Академический Документы

Профессиональный Документы

Культура Документы

Segment Launching Presentation GL (04!02!2013) - D

Загружено:

Gary LoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Segment Launching Presentation GL (04!02!2013) - D

Загружено:

Gary LoАвторское право:

Доступные форматы

Highways Department Major Works Project Management Office

Contract No. HY/2009/19

Central - Wan Chai Bypass Tunnel (North Point

Section) and Island Eastern Corridor Link

Segment Launching for Bridgework

Date: Jan 2013

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Presentation Contents

Introduction

Segment Casting

Storage Yard in the Site

Delivery and Storage of Segments

Movement of Launching Girder

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Presentation Contents

Introduction

Contract Details

Overview of Contract Works

Bridge Arrangement

Segment Casting

Delivery and Storage of Segments

Bridge Segment Erection

Movement of Launching Girder

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Overview of Contract HY/2009/19 Works

HARBOUR GRAND

HONG KONG

CITY GARDEN

HARBOUR

HEIGHTS

VICTORIA

CENTRE

Noise

Enclosure

EXISTING IEC

HING FAT SLIP

ROAD

BOX CULVERT

U1

NEW IEC W/B

TUNNEL APPROACH

RAMP

EXISTING IEC E/B

TO BE

DEMOLISHED

NEW IEC E/B

BOX CULVERT

T1

IEC (Tunnel

Section)

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Bridge Arrangement in HY/2009/19

New Eastbound Bridge

to D2)

Bridg e D (D1

ge

Brid

Bridge D3

Brid ge F

(F

1 to F3)

Brid

ge

F5

Br

id

Bridge C (C1 to

C5)

F3)

Bridge F ( F1 to

City Garden

Harbour

Height

Victoria

Centre

ge

F

Existing Bridge

Precast Segments Bridges

Re-Construct Westbound Bridge

Provident Centre

Span length :

26.5m to 40.0m

Bridge types :

Precast Segments (Bridges D1 to D3, F1 to F3, C2 to C5)

U-beams (Bridges C1, E F4, F5)

Total nos. of segment :

653 segments

Total nos. of U-beam :

60 beams

5

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Presentation Contents

Introduction

Segment Casting

Typical Segments

Casting Yard

Segment Casting

Delivery and Storage of Segments

Bridge Segment Erection

Movement of Launching Girder

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

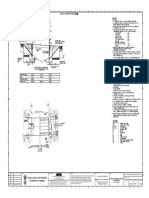

Typical Segment Type

Type of Segments : Single and Twin Cell Segments

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Typical Segment Type

Segment Typical Detail

Span Distance

26.5m to 40.0m

Maximum Super-Elevation

3.7%

Maximum Gradient

4.86%

Minimum Horizontal Radius

350m

Maximum Segment Weight

150 tons

Department Major Works Project Management Office

Contract No. HY/2009/19 Central Wan ChaiHighways

Bypass

Tunnel (North Point

Section) and Island Eastern Corridor Link

Location of Fabrication Yard

Zhongshan,

China

Contract

HY/2009/19 Site

Precast Segment

Fabrication Yard

Hong Kong

Macau

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Fabrication Yard Layout

Area for Segment

Casting

10

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Casting Mould for Segments

3 nos. casting moulds in the casting yard

2 nos. for twin cells segments

1 nos. for single cell segment

1st Twin Cell Segment

Mould

2nd Twin Cell Segment

Mould

Single Cell Segment

Mould

11

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Segment Casting Procedure

Step 1 - Fabrication of Reinforcement Cage

Step 3 - Cleaning Steel Mould

Highways Department Major Works Project Management Office

Step 2 - Matching & Geometric Adjustment

of Match Cast Segment

Step 4- Placing Reinforcement Cage to

Segment Mould

12

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Segment Casting Procedure

Step 5 - Installing Internal Formwork

Step 7 - Demoulding

Highways Department Major Works Project Management Office

Step 6 - Pouring Concrete

Step 8 - Completed Segment

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Presentation Contents

Introduction

Segment Casting

Delivery and Storage of Segments

Delivery Route

Unloading Point

Storage Yard

Bridge Segment Erection

Movement of Launching Girder

14

Department Major Works Project Management Office

Contract No. HY/2009/19 Central Wan ChaiHighways

Bypass

Tunnel (North Point

Section) and Island Eastern Corridor Link

Delivery Route to the Site

Zhongshan,

China

Contract

HY/2009/19 Site

Precast Segment

Fabrication Yard

Hong Kong

Macau

Precast segments deliver to site by barge

15

Department Major Works Project Management Office

Contract No. HY/2009/19 Central Wan ChaiHighways

Bypass

Tunnel (North Point

Section) and Island Eastern Corridor Link

Precast Segment Unloading Point on Site

PORTION III

PORTION VII

16

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Storage Yard Arrangement

Segment Storage

(Max. Capacity = 20 Segments)

Front View

Side View

Stacking Arrangement

Segment Barge

Unloading

Derrick

Bridge Loading

Area

(After

completion of

Bridge D3)

17

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Lifting Equipments at Storage Yard

Highways Department Major Works Project Management Office

Truck for Transporting Segment

(Example Photo)

Portal Crane

Unloading Derrick

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Presentation Contents

Introduction

Segment Casting

Delivery and Storage of Segments

Bridge Segment Erection

Launching Girder

Main Support and Lifting Beam

Install Bearing and Segment at Piers by Crawl Cranes

Segment Erection by Launching Girder

Movement of Launching Girder

19

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Configuration

FRONT LEG (FL)

MASTER

WINCH (MW02)

REAR LEG

(RL)

MAIN SUPPORT

(MS2)

MASTER

WINCH

(MW01)

MAIN TRUSS

MAIN SUPPORT

(MS1)

MAIN SUPPORT

(MS3)

General Specification

Dimension (L x W x H)

103.44m x 8.4m x7.5m

Max. Lifting Capacity

160 T

Max. Hanging Capacity

700 T (7 segments)

Fabrication

Wuhu, China

20

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Main Support

Rotation Table for

Truss Rotation

Jack for adjustment

of transverse

movement

Jack for launching

forward of main

truss

Main Beam Unit

Section

Elevation

Jack for adjustment of

crossfall and longitudinal fall

of segment

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Launching Girder Main Support

Highways Department Major Works Project Management Office

Jack for adjustment for

crossfall and longitudinal

fall of segment

Jack for adjustment

of transverse

movement

Main Beam Unit of

Main Support

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Main Support

Main Truss

Jack for launching

forward of main

truss girder

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Lifting Beam

Jack for adjustment

of crossfall of

segment

Strings hung from

Master Winch

Jack for adjustment

of longitudinal fall of

segment

Pin joint for

connecting with

hanger beam

Jack for adjustment

of longitudinal fall of

segment

Section

Plan

Elevation

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Hanger Beam for Segment Erection

40mm High Strength

Bar

For Single-Cell Arrangement

Pin joint for

connecting with

lifting beam of

master winch

Section

40mm High Strength

Bar

For Twin-Cells Arrangement

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Hanger Beam for Hanging Segment at End Span

1. Erect the segment by master winches

2. Hang and fix the segment by 50 High Strength Bar

3. Release the master winches after fixing with high strength bar

4. Repeat 1 to 3 for the rest of the segment at end span

Main Truss of

Launching Girder

Hanger Beam

Hung From the Main

Truss of Launching

Girder

50mm High Strength

Bar

Hanger Beam

Elevation

Section

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Before Segment Erection

1. Installing the bearing and temporary hydraulic jacks on the piers

Temporary

Hydraulic

Jacks

Bearing

s

(Example Photo)

Temporary Hydraulic

Jack

Adjusting Jack

Bearing

27

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Before Segment Erection

2. Erect MJ and pier segments at the piers by cranes

MJ Segments

Pier

Segments

28

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Before Segment Erection

3. Fix the MJ and pier segments at the piers

Fixed by high

strength bars

At Movement Joint Pier

Fixed by Nailing

At Intermediate Pier

29

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Before Segment Erection

4. Install launching girder on the erected pier/MJ segments:. Install main support main truss girder master winches on main truss girder

3. Install Master

Winches

2. Install Main Truss

Girder

1. Install Main

Support on erected

segment

1. Install Main

Support on erected

segment

30

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Before Segment Erection

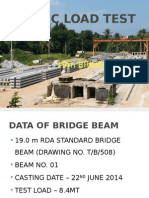

5. Proceed the load test of the launching girder (trial lifting Master Winches)

Additional

. Lift the heaviest segment plus extra10% of SWL (160T)

weight by

concrete block

. Visual check of launching girder after lifting

. Lower the loaded segment after satisfaction by RPE

Load test at the

middle of the span

Example Photo of Load Test of Master Winch

Load test at the

other span

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Before Segment Erection

6. Proceed the load test of the launching girder (Trial Launching)

. Launch the main truss forward/backward for the short distance

. Without any load on Master Winches during trial launching

Launch main truss

forward/backward

7. The certificate of launching girder issued by RPE once the load test is

satisfactory.

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Segment Erection Methods

Types of Segment Erections Methods

Segment Erection at Pier

(Balanced-Cantilever Erection)

At End Span Erection

(Hanging Erection)

33

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Typical Segment Erection at Pier

Temporary Prestress Bars

to connect during each pair

segment erection prior to

the permanent stressing

Temporary

Prestress Bars to

be removed

Permanent Prestressing to carry

out at each pair segment

erection

Design check for permanent structure (e.g. pier) due to segment erection is

required.

34

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Typical Segment Erection at End Span

1 2 3 4 5

Temporary Prestress Bars

to connect the segment

prior to the permanent

stressing

Temporary

Prestress Bars and

Supports to be

removed

6 7

Construct Stitch

Joint

As-constructed

Segment

Cantilever

Permanent Prestressing to carry

out after the completion of

stitch joint

Design check for permanent structure (e.g. pier) due to segment erection is

required.

35

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Segment Erection Applying Glue for Joining Segments

Apply epoxy glue on segment face before joining segment

Amount of epoxy glue in accordance with the manufacturers recommendation

Curing time: 4 8 hrs (initial); 2 7 days (final)

Mixing epoxy glue

Applying epoxy on segment face

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Segment Erection Applying Glue for Joining Segments

PHYSICAL AND CHEMICAL PROPERTYES

Specification

30

50

Density

1685kg/m3

1685kg/m3

Pot time

>35 minutes

>20 minutes

Open time

>60 minutes

>60 minutes

Compressive strength @ 24 hours

>65MPa

>70MPa

Compressive strength @7 days

>80MPa

>80MPa

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Segment Erection - Temporary Prestressing

Segment held by high strength MaCalloy Bars (36mm dia., UTS =1030N/mm2)

Each bar is stressed to the specified force by hydraulic jack.(524KN or 598KN)

During application of epoxy glue, a minimum average compressive stress of 0.2

N/mm2 across the whole section shall be achieved.

To be removed after completion of permanent prestressing.

Steel blister at

bridge deck

Bar is stressed by

Hydraulic Jack

Temporary

Prestressing Bar

At Bridge Deck (Example

Photo)

Bar is stressed

by Hydraulic

Jack

Temporary

Prestressing Bar

Inside the Bridge Deck

(Example Photo)

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Temporary Prestressing General Arrangement

Steel Blisters

Prestressing bars

Prestressing bars

Concrete Blisters

Elevation

Steel Blisters

Recess Hole for

Temp Prestress

Concrete Blisters

For Twin Cell Segment

Recess Hole for

Temp Prestress

For Single Cell Segment

39

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Stitch Joint Construction

Construct between the cantilever and end span or between two cantilevers.

Adjust the vertical and horizontal alignment of the erected cantilever tips

Stitch Joint

Stitch Formwork

40

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Permanent Prestressing

Thread strand through the tendon duct

Apply prestressing force gradually until required stressing force is attained.

(Min=784KN ,Max=4312KN)

Release the pressure, allow the wedge to draw-in and lock strand

Installing Hydraulic Jack

(Example Photo)

Stressing Prestressing Strand

(Example Photo)

41

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Permanent Prestressing

Platform for workers of prestressing work (for balanced cantilever segment

erection only)

It is hung under the main truss of launching girder

Main Truss of

launching girder

Winch for

hanging

hydraulic

jack

Section

Stressing

platform

Erection

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Grouting Tendon Duct after Permanent Prestress

1. Cut the excess strand

2. Check clearance of duct and leakage check

3. Pump the grout into the duct

4. Seal all outlet vents

Completed cutting excess strand

(Example Photo)

Pumping grout into the duct

(Example Photo)

Completed grouting

(Example Photo)

43

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Presentation Contents

Introduction

Segment Casting

Storage Yard in the Site

Bridge Segment Erection

Movement of Launching Girder

Forward Launching

Forward Launching in Curve Section

Typhoon Anchors

General Erection Sequence

44

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Forward Launching

Assemble

LG onLG

pier

D8,9,10 as

Launch

to D9,10,11

shown

Repeat steps before to

Launch LG to D10,11,12

Engage RL,move MS to the positon

LG

forward

MS again

LG forward

until reach

segments

ofasLaunch

Tshown

spanLaunch

by

Install segments

of endInstall

span Move

Erect

segments

of TD11

as shown.

pair

span

Erect temporary prop and

MJ

Erect

pier segments

segment

at D11

Move

MSFLtoon

D11

Erect

T Erectof

engage

it of

Move

MSErect

onto

segments

end

span

D12

segment at D12

span

Erect external

tendons

Cast the

stitch

Pier

D8

Cast the

stitch

Cast the

stitch

Pier

D9

Pier

D10

Cast the

stitch

Pier

D11

Pier

D12

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Forward Launching in Curve Section

1. Shift and rotate the main truss transversely by hydraulic jack on main truss

Main Truss

Main Support

2. Launch the main truss forward to the designated position

Main Truss

Main Support

46

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Forward Launching in Curve Section

1. Main truss will not extend to existing bridge.

Main Support

Main Truss

Edge of Existing

Bridge

47

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Forward Launching in Curve Section

1. Supporting beam will not extend to existing bridge.

300mm

Pier

F8

48

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Launching Girder Typhoon Anchorage Operation

40 HIGH-STENGTH PT BAR

(PRELOADED TO 700KN

EACH)

40 HIGH-STENGTH PT BAR

(PRELOADED TO 700KN

EACH)

49

Contract No. HY/2009/19

Central Wan Chai Bypass Tunnel (North Point Section) and Island Eastern Corridor Link

Highways Department Major Works Project Management Office

Segment Erection Sequence

Bridges

Sequence

Duration (Approx.)

New Eastbound Bridge

Pier D8 to Pier F8 > Pier D8 to Pier D1

206 Days

Re-Construct Westbound Bridge

(Towards Causeway Bay Direction)

Pier 28 to Pier 43 > Pier 28 to Pier 22

187 Days

Re-Construct Westbound Bridge

(Connect to Approach Ramp)

Abutment D12 to Pier F8 >

Abutment D12 to Pier F3

100 Days

New Eastbound Bridge

Pier

D8

Pier

D1

Pier

22

Abut

D12

Pier

F3

Pier

28

Re-construct Westbound Bridge

(Towards Causeway Bay Direction)

Pier

F8

Pier

43

Re-construct Westbound Bridge

(Connect to Approach Ramp)

Highways Department Major Works Project Management Office

THE END

51

51

Вам также может понравиться

- Driving Goods VehiclesДокумент336 страницDriving Goods VehiclesAsmawi AkhirОценок пока нет

- Method Statement For Construction of Drainage and ManholesДокумент18 страницMethod Statement For Construction of Drainage and ManholesGary Lo79% (14)

- Method Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Документ16 страницMethod Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Gary Lo0% (2)

- Method Statement For Demolition & Modification Works at Existing Retaining Wall RW5Документ47 страницMethod Statement For Demolition & Modification Works at Existing Retaining Wall RW5Gary Lo75% (4)

- Method Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Документ16 страницMethod Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Gary Lo0% (2)

- Yamuna Bridge PresentationДокумент3 страницыYamuna Bridge Presentationnk229330Оценок пока нет

- Chenab Bridge - Cost, Construction, Images, Status, InaugurationДокумент7 страницChenab Bridge - Cost, Construction, Images, Status, InaugurationIndra MishraОценок пока нет

- BD List of Approved Foundation SystemДокумент2 страницыBD List of Approved Foundation SystemGary LoОценок пока нет

- Zaxis 75Документ2 страницыZaxis 75Gary Lo100% (1)

- Load TestДокумент35 страницLoad Testdhee2608Оценок пока нет

- Civl432 Bridge Design SummaryДокумент5 страницCivl432 Bridge Design SummarySheikh Mizanur RahmanОценок пока нет

- Zojila Tunnel Project LadakhДокумент16 страницZojila Tunnel Project LadakhRinchen Tundup100% (1)

- Bandra-Worli Sea LinkДокумент61 страницаBandra-Worli Sea LinkBala-GОценок пока нет

- Draft Well PileДокумент42 страницыDraft Well Pilehj_civil081206100% (1)

- IE Iocl Captive Jetty Apr2019Документ160 страницIE Iocl Captive Jetty Apr2019dheeraj sehgalОценок пока нет

- 1 - Depth of Fixity of Piles in Clay Under Dynamic Lateral PDFДокумент15 страниц1 - Depth of Fixity of Piles in Clay Under Dynamic Lateral PDFSwapan PaulОценок пока нет

- Railway Siding TSPLДокумент9 страницRailway Siding TSPLRaj KodainОценок пока нет

- LDC Opinion On Monopile Option - Draft PDFДокумент1 страницаLDC Opinion On Monopile Option - Draft PDFSeetharam MahanthiОценок пока нет

- Box Pushing Technology PresentationДокумент13 страницBox Pushing Technology PresentationVirendra Kumar PareekОценок пока нет

- Girder Erection MethodologyДокумент4 страницыGirder Erection MethodologyTanmay Mukherjee100% (1)

- The Books On The BottomДокумент53 страницыThe Books On The BottomJr BongabongОценок пока нет

- Trolley Refuge CodeДокумент3 страницыTrolley Refuge Codesiva_civil4051100% (1)

- BRIDGES - PPT by VASUMATHIДокумент48 страницBRIDGES - PPT by VASUMATHIVASUMATHIОценок пока нет

- A-165 (13-41) PC - House - For - Incheon - Bridge - Pile-Cap PDFДокумент7 страницA-165 (13-41) PC - House - For - Incheon - Bridge - Pile-Cap PDFKwon Joon myoungОценок пока нет

- 012-OKK-Final Culvert Design Report (Bhawanipatna - Khariar)Документ40 страниц012-OKK-Final Culvert Design Report (Bhawanipatna - Khariar)Jimmy Villca Sainz100% (1)

- Static Load TestДокумент9 страницStatic Load TestMuhunthan MurugananthanОценок пока нет

- Suhas P KhedkarДокумент114 страницSuhas P KhedkarAndresendeОценок пока нет

- Larsen & Toubro Limited - Ecc Division: Page 1 of 4Документ4 страницыLarsen & Toubro Limited - Ecc Division: Page 1 of 4Akhilesh DwivediОценок пока нет

- Bored Piling BrochureДокумент4 страницыBored Piling BrochureMahendran MaheОценок пока нет

- Mega Bridges Using Precast Technology SKDДокумент47 страницMega Bridges Using Precast Technology SKDpvrk_78100% (1)

- NhaiДокумент53 страницыNhairmpklОценок пока нет

- Notes For RobДокумент7 страницNotes For RobAmajdОценок пока нет

- Interpreter of MaladiesДокумент50 страницInterpreter of MaladiesmahakОценок пока нет

- Bridge Foundations Training For UACEДокумент20 страницBridge Foundations Training For UACEMichael KaziОценок пока нет

- Tinau Bridge MaintenanceДокумент14 страницTinau Bridge MaintenancesurendramaharjanОценок пока нет

- Launching GantryДокумент3 страницыLaunching GantryStrukturasОценок пока нет

- PKG 3Документ28 страницPKG 3nk229330Оценок пока нет

- Ashok Kumar Bridge EngineerДокумент12 страницAshok Kumar Bridge EngineerabhilashОценок пока нет

- RaviabstractДокумент21 страницаRaviabstractSunil Kumar IndiaОценок пока нет

- Construction Stage Analysis of Segmental BridgesДокумент19 страницConstruction Stage Analysis of Segmental BridgesSHRADDHA KADAMОценок пока нет

- Dedicated Freight Corridor Corporation of India Limited Western Dedicated Freight Corridor (Package Ctp11 - JNPT To Vaitarana)Документ66 страницDedicated Freight Corridor Corporation of India Limited Western Dedicated Freight Corridor (Package Ctp11 - JNPT To Vaitarana)Eswara PrasadОценок пока нет

- 01bandra Worli Sea Link Project-SantoshraiДокумент29 страниц01bandra Worli Sea Link Project-SantoshraiPrashant PatilОценок пока нет

- IRC 37 MORT&H - Standing Commitee Introduction of NEW TECHNOLOGY or ALTERNATE DES PDFДокумент15 страницIRC 37 MORT&H - Standing Commitee Introduction of NEW TECHNOLOGY or ALTERNATE DES PDFkhushwant Singh RaoОценок пока нет

- DYNA Link+Dokument+01Документ4 страницыDYNA Link+Dokument+01Kifli PeluОценок пока нет

- Fabrication Work For The Construction of Chenab Bridge Part IДокумент2 страницыFabrication Work For The Construction of Chenab Bridge Part IIndra Mishra100% (2)

- Apsara BorderДокумент15 страницApsara BorderskumarsrОценок пока нет

- BS-88R 2018 Literature On Corrosion Protection in Concrete StructuresДокумент48 страницBS-88R 2018 Literature On Corrosion Protection in Concrete StructuresM PMОценок пока нет

- Bridges and Elevated StructuresДокумент75 страницBridges and Elevated StructuresGiuseppe GentileОценок пока нет

- Steel Bridges SeminarДокумент21 страницаSteel Bridges SeminarAamodh Kuthethur100% (2)

- Nit WBHDCLДокумент194 страницыNit WBHDCLManish Choudhary100% (1)

- Girder ErrectionДокумент16 страницGirder ErrectionSujeet DubeyОценок пока нет

- Chap-5-T-Girder Example-1Документ72 страницыChap-5-T-Girder Example-1Abera Mamo JaletaОценок пока нет

- Segmental Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and Manufacturer PDFДокумент6 страницSegmental Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and Manufacturer PDFTarek HareedyОценок пока нет

- 3.3 Bridge DesignДокумент24 страницы3.3 Bridge DesignSannyBombeoJomoc100% (1)

- Method Launching GirderДокумент10 страницMethod Launching GirderAgung Sahdi50% (2)

- Shinso Pile - APMДокумент9 страницShinso Pile - APMHimang Jain100% (1)

- Girder LaunchingДокумент10 страницGirder Launchingmitnath100% (1)

- Appendix B3 GAD Major BridgeДокумент6 страницAppendix B3 GAD Major BridgeMAULIK RAVALОценок пока нет

- Goa Cable StayДокумент2 страницыGoa Cable Staydarmumbai100% (1)

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Документ1 страницаPile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiОценок пока нет

- Assignment - 1 OF Project Management Topic-: Submitted To Submitted byДокумент13 страницAssignment - 1 OF Project Management Topic-: Submitted To Submitted bynaushavaОценок пока нет

- Hongkong Zhuhai Macau BridgeДокумент22 страницыHongkong Zhuhai Macau BridgeArni Allyson ValenciaОценок пока нет

- Bangladesh RailwayДокумент12 страницBangladesh RailwaySharmistha Talukder KhastagirОценок пока нет

- Bridge Launching Girder - Lecture NotesДокумент6 страницBridge Launching Girder - Lecture NotesVivek G. Abhyankar0% (1)

- Bridges & Structures PDFДокумент6 страницBridges & Structures PDFDeeptiranjan NagОценок пока нет

- Wyong Road Enviro Factors Appendix PДокумент314 страницWyong Road Enviro Factors Appendix PAniculaesi MirceaОценок пока нет

- 2013-296 - Res 2-3Документ24 страницы2013-296 - Res 2-3Bob MackinОценок пока нет

- Astm C603Документ2 страницыAstm C603Gary Lo100% (1)

- Location Plan: East RailДокумент1 страницаLocation Plan: East RailGary LoОценок пока нет

- 1102 W Hik SWL C10 301aДокумент1 страница1102 W Hik SWL C10 301aGary LoОценок пока нет

- Short Term Program - Pit by Pit (7sw-D-fr65)Документ3 страницыShort Term Program - Pit by Pit (7sw-D-fr65)Gary LoОценок пока нет

- APP129Документ10 страницAPP129Gary LoОценок пока нет

- Central Data Bank List For FixingДокумент49 страницCentral Data Bank List For FixingGary LoОценок пока нет

- FR65 (Instrumentation) Initial ReportДокумент1 страницаFR65 (Instrumentation) Initial ReportGary LoОценок пока нет

- Appendix - A Details of Temporary OHL Mast, Back-Tie Brackets & Protective FenceДокумент6 страницAppendix - A Details of Temporary OHL Mast, Back-Tie Brackets & Protective FenceGary LoОценок пока нет

- 1102 W Hik SWL Q08 395aДокумент1 страница1102 W Hik SWL Q08 395aGary LoОценок пока нет

- RA-003-Risk Assessment For Installation of Temporary OHL Masts & Back-TiesДокумент5 страницRA-003-Risk Assessment For Installation of Temporary OHL Masts & Back-TiesGary LoОценок пока нет

- 1102 W Hik SWL C14 018aДокумент1 страница1102 W Hik SWL C14 018aGary LoОценок пока нет

- C U L C U L: Location PlanДокумент1 страницаC U L C U L: Location PlanGary LoОценок пока нет

- 1102 W Hik SWL C14 013aДокумент1 страница1102 W Hik SWL C14 013aGary LoОценок пока нет

- Method Statement For Construction of Drainage and Manholes (Rev. A)Документ53 страницыMethod Statement For Construction of Drainage and Manholes (Rev. A)Gary LoОценок пока нет

- 1102 W Hik SWL C14 012aДокумент1 страница1102 W Hik SWL C14 012aGary LoОценок пока нет

- 1102-ERFC-CM (SCLC) - CS-0001701 (Marked)Документ1 страница1102-ERFC-CM (SCLC) - CS-0001701 (Marked)Gary LoОценок пока нет

- Logic GatesДокумент19 страницLogic GatesblazespiritОценок пока нет

- DPP Series 1 PDFДокумент1 страницаDPP Series 1 PDFsukainaОценок пока нет

- NORMA TORRO Datasheet en PDFДокумент11 страницNORMA TORRO Datasheet en PDFvikaslashkariОценок пока нет

- Chapter 13: Worksheet Mark SchemeДокумент2 страницыChapter 13: Worksheet Mark SchemeAdam DanialОценок пока нет

- NFC Reader LibrarayДокумент63 страницыNFC Reader Libraraysekhar479Оценок пока нет

- 440T4 4T60 4t60e 4t65eДокумент24 страницы440T4 4T60 4t60e 4t65eFTompkins73100% (4)

- Eco ProductsДокумент3 страницыEco Productssreekutty A SОценок пока нет

- Lista Preturi Linhai 300 2014 PDFДокумент25 страницLista Preturi Linhai 300 2014 PDFSimonaVătafuОценок пока нет

- BOQ For Interior WorkДокумент2 страницыBOQ For Interior WorkSudhanshu MandlikОценок пока нет

- List of International and National Professional Bodies - PECДокумент4 страницыList of International and National Professional Bodies - PECerumerОценок пока нет

- CRMДокумент15 страницCRMPradeep ChintadaОценок пока нет

- Poly BoreДокумент2 страницыPoly BoreMarian OpreaОценок пока нет

- BPQ REV. 0 Interactive FormДокумент2 страницыBPQ REV. 0 Interactive FormcosmicbunnyОценок пока нет

- 27U RackДокумент6 страниц27U Racknitin lagejuОценок пока нет

- Homework 1&2 Report EE440Документ19 страницHomework 1&2 Report EE440Võ Hoàng Chương100% (1)

- Dodge Journey 2017 - Owner's ManualДокумент510 страницDodge Journey 2017 - Owner's Manualandres camachin100% (1)

- 390 Track Bolt M0079195Документ2 страницы390 Track Bolt M0079195joshpbenzОценок пока нет

- NessusДокумент23 страницыNessusShivaprakash TimmapurОценок пока нет

- 888 Gallant Security Services Corp NewДокумент12 страниц888 Gallant Security Services Corp Newnareyes11Оценок пока нет

- Palfinger PK 15500 Load ChartДокумент2 страницыPalfinger PK 15500 Load ChartD Chandra Sekhar100% (2)

- Wire CodeДокумент7 страницWire CodeAryans Kumar0% (1)

- Kevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterДокумент37 страницKevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterRejinОценок пока нет

- MARTA: 2012 KPMG Phase II Final DraftДокумент114 страницMARTA: 2012 KPMG Phase II Final DraftthomaswheatleyОценок пока нет

- Eminence Deltalite II 2515Документ1 страницаEminence Deltalite II 2515Suto BandОценок пока нет

- 01.2 Small-Cell Report - Full ReportДокумент31 страница01.2 Small-Cell Report - Full Reportwalia_anujОценок пока нет

- Tutorial Joint Push Pull - English - V1.1 - 20 Feb 08Документ31 страницаTutorial Joint Push Pull - English - V1.1 - 20 Feb 08shadownrunОценок пока нет

- Individual: DR Winnie Louis LeeДокумент27 страницIndividual: DR Winnie Louis Leeedn_mj1645Оценок пока нет

- Parts List: 8108.010 MagnumДокумент16 страницParts List: 8108.010 MagnumRoque LlamoccaОценок пока нет