Академический Документы

Профессиональный Документы

Культура Документы

Vlsi Presentation

Загружено:

Atul Narkhede0 оценок0% нашли этот документ полезным (0 голосов)

26 просмотров40 страницpresentation is related to mos transistor.

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документpresentation is related to mos transistor.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

26 просмотров40 страницVlsi Presentation

Загружено:

Atul Narkhedepresentation is related to mos transistor.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 40

Introduction :

‘Silicon LSIs (large-scale integrated circuit) have progressed remarkably in the

past 25 years. In particular, complementary metal-oxide-semiconductor technology

has plated a grate role in the progress of LSIs. By downsizing MOS field effect

transistors (FETs), the number of transistors in a chip increases, and the functionality

of the LSIs is improved, At the same time, the switching speed of MOSFETs

citcuits increases and operation, speed of LSIs is improved.

On the other hand system on chip technology has come in to widespread

and as a result the LST system requires several functions such as logic, memory.

analog functions. Moreover, the LS] system sometimes needs ultra-high speed logy

or an ultra high-speed analog function,

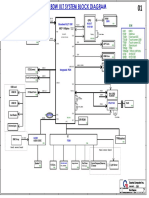

The MOS Transistor :

The most basic element in the design of a large scale integrated circuit is the

transistor. For the processes we will discuss, the type of transistor available is the

“Metal-Oxide-Semiconductor Field Effect Transistor (MOSFET). These transistors are

formed as a “sandwich” consisting of a semiconductor layer, usually a slice, or wafer,

from a single crystal of silicon; a layer of silicon dioxide (the oxide) and a layer of

metal. These layers are pattemed in a manner which permits transistors to be formed

in the semiconductor material (the “substrate”); a diagram showing a typical

(idealized) MOSFET is shown in Fig, 4.1.1, Silicon dioxide is a very good insulator,

soa very thin layer, typically only a few hundred molecules thick, is required.

Actually, the transistors which we will use do not use metal for their gate

regions, but instead use polycrystalline silicon (poly). Polysilicon gate FET’s have

replaced virtually all of the older devices using metal gates in large scale integrated

circuits, (Both metal and polysilicon FET’s are sometimes referred to as IGFET’s ---

insulated gate field effect transistors, since the silicon dioxide under the gate is an

insulator. We will still continue to use the term MOSFET to refer to polysilicon gate

FET’s.)

The transistor consists of three regions, labeled the “source”, the “gate” and the

“drain”, The area labeled as the gate region is actually a “sandwich” consisting of the

underlying substrate material, which is a single crystal of semiconductor material

(usually silicon); a thin insulating layer (usually silicon dioxide); and an upper metal

layer. Electrical charge, or current, can flow from the source to the drain depending

on the charge applied to the gate region.

The semiconductor material in the source and drain region are “doped” with a

different type of material than in the region under the gate, so an NPN or PNP type

structure exists between the source and drain region of a MOSFET. Fig. 4.1.1 shows

a cross section of both types of MOSFET. In Fig. 4.1.1(a), the source and drain

regions are doped with N type material and the substrate doped with P type material.

Such a transistor is called an N channel MOSFET. If they were doped with P type

material, and the substrate doped with N type material as in Fig. 4.1.1(c) the device

would be called a P channel MOSFET.

The source and drain regions are quite similar, and are labeled depending on to

what they are connected. The source is the terminal, or node, which acts as the source

of charge carriers, charge carriers leave the source and travel to the drain. In the case

of an N channel MOSFET, the source is the more negative of the terminals; in the

case of a P channel device, it is the more positive of the terminals. The area under the

gate oxide is called the “channel”

Source Gate Drain

Vs

OT

RSs

TT)

(a) nMOS enhancement mode transistor

Source Gate Drain

(b) nMOS depletion mode transistor

Source Gate Drain

moun

Pinon

esos

TTT) CT

BRERE V.

SON Sore errr eh ORIEN Lr ST ERTRRTI RN ON NO)

PR XR RMR RR ON NRL SN ROM OOO NT

SESSION, asa si

“ Bes ORSON

SS

SS

SS

BORON NK NON CUCU OE

SDS RNS SISK eh RS ROSSI SSIS SMS

(c) PMOS enhancement mode transistor

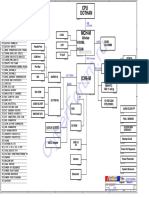

The MOSFET can operate as a very efficient switch for current flowing

between the source and drain region of the device. For the simplest type of MOSFET,

the “enhancement mode MOSFET”, which acts as a “normally open” switch, the

operation of the device can be described qualitatively with reference to Fig. 4.1.2

+Vos + Vos

(a) (b)

Fig. 4.1.2 : Enhancement mode nMOS operation

Fig. 4.1.2(a) shows an N-channel MOSFET with the source and drain

connected to power (Vpp) and ground (Vss); the substrate, or body of the device, is

also connected to ground. In this case, there is a reverse biased PN junction between

at least one of the N wells and the substrate, so no current can flow through the

substrate. In particular, there will be no current flow in the channel region under the

gate of the transistor, and therefore no current will flow between the source and drain

of the device. Under these conditions, the MOSFET is tuned off.

Fig. 4.1.2(b) shows the same N-channel MOSFET with a positive charge

applied to the gate of the device. Under these circumstances. if the gate is given a

sufficiently large charge, negative charge carriers (clectrons) will be attracted from

the bulk of the substrate material into the channel region immediately below the

oxide under the gate. When more electrons are attracted into this region than there are

positive charge carriers (holes) in the channel, then the channel effectively behaves as

an N type region, and current can flow between the source and the drain. When this

happens, the MOSFET is turned on.

Note that a certain minimum charge must be appiied to the gate to overcome

the excess of holes already in the channel region because of the P type doping in the

substrate. This means that the switch is not turned on immediately; rather there must

be some minimum amount of charge applied to the gate before the transistor is

switched on. The voltage which must be applied to the gate before the transistor

allows current to flow between the source and drain is called the “threshold voltage”,

designated as VT,,.

This type of transistor is called an N channel enhancement mode MOSFET. (It

is called N channel because the conduction in the channel is due to N type charge

carriers; it is said to be an “enhancement mode” device because the channel

conduction is enhanced by a charge applied to the gate.) Fig. 4.1.4 shows a set of

typical characteristic curves for the current Ips between the drain and source of a

MOSFET as a function of the voltage Vijg for a range of gate voltages, Vos

al

(a)

Fig. 4.1.3:

(b)

Depletion mode nMOS operation

A second type of MOSFET can also be constructed; this type of device is

commonly used in purely NMOS designs, but is not used in CMOS designs

(Presently, we only have access to CMOS processes.) This type of MOSFET, the

“depletion mode MOSFET”, acts as a “normally closed” switch. Its behavior can

qualitatively be explained with reference to Fig. 4.1.4 which shows an N channel

depletion mode MOSFET. 7

'p

Vest

VGs:

Ves3.

Vos

Fig. 4.1.4 : Characteristics of MOSFET

In the depletion mode MOSFET, a thin layer of semiconductor material

immediately beneath the gate oxide is permanently doped with the same ‘type material

as the source and drain regions (but different from the bulk of the substrate

semiconductor material). This thin layer allows conduction to occur in the channel

region when no charge is applied to the gate. If a negative charge is applicd to the

gate, then the negative charge carriers in the thin N-doped region immediately

beneath the gate oxide will be repelled from this region, leaving no free charge

carriers, and conduction will cease. In the depletion mode MOSFET, a charge (with

the same polarity as the drain dopant) applied to the gate turns the transistor off.

Depletion mode MOSFETs find their most common use not as switches but as

tesistors. As a permanently “on” transistor, the device has a high resistance compared

with the doped semiconductor material itself, and the resistance is readily variable by

modifying the size of the transistor. (At fabrication time, the resistance can be

modified by varying the number of ions which are implanted in the gate region of the

device).

Both enhancement and depletion mode transistors are used in many of today’s

microelectronic circuits, The most popular circuit technology using both

enhancement and depletion mode devices is the conventional NMOS technology. In

this technology, depletion mode transistors are mainly as resistors and enhancement

mode transistors are used as switches.

Physical Structure of the MOSFET :

In this section, a description of a structure of a MOSFET in order to delinate

the physical and geometrical regions of the device and to define electrodes and

terminals. The n-type inversion channel silicon MOSFET is shown in Fig. 4.2.1

V5 @ Source Vv. Oe Drain

x n-type inversion Kw

substrate channel

‘Substrate body

Gate oxide

1) Co-ordinate System :

The most common geometry used in VLSI chips is rectangular co-ordinate

system as shown in Fig. 4.2.1

i) The x-axis denotes the depth direction into the silicon substrate

ii) The y-axis denotes the channel length direction along which the current flows

known also as the longitudinal direction since it is longitudinal to current flow.

iii) Thus, the x-direction in the oxide film is the direction of the transverse electric

field that controls the current i.e. the oxide field (x-direction) is transverse to

the current (y-direction)

iv) The z-axis denotes the width direction both for the gate width and the channel

width.

2) Body of the Semiconductor :

i) The semiconductor body of the n-channel MOSFET is the p-type substrate. It

is also known as bulk or base

ii) The d.c. voltage applied to the wire connected to the body electrode is denoted

by V, (from x-axis)

3)

ii)

iii)

iv)

4)

ii)

Source and Drain :

The two n+ regions form the two n+ / p junctions, The ‘+’ sign means the n-

type region is heavily doped and has very high conductivity.

nt source region is the source of the charge carriers that flow in the channel.

The n-type drain region is the sink or drain of the charge carriers.

‘The source and drain junction areas are different and the adjacent gate oxides

contain different densities of oxide and interface trap created by the different

high electric fields near the source and drain junctions.

Gate oxide, Gate contact, Gate width :

The third region of the MOSFET is the surface oxide layer between the source

and drain. This layer is thin, pure, defect free and 50-2000 A° thick thermally

grown oxide. It serves as the dielectric layer so that the gate can sustain as

high as I x 10° to 5 x 10° V/cm transverse electric field in order to strongly

modulate the conductance of the channel. This is known as Gate oxide.

Above the gate oxide is a thin gate electrode layer made of metal which can be

aluminium, a highly doped silicon.

iii)

5)

iii)

The geometrical width of the gate conductor electrode Z :s called pats x.

Symbol W is often used for gate width instead of Z.

Channel type, Channel length and Channel thickness :

Below the gate oxide is a thin n-type inversion layer on the surface of the p-

type substrate. It is induced by the oxide electric field from the applied gate

voltage V,. This is known as inversion channel. It is the conduction chains!

that allows, the electrons to flow from source to the drain.

The geometrical channel length is labeled by ‘L’. The electrical channel is

shorter than geometrical channel

The clectrical channel thickness is labeled by X.. In doped n-channel

MOSFET, this is equal to the geometrical thickness of the doped channe! or

the depth of the n/p+ junction of the doped layer minus the thickness of the

junction space-charge layer on the doped n-channel side

6) Field oxide, Pad oxide :

The oxide layers under the source and drain contact bonding pads about

5000°A, this reduces the loading capacitance and increases the diclectric breakdown

voltage to allow the drain to be biased to higher voltages.

The oxide at the two width edges (Z-direction) of the gate is also thicker.

These thick oxides, surrounding the thin gate oxide and covering the drain and source

junctions are known as the field oxides and those under the wire bonding metal pad

are known as pad oxides.

MOS Structure :

The metal oxide semiconductor (MOS) structure is shown in Fig. 4.4.1. The

structure consist of three layers, semiconductor substrate (generally P type),

insulating layer of silicon oxide (SiO,) and metal gate of aluminium (now a days

polysilicon is used instead of aluminium)

Al

SiO.

Ohmic

contact

This structure is also known as MOS capacitor with metal plate and

semiconductor plate and oxide as an dielectric. The energy band diagram of an ideal

P-type semiconductor MOS at V = 0 is shown in Fig. 4.4.1.

1) The work function is the energy difference between the Fermi level and the

vaccum level (i.e. q >, for metal and q , for the semiconductor)

2) Also shown are the electron affinity qx which is the energy difference between

the conduction band edge and the vaccum level in the semiconductor.

3) q bpp, which is the energy difference between the Fermi level E,, and the

intrinsic level E,

Vaccum level

E,, (Freespace)

£, (Conduction Band)

E; (Intrinsic fermi level)

E, (Fermi level)

VATA, Walence Band)

Semiconductor

oxide

Fig. 4.4.2 : Energy band diagram of ideal MOS structure at V = 0

An ideal MOS is defined as, at zero applied bias, the energy difference

between the metal work function q $,, and the semiconductor work function q hors

zero or the work function differene q ,,. is zero.

E 4

Gus = 44,794) =46,-| 145 +4 4| =0

For p-type substrate

as = Om [xB aby] <0

For n-type substrate

where

E, - Energy bandgap

$,, ~ Metal work function in eV

x - Electron affinity

orp ~ Energy difference between E, and E, for p-type

44, ~ Energy difference between E,, and E, for n-type

In other words,

(1) The energy band is flat (Flat band condition) when there is no applied voltage

(2) The only charges that exist in the diode under any biasing conditions are thos:

in the semiconductor and those with equal but opposite sign on the meta

surface adjacent to the oxide.

There is no carrier transprrt through the oxide under direct current biasing

(3)

conditions or resistivity of the oxide is infinite.

The above condition is also known as flat band condition

where

t “n,

byp= gm NU | (N, >> n)

and by,= Sin () (N, >> n)

Where.

N,, = Donor ion concentration

N, = Acceptor ion concentration

In the semiconductor, the bottom of the conduction band E.. 1s located at a

fixed energy separation from E,. This energy difference between E, and E, in the

semiconductor is labeled as electron affinity and denoted by greck letter x (chi). The

affinity is therefore the energy needed to move an electron from the bottom of the

conduction band and place it at rest outside the solid. This work function can be

Tepresented as

qd, = HTL E.-E, |

E Metal (Al) c Oxide (SiO, ) - __ Semiconductor (Si)

4, ; | G7 0.95 eV |

06

| %, |

|

le =11eV

Band gap energy g

| E,=8eV ne

Ha i

| \ | ee 9

i FP 7

Fig, 4.4.3 : Energy band diagram for components of MOS structure

1) The substrate has a bandgap of about 1.1 eV (for silicon) and electron affinity

of about 4.15 eV.

2) The insulating silicon dioxide between silicon and metal gate has large

bandgap of about 8 eV and electron affinity of 0.95 V.

3) The work function of a metal (A1) is about 4.1 eV.

The flat band voltage Vrp is obtained when the applied gate voltage cquals the

work function difference between the gate metal and the semiconductor. If there is

also a fixed charge in the oxide and or at the oxide-silicon interface, the expression

for the flat band voltage must be modified accordingly.

Flat band voltage can be given as

Ven = bm-, Volts or Veg = on. a

ox

Built in potential V,; can be as

Vii = Weep =9 bm — 4, Volts

$,>,, or V,,<0 for p-type silicon

b,<$, or V,,>0 — for n-type silicon

9, = Surface potential

Fig, 4.4.4 : Energy band diagram for MOS structure showing the band bending

Biasing of MOS Structure :

When the MOS structure is biased with positive or negative voltages at the

gate and the substrate, the energy band diagram changes. The electrical behaviour of

the MOS structure under external bias is discussed in this section. In this case the

substrate voltage V,, is assumed to be zero. Then three different cases arise. In the

following each case is explained in detail.

1) Accumulation Region :

The situation for large negative bias on the gate w.r.t. the substrate is depicted

in the Fig. 4.5.1.

1) The large negative charge on the metal plate is balanced by holes attracted to

the silicon-silicon dioxide (Si-SiO.) interface directly below the gate.

2) For the bias condition shown the hole density at the. surface exceeds that

which is present in the original P-type substrate and the surface is said to be

operating in the accumulation region or just in accumulation.

3) This accumulation layer is extremely shallow, existing primarily as a charge

sheet directly below the gate.

4) The oxide electric field is directed towards the gate. So the negative surface

potential causes the energy bands to bend upward near the surface

5) Since the majority carriers are attracted towards the gate the minority carriers

(clectrons) are pushed into the substrate because of negative voltage.

6) The valance band bends upwards and is closer to the fermi level and the fermi

levels remain constant through the MOS structure.

Metal

Fm

oxide

Hole

accumulation

substrate

teettettes

metal Semiconductor

Fig, 4.5.1; Accumulation in MOS structure

2)

Depletion Region :

A small positive voltage is applied to the gate, then

1)

2)

5)

The holes are repelled from the surface.

Eventually. the hole density near the surface is reduced below the majerity

carrier level set by the substrate doping level as shown in Fig. 4.5.2. This

condition is called as depletion and region is called depletion region

The region beneath the metal clectrode is depleted of free carriers in much the

same way as the depletion region that exists near the metallurgical junction of

the pn junction diode

In the Fig. 4.5.2, positive charge on the gate clectrode is balanced by the

negative charge of the ionized acceptor atoms in the depletion layer,

The depletion region width X, can range from a fraction of a micron to many

tens of microns depending on the applicd voltage and substrate doping levels

V2 0 (Small)

Metal

P-type substrate |

\_ Depletion

GND region

Fig, 4.5.2 : Depletion in MOS structure

Mobile hole charge density in thin layer parallel to silicon surface can be

represented as,

dQ =-qN,dx

Change in the surface potential to displace dQ (Poisson equation) can be given as

d= -2aQ

si

. Na

=x dx

By solving above equation

WN, 2

QQ = Ze,

_ Ped @i

xy aN, ol)

6) — Depletion region charge density is given by

Q = - WN,

Q = ~Y2ONy esl Q-QI -Q)

3)

2)

3)

4)

Inversion Region :

As the voltage of the gate electrode increases further then

The electrons are attracted to the surface and the electron density at the surface

will exceed the hole density.

At this voltage, the surface has inverted polarity from the p-type of the:

original substrate to an n-type inversion layer, directly underneath the top

plate.

This inversion region is an extremely shallow layer existing primarily as a

charge sheet directly below the gate. The high density of electrons in the

inversion layer is supplied by the electron — hole generation process within the

depletion layer.

The positive charge on the gate is balanced by the combination of negative

charge in the inversion layer plus negative ionic acceptor charge in the

depletion layer.

5) — The voltage at which the surface inversion layer. forms plays an extremely

important role in MOSFET and is called the threshold voltage V,,,,.

by putting the inversion condition in Equation (2) we get the inversion region depth

Xam aS

_ [212 op |

(Q,=~ op) ~ aNa

The depletion charge density at surface inversion Q,,,can be given as

‘dm

Xam = Xq

Qo = Dean =-qNa Xan

-\ 2qN, €y! 2 op |

V> 0 (large)

Metal

oxide

inversion

region

7

~cywene | en ie |

P-type substrate a

Metal (al) | oxide | Semiconductor (Si)

GND

Fig, 4.5.3 : Inversion in the MOS structure

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Msi MS 7529 Rev 1.1 PDFДокумент33 страницыMsi MS 7529 Rev 1.1 PDFMisael Alves67% (3)

- Design of Fractional - Order PID Controller Based On Genetic AlgorithmДокумент6 страницDesign of Fractional - Order PID Controller Based On Genetic AlgorithmAtul NarkhedeОценок пока нет

- Review, Design, Optimization and Stability Analysis of Fractional-Order PID ControllerДокумент24 страницыReview, Design, Optimization and Stability Analysis of Fractional-Order PID ControllerAtul NarkhedeОценок пока нет

- Jamech: Fractional Order PID Controller For Diabetes PatientsДокумент8 страницJamech: Fractional Order PID Controller For Diabetes PatientsAtul NarkhedeОценок пока нет

- Cost, Expressed by The Complexity and Area: V V V CДокумент1 страницаCost, Expressed by The Complexity and Area: V V V CAtul NarkhedeОценок пока нет

- St. Francis Institute of Technology: (Engineer IngДокумент1 страницаSt. Francis Institute of Technology: (Engineer IngAtul NarkhedeОценок пока нет

- Function: 'Buffalo (I,:) BP - K (I) 'Документ5 страницFunction: 'Buffalo (I,:) BP - K (I) 'Atul NarkhedeОценок пока нет

- Atul RESUMEДокумент3 страницыAtul RESUMEAtul NarkhedeОценок пока нет

- Electro Hydraulic System Components and Their OperationДокумент3 страницыElectro Hydraulic System Components and Their OperationAtul NarkhedeОценок пока нет

- Indala Institute of Pharmacy Diploma in Pharmacy (D-Pharmacy) Bachelor of Pharmacy (B - Pharmacy)Документ4 страницыIndala Institute of Pharmacy Diploma in Pharmacy (D-Pharmacy) Bachelor of Pharmacy (B - Pharmacy)Atul NarkhedeОценок пока нет

- Innovative Engineers' and Teachers' Education Society's Bharat College of Engineering, Badlapur (W)Документ2 страницыInnovative Engineers' and Teachers' Education Society's Bharat College of Engineering, Badlapur (W)Atul NarkhedeОценок пока нет

- On Biometrics For Secure Identity VerificationДокумент1 страницаOn Biometrics For Secure Identity VerificationAtul NarkhedeОценок пока нет

- Biometric For Secure Identity VerificationДокумент28 страницBiometric For Secure Identity VerificationAtul NarkhedeОценок пока нет

- ARC1680 Series SpecificationДокумент2 страницыARC1680 Series SpecificationvvvolnyОценок пока нет

- Altium User GuideДокумент36 страницAltium User Guideuma_shankar_100Оценок пока нет

- LNP ProjectДокумент12 страницLNP ProjectbugyourselfОценок пока нет

- Aspire R3 471T Quanta ZQX DDR3Документ43 страницыAspire R3 471T Quanta ZQX DDR3Luciano LucasОценок пока нет

- OptiPlex XE3 Spec SheetДокумент4 страницыOptiPlex XE3 Spec SheetIrving ChamosaОценок пока нет

- Analysis of Energy Efficient PTL Based Full Adders Using Different Nanometer TechnologiesДокумент6 страницAnalysis of Energy Efficient PTL Based Full Adders Using Different Nanometer TechnologiesDwarakaManeekantaAddagiriОценок пока нет

- 8662QxxB 300M-2256558Документ33 страницы8662QxxB 300M-2256558ManunoghiОценок пока нет

- CS2002Документ2 страницыCS2002Satya DasОценок пока нет

- Ii Year Iv Sem CS8491 Computer ArchitectureДокумент63 страницыIi Year Iv Sem CS8491 Computer ArchitectureRakshith RahulОценок пока нет

- CPU y Sus ComponentesДокумент1 страницаCPU y Sus ComponentesStarlyn ElDistinguidoОценок пока нет

- Module 1 - Rapid Recall QuestionsДокумент3 страницыModule 1 - Rapid Recall QuestionsSatvir GillОценок пока нет

- DebugДокумент14 страницDebugTenRyuujiОценок пока нет

- Aishwariya RanjanДокумент7 страницAishwariya RanjanAiОценок пока нет

- c220m5 SFF Specsheet PDFДокумент93 страницыc220m5 SFF Specsheet PDFstagiraОценок пока нет

- PIC PortsДокумент4 страницыPIC PortsPranav vigneshОценок пока нет

- Chapter 1 Introduction To The Semiconductor Industry 2005 VLSI TECH.1Документ28 страницChapter 1 Introduction To The Semiconductor Industry 2005 VLSI TECH.1samactrangОценок пока нет

- Vivado I/O Clock Planning User GuideДокумент76 страницVivado I/O Clock Planning User Guideg7812Оценок пока нет

- Chapter 2 - Introduction To Logic CircuitsДокумент80 страницChapter 2 - Introduction To Logic CircuitsKarimovaRaikhanovnaОценок пока нет

- Tomasulo Algorithm: Register Renaming ProvidedДокумент12 страницTomasulo Algorithm: Register Renaming ProvidedThiravia SelviОценок пока нет

- Design and Implementation of BCD Adders Using Quantum Dot Cellular Automata For Area Efficient ApplicationsДокумент7 страницDesign and Implementation of BCD Adders Using Quantum Dot Cellular Automata For Area Efficient ApplicationsSaiKumarОценок пока нет

- Nr310501 Interfacing Through Microprocessors Set1Документ2 страницыNr310501 Interfacing Through Microprocessors Set1Srinivasa Rao GОценок пока нет

- Questions: B. Write Notes On: FpgaДокумент2 страницыQuestions: B. Write Notes On: FpgaunnidigiОценок пока нет

- RP 5810Документ45 страницRP 5810Yolanda Fernandez Del AmoОценок пока нет

- L3 Logic GateДокумент36 страницL3 Logic GateInnocentОценок пока нет

- 1ETM (Extracted Timing Models) Basics - VLSI ConceptsДокумент3 страницы1ETM (Extracted Timing Models) Basics - VLSI ConceptsSudheer Gangisetty0% (1)

- Traffic Light ControllerДокумент16 страницTraffic Light ControllerJoshua Jebaraj JosephОценок пока нет

- 5345 ScicompbookДокумент339 страниц5345 ScicompbookHrncic HimzoОценок пока нет

- Asus A3H (2005-08-09) Rev 2.0 SchematicДокумент53 страницыAsus A3H (2005-08-09) Rev 2.0 SchematicAzimute Paravital100% (1)

- Unit09.programmable Logic Devices EnglishДокумент20 страницUnit09.programmable Logic Devices EnglishRufo LemurОценок пока нет