Академический Документы

Профессиональный Документы

Культура Документы

DPWH Standard Specifications On Prime Coat, Tack

Загружено:

ChesterMercado100%(2)100% нашли этот документ полезным (2 голоса)

1K просмотров8 страницstandard specification by dpwh

Оригинальное название

Dpwh Standard Specifications on Prime Coat, Tack

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документstandard specification by dpwh

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

100%(2)100% нашли этот документ полезным (2 голоса)

1K просмотров8 страницDPWH Standard Specifications On Prime Coat, Tack

Загружено:

ChesterMercadostandard specification by dpwh

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

DPWH STANDARD SPECIFICATIONS

ON PRIME COAT, TACK COAT, AND

SEAL COAT

BITUMINOUS PRIME COAT

- A prime coat is an application of a low viscosity asphalt to a granular

base in preparation for an initial layer (or surface course layer) of asphalt. The

purpose of the prime coat is; to coat and bond loose material particles on the

surface of the base, to harden or toughen the base surface to provide a work

platform for construction equipment, to plug capillary voids in the base course

surface to prevent migration of moisture, and to provide adhesion between the

base course and succeeding asphalt course. After applying the prime coat, it

must cure for a minimum of 48-72 hours before asphalt is placed, with no rain

in the forecast.

BITUMINOUS TACK COAT

A tack coat is sprayed on the surface of an existing asphalt or concrete

pavement by a distributor truck immediately prior to placing an overlay. The

goal is to achieve uniform coverage over the entire surface to be paved.

Once the tack coat is in place it should be given time to cure and become

tacky. Normally this would only require a few minutes.

BITUMINOUS SEAL COAT

Seal coating is actually a common type of road resurfacing done on

highways. It involves the application of a special mixture to the road that

protects the road base from additional wear and tear. So its kind of like a

little jacket, but for roads. When its applied over existing pavement, seal

coating is a really cost-effective way of resurfacing that extends the life of

the road by sealing out moisture. It also provides a skid-resistant, anti-glare

surface during wet weather and, because it hardens the surface of gravel

roads, it provides a dust-free driving surface.

BITUMINOUS PRIME COAT

MaterialRequirements

Bituminous material shall be either Rapid Curing (RC) or Medium Curing(MC) Cut-

back Asphalt,whichever iscalled forin the Billof Quantities.It shall

conformtotherequirementsofItem702,Bituminous Materials.Thetypeand

grade shall be specified in the Special Provisions.

ConstructionRequirements

SurfaceCondition

Prime coat shall be applied only to surfaces which are dry or slightly moist. No

prime coat shall be applied when the weather is foggy or rainy.

Equipment

The liquid bituminous material shall be sprayed by means of a pressure distributor of not

less than 1000 liters capacity, mounted on pneumatic tires of such width and number that

the load produced on the road surface will not exceed1 kN(100 kgf) per cm width of tire.

The tank shall have a heating device able to heat a complete charge of bituminous liquid

to 180C.Theheating deviceshall besuchthatoverheating will not occur.Consequently,

theflames mustnot directlytouch thecasing ofthe tank containingthe

bituminousliquid.The liquidshall beinsulated insucha way that the drop in temperature

when the tank is filled with bituminous liquid at 180C and not heated will be less than

2Cperhour.Athermometershallbefixedto the tank in order to be able to measure

continuously the temperature of the liquid. The thermometer shall be placed in such a

way that the highest temperature in

tankismeasured.Thetankshallbefurnishedwithacalibrated dipstickto indicate

thecontents.Thepipes forfilling thetank shall befurnished withan easily changeable

filter.

The distributor shall be able to vary the spray width of the bituminous liquid in maximum

stepsof 100 mmto a totalwidth of 4m.The sprayingbar shall have nozzles from which

the liquid is sprayed fan-shaped on the road surface equally distributed over the total

spraying width.

For adding the liquid bituminous material, the distributor shall have a pump either driven

by a separate motor, or with a device to synchronize its speed with

thespeedofthedistributor.Thepumpshallbefurnishedwithanindicator showing

therateof flow.Thesuction sideof thepump shallhave aneasily

changeablefilter.Athermometershallbefixed,suchthatitindicatesthe temperature of

the liquid immediately before it leaves the spraying bar.

The distributor shall be furnished with a tachometer, indicating its forward

speed,whichshallbevisible fromthedriversseat.Thedistributorshallbe designed so

that the deviation from the prescribed rate of application does not exceed 10% and shall

be equipped with a device for hand spraying of the bituminous liquid.

ApplicationofBituminousMaterial

Immediately before applying the prime coat, the full width of surface to be

treated shall be swept with a power broom and if necessary, scraped to

remove all dirtandotherobjectionablematerials.

WhenrequiredbytheEngineer, immediately prior to the application of the

prime coat, the surface shall be slightly

sprayedwithwaterbutnotsaturated.

Bituminous materialshallbeapplied by means of a pressure distributor at

the temperature.Therate ofapplication ofthebituminous materialshall

bewithin the range of 1 to 2 liters/m, the exact rate to be ordered by the

Engineer.

The prime coat shall be left undisturbed for a period of at least 24 hours and

shall not be opened to traffic until it has penetrated and cured sufficiently so

that itwill notbe pickedup bythe wheelsof passingvehicles.

The Contractor shall maintain theprime coatuntil the nextcourse

isapplied.Care shallbe taken that the application of bituminous material is

not in excess of the specified amount, any excess shall be blotted with sand

or removed as directed by the Engineer.

Allareasinaccessibletothedistributorshallbesprayedmanually using

thedevice forhand spraying.The surfaceof structuresand treesadjacent to

the areas being treated shall be protected in such a manner as to prevent

their being spattered or marred.

BITUMINOUS TACK COAT

The standard specification for Tack Coat is the same as that of the Prime coat.

The difference will be enumerated as follows:

Therate of application of either the Rapid Curing Cut-back or the Emulsified

Asphalt shall be within the range of 0.2 to 0.7 liter/m

The tackcoat shallbe sprayed only so far in advance on the surface course as

will permit it to dry to a

"tackycondition.TheContractorshallmaintainthetackcoatuntilthenext

coursehasbeenapplied.Anyareathathasbecomefouledbytrafficor

otherwise, shall be cleaned and re-sprayed at the Contractors expense before

the next course is applied.

BITUMINOUS SEAL COAT

Description

This Item shall consist of an application of bituminous material with or without an

application of aggregate on an existing bituminous surface course in accordance with the

Plans and Specifications.

MaterialRequirements

QuantitiesofMaterials

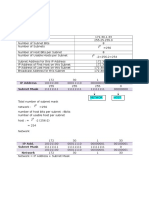

The approximate amounts of materials per square meter for seal coats of the

severaltypes shallbe asprovided inTable

Table 303.1 Quantities ofMaterials for Seal Coats

Type1Type2Type3Bituminous material L/m

Cover Aggregate, kg/m 0.20 0.50none0.50 1.005.00 10.000.85 1.508.00 14.00

Bituminous material shall be Asphalt Cement, Penetration Grade 120-150,Rapid

Curing(RC) orMedium Curing(MC) Cut-backAsphalt.It shallconform to the requirements

of Item 702, Bituminous Materials, whichever is called for in the Bill ofQuantities.The

typeand gradeof asphaltcement orcut-back asphaltwill be specified in the Special

Provisions.

Cover Aggregate for Type 2 seal coat shall consist of sand and fine screenings, reasonably

free from dirt or other organic matter.

Вам также может понравиться

- PCCP Minimum StandardДокумент3 страницыPCCP Minimum StandardJanssen Gerardo Valbuena100% (4)

- DPWH Design Criteria and GuidelinesДокумент228 страницDPWH Design Criteria and GuidelinesJonas de Silva100% (2)

- Math Quiz Bee Grade 6Документ4 страницыMath Quiz Bee Grade 6ChesterMercado94% (35)

- DPWH Blue Book Volume 3Документ178 страницDPWH Blue Book Volume 3Kevin John MaximoОценок пока нет

- DPWH Road & Gutter Details PDFДокумент10 страницDPWH Road & Gutter Details PDFRandy Cerna100% (1)

- DPWH Blue BookДокумент548 страницDPWH Blue Bookjulesjusayan100% (5)

- DPWH Road Design StandardsДокумент1 страницаDPWH Road Design StandardsBenson James Chan100% (4)

- 5.1 AASHTO and DPWH Design of Rigid PavementsДокумент32 страницы5.1 AASHTO and DPWH Design of Rigid PavementsJefferson R. Vallente Jr.100% (2)

- DPWH Min. Pavement Thickness & Width of Nat'l. Road With DESIGN COMPUTATION PDFДокумент8 страницDPWH Min. Pavement Thickness & Width of Nat'l. Road With DESIGN COMPUTATION PDFRandy CernaОценок пока нет

- Item 310Документ18 страницItem 310Mohammad Ali Salem MaunaОценок пока нет

- DPWH Volume 3Документ177 страницDPWH Volume 3Lye Caelum88% (8)

- Item 105 Subgrade PreparationДокумент2 страницыItem 105 Subgrade PreparationGerry Velicaria80% (5)

- DPWH MATERIALS ENGINEERING EXAM REVIEWER FOR ITEM 300 WITH NOTES FROM A MATERIALS ENGINEER LLДокумент76 страницDPWH MATERIALS ENGINEERING EXAM REVIEWER FOR ITEM 300 WITH NOTES FROM A MATERIALS ENGINEER LLWillard Apeng97% (38)

- Concrete For PE Exam DPWHДокумент251 страницаConcrete For PE Exam DPWHLanmerck Pimentel100% (4)

- Math Quiz Bee Grade 4Документ5 страницMath Quiz Bee Grade 4ChesterMercado89% (27)

- Design Fundamentals DPWHДокумент96 страницDesign Fundamentals DPWHJerome Angelo B. Baybay100% (1)

- DPWHДокумент92 страницыDPWHLem Lemlem67% (3)

- DPWH ReviewerДокумент597 страницDPWH Reviewercharles sedigoОценок пока нет

- DO - 063 - S2014 - Item 522A Slope ProtectionДокумент5 страницDO - 063 - S2014 - Item 522A Slope ProtectionRay RamiloОценок пока нет

- DPWH 2004 BluebookДокумент452 страницыDPWH 2004 BluebookRoel Briones100% (4)

- DPWH Road Signs and Pavement Markings May 2011 Complete PDFДокумент360 страницDPWH Road Signs and Pavement Markings May 2011 Complete PDFManuel Lawrence Kenniker100% (3)

- Pavement DesignДокумент88 страницPavement DesignNiraj Bohara100% (1)

- DPWH Minimum Test Requirements PDFДокумент30 страницDPWH Minimum Test Requirements PDFWilliam100% (4)

- DPWH General Notes For ROADSДокумент7 страницDPWH General Notes For ROADSFerdie Tolosa100% (1)

- Amiantit. Field Installation ProcedureДокумент37 страницAmiantit. Field Installation ProcedureABAID ULLAHОценок пока нет

- Materials Engineer REVIEWERДокумент27 страницMaterials Engineer REVIEWERrekcah eht94% (110)

- 24 BitcoinДокумент36 страниц24 Bitcoind0c0ngthanhОценок пока нет

- Pavement Design DPWHДокумент8 страницPavement Design DPWHSwerthson Wasawas83% (6)

- PCCP Construction MethodДокумент11 страницPCCP Construction Methodknight kingОценок пока нет

- Materials Engineer Reviewer Min Req - 2Документ88 страницMaterials Engineer Reviewer Min Req - 2Zner NivlekОценок пока нет

- Math Quiz Bee Grade 5Документ4 страницыMath Quiz Bee Grade 5ChesterMercado85% (13)

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Method of Test ForДокумент8 страницBulk Density ("Unit Weight") and Voids in Aggregate: Standard Method of Test ForChesterMercadoОценок пока нет

- Summary of DPWH Standard Specs and Min Test RequirmentДокумент35 страницSummary of DPWH Standard Specs and Min Test RequirmentWynna Segundo86% (14)

- Pocketbook On Routine MaintenanceДокумент94 страницыPocketbook On Routine MaintenanceKevinNeilPe-il100% (3)

- DPWH Geotextile StandardsДокумент12 страницDPWH Geotextile StandardsFatima Jade Castillo Ang100% (1)

- Specifications in Blue BookДокумент6 страницSpecifications in Blue BookLye CaelumОценок пока нет

- DPWH Standard Specification (2004 Edition)Документ147 страницDPWH Standard Specification (2004 Edition)Jasper Kenneth Peralta100% (4)

- DO - 041 - S2012 - Adoption of The Revised Manual On DPWH Highway Safety Design Standards May 2012Документ16 страницDO - 041 - S2012 - Adoption of The Revised Manual On DPWH Highway Safety Design Standards May 2012mcdale100% (1)

- Clauses & PhrasesДокумент2 страницыClauses & PhrasesmrskumarОценок пока нет

- Dowel Bars For PCCPДокумент2 страницыDowel Bars For PCCPKristelle Ramos100% (2)

- Simplified Reinforced Concrete Design 2010 NSCPДокумент258 страницSimplified Reinforced Concrete Design 2010 NSCPKevin CalpitoОценок пока нет

- Simplified Reinforced Concrete Design 2010 NSCPДокумент258 страницSimplified Reinforced Concrete Design 2010 NSCPKevin CalpitoОценок пока нет

- Simplified Reinforced Concrete Design 2010 NSCPДокумент258 страницSimplified Reinforced Concrete Design 2010 NSCPKevin CalpitoОценок пока нет

- Item 311Документ85 страницItem 311MewnEProwt100% (2)

- Math Quiz Bee Grade 7Документ4 страницыMath Quiz Bee Grade 7ChesterMercado100% (10)

- Method Statement Asphalt PavingДокумент3 страницыMethod Statement Asphalt PavingHussam WaleedОценок пока нет

- AASHTO T 2-91 (2015) - Sampling Aggregates PDFДокумент1 страницаAASHTO T 2-91 (2015) - Sampling Aggregates PDFChesterMercado50% (2)

- DPWH Standard Specification For Chevron Signs Item 620Документ9 страницDPWH Standard Specification For Chevron Signs Item 620Son GokouОценок пока нет

- AASHTO T 85-14 - Specific Gravity and Absorption of Coarse AggregateДокумент9 страницAASHTO T 85-14 - Specific Gravity and Absorption of Coarse AggregateChesterMercadoОценок пока нет

- Math Quiz Bee Grade 9Документ4 страницыMath Quiz Bee Grade 9ChesterMercadoОценок пока нет

- AristotleДокумент126 страницAristotlenda_naumОценок пока нет

- Premix Carpet Seal CoatДокумент32 страницыPremix Carpet Seal CoatAsit MohantyОценок пока нет

- Method of StatementДокумент8 страницMethod of StatementHisham BerrasaliОценок пока нет

- Aashto T-96 (2015)Документ2 страницыAashto T-96 (2015)sidiq767% (3)

- ITEM 300 Latest 2004Документ75 страницITEM 300 Latest 2004Shammir Tabayag MangidaОценок пока нет

- Uganda Standard Specification Series 4000 - Bituminous Layers and SealsДокумент52 страницыUganda Standard Specification Series 4000 - Bituminous Layers and SealsKintu Munabangogo100% (3)

- Materials Engineer REVIEWER 2Документ2 страницыMaterials Engineer REVIEWER 2Jimuel Gonzales100% (1)

- Highway RehabilitationДокумент31 страницаHighway Rehabilitationketh patrickОценок пока нет

- Bituminous Prime Coat: DescriptionДокумент4 страницыBituminous Prime Coat: DescriptionHurriyat AliОценок пока нет

- Hot Chip Seal Specifications Description: Tests On CRS-2P Emulsion Minimum Maximum Test MethodДокумент6 страницHot Chip Seal Specifications Description: Tests On CRS-2P Emulsion Minimum Maximum Test MethodAnonymous iinjEi4E2Оценок пока нет

- ITEM 300 Latest 2004Документ75 страницITEM 300 Latest 2004Avelino De Leon JrОценок пока нет

- Integrated Gas Surface Facilities For RDG Field Project Method Statement For Road WorkДокумент7 страницIntegrated Gas Surface Facilities For RDG Field Project Method Statement For Road WorkfirozОценок пока нет

- Bituminous MacadamДокумент4 страницыBituminous MacadamPremalata NaiduОценок пока нет

- Dry&wet Shotcrete MethodologyДокумент5 страницDry&wet Shotcrete Methodologykavi rajОценок пока нет

- 2287 Technical SpecificationДокумент9 страниц2287 Technical SpecificationBasava NОценок пока нет

- Extracted Pages From SAES-Q-006Документ2 страницыExtracted Pages From SAES-Q-006Sarah AzizОценок пока нет

- Soil Cement SpecificationДокумент4 страницыSoil Cement SpecificationHoa PhamОценок пока нет

- Bituminous Prime Coat PDFДокумент3 страницыBituminous Prime Coat PDFMuhammad ArifОценок пока нет

- Upgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanДокумент8 страницUpgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanSidney MusondaОценок пока нет

- Tream Paper 2.8.editedДокумент5 страницTream Paper 2.8.editedPartho BasakОценок пока нет

- Nitocote cm210Документ4 страницыNitocote cm210pravi3434Оценок пока нет

- Construction Methodolgy For CTB CTSB by Machine InsituДокумент3 страницыConstruction Methodolgy For CTB CTSB by Machine InsituNM2104TE06 PRATHURI SUMANTHОценок пока нет

- Example of Stress Absorbing Membrane InterlayerДокумент7 страницExample of Stress Absorbing Membrane Interlayershanil3001Оценок пока нет

- Methodology RehabilationДокумент3 страницыMethodology RehabilationbvsubramanyamОценок пока нет

- DO - 088 - s2019 CFS PDFДокумент10 страницDO - 088 - s2019 CFS PDFShan AdriasОценок пока нет

- Republic of The Philippines AJ: (0 - U - .zJJ1'rДокумент2 страницыRepublic of The Philippines AJ: (0 - U - .zJJ1'rChesterMercadoОценок пока нет

- Centraloffice: Republic of The PhilippinesДокумент8 страницCentraloffice: Republic of The PhilippinesChesterMercadoОценок пока нет

- III III: ManilaДокумент1 страницаIII III: ManilaChesterMercadoОценок пока нет

- DO 149 s2019Документ9 страницDO 149 s2019Anne Bethany BasilioОценок пока нет

- .TJ FJW (: 5If'fJДокумент3 страницы.TJ FJW (: 5If'fJChesterMercadoОценок пока нет

- Materials Finer Than 75-μm (No. 200) Sieve in Mineral Aggregates by WashingДокумент5 страницMaterials Finer Than 75-μm (No. 200) Sieve in Mineral Aggregates by WashingChesterMercadoОценок пока нет

- 2015 - Standard Method of Test For Sieve Analysis of Fine and Coarse AggregatesДокумент9 страниц2015 - Standard Method of Test For Sieve Analysis of Fine and Coarse AggregatesSameh AhmedОценок пока нет

- AASHTO T 84-13 - Specific Gravity and Absorption of Fine AggregateДокумент9 страницAASHTO T 84-13 - Specific Gravity and Absorption of Fine AggregateChesterMercadoОценок пока нет

- Aashto Fractured FaceДокумент6 страницAashto Fractured FaceChesterMercadoОценок пока нет

- 2014 - 001 Introduction To House PlumbingДокумент16 страниц2014 - 001 Introduction To House PlumbingRon Julienne RebugioОценок пока нет

- Do 053 S2019Документ14 страницDo 053 S2019ChesterMercadoОценок пока нет

- Arraignment ScriptДокумент19 страницArraignment ScriptBerna Bramaje AntonioОценок пока нет

- Arraignment ScriptДокумент19 страницArraignment ScriptBerna Bramaje AntonioОценок пока нет

- Shrimp Salad KareДокумент8 страницShrimp Salad KareChesterMercadoОценок пока нет

- Case Study IN Java: Submitted By: Raymond Perez Submitted To: M/Michael E. BensiДокумент1 страницаCase Study IN Java: Submitted By: Raymond Perez Submitted To: M/Michael E. BensiChesterMercadoОценок пока нет

- Hydraulics ThesisДокумент7 страницHydraulics ThesisChesterMercadoОценок пока нет

- Chapter Seven: GS Ohlins Installation, Adjustment Tips & TricksДокумент29 страницChapter Seven: GS Ohlins Installation, Adjustment Tips & TricksWhattonОценок пока нет

- SSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Документ14 страницSSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Shrishanti Kale100% (1)

- Lec.06.pptx STRUCTURAL GEOLOGY LECTURE NOTESДокумент9 страницLec.06.pptx STRUCTURAL GEOLOGY LECTURE NOTESSalvadora1Оценок пока нет

- NewДокумент3 страницыNewShreyanshu KodilkarОценок пока нет

- Vacuum TubeДокумент1 страницаVacuum Tubejose condoriОценок пока нет

- Air Dan BiomolekulДокумент61 страницаAir Dan BiomolekulgabbymonicaputriОценок пока нет

- Reference Guide: TMS320C674x DSP CPU and Instruction SetДокумент770 страницReference Guide: TMS320C674x DSP CPU and Instruction SetSamreen tabassumОценок пока нет

- Electrochemistry and Its Applications: © 2008 Brooks/Cole 1Документ65 страницElectrochemistry and Its Applications: © 2008 Brooks/Cole 1Niel Karlo AtienzaОценок пока нет

- NTSE Stage - 1 Mock Test - 3Документ16 страницNTSE Stage - 1 Mock Test - 3Apex Institute100% (1)

- Random Sampling - QuizizzДокумент7 страницRandom Sampling - Quizizzmacjoven101Оценок пока нет

- Glut 3Документ68 страницGlut 3Lê Quốc HoàngОценок пока нет

- Chapter 5 - Electric FieldДокумент5 страницChapter 5 - Electric FieldTHIÊN LÊ TRẦN THUẬNОценок пока нет

- Jain 2018Документ10 страницJain 2018Pablo Ignacio Contreras EstradaОценок пока нет

- Electronic Door LockДокумент2 страницыElectronic Door LocktaindiОценок пока нет

- MKT4419 Final ReportДокумент28 страницMKT4419 Final ReportGlenn HengОценок пока нет

- Information Data and ProcessingДокумент10 страницInformation Data and ProcessingarshdeepsinghdhingraОценок пока нет

- MATHSДокумент221 страницаMATHSAbdulai FornahОценок пока нет

- Lerdge-Gcode List V3.0.5Документ108 страницLerdge-Gcode List V3.0.5osman perez vidalОценок пока нет

- Communication ManagementДокумент20 страницCommunication Managementmandalapu_devi5240Оценок пока нет

- Base Tree PropertyДокумент17 страницBase Tree PropertyMario Jardon SantosОценок пока нет

- Lista Ejercicios 3 PPEДокумент25 страницLista Ejercicios 3 PPEKarla HermorОценок пока нет

- Ee 494 AДокумент43 страницыEe 494 AGopinath B L NaiduОценок пока нет

- AutoCAD - Modify ToolbarДокумент18 страницAutoCAD - Modify ToolbarMarcusОценок пока нет

- Mep - July 2013 - January 2010Документ47 страницMep - July 2013 - January 2010sunchit1986Оценок пока нет

- Geotextiles and Geomembranes: E.C. Lee, R.S. DouglasДокумент8 страницGeotextiles and Geomembranes: E.C. Lee, R.S. DouglasPaula T. LimaОценок пока нет

- Assigment Sheet Tast 2 Aina MardianaДокумент10 страницAssigment Sheet Tast 2 Aina MardianaAina MardianaОценок пока нет