Академический Документы

Профессиональный Документы

Культура Документы

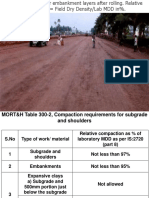

WMM CM

Загружено:

ashoknr0 оценок0% нашли этот документ полезным (0 голосов)

106 просмотров14 страницWMM layer construction

Оригинальное название

WMM cm

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документWMM layer construction

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

106 просмотров14 страницWMM CM

Загружено:

ashoknrWMM layer construction

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 14

IS Sieve Per cent passing

Gradation I (MoRTH) Gradation II

53.0 mm 100

45.0 mm 95 100

26.5 mm 100

22.4 mm 60 80 50 100

11.2 mm 40 60

4.75 mm 25 40 35 55

2.36 mm 15 30

600 micron 8 22 10 30

75 micron 08 29

WET MIX PLANT

Components of Wet Mix Plant

- Cold Aggregate Feeder:

- Vibratory Screen

- Mixing Unit

- Control Panel

Wet Mix Macadam

Quality control tests

Sl Test Relevant code Frequency of

No test

1. Los Angeles abrasion IS:2386 (Part 4) 1 test / 200 m 3

value or

Aggregate impact value

2. Aggregate gradation IS:2386 (Part 1) 1 test / 100 m 3

3. Combined flakiness and IS:2386 (Part 1) 1 test / 200 m 3

elongation index

4. Atterberg limit test on IS:2720 (Part 5) 1 test / 100 m 3

portion of aggregate

passing 425 sieve

5. Density of compacted IS:2720 (Part 28) 1 test / 500 m 2

layer

Advantages of Using WMM

- Homogeneous mix as it is controlled

mechanically

- Laying by Pavers , Graders hence better

surface finish

- Quicker

- Mix can be mixed at suitable locations - where

water is available

- Because of premixing with water seggregation

reduces

- Can achieve higher unit weight hence higher

- Less compactive effort to achieve max density

uniform coating of moisture film around

aggregates

- More output in construction

- Controlled gradation / crushed

Limitations

- After construction of top layer immediate

sealing with bituminous surface

- Lateral confinement

- Normally mechanically crushed aggregates

tends to be rounded than manually crushed

aggregates

Construction Operations

1. Preparation of Base

2. Provision of lateral confinement of aggregates

3. Preparation of Mix

- for small quantity concrete mixer may be

used

- find OMC after replacing retained on

22.4 mm with material 4.75 to 22.4 mm

4. Spreading of Mix

- Spreading of mix to be done uniformly / evenly

- should not be dumped in heaps

- finishing by Paver / grader

- Due importance for segregation

5. Compaction

- 8to 10 tonne static compactor up to 100 mm

- 8-10 vibratory roller up to 200 mm

- Speed of compactor not to exceed 5 km/hour

- displacement occuring due to roller operations

are to be rectified

- Use small compactors near kerb/places not

assessable to roller

- Rolling not be done when subgrade is

soft/yielding /causes wave like motion

- If irregularities during rolling more than 12 mm for

straight edge , surface to be loosned and

premixed material to be added

6. Any defections on the surface to be rectified

7. Setting and Drying

8. Opening to traffic after sealing

Ref:

1. IRC 109- 1997 guidelines for wet Mix

Macadam

2.IRC : SP: 11 State of the Art : Granular

and Bound Bases and Sub Bases

Вам также может понравиться

- Method Statement For Wet Mix MacadamДокумент7 страницMethod Statement For Wet Mix Macadammadhu arepelliОценок пока нет

- Wet Mix Macadam: FunctionДокумент6 страницWet Mix Macadam: FunctionPathankot MandiОценок пока нет

- Methodology of StabilizationДокумент12 страницMethodology of StabilizationRISHI SINGHCHHBARA100% (1)

- Marshall Stability TestДокумент10 страницMarshall Stability Testanon_789699787Оценок пока нет

- Marshall Stability TestДокумент10 страницMarshall Stability TestBVS NAGABABUОценок пока нет

- By: Hiralal Agrawal: Executive EngineerДокумент38 страницBy: Hiralal Agrawal: Executive EngineerCheng EngiОценок пока нет

- BREN - Mix Design WMMДокумент8 страницBREN - Mix Design WMMJoydeep NeogiОценок пока нет

- Quality Control - PavementДокумент28 страницQuality Control - PavementNageshwaran BjlcОценок пока нет

- Quality ControlДокумент35 страницQuality ControlvijayОценок пока нет

- Transportation, Spreading, Compaction and Finishing:: Plants, Equipment and Machinery For Wet Mix MacadamДокумент6 страницTransportation, Spreading, Compaction and Finishing:: Plants, Equipment and Machinery For Wet Mix MacadamRAMPALLI GATTAIAHОценок пока нет

- QA in Highway Sector-Part-3Документ10 страницQA in Highway Sector-Part-3boomiОценок пока нет

- MoRTH Sec 400Документ9 страницMoRTH Sec 400mano3mmmОценок пока нет

- Granular Sub Base LayerДокумент7 страницGranular Sub Base LayerPathankot MandiОценок пока нет

- Types of MixesДокумент68 страницTypes of MixesVinamraMishraОценок пока нет

- IGNOU New Exam Time Table Dec 2018 TentativeДокумент62 страницыIGNOU New Exam Time Table Dec 2018 Tentativejyothis_joy8315Оценок пока нет

- Method Statement For WMMДокумент6 страницMethod Statement For WMMKeerti BonguОценок пока нет

- Dense Bituminous Macadam-DbmДокумент14 страницDense Bituminous Macadam-DbmCheng Engi50% (2)

- Morth + Irc 37 ProbДокумент60 страницMorth + Irc 37 ProbkevalОценок пока нет

- Morth (Ministry of Road Transport and Highways) Important PointsДокумент57 страницMorth (Ministry of Road Transport and Highways) Important PointskevalОценок пока нет

- Marshall Mix Design MethodДокумент21 страницаMarshall Mix Design MethodAltaf HossainОценок пока нет

- P 209Документ6 страницP 209Bhanuka SamarakoonОценок пока нет

- Fineness Modulus of Sand - Fineness Modulus of Fine Aggregate - Fineness Modulus of Sand CalculationДокумент7 страницFineness Modulus of Sand - Fineness Modulus of Fine Aggregate - Fineness Modulus of Sand CalculationWaqas SadiqОценок пока нет

- Bituminous Mix DesignДокумент62 страницыBituminous Mix Designer_kenedy75% (12)

- MoRTH Specifications Pocket Book 25.03.2019 02.00 AMДокумент72 страницыMoRTH Specifications Pocket Book 25.03.2019 02.00 AMsombans100% (2)

- Construction of Bituminous Layers BBMPДокумент84 страницыConstruction of Bituminous Layers BBMPajay chauhanОценок пока нет

- Sieve Analysis2 PDFДокумент4 страницыSieve Analysis2 PDFAnonymous 8BXDrNxZP6Оценок пока нет

- Methodology For Wet Mix MacadamДокумент11 страницMethodology For Wet Mix MacadamRAMPALLI GATTAIAHОценок пока нет

- Testing of AggregatesДокумент22 страницыTesting of AggregatesRahul SharmaОценок пока нет

- Specification ForvvДокумент3 страницыSpecification ForvvTarunОценок пока нет

- @civilbest, Superpave SummaryДокумент60 страниц@civilbest, Superpave Summarymehdi zalnezhadОценок пока нет

- 3 Sieve AnalysisДокумент54 страницы3 Sieve AnalysisjjaavenidoОценок пока нет

- An Easy and Handy Method of Mending Pot-HolesДокумент42 страницыAn Easy and Handy Method of Mending Pot-HolesRajib ChattarajОценок пока нет

- Concrete Construction Manual MethodologiesДокумент73 страницыConcrete Construction Manual Methodologiesvenkateswara rao PothinaОценок пока нет

- Sub-Base, Base and ShouldersДокумент10 страницSub-Base, Base and Shoulderstrilokbist04Оценок пока нет

- UntitledДокумент8 страницUntitledAishath ShahaОценок пока нет

- Concrete LabДокумент97 страницConcrete LabSiva NatОценок пока нет

- Specification For Concrete (Haunching)Документ11 страницSpecification For Concrete (Haunching)jenОценок пока нет

- 01-Sieve Analysis Coarse and Fine Aggregate.Документ7 страниц01-Sieve Analysis Coarse and Fine Aggregate.gsv988Оценок пока нет

- Use of Plastic Waste in Bituminous PavementДокумент19 страницUse of Plastic Waste in Bituminous Pavementparvezahamed563Оценок пока нет

- Aggregates For Asphalt Concrete 880Документ2 страницыAggregates For Asphalt Concrete 880melvinkorahОценок пока нет

- Lec 4 - Road MaterialsДокумент51 страницаLec 4 - Road MaterialsRuel B. Ramos Jr.Оценок пока нет

- Water Bound Macadam Base: DescriptionДокумент4 страницыWater Bound Macadam Base: DescriptionHurriyat AliОценок пока нет

- Reference 2. Setting Out. 3. Selection of Material. 4. Equipments. 5. Methods of Operation. 6. Quality Control. 7. Work Safety. 8. Environmental Safety. 2.0 Setting OutДокумент5 страницReference 2. Setting Out. 3. Selection of Material. 4. Equipments. 5. Methods of Operation. 6. Quality Control. 7. Work Safety. 8. Environmental Safety. 2.0 Setting OutRAMPALLI GATTAIAHОценок пока нет

- 26 12 18 26384 Court 26 12 18 26385 Court 26 12 18 26386 Court 26 12 18 26387 Court 26 12 18 26388 Court Compound WallДокумент11 страниц26 12 18 26384 Court 26 12 18 26385 Court 26 12 18 26386 Court 26 12 18 26387 Court 26 12 18 26388 Court Compound Wallilam bharathiОценок пока нет

- DEsign, Cons and Maintenance RP) PDFДокумент215 страницDEsign, Cons and Maintenance RP) PDFShiba Shankar Satapathy100% (1)

- Tcs Q 11302 r0 Earth WorksДокумент5 страницTcs Q 11302 r0 Earth Workschand saigvОценок пока нет

- Method Statement For Granular Sub BaseДокумент5 страницMethod Statement For Granular Sub Basemadhu arepelli100% (1)

- PPT-Marshal Mix DesignДокумент19 страницPPT-Marshal Mix DesignAshok Kumar Rajanavar100% (1)

- Chapter 2Документ13 страницChapter 2sainathОценок пока нет

- Job Mix Formula For G.S.B. Closer Grade - 1 For 115 MM Thickness As Per Table 400-1 MonthДокумент1 страницаJob Mix Formula For G.S.B. Closer Grade - 1 For 115 MM Thickness As Per Table 400-1 MonthEr Nitin SonkerОценок пока нет

- Foundation, Deep Foundation Llpile PDFДокумент145 страницFoundation, Deep Foundation Llpile PDFShiba Shankar Satapathy100% (1)

- Bituminous Pavement ConstructionДокумент24 страницыBituminous Pavement ConstructionSatish SajjaОценок пока нет

- Spread The LoveДокумент5 страницSpread The LoveRAMPALLI GATTAIAHОценок пока нет

- Wet Mix Macadam-WmmДокумент7 страницWet Mix Macadam-WmmCheng Engi33% (3)

- Quality Control Measures in Asphalt Pavement Constructio BetongДокумент125 страницQuality Control Measures in Asphalt Pavement Constructio BetongMark James MateoОценок пока нет

- Micro Surfacing: Cost Effective Solution For Pavement Preservation and RenewalДокумент16 страницMicro Surfacing: Cost Effective Solution For Pavement Preservation and RenewalCristhian Riveros RojasОценок пока нет

- Quality Control and Quality Assurance LabДокумент6 страницQuality Control and Quality Assurance LabDIVYA MAHALSEKAR-2GI18CV026Оценок пока нет

- Dense Bitumen Macadam (DBM) LayerДокумент12 страницDense Bitumen Macadam (DBM) LayerPathankot MandiОценок пока нет

- 09 Construction WMMДокумент3 страницы09 Construction WMMDevesh KumarОценок пока нет

- Mini Proj Sample Report BPPДокумент50 страницMini Proj Sample Report BPPashoknrОценок пока нет

- Certificate-11-"Hydrological Studies of Panchaganga River'Документ3 страницыCertificate-11-"Hydrological Studies of Panchaganga River'ashoknrОценок пока нет

- Certificate-12-"Hydrological Studies of Chandrabhaga River'Документ3 страницыCertificate-12-"Hydrological Studies of Chandrabhaga River'ashoknrОценок пока нет

- A Seminar Report On Self Sustainable BuildingДокумент32 страницыA Seminar Report On Self Sustainable BuildingashoknrОценок пока нет

- Certificate-10-"Hydrological Studies of Kishna RiverДокумент26 страницCertificate-10-"Hydrological Studies of Kishna RiverashoknrОценок пока нет

- Certificate-9-"SUITABLE CONDITIONS FOR ROOTZONE-UbaleДокумент3 страницыCertificate-9-"SUITABLE CONDITIONS FOR ROOTZONE-UbaleashoknrОценок пока нет

- Biomediacal Waste Project FinalДокумент43 страницыBiomediacal Waste Project Finalashoknr100% (1)

- Justifications 17.9.18Документ23 страницыJustifications 17.9.18ashoknrОценок пока нет

- Certificate 1 Biomedical Waste Management PVDДокумент3 страницыCertificate 1 Biomedical Waste Management PVDashoknrОценок пока нет

- PROJECT REPORT (ITS) - Mini Project-Bipin PatilДокумент51 страницаPROJECT REPORT (ITS) - Mini Project-Bipin PatilashoknrОценок пока нет

- Certificate 1 Biomedical Waste Management PVDДокумент3 страницыCertificate 1 Biomedical Waste Management PVDashoknrОценок пока нет

- S. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentДокумент5 страницS. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentashoknrОценок пока нет

- Certificate 1 Biomedical Waste Management PVDДокумент3 страницыCertificate 1 Biomedical Waste Management PVDashoknrОценок пока нет

- Po 1Документ1 страницаPo 1ashoknrОценок пока нет

- NHAI LetterДокумент1 страницаNHAI LetterashoknrОценок пока нет

- Presented BY: Ashok KumarДокумент50 страницPresented BY: Ashok KumarashoknrОценок пока нет

- Justifications 17.9.18Документ23 страницыJustifications 17.9.18ashoknrОценок пока нет

- Raw Materials of Portland: - Lime - Silica - Alumina - Iron OxideДокумент10 страницRaw Materials of Portland: - Lime - Silica - Alumina - Iron OxideashoknrОценок пока нет

- S. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentДокумент5 страницS. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentashoknrОценок пока нет

- Po 1Документ1 страницаPo 1ashoknrОценок пока нет

- NHAI LetterДокумент1 страницаNHAI LetterashoknrОценок пока нет

- Road Note No. 4 Method/DOE MethodДокумент11 страницRoad Note No. 4 Method/DOE MethodashoknrОценок пока нет

- Lab Manual of Concrete Technology: Chetan S. PatilДокумент76 страницLab Manual of Concrete Technology: Chetan S. PatilashoknrОценок пока нет

- Unit-I-Aggregate GradingДокумент22 страницыUnit-I-Aggregate GradingashoknrОценок пока нет

- ACI MethodДокумент57 страницACI MethodashoknrОценок пока нет

- Proposals For IIC in WIT SolapurДокумент1 страницаProposals For IIC in WIT SolapurashoknrОценок пока нет

- Chapter Name-Airport Obstructions Add Sections: 1) Imaginary Surfaces: A) Add Video B) Quiz C) Lecture Notes In-Video QuizДокумент1 страницаChapter Name-Airport Obstructions Add Sections: 1) Imaginary Surfaces: A) Add Video B) Quiz C) Lecture Notes In-Video QuizashoknrОценок пока нет

- Walchand Institute of Technology, Solapur B.E. Part-II 2018-19 (CBCS Pattern) In-Sem. Examination - IIIДокумент2 страницыWalchand Institute of Technology, Solapur B.E. Part-II 2018-19 (CBCS Pattern) In-Sem. Examination - IIIashoknrОценок пока нет

- External Audit Format - 25022021Документ17 страницExternal Audit Format - 25022021ashoknrОценок пока нет

- Live Interactions Via Google Meet: Kameswari Chebrolu Department of CSE, IIT BombayДокумент5 страницLive Interactions Via Google Meet: Kameswari Chebrolu Department of CSE, IIT BombayAshok Kumar RajanavarОценок пока нет

- Transport Phenomena 18.4.CДокумент3 страницыTransport Phenomena 18.4.CDelyana RatnasariОценок пока нет

- Subsistence and Travel FormsДокумент3 страницыSubsistence and Travel FormsAnonymous YRLhQY6G6jОценок пока нет

- Computer Graphics Mini ProjectДокумент25 страницComputer Graphics Mini ProjectGautam Singh78% (81)

- Instructions: This Affidavit Should Be Executed by The PersonДокумент1 страницаInstructions: This Affidavit Should Be Executed by The PersonspcbankingОценок пока нет

- Mittal Corp LTD 22ND November 2022Документ4 страницыMittal Corp LTD 22ND November 2022Etrans 9Оценок пока нет

- INSURANCE BROKER POLICIES Erna SuryawatiДокумент7 страницINSURANCE BROKER POLICIES Erna SuryawatiKehidupan DuniawiОценок пока нет

- About UPSC Civil Service Examination Schedule and Subject ListДокумент4 страницыAbout UPSC Civil Service Examination Schedule and Subject Listjaythakar8887Оценок пока нет

- Balanza Pediatrica Health o Meter 549KL Mtto PDFДокумент18 страницBalanza Pediatrica Health o Meter 549KL Mtto PDFFix box Virrey Solís IPSОценок пока нет

- Oil Refinery OpsДокумент3 страницыOil Refinery OpsPhiPhiОценок пока нет

- Galanz - Galaxy 7-9-12K - SPLIT PDFДокумент42 страницыGalanz - Galaxy 7-9-12K - SPLIT PDFUbaldo BritoОценок пока нет

- Hi 3 Yt 318201Документ3 страницыHi 3 Yt 318201partha khatuaОценок пока нет

- System Requirements For Autodesk Revit 2018 ProductsДокумент8 страницSystem Requirements For Autodesk Revit 2018 ProductsDaryobmsОценок пока нет

- Steris Amsco Century v120Документ2 страницыSteris Amsco Century v120Juan OrtizОценок пока нет

- General Description Product Summery: Bvdss Rdson IDДокумент4 страницыGeneral Description Product Summery: Bvdss Rdson IDJose Angel TorrealbaОценок пока нет

- RS485 ManualДокумент7 страницRS485 Manualndtruc100% (2)

- CIVREV!!!!Документ5 страницCIVREV!!!!aypod100% (1)

- LG+32LX330C Ga LG5CBДокумент55 страницLG+32LX330C Ga LG5CBjampcarlosОценок пока нет

- You Wouldnt Want To Sail On A 19th-Century Whaling Ship 33 Grisly EnglishareДокумент36 страницYou Wouldnt Want To Sail On A 19th-Century Whaling Ship 33 Grisly EnglishareDušan MićovićОценок пока нет

- East St. Louis, Illinois - Wikipedia, The Free EncyclopediaДокумент9 страницEast St. Louis, Illinois - Wikipedia, The Free Encyclopediadavid rockОценок пока нет

- Cost Volume Profit AnalysisДокумент7 страницCost Volume Profit AnalysisMatinChris KisomboОценок пока нет

- Kilifi HRH Strategic Plan 2018-2021Документ106 страницKilifi HRH Strategic Plan 2018-2021Philip OlesitauОценок пока нет

- CS506 Mid SubjectiveДокумент2 страницыCS506 Mid SubjectiveElma AlamОценок пока нет

- 2 1 PDFДокумент18 страниц2 1 PDFالمهندسوليدالطويلОценок пока нет

- Asme Pvho-2-2019Документ61 страницаAsme Pvho-2-2019Vijay KumarОценок пока нет

- PDFДокумент18 страницPDFDental LabОценок пока нет

- Alfa Laval Plate Heat Exchangers: A Product Catalogue For Comfort Heating and CoolingДокумент8 страницAlfa Laval Plate Heat Exchangers: A Product Catalogue For Comfort Heating and CoolingvictoryanezОценок пока нет

- Business Mathematics and Statistics: Fundamentals ofДокумент468 страницBusiness Mathematics and Statistics: Fundamentals ofSamirОценок пока нет

- Top Ten Helicopter Checkride TipsДокумент35 страницTop Ten Helicopter Checkride TipsAbhiraj Singh SandhuОценок пока нет

- LG LCD TV 32lp1dc - Al-04ca Service ManualДокумент47 страницLG LCD TV 32lp1dc - Al-04ca Service ManualJavin GallardoОценок пока нет

- TIP - IPBT M - E For MentorsДокумент3 страницыTIP - IPBT M - E For Mentorsallan galdianoОценок пока нет