Академический Документы

Профессиональный Документы

Культура Документы

DYCOPS13 Presentation Minasidis

Загружено:

HarshaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DYCOPS13 Presentation Minasidis

Загружено:

HarshaАвторское право:

Доступные форматы

1

Economic Plantwide Control:

Automated Controlled Variable Selection for a

Reactor-Separator-Recycle Process

Vladimiros Minasidis, Johannes Jschke and

Sigurd Skogestad

Department of Chemical Engineering,

Trondheim, Norway

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

2

Outline

Introduction

Economic Plantwide Control

Case study - RSR process

Conclusions and future work

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

3

Introduction

Most industrial process control strategies are not

designed to optimally handle frequent market

conditions changes.

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

4

Introduction

Most industrial process control strategies are not

designed to optimally handle frequent market

conditions changes.

Integration between process optimization and control

is needed to reduce the production cost

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

5

Introduction

Industry adapts simple control strategies that are

easily understood by the operators and engineers.

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

6

Introduction

Industry adapts simple control strategies that are

easily understood by the operators and engineers.

Essential characteristics:

1. It has to be fairly simple

2. It has to be able to keep the process operation close-to-optimal

while satisfying the operational constraints

3. It has to be easily designed

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

7

Introduction

Industry adapts simple control strategies that are

easily understood by the operators and engineers.

Essential characteristics:

1. It has to be fairly simple

2. It has to be able to keep the process operation close-to-optimal

while satisfying the operational constraints

3. It has to be easily designed.

Economic plantwide control can be used to design

control structures that satisfy the first two

characteristics

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

8

Economic Plantwide Control

Formulate the economic operation as a mathematical

optimization problem and then design a control structure

that results in a close-to-optimal operation while satisfying

the stability and robustness requirements.

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

9

Economic Plantwide Control

Formulate the economic operation as a mathematical

optimization problem and then design a control structure that

results in a close-to-optimal operation while satisfying the

stability and robustness requirements.

Top-down part:

Aims to find an optimal control structure

based on plant steady state economics

Bottom-up part:

Aims to find a simple and robust

regulatory control

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

10

Economic Plantwide Control

Steps from top-down part of plantwide control design

procedure:

1. Define the operational objectives (economics) and

constraints.

Details in [Skogestad, 2012]

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

11

Economic Plantwide Control

Steps from top-down part of plantwide control design

procedure:

1. Define the operational objectives (economics) and

constraints.

2. Determine the steady state optimal operation:

a) Identify the steady-state DOFs

b) Identify the important disturbances and their expected

range

c) Identify the expected active constrains regions

Details in [Skogestad, 2012]

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

12

Economic Plantwide Control

Steps from top-down part of plantwide control design

procedure:

1. Define the operational objectives (economics) and

constraints.

2. Determine the steady state optimal operation:

a) Identify the steady-state DOFs

b) Identify the important disturbances and their expected

range

c) Identify the expected active constrains regions

3. Select primary (economic) controlled variables:

a) Control the active constraints

b) Select self-optimizing CVs

Details in [Skogestad, 2012]

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

13

PC

Process description

PI

LC

CSTR MD

P

XD

1st order kinetics L

R D

A B

A 2C (undesired)

F0

XF

S

MR

F

FC V

TI FI

TR

MB

LC XB

B

Details can be found in Jacobsen et. al, [2011]

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

14

PC

Process description

PI

LC

CSTR MD

P

XD

1st order kinetics L

R D

A B

A 2C (undesired)

F0

XF

Column

S

30 stages MR

F

LV - configuration FC V

TI FI

TR

Assumptions: MB

Constant relative volatilities

Constant molar overflows

Constant pressure LC

B

XB

Details can be found in Jacobsen et. al, [2011]

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

15

Economic Plantwide Control

Step 1:

Define the operational objectives (economics) and

constraints.

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

16

PC

Step 1:

PI

LC

Cost function: steam cost

P

MD

XD

J pF F0 pV V pP P pB B R D L

cost feed value products

F0

XF

S

MR

F

FC V

TI FI

TR

MB

LC XB

B

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

17

PC

Step 1:

PI

LC

Cost function: steam cost

P

MD

XD

J pF F0 pV V pP P pB B R D L

cost feed value products

F0

[ pF , pV , pP , pB ] [1, 0.01, 0.5, 2] XF

prices in $/kmol

S

MR

F

FC V

TI FI

TR

MB

LC XB

B

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

18

PC

Step 1:

PI

LC

Cost function: steam cost

P

MD

XD

J pF F0 pV V pP P pB B R D L

cost feed value products

F0

[ pF , pV , pP , pB ] [1, 0.01, 0.5, 2] XF

prices in $/kmol

S

MR

F

FC V

TI FI

TR

Operational constraints*: MB

xB , B 0.9 TR 390 K

M R 11000 mol V 30 mol/s LC XB

B

R 0 mol/s

*values are based on the work of Jacobsen et. al, [2011]

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

19

Economic Plantwide Control

Step 2:

Determine the steady state optimal operation:

a) Identify the steady-state DOFs

b) Identify the important disturbances and their expected

range

c) Identify the expected active constrains regions

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

20

PC

Step 2a:

PI

LC

Degrees of freedom: P

MD

XD

Steady state degrees of freedom: D L

R

uSS [ L,V , F , R, S ]

F0

XF

S

MR

F

FC V

TI FI

TR

MB

LC XB

B

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

21

PC

Step 2b:

PI

LC

Degrees of freedom: P

MD

XD

Steady state degrees of freedom: D L

R

uSS [ L,V , F , R, S ]

F0

XF

Disturbances

S

MR

Main disturbances: F

FC V

Feed flow TR

TI FI

Energy price

MB

d [ F0 , pV ]

Expected disturbance range 30% LC XB

B

V. Minasidis et al, Systematic controlled variable selection for a RSR process

22

Step 2c:

Always active:

xB , B , TR , M R

Remaining

active constraints regions:

(I ) R

(II )

(III ) V

(IV ) V , R

(V ) Infeasible Operational constraints:

Maximum number of xB , B 0.9 TR 390 K

active constraint regions M R 11000 mol V 30 mol/s

ncon R 0 mol/s

2

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

23

Step 2c:

Always active:

xB , B , TR , M R

Remaining

active constraints regions:

(I ) R

(II )

(III ) V

(IV ) V , R

(V ) Infeasible Operational constraints:

xB , B 0.9 TR 390 K

Operating point M R 11000 mol V 30 mol/s

R 0 mol/s

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

24

Economic Plantwide Control

Step 3:

Select primary (economic) controlled variables:

a) Control the active constraints

b) Select the self-optimizing variables

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

25

PC

Step 3a:

PI

LC

An optimal operational point: P

MD

XD

F0,nom 0.8 [kmol/s] R D L

pV ,nom 0.06 [$/kmol]

F0 LC

XF

Active constraints:

xB , B , TR , M R , R S

MR

F

FC V

TI

Steady-state DOFs: TC

FI CC

TR

uSS [ L, V , F , R, S ] MB

Active constraints pairings (input, output): LC

B

XB

(V , xB , B ) ( S , TR ) ( F , M R ) ( R, Closedvalve)

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

26

Economic Plantwide Control

Step 3:

Select primary (economic) controlled variables:

a) Control the active constraints

b) Select the self-optimizing variables

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

27

Self-optimizing CVs

Linearized model

y G y u Gdy d

c HG y u HGdy d

Setpoint control

c cS H y 0

Feedback implementation of optimal

operation with separate layers for

optimization (RTO) and control

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

28

PC

Available measurements

PI

LC

MD

P

Candidate measurements (y): XD

D L

R

Compositions (noise 0.01):

xB , D , xB , B , xB , F

F0 LC

XF

Input flows (noise 10%):

S

L,V , D, B, F , F0 , R, P MR

F

Reactor level (noise 100 mol): TI

FC

FI

V

CC

MR TC

TR

MB

Column and reactor temperatures (noise 1 K):

T1 , T5 , T9 , T13 , T17 , T21 , T25 , T30 , TR LC XB

B

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

29

Self-optimizing CVs selection

Combination of measurements based on Nullspace

method [Alstad et. Al, 2009]

Analytical solution using all the measurements based

on the Exact Local method [Halvorsen, 2003]

Individual or combination of measurements based on

Branch&Bound method [Kariwala et. al, 2008]

Individual or combination of measurements with

structural constraints based on MIQP formulation

[Yelchuru et. al, 2011]

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

30

Self optimizing CVs selection

Remaining DOFs for Self-optimizing control:

uSS [ L]

31

Self optimizing CVs selection

Remaining DOFs for Self-optimizing control:

uSS [ L]

Nullspace method [Alstad et. al, 2009]

H N (F T )

where N - nullspace

F - optimal sensitivity to disturbances

y opt

Need to estimate : F

d

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

32

Self optimizing CVs selection

Remaining DOFs for Self-optimizing control:

uSS [ L]

Select the self-optimizing CV for L based on the

analytical solution [Yelchuru et al, 2011]:

H T (YY T )1 G y Q Scaled disturbances

where Y [ FWd Wn ] and noise

Q - any non singular matrix of n n d Wd d '

c c

n y Wn y n y

y opt y

Need to estimate : F and G y

d u

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

33

Performance comparisson

Relative loss

J (u, d ) J opt (d )

LRel

J opt (d )

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

34

Conclusions

Automated economic CVs selection could be

considered a successful first step for automating the

entire procedure

Integration of Economic Plantwide Control design

procedure in to popular process simulators could

potentially improve the production costs on a global

scale

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

35

Future Work

Handling active constraint changes

Finding a single control structure over multiple active

constraints regions with an acceptable loss

Using the information from the active constraint maps

to estimate G y , Gdy , J uu

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

36

Future Work

Handling active constraint changes

Finding a single control structure over multiple active

constraints regions with an acceptable loss

Using the information from the active constraint maps

to estimate G y , Gdy , J uu

Thank you !

V. Minasidis et al, Automated Controlled Variable Selection for a Reactor-Separator-Recycle Process

Вам также может понравиться

- Comparative Evaluation of SiC and Si PV Inverter Systems Based On Power Density and Efficiency As Indicators of Initial Cost and Operating RevenueДокумент6 страницComparative Evaluation of SiC and Si PV Inverter Systems Based On Power Density and Efficiency As Indicators of Initial Cost and Operating Revenueelectronic systemsОценок пока нет

- 04a - SCN 2G Call - Control - Message - in - Call - SetupДокумент60 страниц04a - SCN 2G Call - Control - Message - in - Call - SetupYounes RaacheОценок пока нет

- Advanced Multilevel Converters and Applications in Grid IntegrationОт EverandAdvanced Multilevel Converters and Applications in Grid IntegrationAli Iftekhar MaswoodОценок пока нет

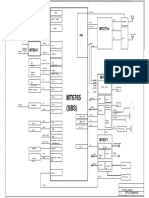

- Schematic Block Diagram Redmi 6AДокумент1 страницаSchematic Block Diagram Redmi 6AUmar RasheedОценок пока нет

- Design Steel I-Beam Bridge With Composite Slab: 8.1 Section PropertiesДокумент38 страницDesign Steel I-Beam Bridge With Composite Slab: 8.1 Section PropertiesDisepro Eirl CSi CaribeОценок пока нет

- Turbine Stress Evaluator: May 9, 2022 PMI Revision 00 1Документ23 страницыTurbine Stress Evaluator: May 9, 2022 PMI Revision 00 1Kuldeep SinghОценок пока нет

- TNG & JBT 'S Fan Coil Unit (FCU) Submittal 15.9.23Документ46 страницTNG & JBT 'S Fan Coil Unit (FCU) Submittal 15.9.23Bittu kumarОценок пока нет

- InTech-Capacitor Bank and Harmonic Filters Operation in Power Supply System Cases StudiesДокумент30 страницInTech-Capacitor Bank and Harmonic Filters Operation in Power Supply System Cases StudiesAlfredo Lopez Cordova100% (1)

- Ch-1Technology Trend: University Questions Subject: - VLSI Design (T.E. ETRX) Sem:-VIДокумент10 страницCh-1Technology Trend: University Questions Subject: - VLSI Design (T.E. ETRX) Sem:-VIHimanshu ShrivastavaОценок пока нет

- Online High-Speed PMSM Parameters Estimation and Stability AnalysisДокумент20 страницOnline High-Speed PMSM Parameters Estimation and Stability Analysisanon_688042049Оценок пока нет

- 04MSC501Документ1 страница04MSC501MokbelОценок пока нет

- Onur 447 Spring13 Lecture8 Pipelining AfterlectureДокумент76 страницOnur 447 Spring13 Lecture8 Pipelining AfterlectureWing-Kwong WongОценок пока нет

- 20ME68 - Analysis of Beams - IIДокумент35 страниц20ME68 - Analysis of Beams - IIranjithkrajОценок пока нет

- Bd91364bmuu eДокумент31 страницаBd91364bmuu eRaguraman Bems - R&DОценок пока нет

- C Biaya Penerimaan ProfiДокумент13 страницC Biaya Penerimaan ProfiLioviani GОценок пока нет

- Oppo Realme 3 SchematicДокумент37 страницOppo Realme 3 SchematichulkОценок пока нет

- MT6765 (SBS) : Project: MT6765 LPDDR3 Ref - SCH Top LevelДокумент35 страницMT6765 (SBS) : Project: MT6765 LPDDR3 Ref - SCH Top LevelHarry ahmad Iqbal100% (4)

- ETABS 2016 Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)Документ2 страницыETABS 2016 Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)Khaled Abdel SalamОценок пока нет

- CD4027B CMOS Dual J-K Flip Flop: 1 Features 3 DescriptionДокумент26 страницCD4027B CMOS Dual J-K Flip Flop: 1 Features 3 DescriptionMazhar IqbalОценок пока нет

- Ams ElectricДокумент5 страницAms ElectriczuhasgdОценок пока нет

- LIWA Grid Pre-CommissioningДокумент2 страницыLIWA Grid Pre-CommissioningFeroz HakkimОценок пока нет

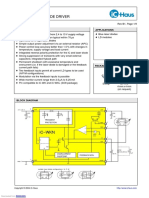

- iC-WKN: 15 V CW Laser Diode DriverДокумент9 страницiC-WKN: 15 V CW Laser Diode DriverYilmer Nolasco FabianОценок пока нет

- Control Tuning of Energy Storage Systems Based On Operating Point ConsistencyДокумент5 страницControl Tuning of Energy Storage Systems Based On Operating Point ConsistencyMarchena Segil ErikОценок пока нет

- Isl 94202Документ89 страницIsl 94202Aura SantiagoОценок пока нет

- Redmi 6a Schematic DiagramДокумент34 страницыRedmi 6a Schematic DiagramKaran Matale80% (5)

- ADC For Biomedical SignalДокумент23 страницыADC For Biomedical SignalPatryk PrusОценок пока нет

- A New Trans-Admittance Mode Biquad Filter Using MO-VDTAДокумент11 страницA New Trans-Admittance Mode Biquad Filter Using MO-VDTAtritranОценок пока нет

- Experiment No.4 Jaw CrusherДокумент6 страницExperiment No.4 Jaw CrusherShubham Kumar100% (2)

- ACS Unit 001Документ9 страницACS Unit 001sarifnОценок пока нет

- MT6765 (SBS) : Project: MT6765 LPDDR3 Ref - SCH Top LevelДокумент32 страницыMT6765 (SBS) : Project: MT6765 LPDDR3 Ref - SCH Top LevelMarcio PimentelОценок пока нет

- Optimize Output Filter On D-CAP2™ For Stability Improvement: Application ReportДокумент8 страницOptimize Output Filter On D-CAP2™ For Stability Improvement: Application ReportLeonardo SoaresОценок пока нет

- 24 - 10 - 21 PS Cheklist Electrical NetworkДокумент3 страницы24 - 10 - 21 PS Cheklist Electrical NetworkChobul BudianaОценок пока нет

- Analysis, Modeling and Control of Half-Bridge Current-Source Converter For Supercapacitor ApplicationsДокумент8 страницAnalysis, Modeling and Control of Half-Bridge Current-Source Converter For Supercapacitor ApplicationsgabrielОценок пока нет

- ITP Aluminum DCM Rev 00Документ1 страницаITP Aluminum DCM Rev 00maheshpanditОценок пока нет

- Esp LVДокумент104 страницыEsp LVAbdullaKakkadKarumbilОценок пока нет

- iC-WK, iC-WKL: Laser DiodesДокумент10 страницiC-WK, iC-WKL: Laser DiodesYilmer Nolasco FabianОценок пока нет

- MT6768 (SBS) : MT6177M (LWG+LTG)Документ31 страницаMT6768 (SBS) : MT6177M (LWG+LTG)pc partnerОценок пока нет

- Otis Sigma SI210 PDFДокумент345 страницOtis Sigma SI210 PDFAnthony Rafaga Ortiz91% (11)

- ETABS Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)Документ2 страницыETABS Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)statikaОценок пока нет

- ISL62883 RenesasДокумент37 страницISL62883 Renesasanh_sao_dem_92Оценок пока нет

- PT10'' BodegaДокумент2 страницыPT10'' BodegaIvan PorrasОценок пока нет

- DownloadДокумент3 страницыDownloadKrishna RaoОценок пока нет

- Gacuityloadlateral: Dat JДокумент6 страницGacuityloadlateral: Dat JKaran ParmarОценок пока нет

- ZTE 2G Handover Algorithm: Why Do We Need Handover ?Документ37 страницZTE 2G Handover Algorithm: Why Do We Need Handover ?syrish2622Оценок пока нет

- Dynamic Modeling of A VSC-HVDC Converter: Markus Imhof, Student Member, IEEE, G Oran Andersson, Fellow, IEEEДокумент6 страницDynamic Modeling of A VSC-HVDC Converter: Markus Imhof, Student Member, IEEE, G Oran Andersson, Fellow, IEEEFelix GamarraОценок пока нет

- AN12626Документ31 страницаAN12626James Andy CОценок пока нет

- Book BookДокумент146 страницBook BookTurpial Airlines OMAC-N 683Оценок пока нет

- 9 - Rotor Current Fuzzy Control of A DFIG With An Indirect Matrix ConverterДокумент7 страниц9 - Rotor Current Fuzzy Control of A DFIG With An Indirect Matrix ConvertermohammedОценок пока нет

- Plume P8-PGN605 DiagramДокумент1 страницаPlume P8-PGN605 DiagramncirОценок пока нет

- GSM ChannelsДокумент44 страницыGSM ChannelsSergio BuonomoОценок пока нет

- HOT Induction Bend MPS - CommentedДокумент11 страницHOT Induction Bend MPS - CommentedHASAN SHAHRIAR100% (1)

- Paperid396 PDFДокумент7 страницPaperid396 PDFHitesh JoshiОценок пока нет

- Paperid396 PDFДокумент7 страницPaperid396 PDFHitesh JoshiОценок пока нет

- Isolated DC-DC ConverterДокумент4 страницыIsolated DC-DC ConverterUge AjjaОценок пока нет

- Direct Fuzzy Logic Controller For Voltage Control of Standalone Three Phase InverterДокумент4 страницыDirect Fuzzy Logic Controller For Voltage Control of Standalone Three Phase Inverterdckien2002Оценок пока нет

- Methods of Determining Safety Integrity Level (SIL) Requirements - Pros and ConsДокумент16 страницMethods of Determining Safety Integrity Level (SIL) Requirements - Pros and Consibaig80100% (1)

- ETABS Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)Документ2 страницыETABS Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)Khaled Abdel SalamОценок пока нет

- 2ch Half-Bridge Gate Driver: BD16950EFV-CДокумент55 страниц2ch Half-Bridge Gate Driver: BD16950EFV-CAravind Prasad Sounder RajОценок пока нет

- Savings With Uber/Ola: 3 Years CalculationДокумент2 страницыSavings With Uber/Ola: 3 Years CalculationHarshaОценок пока нет

- Itr2 2018 PR1.1Документ98 страницItr2 2018 PR1.1HarshaОценок пока нет

- Thomas Edgar C Se 022013Документ1 страницаThomas Edgar C Se 022013HarshaОценок пока нет

- Following Is The Feed Back of System Engineer MRДокумент1 страницаFollowing Is The Feed Back of System Engineer MRHarshaОценок пока нет

- Understanding Particle SegДокумент10 страницUnderstanding Particle SegHarshaОценок пока нет

- RingtonesДокумент60 страницRingtonesHarshaОценок пока нет

- Crackers Standard Fireworks Price List 2017Документ12 страницCrackers Standard Fireworks Price List 2017HarshaОценок пока нет

- Question Paper Preview: Scientific No No No No No NoДокумент32 страницыQuestion Paper Preview: Scientific No No No No No NoHarshaОценок пока нет

- Unit TДокумент6 страницUnit THarshaОценок пока нет

- !"#$%&%' +, - ./01 +, 23"45267 +, 898:' ' (?,+, @"45267 +, @"a ' (?,+, ?,) B'C'#$ +, ?,D5 E'f (?,+, Ghij6h (?,+, G"#$K26 (L%M+,NДокумент4 страницы!"#$%&%' +, - ./01 +, 23"45267 +, 898:' ' (?,+, @"45267 +, @"a ' (?,+, ?,) B'C'#$ +, ?,D5 E'f (?,+, Ghij6h (?,+, G"#$K26 (L%M+,NHarshaОценок пока нет

- #$%&'# +, - . /0123 /04) 5 6789:3 $?@ Abcde'abf (G'# Hijk$l M'anc (G$?@Документ6 страниц#$%&'# +, - . /0123 /04) 5 6789:3 $?@ Abcde'abf (G'# Hijk$l M'anc (G$?@HarshaОценок пока нет

- Preventive Maintenance ProgramДокумент15 страницPreventive Maintenance Programjayson bastian marchan sotoОценок пока нет

- 2.industry 4.0 Concept, Background-R2Документ58 страниц2.industry 4.0 Concept, Background-R2Manav IsraniОценок пока нет

- Fiza ProjectДокумент73 страницыFiza ProjectafifakhanОценок пока нет

- Lecture-10 Impulse Response & Convolution Sum in DT LTI SystemДокумент40 страницLecture-10 Impulse Response & Convolution Sum in DT LTI SystemThe LifeОценок пока нет

- SOP On Machine Maintenance-BanglaДокумент4 страницыSOP On Machine Maintenance-BanglashahinОценок пока нет

- Multilayer PerceptronДокумент24 страницыMultilayer PerceptronRupinder KaurОценок пока нет

- All You Need To Know About Artificial IntelligenceДокумент18 страницAll You Need To Know About Artificial Intelligenceobialor ikennaОценок пока нет

- PreviewpdfДокумент61 страницаPreviewpdfUzair Khaleeq uz ZamanОценок пока нет

- PID ControlerДокумент30 страницPID ControlerRachmah RizkyОценок пока нет

- CBAD2103 Topic 11Документ23 страницыCBAD2103 Topic 11djaljdОценок пока нет

- Artificial IntelligenceДокумент2 страницыArtificial IntelligencebhargaviОценок пока нет

- ME451: Control Systems Course RoadmapДокумент5 страницME451: Control Systems Course RoadmapVu NghiaОценок пока нет

- Lect01-Annotated DBДокумент31 страницаLect01-Annotated DBMadhulika BalakumarОценок пока нет

- 5 Software DesignДокумент34 страницы5 Software DesignSahil GuptaОценок пока нет

- TPM KN MMHДокумент12 страницTPM KN MMHKn ShaplaОценок пока нет

- Signals and Systems SyllabusДокумент3 страницыSignals and Systems SyllabusSeema P DiwanОценок пока нет

- AI-Introduction and History (4l)Документ74 страницыAI-Introduction and History (4l)Ravi RanjanОценок пока нет

- Application of FMEA and FMECA To Subsea Drilling SystemДокумент2 страницыApplication of FMEA and FMECA To Subsea Drilling SystemKhánh Tuyền Nguyễn ThịОценок пока нет

- Presentation 1Документ29 страницPresentation 1gorayahamza49Оценок пока нет

- Pulse Transfer Function and Manipulation of Block Diagrams: The Output Signal Is Sample To ObtainДокумент41 страницаPulse Transfer Function and Manipulation of Block Diagrams: The Output Signal Is Sample To ObtainArif HassanОценок пока нет

- Failure Mode Effect AnalysisДокумент36 страницFailure Mode Effect AnalysisCharanjeet SinghОценок пока нет

- ISTQB Question Paper Dump 1Документ8 страницISTQB Question Paper Dump 1tammasarathОценок пока нет

- Use of Artificial Intelligence Techniques / Applications in Cyber DefenseДокумент6 страницUse of Artificial Intelligence Techniques / Applications in Cyber DefenseAsher AlexanderОценок пока нет

- Linear-Quadratic Regulator - WikipediaДокумент6 страницLinear-Quadratic Regulator - WikipediaSerethОценок пока нет

- Reliability FundamentalsДокумент17 страницReliability FundamentalsSachin DhimanОценок пока нет

- Root Cause AnalysisДокумент4 страницыRoot Cause AnalysisLeslie Faye CabigaoОценок пока нет

- Table: Joint Coordinates Joint Coordsys Coordtype Xorr Y Z Specialjt Globalx GlobalyДокумент34 страницыTable: Joint Coordinates Joint Coordsys Coordtype Xorr Y Z Specialjt Globalx Globalyabd rahmanОценок пока нет

- Machine Learning: Course Code:17EC3681Документ23 страницыMachine Learning: Course Code:17EC3681Mahaboob PashaОценок пока нет

- Chapter 4 Requirements EngineeringДокумент78 страницChapter 4 Requirements EngineeringShabana TahirОценок пока нет

- Introduction To Software EngineeringДокумент21 страницаIntroduction To Software EngineeringDavid ChandraОценок пока нет