: Temperature Measurement

Radiation Temperature Detector (Pyrometer)

SENSOR AUXILIARY LEN

MAIN LEN

RADIATION FROM TARGET

ELECTRONIC

AMPLIFIER

CONNECTOR-

PLUG AND SOCKET

Unit I-07: Temperature Measurement

Thermopile for use in a Radiation Pyrometer

COLD JUNCTION

HOT JUNCTION

OUTPUT mV

Unit I-07: Temperature Measurement

RANGER P.M

LASER SIGHT

Pistol Grip Type Radiation Thermometer

Unit I-07: Temperature Measurement

Thermowell

THERMOWELL

THERMOWELL PROBE

(RTD, T/C, FILLED SYSTEM, ETC)

CONNECTION TO INDICATOR

HEAT

TRANSFER

HEAT

TRANSFER

Unit I-07: Temperature Measurement

Electrical/Electronic Temperature Transmitter

LOCAL INDICATOR

ELECTRONICS UNIT

SENSOR

Unit I-07: Temperature Measurement

Typical Temperature Transmitter Installation

INSULATION (IF REQUIRED)

UNION OR COUPLING

EXTENSION ROD

EXTENSION

LENGTH

2.2

WALL OF PIPE OR

PROCESS CONTAINER

SENSITIVE PORTION

OF SENSOR

THERMOWELL

TRANSMITTER

CONDUIT FOR

FIELD WIRING

Petrofac Training

Training. Competence. Excellence.

Unit I-07

Temperature Measurement

Вам также может понравиться

- Downloads Drivers Hart DD List Ams en 38560 PDFДокумент30 страницDownloads Drivers Hart DD List Ams en 38560 PDFMahmoud ShaheenОценок пока нет

- Surge Protection TAN1004B15DДокумент7 страницSurge Protection TAN1004B15DMohan ArumugavallalОценок пока нет

- Pocket Guides - Free Download: Price: $0.00Документ2 страницыPocket Guides - Free Download: Price: $0.00Mahmoud ShaheenОценок пока нет

- Gases Subdivision and Ignition TemperaturesДокумент11 страницGases Subdivision and Ignition TemperaturesAN.ADAMMSОценок пока нет

- Manual Upgrade Procedure 475 375 Field Communicator For Version 3 X Ams en 38592 PDFДокумент11 страницManual Upgrade Procedure 475 375 Field Communicator For Version 3 X Ams en 38592 PDFMahmoud ShaheenОценок пока нет

- Control Valve SelectionДокумент3 страницыControl Valve SelectionAlexander Ariza NadjarОценок пока нет

- 7ml19981ev01 2Документ2 страницы7ml19981ev01 2Mahmoud ShaheenОценок пока нет

- (FPD 1006 Ebook (E) Cameron 20th Edition TOCДокумент11 страниц(FPD 1006 Ebook (E) Cameron 20th Edition TOCChristopher Kenneth Choa0% (1)

- Emerson 475 and AMS Installation InstructionsДокумент3 страницыEmerson 475 and AMS Installation Instructionsheppy prastyo nugrohoОценок пока нет

- (FPD 1006 Ebook (E) Cameron 20th Edition TOCДокумент11 страниц(FPD 1006 Ebook (E) Cameron 20th Edition TOCChristopher Kenneth Choa0% (1)

- (FPD 1006 Ebook (E) Cameron 20th Edition TOCДокумент11 страниц(FPD 1006 Ebook (E) Cameron 20th Edition TOCChristopher Kenneth Choa0% (1)

- En 61032Документ1 страницаEn 61032Mahmoud Shaheen0% (1)

- (FPD 1006 Ebook (E) Cameron 20th Edition TOCДокумент11 страниц(FPD 1006 Ebook (E) Cameron 20th Edition TOCChristopher Kenneth Choa0% (1)

- (FPD 1006 Ebook (E) Cameron 20th Edition TOCДокумент11 страниц(FPD 1006 Ebook (E) Cameron 20th Edition TOCChristopher Kenneth Choa0% (1)

- Control Valve P and P For 0 To 150% of Maximum Design Flow: Process DataДокумент7 страницControl Valve P and P For 0 To 150% of Maximum Design Flow: Process DataramkrishnaОценок пока нет

- Communications Foundation Fieldbus For Level InstrumentsДокумент68 страницCommunications Foundation Fieldbus For Level InstrumentsYoga SanОценок пока нет

- A5e34590123 AbДокумент42 страницыA5e34590123 AbMahmoud ShaheenОценок пока нет

- Control Valve Sizing - Gas Rev 2aДокумент2 страницыControl Valve Sizing - Gas Rev 2aMahmoud ShaheenОценок пока нет

- 7ML19985XT81 PDFДокумент1 страница7ML19985XT81 PDFMahmoud ShaheenОценок пока нет

- 7ML19981EU01Документ2 страницы7ML19981EU01Mahmoud ShaheenОценок пока нет

- Control Valve P and P For 0 To 150% of Maximum Design Flow: Process DataДокумент7 страницControl Valve P and P For 0 To 150% of Maximum Design Flow: Process DataramkrishnaОценок пока нет

- Calibration WorksheetДокумент4 страницыCalibration WorksheetRaju SkОценок пока нет

- كتاب الحرب العالمية الثالثة قادمةل منصور عبد الحكيم PDFДокумент111 страницكتاب الحرب العالمية الثالثة قادمةل منصور عبد الحكيم PDFMahmoud ShaheenОценок пока нет

- 7ml19981eg01 1Документ2 страницы7ml19981eg01 1Mahmoud ShaheenОценок пока нет

- Control Valve Sizing - Liquid Rev 2aДокумент2 страницыControl Valve Sizing - Liquid Rev 2aQC osbl100% (1)

- FprEN 50216-12 2010Документ13 страницFprEN 50216-12 2010Mahmoud ShaheenОценок пока нет

- FPRHD 60364-7-722Документ8 страницFPRHD 60364-7-722Mahmoud ShaheenОценок пока нет

- FprEN 62561-5 2011Документ3 страницыFprEN 62561-5 2011Mahmoud ShaheenОценок пока нет

- FPRHD 60364-7-715Документ6 страницFPRHD 60364-7-715Mahmoud ShaheenОценок пока нет

- FPRHD 60364-4-42Документ9 страницFPRHD 60364-4-42Mahmoud ShaheenОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- PAL RefiningДокумент1 страницаPAL Refiningjh gdgfgОценок пока нет

- Cell Wall: Presented by M. Vijaya LakshmiДокумент9 страницCell Wall: Presented by M. Vijaya LakshmiATCHUNALA SAIОценок пока нет

- Interconection Pipe RackДокумент16 страницInterconection Pipe RackPhucChuVanОценок пока нет

- Artificial Blood: Dr. Pragasam Viswanathan, Professor, SBSTДокумент21 страницаArtificial Blood: Dr. Pragasam Viswanathan, Professor, SBSTMaru Mengesha Worku 18BBT0285Оценок пока нет

- S.No. Type Medicine NameДокумент6 страницS.No. Type Medicine Namered petalsОценок пока нет

- Part A: Multiple - Choice QuestionsДокумент14 страницPart A: Multiple - Choice QuestionsGora PostingОценок пока нет

- Gas Chromatography AmmoniaДокумент10 страницGas Chromatography AmmoniacurlychemОценок пока нет

- Biomechanical Properties of A New Fiber-Reinforced CompositesДокумент10 страницBiomechanical Properties of A New Fiber-Reinforced Compositesazam ahmedОценок пока нет

- Indice Combinado Eph 9TH Hasta S 9.8 - 2019Документ56 страницIndice Combinado Eph 9TH Hasta S 9.8 - 2019Diana PortilloОценок пока нет

- Organic Chemistry PDFДокумент181 страницаOrganic Chemistry PDFShyam Yadav100% (1)

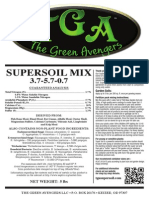

- TGA Supersoil 5lbДокумент1 страницаTGA Supersoil 5lbKatherine CampbellОценок пока нет

- Industrial ReportДокумент64 страницыIndustrial Reportfuad ullahОценок пока нет

- RingMethod Zuidema WatersДокумент2 страницыRingMethod Zuidema WatersJack Yoseph Martinez OrtegaОценок пока нет

- Chili Pepper Extract As TreatmentДокумент29 страницChili Pepper Extract As TreatmentRC Yvann Dela CruzОценок пока нет

- Chapter Four, Cycloalkanes (Part One - Monocyclic Alkane)Документ8 страницChapter Four, Cycloalkanes (Part One - Monocyclic Alkane)Amin JamjahОценок пока нет

- Rotary PumpsДокумент31 страницаRotary PumpsalbertОценок пока нет

- J.ultsonch.2014.08.022 InglesДокумент48 страницJ.ultsonch.2014.08.022 InglesBrayan LuisОценок пока нет

- Orthodontic Wires - Properties / Orthodontic Courses by Indian Dental AcademyДокумент226 страницOrthodontic Wires - Properties / Orthodontic Courses by Indian Dental Academyindian dental academy100% (1)

- Qw/Qb-422 Ferrous/Nonferrous P-Numbers (Cont'D) Grouping of Base Metals For QualificationДокумент7 страницQw/Qb-422 Ferrous/Nonferrous P-Numbers (Cont'D) Grouping of Base Metals For QualificationHgagselim SelimОценок пока нет

- InternshipДокумент16 страницInternshipSarthak SinghОценок пока нет

- Sarcosine MsdsДокумент41 страницаSarcosine MsdsAnonymous ZVvGjtUGОценок пока нет

- Yanmar BulletinsДокумент10 страницYanmar BulletinsBill Carter100% (2)

- Aerospace Material SpecificationДокумент7 страницAerospace Material SpecificationAnonymous T6GllLl0Оценок пока нет

- Who We Are: Case Study-Mahindra ChlorisДокумент25 страницWho We Are: Case Study-Mahindra ChlorisSUNIDHI VERMAОценок пока нет

- Work Instructions (W.I.)Документ18 страницWork Instructions (W.I.)Shamsul Azhar MohdОценок пока нет

- Soda AshДокумент10 страницSoda Ashdr chatti hanumantha rao0% (1)

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFДокумент13 страницRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesОценок пока нет

- Green Glue Material Safety DataДокумент4 страницыGreen Glue Material Safety DatawilldoyeahОценок пока нет

- Carbon Fiber - CoursДокумент33 страницыCarbon Fiber - Courstrannhu1293599Оценок пока нет