Академический Документы

Профессиональный Документы

Культура Документы

Steam Cracking

Загружено:

Prem Kumar0 оценок0% нашли этот документ полезным (0 голосов)

123 просмотров2 страницыMethanol can be converted to olefins like ethylene and propylene through steam cracking in a pyrolysis process. The process involves heating a methanol-steam mixture in tubes inside a furnace between 800-850°C under pressures of 2-3 bar for less than one second. Short residence times and lower pressures favor primary reactions forming olefins, while longer residence times and higher pressures promote secondary reactions that destroy olefins. Careful control of temperature, pressure, residence time and steam dilution is required to maximize olefin selectivity and yield from 70-85%.

Исходное описание:

like

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документMethanol can be converted to olefins like ethylene and propylene through steam cracking in a pyrolysis process. The process involves heating a methanol-steam mixture in tubes inside a furnace between 800-850°C under pressures of 2-3 bar for less than one second. Short residence times and lower pressures favor primary reactions forming olefins, while longer residence times and higher pressures promote secondary reactions that destroy olefins. Careful control of temperature, pressure, residence time and steam dilution is required to maximize olefin selectivity and yield from 70-85%.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

123 просмотров2 страницыSteam Cracking

Загружено:

Prem KumarMethanol can be converted to olefins like ethylene and propylene through steam cracking in a pyrolysis process. The process involves heating a methanol-steam mixture in tubes inside a furnace between 800-850°C under pressures of 2-3 bar for less than one second. Short residence times and lower pressures favor primary reactions forming olefins, while longer residence times and higher pressures promote secondary reactions that destroy olefins. Careful control of temperature, pressure, residence time and steam dilution is required to maximize olefin selectivity and yield from 70-85%.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

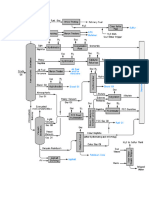

METHANOL TO OLEFIN PRODUCTION VIA STEAM CRACKING PROCESS

Residence time (0.1 0.5 sec )

Steam G Short residence time favours TAGES

N cracking is a pyrolysis process I

N

TIOwhereby a hydrocarbon mixture is heated CK Nprimary

S VAN

CR IP A

CR ITIO reactions where olefins AD AND AGES

DES in metal tubes inside a furnace in the CO

N D are formed VAN

T

AD

presence of steam to a temperature at Long residence time favours DIS

which the hydrocarbon molecules secondary reactions where

thermally decomposes olefins are destroyed Advantages

These reactions require a residence time Pressure (2 3 bar) High energy efficiency and minimum

of less than one second and are High pressure favours secondary environmental emissions

endothermic reactions High plant reliability

Methanol can be produced both Low pressure favours primary Simple operation

from biomass and from fossil reactions Good maintainability

feedstocks and most of the Dilution steam (0.3 0.8 Minimum losses

methanol currently available on kg/kg)

the world market today is Reduces partial pressure of HC

produced from coal or natural Suppresses secondary reactions Disadvantages

gas Prevents excessive coke High cost of operation due to higher

The heat from methanol formation amount of energy (800 850 C )

synthesis can be used to convert Heavier feedstock needs more used

part of methanol into DME steam heat exchangers are prone to

(dimethyl-ether CH3OCH3) and Temperature 800 850 C fouling and therefore need both

water. High temperature promotes the scheduled and unscheduled

Then, DME is converted into formation of lower olefins, low shutdowns

olefins through olefin synthesis temperatures favour An additional issue is coking.

reactions. A fluidized or fixed oligomerization Regular decoking is required in

bed reactor is used. Fast temperature rise favours various parts of the pyrolysis

Temperature is controlled ethylene and propylene section.

between 800 t0 850 degree The heavier the feed the lower Before decoking, the furnace has

celcius in steam cracking.The the temperature to be shut down

pressure maintained between 2 Selectivety

to 3 bar 70% to 85% towards ethylene and

propylene

Yield

BLOCK FLOW DIAGRAM OF METHANOL TO OLEFIN PRODUCTION VIA STEAM CRACKING METHOD

Вам также может понравиться

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Petrochemistry: Instructor: DAO THI KIM THOAДокумент25 страницPetrochemistry: Instructor: DAO THI KIM THOASong Nguyên NguyễnОценок пока нет

- Enhanced Viscosity Reduction in Heavy Oils by Subcritical WaterДокумент8 страницEnhanced Viscosity Reduction in Heavy Oils by Subcritical WaterAleОценок пока нет

- 5.5 Reformer Design-5Документ7 страниц5.5 Reformer Design-5khawarОценок пока нет

- Petrochemical Manufacturing & Application: Mohamad Zarqani Bin YeopДокумент26 страницPetrochemical Manufacturing & Application: Mohamad Zarqani Bin YeopNUR DAMIA MOHAMAD AZIZIОценок пока нет

- Assignment 1Документ8 страницAssignment 1Sulman KhalidОценок пока нет

- Module 2 Steam CrackingДокумент45 страницModule 2 Steam CrackingAfiq AsrafОценок пока нет

- Production of OlefinsДокумент39 страницProduction of OlefinsshubhamОценок пока нет

- Chap 4. Design of ReactorДокумент15 страницChap 4. Design of ReactorAli AhsanОценок пока нет

- Modelling of Naphtha Cracking For Olefins Production - Joao MarcosДокумент9 страницModelling of Naphtha Cracking For Olefins Production - Joao MarcosBahar MeschiОценок пока нет

- CPT Lecture 17 Steam Cracking 2022Документ24 страницыCPT Lecture 17 Steam Cracking 2022saisounyaОценок пока нет

- Manufacturing of EthylbenzeneДокумент61 страницаManufacturing of EthylbenzeneAbdullah IyadОценок пока нет

- Appunti AlbaneseДокумент192 страницыAppunti Albanesej77wn7j9yvОценок пока нет

- An Undesirable Effect During Thermal Cracking Is Coke Deposition On The Walls of The Tubular Reactor. Coke Deposits Build With Reactor Operation Time and Increase Up To A Point in WhichДокумент2 страницыAn Undesirable Effect During Thermal Cracking Is Coke Deposition On The Walls of The Tubular Reactor. Coke Deposits Build With Reactor Operation Time and Increase Up To A Point in WhichWindhi Hoshi Yumemizu IIОценок пока нет

- Part IДокумент3 страницыPart Ingothihonghanh13Оценок пока нет

- Steam CrackingДокумент2 страницыSteam CrackingPrem KumarОценок пока нет

- CATALYSTSДокумент21 страницаCATALYSTSJhon Jairo Rico CerqueraОценок пока нет

- Boiler FundamentalsДокумент39 страницBoiler FundamentalsaksjnОценок пока нет

- Interview Ethyle Benzene PlantДокумент65 страницInterview Ethyle Benzene PlantHimanshu BajajОценок пока нет

- AmmoniaДокумент49 страницAmmoniaAnonymous fhKOhG6Оценок пока нет

- Chen 2007Документ9 страницChen 2007Arisya JulvianaОценок пока нет

- Sustainable Energy: Linfeng ZhangДокумент49 страницSustainable Energy: Linfeng ZhangLuli NikiОценок пока нет

- Petrochemical Technology: GV: Ñaøo Thò Kim Thoa Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMДокумент25 страницPetrochemical Technology: GV: Ñaøo Thò Kim Thoa Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMlinhngan123Оценок пока нет

- SPE 93901 Improved In-Situ Combustion Performance With Metallic Salt AdditivesДокумент17 страницSPE 93901 Improved In-Situ Combustion Performance With Metallic Salt AdditivesAngelCastilloОценок пока нет

- Geothermal Plant SystemsДокумент13 страницGeothermal Plant SystemsKant KanyarusokeОценок пока нет

- Optimal Designof Ethane Pyrolysis ReactorДокумент7 страницOptimal Designof Ethane Pyrolysis ReactorBERLY ALDRO ALFARIDZI -Оценок пока нет

- 49 e TRN 323Документ10 страниц49 e TRN 323Javad Rahmany FardОценок пока нет

- A Novel Reverse Flow Strategy For Ethylbenzene Dehydrogenation in A Packed-Bed ReactorДокумент17 страницA Novel Reverse Flow Strategy For Ethylbenzene Dehydrogenation in A Packed-Bed ReactorMuhammad Akbar FahleviОценок пока нет

- Reducing The Cost To Process Molten AluminumДокумент54 страницыReducing The Cost To Process Molten AluminumKen McgownОценок пока нет

- Petrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMДокумент25 страницPetrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMhatucdao2712Оценок пока нет

- 02 PCRA NitendraDewanganДокумент127 страниц02 PCRA NitendraDewanganGovind RaoОценок пока нет

- Hydrogen Production by Alkaline Water ElectrolysisДокумент22 страницыHydrogen Production by Alkaline Water ElectrolysisAkash GadekarОценок пока нет

- Spe 71460 MS PDFДокумент11 страницSpe 71460 MS PDFLeonela PantojaОценок пока нет

- Petrochemical Manufacturing & Application: 2.0 Fuels and Derivatives Steam Cracking: Production of Lower AlkenesДокумент64 страницыPetrochemical Manufacturing & Application: 2.0 Fuels and Derivatives Steam Cracking: Production of Lower AlkenesFadhli JapryОценок пока нет

- Styrene Methods 2520of ProductionДокумент9 страницStyrene Methods 2520of ProductionMohd Zulazreen50% (2)

- 09Документ35 страниц09Anand kesanakurtiОценок пока нет

- Design and Control of Distillation Columns With Intermediate ReboilersДокумент7 страницDesign and Control of Distillation Columns With Intermediate ReboilersP.R. VarshiniОценок пока нет

- Chapter4. GasificationДокумент19 страницChapter4. GasificationdaniadaniellaaaaaОценок пока нет

- Diemer2010 PDFДокумент18 страницDiemer2010 PDFDaniela Suárez CárdenasОценок пока нет

- Boiler: - IBR Boiler 22.75 Liters in CapacityДокумент23 страницыBoiler: - IBR Boiler 22.75 Liters in CapacitySachin ParasharОценок пока нет

- Field Application of A Chemical Heat and Nitrogen Generating SystemДокумент7 страницField Application of A Chemical Heat and Nitrogen Generating SystemEslamSheblОценок пока нет

- Assignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsДокумент6 страницAssignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsMilan MoradiyaОценок пока нет

- MainДокумент7 страницMainDiego MaportiОценок пока нет

- (2003) Wagner. Prediction of Deactivation Rates and Mechanisms of Methane Reforming Over Nickel CatalystsДокумент2 страницы(2003) Wagner. Prediction of Deactivation Rates and Mechanisms of Methane Reforming Over Nickel CatalystsSarahEkaPutriDarlismawantyaniОценок пока нет

- Journal - Self-Cleaning Fluidised Bed HE For Severely Fouling Liquids and Their ImpactДокумент38 страницJournal - Self-Cleaning Fluidised Bed HE For Severely Fouling Liquids and Their ImpactIynulF.OmarОценок пока нет

- Pressure Influence On Unsteady Film Boiling of Water-Ethanol MixturesДокумент8 страницPressure Influence On Unsteady Film Boiling of Water-Ethanol MixturesCsaba AndrásОценок пока нет

- Phisical Propertis Palm and Cooking OilДокумент10 страницPhisical Propertis Palm and Cooking OilArifin HidayatОценок пока нет

- Manufacture of Acetylene by Paraffin Hydrocarbons : Wulff ProcessДокумент8 страницManufacture of Acetylene by Paraffin Hydrocarbons : Wulff ProcessTones&Feels100% (1)

- Lime Kiln Control Using Simple Advanced Pid Control PDFДокумент4 страницыLime Kiln Control Using Simple Advanced Pid Control PDFIwan TirtaОценок пока нет

- Thorium-Fueled Underground Power Plant Based On Molten Salt TechnologyДокумент7 страницThorium-Fueled Underground Power Plant Based On Molten Salt Technologywsteffen33Оценок пока нет

- Improving C1023 Manufacturability: Using Two-Step Heat TreatmentДокумент5 страницImproving C1023 Manufacturability: Using Two-Step Heat TreatmentAnonymous PJP78mSxОценок пока нет

- My Presentation003 Catalyticcracking SteamcrackingДокумент39 страницMy Presentation003 Catalyticcracking SteamcrackingAiaru BektemirОценок пока нет

- Experimental Comparison of Biomass Chars With Other Catalysts For Tar ReductionДокумент10 страницExperimental Comparison of Biomass Chars With Other Catalysts For Tar ReductionAbdullah KhudariОценок пока нет

- Ethylene Midterms PetrochemДокумент8 страницEthylene Midterms PetrochemEfraim AbuelОценок пока нет

- Tar Content and Composition PDFДокумент9 страницTar Content and Composition PDFSyed Waheed Ul HasanОценок пока нет

- Modeling of Adiabatic Movingbed Reactor For Dehydrogenation of Isobutane To IsobuteneДокумент7 страницModeling of Adiabatic Movingbed Reactor For Dehydrogenation of Isobutane To IsobuteneForcus onОценок пока нет

- PEKK Oligomer Sentezi 2Документ5 страницPEKK Oligomer Sentezi 2Turan ÇetinОценок пока нет

- Poster RecycledДокумент1 страницаPoster RecycledEko PriyadiОценок пока нет

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningОт EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningРейтинг: 5 из 5 звезд5/5 (2)

- Replacement Class AssignmentДокумент2 страницыReplacement Class AssignmentPrem KumarОценок пока нет

- Particle Segregation in Fluidised Binary Mixtures: PressДокумент10 страницParticle Segregation in Fluidised Binary Mixtures: PressPrem KumarОценок пока нет

- One-Way Anova: Groups Count Sum AverageДокумент3 страницыOne-Way Anova: Groups Count Sum AveragePrem KumarОценок пока нет

- 3 Chapter3 Media FormulationДокумент47 страниц3 Chapter3 Media FormulationPrem Kumar0% (1)

- Is A Vector or Matrix Division While Is A Element Wise DivisionДокумент2 страницыIs A Vector or Matrix Division While Is A Element Wise DivisionPrem KumarОценок пока нет

- Activation Energy Ref Cabeq 2014-01-05 PDFДокумент11 страницActivation Energy Ref Cabeq 2014-01-05 PDFPrem KumarОценок пока нет

- Solution For Tutorial ECH3602Документ23 страницыSolution For Tutorial ECH3602Prem KumarОценок пока нет

- CEL 2106 - Worksheet - Week 13 and 14Документ2 страницыCEL 2106 - Worksheet - Week 13 and 14Prem Kumar0% (1)

- Steam CrackingДокумент2 страницыSteam CrackingPrem KumarОценок пока нет

- Eh ColiformfactsheetДокумент2 страницыEh ColiformfactsheetPrem KumarОценок пока нет

- Lecture Planner - Inorganic Chemistry - Prayas JEE 2.0 2024Документ1 страницаLecture Planner - Inorganic Chemistry - Prayas JEE 2.0 2024Ankit MatthОценок пока нет

- White Paper Overview of Rotating Disc Electrode (RDE) Optical Emission Spectroscopy For In-Service Oil Analysis14Документ7 страницWhite Paper Overview of Rotating Disc Electrode (RDE) Optical Emission Spectroscopy For In-Service Oil Analysis14Veeresh Nayak VeereshОценок пока нет

- Physics Project 1Документ19 страницPhysics Project 1Amarjeet Singh33% (3)

- Montreal ProtocolДокумент17 страницMontreal ProtocolJan Aldrin AfosОценок пока нет

- Fsiheries Environment JRFДокумент38 страницFsiheries Environment JRFCandy BoyОценок пока нет

- Nasa TM-86556Документ470 страницNasa TM-86556murphygtОценок пока нет

- A1. Protego - Venting of Atmospheric and Low-Pressure Storage TanksДокумент56 страницA1. Protego - Venting of Atmospheric and Low-Pressure Storage TanksAnnie De WildeОценок пока нет

- Manual de Chillers 2Документ10 страницManual de Chillers 2Winderson Macauran0% (1)

- Allowable DP CalculationДокумент22 страницыAllowable DP CalculationAJAY1381Оценок пока нет

- SL MC Test s2 Models of Bonding - Structure (Second Test)Документ7 страницSL MC Test s2 Models of Bonding - Structure (Second Test)Amira Selpa KhairunnisaОценок пока нет

- 0620 s14 QP 61Документ12 страниц0620 s14 QP 61Michael HudsonОценок пока нет

- Rana Ahmad MSC MATL March 2020Документ140 страницRana Ahmad MSC MATL March 2020Paul JaniОценок пока нет

- Handbook Sewage HandlingДокумент147 страницHandbook Sewage HandlingMannar MannanОценок пока нет

- Challenges in Sustainable Wet Processing PDFДокумент38 страницChallenges in Sustainable Wet Processing PDFJuan CubasОценок пока нет

- Selection of The Disc Brake Material Using Pin On Disc ApparatusДокумент7 страницSelection of The Disc Brake Material Using Pin On Disc ApparatusIJIERT-International Journal of Innovations in Engineering Research and TechnologyОценок пока нет

- Galacid Food 80 (GB)Документ5 страницGalacid Food 80 (GB)Abc AbcdОценок пока нет

- FDA CajetinДокумент5 страницFDA CajetinContempla designОценок пока нет

- Astm Article Bio Deg PlasticsДокумент7 страницAstm Article Bio Deg PlasticsAnonymous kTVBUxrОценок пока нет

- 3 Way Control Valve STEVI 450-451Документ22 страницы3 Way Control Valve STEVI 450-451Ricky 83Оценок пока нет

- MS Fragmentation Functional Groups (Compatibility Mode)Документ68 страницMS Fragmentation Functional Groups (Compatibility Mode)Adriana Estefanía HPОценок пока нет

- Naked Egg ExperimentДокумент7 страницNaked Egg ExperimentAubrey PerezОценок пока нет

- Thermowells 233Документ42 страницыThermowells 233Đoàn TrangОценок пока нет

- KDP Well Test Procedures ManualДокумент77 страницKDP Well Test Procedures ManualJacob Keemink100% (2)

- Safety Data Sheet 20W/50 Motor OilДокумент7 страницSafety Data Sheet 20W/50 Motor OilbabjihanumanthuОценок пока нет

- DRI Charging in EAFДокумент3 страницыDRI Charging in EAFMuhammad NbОценок пока нет

- Novo GO ALKYD GlossyДокумент1 страницаNovo GO ALKYD Glossysarah magdyОценок пока нет

- AGW TrainingДокумент23 страницыAGW TraininglimasmildredОценок пока нет

- Lab Report Emulsion PolymerizationДокумент7 страницLab Report Emulsion PolymerizationNUR AMNI QHAIRUNNAJWA BINTI ARIFFIN STUDENTОценок пока нет

- Capsules: Examples: Lactose, Microcrystalline Cellulose and StarchДокумент2 страницыCapsules: Examples: Lactose, Microcrystalline Cellulose and StarchMnemo SyneОценок пока нет