Академический Документы

Профессиональный Документы

Культура Документы

001 Diesel Engine Technology

Загружено:

ZackTerengganuАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

001 Diesel Engine Technology

Загружено:

ZackTerengganuАвторское право:

Доступные форматы

Malaysian Institute of Aviation Technology

DIESEL ENGINE

EASA Part 66 (M5 )

Page No: 1

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

HISTORY

First prototype diesel was developed by Rudolph

Diesel in 1893.

During initial testing, a cylinder head separated.

Four years subsequent to this initial failure, another

engine was developed that proved more reliable.

Engine was found suited for use in marine and heavy

equipment.

Prime advantage was that it provided the lowest

specific fuel consumption of any powerplant available

at the time (as low as .26 lb/hp/hr).

Initially used in airplanes and airships in the 1930s.

e.g. The Jumo diesel, delivered full sea level

horsepower up to 40,000 feet while developing a BSFC

of .356 lb/hp/hr, which equated to developing one

horsepower for each 1.5 pounds of engine weight.

EASA Part 66 (M5 )

Page No: 2

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

INTRODUCTION

Due to economic necessity, many oil companies have

announced plans to curtail or even eliminate the

production of aviation gasoline (avgas).

In an effort to eliminate avgas use, manufacturers are

developing engines that take advantage of alternative

fuels.

Some manufacturers have redesigned engines to

operate on the unleaded gasoline that is presently being

used in the automotive industry while others have

elected to design engines that operate using diesel and

jet fuel

Diesel engine technology has been around for many

decades, used in heavy commercial vehicle applications.

EASA Part 66 (M5 )

Page No: 3

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

INTRODUCTION cond

In previous years the diesel engines used in aircraft

were reasonably efficient and powerful, but

improvements in Otto cycle engines progressed

faster which caused most aircraft manufacturers to

abandon diesel engine designs.

Recently, however, diesel engine technology has

progressed sufficiently to become a practical and

more economical powerplant alternative.

New construction materials and advances in

electronic engine monitoring and control devices,

the use of diesel engines in aircraft is beginning to

gain popularity.

In the United States, the FAA has granted Type

Certification to a number of engines, but most of

those were developed by foreign manufacturers.

EASA Part 66 (M5 )

Page No: 4

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

ADVANTAGES OF DIESEL ENGINES IN AIRCRAFT

Diesel engines are often thought of as being noisy and

heavy.

New technology has reduced noise emissions and weight to

very near or even less than that of avgas engines currently

used in aircraft.

The low RPM and high torque of diesel engines make them

ideal for aircraft by permitting the use of a larger diameter

propeller turning at a slower, more efficient speed.

Diesel aircraft engines run on heavy fuels such as Jet-A or

diesel fuel.

Even though these fuels weigh more per gallon than avgas,

the BTUs produced per gallon are greater than those

provided by avgas.

Heavy fuels also have a higher flashpoint, and cost less to

refine.

Certain countries, avgas is two or three times more

expensive, making a diesel engine much more economical to

operate.

EASA Part 66 (M5 )

Page No: 5

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

ADVANTAGES OF DIESEL ENGINES IN AIRCRAFT cond

Diesel engines have a much lower brake specific fuel

consumption (BSFC) than engines that use avgas

which results in increased range and endurance.

A diesel engine consumes around .32 to .38 pounds of

fuel for each horsepower produced in one hour

(lbs/hp/hour).

For e.g. At full power, a 15OHP diesel engine burns

55.5 pounds or 8.3

gallons of fuel per hour (.37

pounds of fuel x 15OHP).

At full power, an Otto cycle engine using avgas

consumes

around .53-.59 lbs/hp/hour

which, at 15OHP, equates to 88.5

pounds or 14.75

gallons per hour.

EASA Part 66 (M5 )

Page No: 6

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

ADVANTAGES OF DIESEL ENGINES IN AIRCRAFT cond

Diesel engines are more durable than Otto cycle engines

because the higher lubricity of jet and diesel fuels reduces

engine wear.

The lack of an ignition system increases reliability and

eliminates the possibility of electromagnetic interference

(EMI), thereby reducing noise in navigation and

communication equipment.

Many diesel engines are equipped with Full-Authority

Digital Engine Control systems (FADEC).

In many cases, the FADEC system is comprised of a single

power lever control with automatic propeller pitch control.

This combination of factors enables the propeller to

develop the maximum amount of thrust for a given

condition.

The simplicity of operating a diesel engine greatly reduces

pilot workload - an important aspect in aviation

advancement.

EASA Part 66 (M5 )

Page No: 7

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

DIESEL COMBUSTION

Diesel engine has no throttle, spark plugs, or air/fuel

metering device.

During operation, a diesel engine draws in as much air

as it can and, coupled with the addition of a

supercharger and/or turbocharger, has a greatly

increased volume of air delivered to the cylinders.

The increased pressure causes a large increase in

temperature beyond the ignition temperature of the

fuel.

At a specific time before top dead center on the

compression stroke, fuel is injected into the cylinder.

As the fuel initially enters the cylinder, it is too rich

near the injector to burn.

As the fuel mixes with the air and reaches the proper

ratio, the fuel/air charge ignites, or combusts, as a

result of the high temperature and pressure.

EASA Part 66 (M5 )

Page No: 8

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

DIESEL COMBUSTION cond

Because a diesel engine does not pre-mix the fuel and

air before entering the cylinder, the mixture can be

extremely lean.

However, the mixture in a diesel engine is often in the

30:1 to 35:1 ratio, and at idle may be as high as 80:1.

Detonation is not a problem with diesel engines,

turbochargers and superchargers are often used to

increase power output.

Turbocharging uses exhaust gases to drive a

compressor impeller which increases intake manifold

air pressure. Supercharging uses an impeller that is

either gear or belt driven by the engine to drive the

compressor.

EASA Part 66 (M5 )

Page No: 9

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

DIESEL COMBUSTION cond

In most designs utilizing a turbo or supercharger,

greater efficiency and power is obtained by cooling

the intake air before it is delivered to the cylinders.

Higher temperature air is less dense and less

efficient for combustion, so the hot induction air is

first ducted through an intercooler to reduce its

temperature before being delivered to the cylinders.

An intercooler is a heat exchanger, similar in design

to a radiator. The hot air exiting the turbo or

supercharger is directed through the intercooler

wherein ambient air flowing over the intercooler core

transfers some of the heat from the induction air to

the atmosphere.

The induction air, once cooled, is then directed into

the intake manifold, and subsequently into the

cylinders.

EASA Part 66 (M5 )

Page No: 10

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

Fuel Injection

Without a throttle plate, engine power is controlled

by the amount of fuel injected into the cylinders.

The amount of fuel is increased by increasing the

volume, the duration of injection, or both.

Various types of fuel pumps are used to deliver the

fuel to the injectors, but each essentially perform

the same functions.

delivering the fuel in the proper amount, at the

appropriate time, and for the proper duration.

EASA Part 66 (M5 )

Page No: 11

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

Design types

Diesel engines may be two or four stroke designs, in

horizontally opposed, radial, inline, or V configurations.

However, diesel two and four stroke designs have some

unique characteristics.

Four stroke diesel engines generally have better fuel

efficiency than two stroke diesels.

On a two stroke diesel, as the piston moves down and

uncovers the intake and exhaust ports, the expanding gases

no longer exert pressure on the piston.

This causes a slight loss of efficiency as compared to a four

stroke diesel engine, where the force of the expanding gas is

applied to the piston throughout the power stroke.

The loss of efficiency with a two stroke diesel engine is much

less than that of a two stroke gasoline engine since there is

no fuel loss through the exhaust port while fuel is entering

the intake port.

This characteristic also helps to reduce the emissions emitted

by a two stroke diesel, since there is less chance for

unburned fuel to escape through the exhaust port.

EASA Part 66 (M5 )

Page No: 12

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

Diesel and Otto cycle engine comparisons

One major advantage of any diesel engine is its durability.

Unlike avgas, diesel and Jet fuels help lubricate internal

engine parts. Because of this, diesels tend to have less wear

on valve stems and guides, as well as reduced cylinder wall

and piston ring wear.

When compared to a comparable avgas powered engine, this

permits diesel engines to be rated for longer times between

overhaul (TBO) or between replacement (TBR).

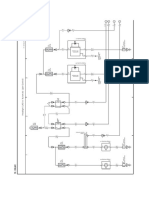

Figure 1-79 compares a Textron Lycoming IO-540 and O-360

against four currently manufactured aircraft diesel engine

designs.

The diesel engines have better fuel efficiency than their

avgas engine. Brake Specific Fuel Consumptions (BSFC),

measured in pounds per horsepower per hour, is 6-19% lower

at 75% power. To approximate this type of fuel economy in

an avgas engine, the fuel mixture would need to be

aggressively leaned, which significantly increases

temperatures, ultimately reducing octane and detonation

margins.

EASA Part 66 (M5 )

Page No: 13

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

Diesel and Otto cycle engine comparisons

Although three of the four diesels in the table have lower

horsepower/pound ratios than the avgas engines, it is

likely these weights will drop and the power developed will

increase as technical improvements are made over time.

Also, diesel engines generally have more torque at lower

RPM This allows the use of a larger, slower turning

propeller.

When a propeller turns at a slower RPM, its efficiency

improves, especially near the blade tips where high speed

tends to generate shock waves that inhibit smooth airflow

over the blade.

E.g. - the Centurion 1.7 is rated at 135HP, but it is

expected to replace engines in the 18OHP range because

the thrust produced by the propeller on the Centurion 1.7

is equivalent to the thrust delivered by a typical 18OHP

avgas engine.

EASA Part 66 (M5 )

Page No: 14

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

AIRCRAFT APPLICATIONS

There are many aircraft equipped with diesel

engines currently involved in the certification

process.

The Diamond DA-42 is a four place twin engine

airplane that is presently undergoing certification

testing. The aircraft is equipped with two Centurion

1.7 engines. The anticipated maximum cruise speed

of this aircraft is 202 knots, burning a mere 11.8 U.S.

gallons per hour. At economy cruise settings, the

anticipated cruise speed is 110 knots, burning 3 U.S.

gallons per hour. This gives an amazing endurance of

nearly 19 hours, and a range of approximately 2200

nautical miles.

EASA Part 66 (M5 )

Page No: 15

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

AIRCRAFT APPLICATIONS

Other aircraft manufacturers such as Maule, Socata, and

Cirrus are planning models that will utilize the Socit de

Motorisations Aronautiques (SMA) R305-230 engine,

which provides lower fuel consumption, and thereby has

an even greater range over an equivilant avgas engine.

Supplemental Type Certification to use this engine is

already being pursued for the Cessna 182 and other

existing airframes.

Deltahawk, another diesel engine manufacturer, is

presently targeting the experimental aircraft market, but

has plans to expand into type certificated aircraft in the

future.

Zoche, a German manufactured diesel engine, will seek

certification in the near future and plans to start installing

their 300HP engine on an Extra 300 aircraft.

Replacing the original Textron Lycoming AEIO-540 will

result in a 200+ pound weight reduction, plus deliver sea

level power up to an expected 24,000 feet.

EASA Part 66 (M5 )

Page No: 16

FOR TRAINING PURPOSE ONLY : ZH

Malaysian Institute of Aviation Technology

THE END

EASA Part 66 (M5 )

Page No: 17

FOR TRAINING PURPOSE ONLY : ZH

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Marine Engines: Customer BenefitsДокумент3 страницыMarine Engines: Customer BenefitsMuhammad RizkiОценок пока нет

- Diagram 3 Brake SwitchДокумент1 страницаDiagram 3 Brake SwitchJuan Carlos Ibarra VelasquezОценок пока нет

- Oil w4015Документ4 страницыOil w4015Ripai AhmadОценок пока нет

- Lexus - GS300 - GS430 - Service - Manual 5Документ40 страницLexus - GS300 - GS430 - Service - Manual 5seregap84100% (5)

- 099 LouiseserДокумент2 страницы099 LouisesersuzukkОценок пока нет

- New Beetle 2.5L 2010Документ116 страницNew Beetle 2.5L 2010Luis Ramon Arguello RealОценок пока нет

- KTA50 Maintenance ProceduresДокумент40 страницKTA50 Maintenance ProceduresWaruna PasanОценок пока нет

- 1986 - Honda HR194-HR214-HRA214 Service Manual - OCR 600dpiДокумент67 страниц1986 - Honda HR194-HR214-HRA214 Service Manual - OCR 600dpiEd Falck80% (5)

- c15 and c18 Engines For Caterpillar Built Engines Fuel SystemДокумент10 страницc15 and c18 Engines For Caterpillar Built Engines Fuel SystemDiegoD'AmbrosioОценок пока нет

- Overall EWD Vehicle Exterior Rear Fog LightДокумент10 страницOverall EWD Vehicle Exterior Rear Fog Lightgabrielzinho43Оценок пока нет

- Air Volume Learn NissanДокумент4 страницыAir Volume Learn NissanNuwan NishanthaОценок пока нет

- Dws4 G Build Engine: Delta SeriesДокумент2 страницыDws4 G Build Engine: Delta Seriesandres tobonОценок пока нет

- Mazda 626 1987 FeДокумент1 865 страницMazda 626 1987 FeJurij Marač100% (1)

- Valvulas EspecificacionesДокумент2 страницыValvulas EspecificacionesAlfonso BerRamОценок пока нет

- YD25 Manual DieselДокумент42 страницыYD25 Manual Dieselalexsandro91537Оценок пока нет

- John Deere 4024TF281 Replacement Part GuideДокумент2 страницыJohn Deere 4024TF281 Replacement Part GuideRamon Pujol PerramonОценок пока нет

- Codigos HondaДокумент25 страницCodigos Hondamarquin84Оценок пока нет

- Finite Element Analysis of Marine Diesel Engine ComponentsДокумент10 страницFinite Element Analysis of Marine Diesel Engine ComponentsInder Mukhopadhyay100% (1)

- Yamaha Exciter 440 EX440 1980Документ18 страницYamaha Exciter 440 EX440 1980mkaukolaОценок пока нет

- C100 Service Training Manual:: Engine Mechanical (2.0L Diesel)Документ40 страницC100 Service Training Manual:: Engine Mechanical (2.0L Diesel)sertex_jo100% (1)

- TM 10 3930 644 14 and PДокумент717 страницTM 10 3930 644 14 and Paravindpeeta100% (1)

- Hunk (Aaka) - (Aug 2012)Документ75 страницHunk (Aaka) - (Aug 2012)KamalRajManickamОценок пока нет

- Autek CitroenДокумент30 страницAutek Citroenegribbell100% (1)

- Parts Manual GDP 040 RG, GDP 050 RG (A875) : Yale Materials Handling CorporationДокумент444 страницыParts Manual GDP 040 RG, GDP 050 RG (A875) : Yale Materials Handling CorporationДмитрий100% (2)

- VDL - KodoviДокумент20 страницVDL - KodoviElmin SkuljОценок пока нет

- JCB 3CX 4CX PartsДокумент9 страницJCB 3CX 4CX PartsLuis Panti Ek50% (16)

- Satoh Bull Instruction Manual OPTДокумент72 страницыSatoh Bull Instruction Manual OPTPere Vila100% (3)

- Caterpillar Remanufactured Products - CrankshaftДокумент4 страницыCaterpillar Remanufactured Products - CrankshaftCHEE SENG LEEОценок пока нет

- The Muncaster Steam-Engine Models: 4-Horizontal Stationary EnginesДокумент4 страницыThe Muncaster Steam-Engine Models: 4-Horizontal Stationary EnginesАлексей МоисеевОценок пока нет

- Goodyear DatasheetДокумент8 страницGoodyear DatasheetasfadsfОценок пока нет