Академический Документы

Профессиональный Документы

Культура Документы

S04420000220104003S0442 Session 3 Heavy Equipment For Earthwork Construction

Загружено:

shaburo0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров25 страницm

Оригинальное название

S04420000220104003S0442 Session 3 Heavy Equipment for Earthwork Construction

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документm

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров25 страницS04420000220104003S0442 Session 3 Heavy Equipment For Earthwork Construction

Загружено:

shaburom

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 25

Course : S0442 - Construction Method

Year : February 2011

Heavy Equipment for Earthwork

Construction

Session 3

DOZERS

A dozer is a tractor unit that has a blade

attached to the machines front. It is designed to

provide tractive power for drawbar work.

A dozer has no set volumetric capacity. The

amount of material the dozer moves is dependent on

the quantity that will remain in front of the blade

during the push

Bina Nusantara University

3

Crawler Dozer & Wheel Type Dozer

Bina Nusantara University

4

Dozers may be used for operations such as :

1. Moving earth or rock for short haul (push)

distances, up to 90 m

2. Spreading earth or rock fills

3. Backfilling trenches

4. Opening up pilot roads through mountains or

rocky terrain

5. Clearing the floors or borrow and quarry pits

6. Helping load tractor-pulled scrapers

7. Clearing land of timber, stumps and root mat

Bina Nusantara University

5

Project Employment

Stripping

Backfilling

Spreading

Slot Dozing

Blad-to-Blade Dozing

Bina Nusantara University

6

Land Clearing

Crawler dozers equipped with special clearing blades are excellent

machines for land clearing. Clearing of vegetation and trees is

usually necessary before undertaking earthmoving operations.

Ripping Rock

Crawler tractors can be fitted with rear-mounted rippers

specifically designed by the manufacturer to match tarctor

characteristics. Rippers penetrate the earth and is pulled by the

crawler tractors to loosen and split hard ground, weak rock or old

pavements and bases.

Bina Nusantara University

7

SCRAPERS

Scrapers are designed to

load, haul and

dump loose

material in controlled lifts

Scrapers are best suited for

haul distances greater than

500 ft but less than 3000

ft, although with very large

units, the maximum distance

can approach a mile

Bina Nusantara University

8

SCRAPERS

The production cycle of a scrapers consists of six

operations :

Loading

Haul travel

Dumping and spreading

Turning

Return travel

Turning and positioning to pick up

another load

Bina Nusantara University

9

Scraper Types

1.Pusher Loaded (conventional)

- Single powered axle

- Tandem powered axle

2.Self loading

- Push pull, tandem-powered axle

- Elevating

- Auger

Bina Nusantara University

10

Push Loaded (conventional)

Many models can achieve speeds up

to 30 mph when fully loaded. This

extends the economic haul distance of

the units

Push loaded scrapers are at a

disadvantage when it comes to

individually providing the high tractive

effort required for economical loading.

For the single powered axle scraper

only a portion, on the order of 50

55% of the total loaded weight, bears

on the drive wheels.

Single engine scrapers become

uneconomical when :

Haul grades > 5% and

Return grades > 12%

Bina Nusantara University

11

Tandem powered (twin engine)

Tandem powered (twin engine) scrapers are good

for job having adverse grades and poor footing

Owning and operating cost are about 25 % higher

Bina Nusantara University

12

Elevating Scrapers

Elevating scrapers are good for short hauls and in

favorable material

Can work alone in the cut

Cost more initially & to operate

Elevator adds weight & takes power

Bina Nusantara University

13

Push Pull Scrapers

Push pull scarpers can work as a team or can

operate individually with a pusher

Tire wear will increase in rock or abrasive

materials because of more slippage from the four-

wheel drive action

Bina Nusantara University

14

Auger Scrapers

Auger scrapers can self-load in difficult

conditions, laminated rock or granular materials

The auger adds weight to the scraper during

travel and it is more costly to own an operate

than a conventional scraper

Bina Nusantara University

15

EXCAVATORS

Hydraulic excavators are designed to

excavate below the ground surface on

which the machine rests. These machines

have good mobility and are excellent for general-

purpose work, such as excavating trenches and pits.

Because of the hydraulic action of their stick and

bucket cylinders, they exert positive forces crowding

the bucket into the material to be excavated.

The major components of the hydraulic hoe are the

boom, the stick (arm), and the bucket.

Bina Nusantara University

16

Excavation Techniques

The hoe is normally associated with two types of

excavations, trenching (linear-type) and

basement (area-type).

The operator should judge the length and depth

of cut to produce a full bucket with every pass

Bina Nusantara University

17

Paralel & Perpendicular Trenches

Parallel Trenches

With the parallel method, center the hoe on the trench, while

keeping the tractor in line with the trench center line. As the

digging progresses, move the machine away from the

excavation and load the material into haul units or stockpile it

along the side of the trench for later use as backfill.

Perpendicular Trenches

When using the perpendicular method, dig the trenches in two

or more cuts or lifts. To excavate the top 35 to 45 percent of

the trench depth, make the first cut with the boom carried high.

To finish the cut and remove the remainder of the material,

move forward about one-half the length of the machine with

the boom carried low. Although this method involves more and

shorter moves, it has better bucket digging angles and shorter

hoisting distance on the top lifts.

Bina Nusantara University

18

Bina Nusantara University

19

Truck and Hauling Equipment

Trucks are hauling units that

provide relatively low hauling

costs because of their speeds.

The weight capacity of a truck

may limit the volume of the

load that a unit can haul.

The productive capacity of a

truck depends on the size of

its load and the number of

trips it can make in an hour

Truck cycle time has four

components : load time, haul

time, dump time and return

time

Bina Nusantara University

20

Bina Nusantara University

21

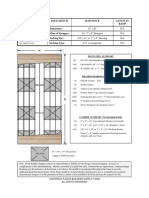

Truck Production

Bina Nusantara University

22

Truck Capacity

Gravimetric the load it will carry, expressed as

a weight

Struck volume the volumetric amount it will

carry, if the load is water level in the body (bowl

or dump box)

Heaped volume the volumetric amount it will

carry, if the load is heaped on a 2 : 1 slope above

the bodt

Bina Nusantara University

23

Tires

Tires are about

35% of a trucks

operating cost

Overloading a

truck abuses the

tires

Bina Nusantara University

24

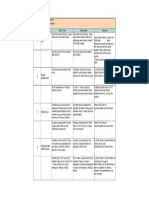

Truck Size Affects Productivity

Small Truck

Advantages Disadvantages

Maneuvering Number

Speed More drivers

Production Loading impediment

Balance of fleet Positioning time

Large Truck

Advantages Disadvantages

Number Cost of truck time at

loading

Driver required Loads heavier

Loading advantage Balance of fleet

Positioning time

Bina Nusantara University Size 25

Вам также может понравиться

- CIVL402 WorksheetsДокумент22 страницыCIVL402 WorksheetsshaburoОценок пока нет

- Transportation Safety Statistics and TrendsДокумент150 страницTransportation Safety Statistics and TrendsshaburoОценок пока нет

- California Bearing Ratio Test ReportДокумент4 страницыCalifornia Bearing Ratio Test ReportshaburoОценок пока нет

- S04420000220104001S0442 Session 1 Introduction To Construction MethodДокумент17 страницS04420000220104001S0442 Session 1 Introduction To Construction MethodshaburoОценок пока нет

- Fix 1Документ34 страницыFix 1shaburoОценок пока нет

- Example of Data From Sieve Analysis Where The Weight Is Equal To The Mass of Soil Retained On A Screen of Particular SizeДокумент24 страницыExample of Data From Sieve Analysis Where The Weight Is Equal To The Mass of Soil Retained On A Screen of Particular SizeshaburoОценок пока нет

- S0793POK p05Документ46 страницS0793POK p05shaburoОценок пока нет

- S04420000220104006S0442 Session 6-7 FoundationДокумент39 страницS04420000220104006S0442 Session 6-7 FoundationshaburoОценок пока нет

- S08440010220124015S0844 P05-06 Design of Compression MemberДокумент45 страницS08440010220124015S0844 P05-06 Design of Compression MembershaburoОценок пока нет

- S04420000220104008S0442 Session 10-11 Concrete and Concrete EquipmentДокумент36 страницS04420000220104008S0442 Session 10-11 Concrete and Concrete EquipmentshaburoОценок пока нет

- S04420000220104002S0442 Session 2 Planning For Earthwork ConstructionДокумент24 страницыS04420000220104002S0442 Session 2 Planning For Earthwork ConstructionshaburoОценок пока нет

- S07530010220124009S0753 P01 - 2Документ38 страницS07530010220124009S0753 P01 - 2shaburoОценок пока нет

- S07430010220114018S0743POK p05 06Документ16 страницS07430010220114018S0743POK p05 06shaburoОценок пока нет

- S04420000220104008S0442 Session 10-11 Concrete and Concrete EquipmentДокумент36 страницS04420000220104008S0442 Session 10-11 Concrete and Concrete EquipmentshaburoОценок пока нет

- Transportation Safety Statistics and TrendsДокумент150 страницTransportation Safety Statistics and TrendsshaburoОценок пока нет

- S08440010220124020S0844 P19-22 Steel ColumnДокумент16 страницS08440010220124020S0844 P19-22 Steel ColumnshaburoОценок пока нет

- Hot Bin 1: Pemeriksaan Analisa Saringan Agregat Halus Dan KasarДокумент8 страницHot Bin 1: Pemeriksaan Analisa Saringan Agregat Halus Dan KasarshaburoОценок пока нет

- S08440010220124014S0844 P03-04 Design of Tension MembersДокумент35 страницS08440010220124014S0844 P03-04 Design of Tension MembersshaburoОценок пока нет

- Ethical Aspects of Information Technology: Course Name: CB142 Year: 2011Документ10 страницEthical Aspects of Information Technology: Course Name: CB142 Year: 2011shaburoОценок пока нет

- S08440010220124012S0844 P23-24 Base PlateДокумент23 страницыS08440010220124012S0844 P23-24 Base PlateshaburoОценок пока нет

- S08440010220124018S0844 P15-16 Weld ConnectionДокумент24 страницыS08440010220124018S0844 P15-16 Weld ConnectionshaburoОценок пока нет

- AMERSHAM Ion Exchange ManualДокумент162 страницыAMERSHAM Ion Exchange ManualNguyen Thi Phuong NhiОценок пока нет

- S08440010220124017S0844 P13-14 Bolt ConnectionДокумент34 страницыS08440010220124017S0844 P13-14 Bolt Connectionshaburo100% (1)

- S08440010220124019S0844 P17-18 High Tension Bolt (HTB)Документ12 страницS08440010220124019S0844 P17-18 High Tension Bolt (HTB)shaburoОценок пока нет

- Klip-Lok 406 271003Документ8 страницKlip-Lok 406 271003kh88hmiОценок пока нет

- S08440010220124015S0844 P05-06 Design of Compression MemberДокумент45 страницS08440010220124015S0844 P05-06 Design of Compression MembershaburoОценок пока нет

- Hot Bin 1: Pemeriksaan Analisa Saringan Agregat Halus Dan KasarДокумент8 страницHot Bin 1: Pemeriksaan Analisa Saringan Agregat Halus Dan KasarshaburoОценок пока нет

- Ba PalowskiДокумент9 страницBa PalowskishaburoОценок пока нет

- George J.critsДокумент55 страницGeorge J.critsshaburo100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Improvement of Soil Properties by Using Jute Fibre As Soil StabilizerДокумент7 страницImprovement of Soil Properties by Using Jute Fibre As Soil StabilizerJanai MarngarОценок пока нет

- Technical Data Sheet - RELY PAINTS PRIVATE LIMITED - 2Документ5 страницTechnical Data Sheet - RELY PAINTS PRIVATE LIMITED - 2iR DesignОценок пока нет

- Pipeline Construction & Maintenance: Drinking-Water Wastewater & Stormwater Trenchless TechnologiesДокумент2 страницыPipeline Construction & Maintenance: Drinking-Water Wastewater & Stormwater Trenchless TechnologiesHuỳnh Thị Kim NgânОценок пока нет

- Rolling Door Details For Concrete Masonry Construction - NcmaДокумент6 страницRolling Door Details For Concrete Masonry Construction - NcmamaricusiaОценок пока нет

- 2374 HSM Imo2Документ14 страниц2374 HSM Imo2Federico QuijanoОценок пока нет

- Catalouge-Two Way Valve JDS PDFДокумент3 страницыCatalouge-Two Way Valve JDS PDFyosi gnscisОценок пока нет

- GeologyДокумент29 страницGeologyMonny MOM100% (1)

- Leser API Series PDFДокумент68 страницLeser API Series PDFVictor RozoОценок пока нет

- Mason Seismic BookДокумент234 страницыMason Seismic BookSergОценок пока нет

- Eaton Plan Book of Ideal Homes PDFДокумент52 страницыEaton Plan Book of Ideal Homes PDFLuciano Dodl100% (1)

- CH 5 RCC SlabДокумент76 страницCH 5 RCC SlabAmanGargОценок пока нет

- Bailey Bridge PDFДокумент373 страницыBailey Bridge PDFdunglxОценок пока нет

- Unit 3Документ59 страницUnit 3P S HARSHITA100% (1)

- A 234 A 234M Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceДокумент8 страницA 234 A 234M Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceILSEN N. DAETОценок пока нет

- Execution SOPДокумент26 страницExecution SOPamit TiwariОценок пока нет

- 220411-WA3420-TNVL-Design Calculation Report - DRAFT - With CommentsДокумент53 страницы220411-WA3420-TNVL-Design Calculation Report - DRAFT - With CommentsHerbee ZevlagОценок пока нет

- Comparative Study of RCC T-Beam Bridge byДокумент32 страницыComparative Study of RCC T-Beam Bridge byPranay Reddy100% (2)

- Elevator Pre-Inspection ChecklistДокумент4 страницыElevator Pre-Inspection Checklistleandro_pescadorОценок пока нет

- Major State-Owned EPC (Refer To P.69)Документ101 страницаMajor State-Owned EPC (Refer To P.69)depzz27Оценок пока нет

- Indian Institute of Management Udaipur: Master of Business Administration 2020-22Документ3 страницыIndian Institute of Management Udaipur: Master of Business Administration 2020-22Aishwarya OgreyОценок пока нет

- FT & FV Comparison - R2Документ1 страницаFT & FV Comparison - R2Waqar Ahmed ShaikhОценок пока нет

- Ordinance Approving Fair Market Values for Real Property in Naga CityДокумент18 страницOrdinance Approving Fair Market Values for Real Property in Naga CityMartin Rilloraza Jr.Оценок пока нет

- Presented By: Syed Sameer Guest Faculty School of Planning and Architecture, MysoreДокумент19 страницPresented By: Syed Sameer Guest Faculty School of Planning and Architecture, MysoreShriya MadooriОценок пока нет

- Keystone f990 920 CatalogoДокумент4 страницыKeystone f990 920 CatalogoGino Chavez ValenciaОценок пока нет

- Hand LayupДокумент3 страницыHand LayupS19M082 KRITHIK AОценок пока нет

- 03 - TDS - Concresive 1414Документ3 страницы03 - TDS - Concresive 1414aahtagoОценок пока нет

- Fundamentals of Post-Tensioned Concrete Design For BuildingsДокумент49 страницFundamentals of Post-Tensioned Concrete Design For BuildingsAmira Syazana100% (1)

- Floating Dock Drawing 10x20 8FD 3416 12and16ocДокумент1 страницаFloating Dock Drawing 10x20 8FD 3416 12and16ocmadsonbaknaОценок пока нет

- Rivet Handbook: Blind Rivets GuideДокумент15 страницRivet Handbook: Blind Rivets GuidenextreaderОценок пока нет

- Wall Panel Brochure - EPCI (PVT) Ltd.Документ18 страницWall Panel Brochure - EPCI (PVT) Ltd.puvitta sudeshilaОценок пока нет