Академический Документы

Профессиональный Документы

Культура Документы

7 Wastes

Загружено:

Joaquim ReisОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

7 Wastes

Загружено:

Joaquim ReisАвторское право:

Доступные форматы

7 WASTES

Click here to see this complete module at six-sigma-

material.com

Six-Sigma-Material.com . All rights reserved. 1

DMAIC APPLICATION MEASURE PHASE

Accuracy / Bias MEASUREMENT Standard Operating Procedures

Resolution / Linearity / Control SYSTEM Measurement Error Quantified

Gage R&R ANALYSIS MSA Validated and Approved

Customer Requirements (VOC) Data Collected per Sampling Plan

O

I Data Collection Plan Process Control Review U

N OEE Process Capability (VOP) T

P Yield Calculations BASELINE Value Stream Map P

U MEASUREMENTS

Descriptive Statistics Refined Project Goals U

T

SPC Charting T

S Refined Financial Estimation

S

Pareto Diagram

Narrowed down PIVs

Fishbone Diagram

Detailed Process Map

Correlation Matrix IDENTIFICATION

OF PIVs Future State (Ideal) Map

FMEA

(root causes xs) Wastes Identified

Brainstorming

RPNs are Known

Spaghetti Diagram

Remove Uncontrollable Inputs

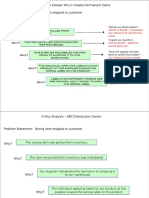

7 Wastes

5-WHY

Six-Sigma-Material.com . All rights reserved. 2

The Seven Wastes

1.Defects

2.Overproduction

3.Excess Transportation

4.Waiting

5.Inventory

6.Excess Motion

7.Excess Processing

Use the acronym DOTWIMP as a mnemonic technique

There is a #8 that is occasionally taught and it is a source of

opportunity in front offices to the factory floor. We will discuss

this later.

Six-Sigma-Material.com . All rights reserved. 3

The Seven Wastes

Purpose:

A primary objective within Lean Manufacturing and DMAIC

projects is to identify waste and eliminate it. This module intends

to teach people to see wastes that are more obvious and seek

out the hidden factory wastes.

These wastes can contribute to degradation in 5S and increase

safety risks among lost profits and possibly revenue and working

capital.

Another form of waste that can be incorporated into this exercise

is the waste and underutilization of human resources and talent.

Misalignment of employee time impedes getting the best results.

4

Six-Sigma-Material.com . All rights reserved.

The Seven Wastes

Waste occurs in very obvious forms to others that are not

obvious. A team is expected to evaluate each form of waste as

they develop process maps and begin to look for improvements.

Waste can occur within:

1. Services

2. Products

3. Transactional processes

Waste can occur within flows of:

4. People

5. Information

6. Products

Six-Sigma-Material.com . All rights reserved. 5

The Seven Wastes

1) OVERPRODUCTION

The reason this one is discussed first in detail, is because it is

the riskiest (and often the most costly) form of waste, since the

other waste also happen within it. Overproduction can have

defects, create more transportation, waiting, etc.

This means building an excess quantity of units or more than the

customer needs or is willing to pay for. This could be due to long

set-up times, very long lead times, and difficulties known at

start-up. This is often done to cover an underlying problem.

In terms of a service, this is the same as doing more than is

required or that the customer is willing to pay for. s to control.

6

Six-Sigma-Material.com . All rights reserved.

The Seven Wastes

2) DEFECTS

For very obvious reasons, making the product right the first time

is ideal and any product that is defective, due to one or more

defects, is an opportunity to reduce costs and lead time.

Defects are products or services that do not meet the customer

specification. Defects always require some degree of additional

attention, whether it they are tracked, scrapped, reworked, or

repaired. These options may result in more waste or others of the

seven wastes.

Remember to consider all the paperwork, confusion, and delays

that might have been associated with the scrap or rework.to

control. Handling defects can create more transportation, 7

Six-Sigma-Material.com . All rights reserved.

The Seven Wastes

3) EXCESS TRANSPORTATION

Manually moving stock to a staging area and dropping off

material and picking it back up to deliver to machine. The goal is

to minimize the transportation and people involved in moving

material.

Transportation waste should be evaluated in the office and

manufacturing floor. Sometimes it is electronic waste in the

corporate environment. Review transportation waste of any

materials (direct or indirect).

Transportation wastes add costs, lead time, and risk of getting

damaged or misplaced. 8

Six-Sigma-Material.com . All rights reserved.

The Seven Wastes

4) WAITING

Downtime waiting for parts, components, raw materials,

approvals, the previous operation down in a cell, and paperwork.

A machine could be waiting for next job, because the current job

is being overproduced. It could be the part is waiting for

something or the people involved are waiting.

Once again, waiting can be a waste that occurs in a transaction

too, such as waiting for a requisition to be approved, or a

purchase order, or a project that requires a sequence of

approvals.

Six-Sigma-Material.com . All rights reserved. 9

The Seven Wastes

5) INVENTORY

Not all inventory is "bad" inventory. A properly sized Kanban or

plan for each unit will dictate the appropriate amounts of

inventory at each phase of a value stream. Moreover, the Kanban

mins and max levels should be dynamic and adjust as conditions

change. It should be capable of looking forward for potential

outliers and using historical performance. Of course, if a business

model exist where all inventory is prepaid by customer and

none is tied up as working capital, then that is an ideal state.

Most often, this isnt possible.

Parts on hand that customer has not purchased yet due to cycle

time and lead time. Buffer stock used to offset variation in

demand and production. Excess inventory ties up cash, creates10

Six-Sigma-Material.com . All rights reserved.

The Seven Wastes

6) MOTION

Excess motion to adjust a machine, frame a house, make a

sandwich, that could be eliminated by rearranging layout, tools,

and personnel. The motion may cause unnecessary fatigue and

long term injury. Proper ergonomics should be applied when

making adjustment to motion studies.

Only have the necessary tools, materials, paperwork at the

operator workstation. The less an item is needed, the further

away it should be. A term commonly used isPOU - Point Of

Use. Use shadowboards and other ideas to keep most frequent

needed items at the operator point of use.

Six-Sigma-Material.com . All rights reserved. 11

The Seven Wastes

7) EXCESS PROCESSING

This is different than the waste of Overproduction. This includes waste such

as over polishing parts, excessing painting, heating parts too long or too

high of temperature, excessive washing, redundant paperwork, excessive

data collection, tumbling, turning, drying parts longer than necessary.

Sometimes this opportunity is less obvious. Your team may find that is can

reduce the production of a part from multiple machines to one machine,

such as putting two components on at the same time, or redesigning tooling

to create more complex stamping in one cycle.

The lack of integrated systems, lack of creative and innovative

spreadsheets, conditional formatting, validation, filtering, can all lead to

over-processing when performing data entry or other clerical and office jobs.

Six-Sigma-Material.com . All rights reserved. 12

The Seven Wastes

Use the 7-Wastes thought process when making improvements

to the process map to help achieve the ideal state. Each of them

are rather obvious when studied individually however it is easier

said than done which refers to actually "seeing" the waste,

identifying it, and eliminating it (or mitigate).

Before the GEMBA walk, creating the process map, or a value

stream map, teach the team members about the seven wastes.

Teach them to see the waste and moreover, dig deeper to find

the hidden factory wastes.

More effective training will include creative examples in their

workplace that are not as obvious. Often, this training comes

across as common sense but if you can surprise them with13

Six-Sigma-Material.com . All rights reserved.

The Seven Wastes

Sometimes the waste is less obvious, found by accident, or may

seem out of scope. The team may be following a product during

a value stream mapping exercise and notice potential

improvements such as:

Lighting that can be converted to more efficient LEDs,

A washer is spraying water when there are not any parts in it,

A dryer is blowing hot air when there are not any parts in it,

Warm air from machines, furnaces, or air compressors is being vented

outside when it could possibly be reclaimed and used to heat a building

or working space,

Gravity that isnt being utilized as a free energy source when it could be

to help the flow of parts or components.

Tools and Dies that arent completely used or that can be reworked

Air compressor and dryer piping inefficiencies

Perhaps some of these are not xs (inputs) that contribute directly to solving .the

Six-Sigma-Material.com gapreserved.

All rights in the14Project

The Seven Wastes REFERENCE GUIDE

1.Defects

2.Overproduction (often the most severe)

3.Excess Transportation

4.Waiting

5.Inventory

6.Excess Motion

7.Excess Processing

Use the acronym DOTWIMP as a mnemonic technique

8. Underutilization and misalignment of human resources time

and talent.

Six-Sigma-Material.com . All rights reserved. 15

Вам также может понравиться

- How To Implement Total Productive MaintenanceДокумент44 страницыHow To Implement Total Productive MaintenanceJoaquim ReisОценок пока нет

- Facts Concerning Dust Air PDFДокумент18 страницFacts Concerning Dust Air PDFJoaquim ReisОценок пока нет

- 4 Steps To VSMДокумент12 страниц4 Steps To VSMJaqui MartinezОценок пока нет

- Acupuntura Aplicada A Patologias PDFДокумент43 страницыAcupuntura Aplicada A Patologias PDF12ab34cd8969Оценок пока нет

- Reiki Master SecretsДокумент96 страницReiki Master SecretsJoaquim Reis100% (3)

- 5W Lean Maintenance PDFДокумент1 страница5W Lean Maintenance PDFJoaquim ReisОценок пока нет

- Dust Collection Technical HandbookДокумент106 страницDust Collection Technical HandbookcassindromeОценок пока нет

- BP Business Plan Financial Tables Jun14Документ7 страницBP Business Plan Financial Tables Jun14ocalmaviliОценок пока нет

- Weibull Analysis ExcelДокумент2 страницыWeibull Analysis ExcelJoaquim ReisОценок пока нет

- 02 - Heat ExchangersДокумент88 страниц02 - Heat ExchangersDana GuerreroОценок пока нет

- 2 Reiki Master SecretsДокумент95 страниц2 Reiki Master SecretsJoão Pereira100% (41)

- Facts Concerning Dust Air PDFДокумент18 страницFacts Concerning Dust Air PDFJoaquim ReisОценок пока нет

- UK2121if 10048Документ2 страницыUK2121if 10048Joaquim ReisОценок пока нет

- Black IPA PDFДокумент1 страницаBlack IPA PDFJoaquim ReisОценок пока нет

- Belgian Pale Ale PDFДокумент1 страницаBelgian Pale Ale PDFJoaquim ReisОценок пока нет

- How To Build A Shipping Container HouseДокумент37 страницHow To Build A Shipping Container Housegschiro93% (14)

- 2 Reiki Master SecretsДокумент95 страниц2 Reiki Master SecretsJoão Pereira100% (41)

- Preview: 30 Shipping Container Homes (120 Page Ebook)Документ120 страницPreview: 30 Shipping Container Homes (120 Page Ebook)ElJay Arem100% (12)

- Build A Container Home Full PDF Book by Warren ThatcherДокумент57 страницBuild A Container Home Full PDF Book by Warren Thatcherwilbur_6980% (44)

- Dust Collection Technical HandbookДокумент106 страницDust Collection Technical HandbookcassindromeОценок пока нет

- Quik House BookletДокумент14 страницQuik House BookletnextSTL.com100% (1)

- KTH Conference Stockholm Keynote 21 October 2016 Final Greg WatsonДокумент51 страницаKTH Conference Stockholm Keynote 21 October 2016 Final Greg WatsonJoaquim ReisОценок пока нет

- 3Cs Principle Document Lean ModelДокумент9 страниц3Cs Principle Document Lean ModelJoaquim ReisОценок пока нет

- ANOVA and experimental design analysis in agricultureДокумент3 страницыANOVA and experimental design analysis in agricultureJoaquim ReisОценок пока нет

- Anderson-Darling Normality Test CalculatorДокумент6 страницAnderson-Darling Normality Test Calculatordelmanto88Оценок пока нет

- 5 WhyДокумент4 страницы5 WhyJoaquim ReisОценок пока нет

- 2.01 Project Charter TemplateДокумент5 страниц2.01 Project Charter TemplateFrancisco HernandezОценок пока нет

- 3.2.3 Template - Project Schedule, V 1.0Документ6 страниц3.2.3 Template - Project Schedule, V 1.0k_jyothiОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- ACS SCPI Programming Guide V1 0Документ29 страницACS SCPI Programming Guide V1 0Pedro Boanerges Paz RomeroОценок пока нет

- Mats Officedocument - Wordprocessingml.documentrendition1 3Документ18 страницMats Officedocument - Wordprocessingml.documentrendition1 3Annie Lyn FaelnarОценок пока нет

- Activities For Teens and AdultsДокумент130 страницActivities For Teens and AdultsDonata Marletta100% (12)

- Spitler McQuiston Lindsey 93 2Документ11 страницSpitler McQuiston Lindsey 93 2Shafawati ShahneelОценок пока нет

- SGSITS Prospectus 2013Документ113 страницSGSITS Prospectus 2013Rohit Kumar Anchaliya100% (1)

- BT 203 Basic Mechanical Engineering May 2019 PDFДокумент2 страницыBT 203 Basic Mechanical Engineering May 2019 PDFKunta PatleОценок пока нет

- Revision WorksheetДокумент1 страницаRevision WorksheetTashana GoweОценок пока нет

- Name: Memory Lunguanga Exam No.: 1131520016 Center No: 3012 Class: 12 N5 Topic: Dairy Milk Processing at Finta Teacher: Mr. Musaka Year: 2014Документ12 страницName: Memory Lunguanga Exam No.: 1131520016 Center No: 3012 Class: 12 N5 Topic: Dairy Milk Processing at Finta Teacher: Mr. Musaka Year: 2014LuzîyêñОценок пока нет

- The Wheel and The BobsleighДокумент2 страницыThe Wheel and The BobsleighHarisОценок пока нет

- Suppliers of Ese Lightning Conductor Kalre Lightning ArresterДокумент2 страницыSuppliers of Ese Lightning Conductor Kalre Lightning ArresterRemedies EarthingОценок пока нет

- Public Service InnovationДокумент112 страницPublic Service InnovationresearchrepublicОценок пока нет

- Payment For Building PermitДокумент1 страницаPayment For Building PermitSterben ShouchiОценок пока нет

- Rupali Bank Final 2003Документ29 страницRupali Bank Final 2003Rupz D TrackerОценок пока нет

- In The Bedroom Missing Letters in Words Esl WorksheetДокумент2 страницыIn The Bedroom Missing Letters in Words Esl Worksheetgirl_blueeyes89Оценок пока нет

- 9-Nietzsche and Super LaughterДокумент18 страниц9-Nietzsche and Super Laughtergannoa02Оценок пока нет

- PredictionAndControllingOfFlyrock PDFДокумент5 страницPredictionAndControllingOfFlyrock PDFikaruskanatlariОценок пока нет

- Chapter 10Документ30 страницChapter 10Fernando Alcala Dela CruzОценок пока нет

- Design & Implementation of Linux Based Network Forensic System Using HoneynetДокумент5 страницDesign & Implementation of Linux Based Network Forensic System Using HoneynetIjarcet JournalОценок пока нет

- Ralph M. McInerny - Aquinas and Analogy (1996, Catholic University of America Press)Документ182 страницыRalph M. McInerny - Aquinas and Analogy (1996, Catholic University of America Press)cuba esquivel amadeoОценок пока нет

- Food Chemistry: Analytical MethodsДокумент7 страницFood Chemistry: Analytical Methodswildan ariefОценок пока нет

- Integrating Information About The Cost of Carbon Through Activity Based Costing 2012 Journal of Cleaner ProductionДокумент10 страницIntegrating Information About The Cost of Carbon Through Activity Based Costing 2012 Journal of Cleaner ProductionLilian BrodescoОценок пока нет

- Lattitude and Longitude PDF ProblemДокумент2 страницыLattitude and Longitude PDF ProblemSatyendranath KarОценок пока нет

- Ice M1Документ36 страницIce M1Irfan ShaikhОценок пока нет

- Use of IT in ControllingДокумент19 страницUse of IT in ControllingSameer Sawant50% (2)

- Competing Risks and Multistate Models With RДокумент249 страницCompeting Risks and Multistate Models With RJuanCarlosAguilarCastro100% (1)

- L o N G e V I T y NotesДокумент24 страницыL o N G e V I T y NotesRajeswara Rao NidasanametlaОценок пока нет

- Public Art, Private PlacesДокумент20 страницPublic Art, Private PlacesLisa Temple-CoxОценок пока нет

- 3rd BeatitudeДокумент18 страниц3rd BeatitudeDonna AОценок пока нет

- Introduction To Pharmaceutical Dosage FormДокумент27 страницIntroduction To Pharmaceutical Dosage FormEshaal KhanОценок пока нет

- Sap Master Data in Materials ManagementДокумент13 страницSap Master Data in Materials Managementedmondo77Оценок пока нет