Академический Документы

Профессиональный Документы

Культура Документы

Week - 9 - Lecture - 16 Power Transmission Thin Walled Vessels and Strain Gauges

Загружено:

Aitizaz KhanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Week - 9 - Lecture - 16 Power Transmission Thin Walled Vessels and Strain Gauges

Загружено:

Aitizaz KhanАвторское право:

Доступные форматы

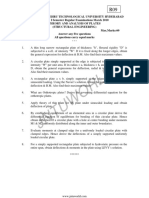

13MMA100 Mechanics of Materials

Thinned Walled Vessels, Strain Gauges

and Power Transmission.

What stresses should we consider for a thin

walled vessel?

What can strain gauges tell us?

How do we calculate shaft power?

How do we calculate torque in geared shafts?

13MMA100 Mechanics of Materials

Thin Walled Pressure

Vessels

We often need to predict the stress in boilers and

tanks.

To calculate the stresses when they are thin walled,

we assume that

The radius to thickness ration is large, i.e., r/t > 10

Stress distribution through thickness is constant

13MMA100 Mechanics of Materials

Gauge Pressure

What is gauge pressure?

It is the pressure above normal atmospheric

pressure.

We are interested in the pressure differential

between the inside and the outside of the vessel.

This means that we generally use the gauge

pressure inside the vessel.

13MMA100 Mechanics of Materials

Cylindrical Vessels

The skin is stressed due to the circumference trying to expand,

assuming positive internal pressure, and due to the ends being

pushed outwards by the internal pressure.

1 Circumferential

2 Longitudinal

1

2

13MMA100 Mechanics of Materials

Circumferential (Hoop)

Stresses

Equilibrium of forces

21 t.dy P 2r.dy 0

dy

t = Vessel wall thickness

P = Vessel pressure

Therefore

Pr

1

t

2r

13MMA100 Mechanics of Materials

Longitudinal Stresses

2

Equilibrium of forces

2 2rt pr

t = Vessel wall thickness

Therefore

pr

2

2t

P

2

2r

13MMA100 Mechanics of Materials

Cylindrical Vessels

Hoop stress is twice as large as longitudinal stress

Longitudinal joints must carry twice as

much stress as circumferential joints

pr

1

t

pr

2

2t

13MMA100 Mechanics of Materials

Spherical Vessels

Equilibrium of forces

2 2rt P r 0

2

Therefore

Pr

2

2t

P

2

But this will be the same in any direction, because

of spherical symmetry.

2r

13MMA100 Mechanics of Materials

Strain Gauges

13MMA100 Mechanics of Materials

Axial Strain

13MMA100 Mechanics of Materials

How do they work?

13MMA100 Mechanics of Materials

The strain is proportional to the voltage measured at V.

13MMA100 Mechanics of Materials

13MMA100 Mechanics of Materials

Strain Rosettes

For each spoke, we can use

gauge X cos 2 Y sin 2 XY cos sin

And we have three equations for three unknowns

13MMA100 Mechanics of Materials

Lets look at the example of a 45 or "rectangular"

rosette

C

B

Measure the three strains

A , B and C

13MMA100 Mechanics of Materials

gauge X cos 2 Y sin 2 XY cos sin Eqn 4.1

cos 0 1

sin 0 0

1

2

1

sin 45

2

cos 45

Using 4.1 we obtain

A X

1

1

1

B X Y XY

2

2

2

C Y

cos 90 0

sin 90 1

13MMA100 Mechanics of Materials

Re arrange

1

1

1

B X Y XY

2

2

2

Therefore we now have the

3 components of planar stress

X A

Y C

XY 2 B A C

13MMA100 Mechanics of Materials

13MMA100 Mechanics of Materials

Power Transmission

through Shafts

Power (Watts) = Torque (Nm) x Angular Speed (rads/Sec)

RPM

The angular speed = 2f 2

60

Power in = Power Out + Losses

13MMA100 Mechanics of Materials

A pump is rated at 135HP (1HP = 746 W) at a speed of 1500 rpm.

The drive shaft to the pump sits in two bearings and ends in a 60 tooth gear wheel enclosed in a gear box.

The gear wheel meshes with a second gear of 20 teeth.

The gear box is driven via an electric motor whose output shaft is 30mm in diameter.

Assuming 10% power losses in the gearbox (pump side), what torque must the motor be able to provide at rated speed?

Pump power consumed (W) = 746 x 135 = 100710 W

Motor power provided (W) = 100710 / 0.9 = 111900 W

Pump speed (Hz) = 1500 / 60

Pump speed (rads/S) = 2 x 3.14 x 1500 / 60 = 157 Rads/S

Motor speed (Hz) = (1500 / 60) x (60/20)

Motor Speed (rads/S) = 471 Rads/S

Motor torque x Motor speed = Motor power

Motor torque (Nm) = 111900 / 471 = 237.58 Nm

If the maximum shear stress allowable is 55 MPa, would a 30mm diameter solid shaft be sufficient for the motor?

MM

max

Motor

Gearbox

Pump

Tc

13MMA100 Mechanics of Materials

Motor torque (Nm) = 237.58 Nm

Max allowable shear stress 55MPa

Shaft diameter = 30mm

max

Tc

J C 4 0.0154

2

2

max

2 237.58

3

0.015

44.81MPa

If the main body of the motor armature had a shaft size of

60mm OD and reduced via a 6mm radius fillet to the

smaller shaft, would the shaft be suitable?

13MMA100 Mechanics of Materials

If the main body of the armature had a shaft size of 60mm OD and reduced via a 6mm radius fillet to the smaller shaft,

would the shaft be suitable?

D 60

2

d 30

r

6

0.2

d 30

K= 1.3 (from chart)

Corrected stress....

max K 44.81

58.26 MPa 55MPa

13MMA100 Mechanics of Materials

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- University of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelДокумент4 страницыUniversity of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelAitizaz KhanОценок пока нет

- Fanno FlowДокумент30 страницFanno FlowAitizaz KhanОценок пока нет

- Atweek 5Документ8 страницAtweek 5Aitizaz KhanОценок пока нет

- Atweek3 3Документ9 страницAtweek3 3Aitizaz KhanОценок пока нет

- Lecture 11 Week 7: Transverse and Longitudinal Shear in Beams. Shear CentresДокумент42 страницыLecture 11 Week 7: Transverse and Longitudinal Shear in Beams. Shear CentresAitizaz KhanОценок пока нет

- A2-Organic Reactions Spider Diagram HANDOUT (Colour)Документ1 страницаA2-Organic Reactions Spider Diagram HANDOUT (Colour)udaymohur100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Transmission MTДокумент29 страницTransmission MTDidier ÁlvarezОценок пока нет

- Midterm Examination (Kittigorn) Ver01Документ10 страницMidterm Examination (Kittigorn) Ver01Namelezz ShadowwОценок пока нет

- A3 PDFДокумент2 страницыA3 PDFChandra Kanth PamarthiОценок пока нет

- Mechanical Engineering Objective - Book - PDFДокумент1 453 страницыMechanical Engineering Objective - Book - PDFanandu vijayan100% (3)

- British Petroleum Standard Multiphase Design ManualДокумент547 страницBritish Petroleum Standard Multiphase Design ManualSakhib100% (2)

- Modelling of Post Tensioning Building FrameДокумент9 страницModelling of Post Tensioning Building FrameHoo Yen HowОценок пока нет

- Chapter 12 Waves 2: NameДокумент32 страницыChapter 12 Waves 2: NamesciencedocsmanОценок пока нет

- Principles of Hydrostatic PressureДокумент25 страницPrinciples of Hydrostatic PressureJherhamy BaguilatОценок пока нет

- Transverse Cantiliver, Free, Simply SupportedДокумент3 страницыTransverse Cantiliver, Free, Simply SupportedmuralidharanОценок пока нет

- ENSC 12 Chapter 1 Part 1Документ52 страницыENSC 12 Chapter 1 Part 1Shyla JopiaОценок пока нет

- Surveying 1 18solДокумент110 страницSurveying 1 18solPrances Pabillore CloribelОценок пока нет

- Discrete Dynamical SystemsДокумент254 страницыDiscrete Dynamical SystemsCarlos Augusto Sánchez Rondón100% (1)

- 76 84Документ10 страниц76 84Carlos Moran CepedaОценок пока нет

- PHYS-2010: General Physics I Course Lecture Notes Section I: Dr. Donald G. Luttermoser East Tennessee State UniversityДокумент17 страницPHYS-2010: General Physics I Course Lecture Notes Section I: Dr. Donald G. Luttermoser East Tennessee State UniversitySteve IsaacsОценок пока нет

- Structural Analysis TYS Exp 249Документ39 страницStructural Analysis TYS Exp 249BIJAY KRISHNA DASОценок пока нет

- Chap 5: Quasi-One-Dimensional FlowДокумент31 страницаChap 5: Quasi-One-Dimensional FlowDev AmirОценок пока нет

- Engine Performance and ModelingДокумент20 страницEngine Performance and ModelingsathishskymechОценок пока нет

- Theory and Analysis of Plates Question PaperДокумент1 страницаTheory and Analysis of Plates Question PaperSandeep ReddyОценок пока нет

- Module 4. Induction Type Indicating InstrumentsДокумент6 страницModule 4. Induction Type Indicating InstrumentsAmit Kr GodaraОценок пока нет

- Cross Regulator TemplateДокумент27 страницCross Regulator TemplateVaibhav PatelОценок пока нет

- The Perfect Gas Expansion Experiment (TH 11)Документ22 страницыThe Perfect Gas Expansion Experiment (TH 11)Muhammad Haidharul Irfan100% (22)

- Aqwa LineДокумент153 страницыAqwa LineEl riza annaml100% (1)

- Tom-I Question Bank UpdatedДокумент174 страницыTom-I Question Bank Updatedkiran_wakchaureОценок пока нет

- Module-2b Fatigue Strength (Bhaskar)Документ35 страницModule-2b Fatigue Strength (Bhaskar)AckshayaОценок пока нет

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Документ3 страницыLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoОценок пока нет

- Lab Report Fluid Mixing (Compile)Документ28 страницLab Report Fluid Mixing (Compile)Nor Elina Ahmad100% (1)

- Tifr Paper 2019Документ16 страницTifr Paper 2019prakash ChoudharyОценок пока нет

- A InstantonДокумент61 страницаA InstantonbayareakingОценок пока нет

- Narayana 14-06-2022 - Outgoing SR - Jee Main Model Gtm-9 - SolДокумент19 страницNarayana 14-06-2022 - Outgoing SR - Jee Main Model Gtm-9 - SolYuva AkhilОценок пока нет