Академический Документы

Профессиональный Документы

Культура Документы

Taguchi Method Helps Optimize Paper Helicopter Experiment

Загружено:

Aswin Rajeevan0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров23 страницыThis document discusses the Taguchi method, which is a statistical technique used to improve process performance and reduce variability. It summarizes the key steps in a Taguchi experiment: (1) formulating the problem and identifying output factors, (2) selecting control factors and their levels, (3) designing an orthogonal array experiment, (4) conducting the experiment and collecting data, and (5) analyzing results using signal-to-noise ratios to identify significant factors and their optimal levels. It then provides an example of a paper helicopter experiment using the Taguchi method to determine the optimal design settings that maximize flight time.

Исходное описание:

Steps on how to do taguchi method

Оригинальное название

CH 5020

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document discusses the Taguchi method, which is a statistical technique used to improve process performance and reduce variability. It summarizes the key steps in a Taguchi experiment: (1) formulating the problem and identifying output factors, (2) selecting control factors and their levels, (3) designing an orthogonal array experiment, (4) conducting the experiment and collecting data, and (5) analyzing results using signal-to-noise ratios to identify significant factors and their optimal levels. It then provides an example of a paper helicopter experiment using the Taguchi method to determine the optimal design settings that maximize flight time.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров23 страницыTaguchi Method Helps Optimize Paper Helicopter Experiment

Загружено:

Aswin RajeevanThis document discusses the Taguchi method, which is a statistical technique used to improve process performance and reduce variability. It summarizes the key steps in a Taguchi experiment: (1) formulating the problem and identifying output factors, (2) selecting control factors and their levels, (3) designing an orthogonal array experiment, (4) conducting the experiment and collecting data, and (5) analyzing results using signal-to-noise ratios to identify significant factors and their optimal levels. It then provides an example of a paper helicopter experiment using the Taguchi method to determine the optimal design settings that maximize flight time.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 23

Presented by

Reesha Bharath K. -CE12D052

K. Kumar -ED11S009

The Taguchi method (Tm) is a powerful statistical

technique used for

improving process performance

yield and productivity

It reduces scrap rates, rework costs and

manufacturing costs due to excessive variability in

processes.

Dr Genichi Taguchi shows how the statistical design of

experiments (SDOE or DOE) can help engineers to design

and manufacture products with high quality and low cost.

Primarily focused on

eliminating the causes of poor quality

making product performance insensitive to variation

Used for determining the optimal factor settings of a process

achieving improved process performance

reduced process variability

improved manufacturability of products and processes.

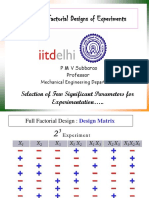

One component of DOE which involves planning,

design, execution, analysis and interpretation of

results

Integrates statistical methods into engineering

process

Uses orthogonal array designs to assign the

factors chosen for the experiment

Process/product Nature of problem Experiment size

Injection moulding High scrap rate due to 8 trials

process excessive process

variability

Diesel injector High rework rate 16 trials

Welding process Low weld strength 8 trials

Biscuit Excessive variability in 16 trials

biscuit length

Wire-bonding process Low wire pull strength 16 trials

1. Formulation of the problem

2. Identification of the output

3. Identification of control factors, noise factors and signal factors

4. Selection of factor levels, possible interactions and the degrees

of freedom associated with each factor and the interaction

effects

5. Design of an appropriate orthogonal array (OA)

6. Preparation of the experiment

7. Running of the experiment with appropriate data collection

8. Statistical analysis and interpretation of experimental results

9. Undertaking a confirmatory run of the experiment

Brainstorming is a useful tool

to identify the most

influencing factors in an

experiment

Control factors and their range of settings for the experiment

Control factor Labels Level 1 Level 2

Paper type A Regular Bond

Body length B 8cm 12cm

Wing length C 8cm 12cm

Body width D 2cm 3cm

Number of clips E 1 2

Wing shape F Flat Angled

Interaction exists when the effect of one factor is

not the same at different levels of the other factor

Three interactions were considered from brain

storming

1. Body length x Wing length (BC)

2. Body length X Body width (BD)

3. Paper type X Body length (AB)

Based on the total number of degrees of freedom type of

orthogonal array is chosen.

DOF for 6 Factors at 2 levels = 6

DOF for 3 two way Interactions =3

So Total DOF =9

Note:- It is important to notice that the number of

experimental trails must be greater than the total degrees

of freedom required for studying the effects.

From the available standard orthogonal arrays for two

levels,L4,L8,L16,L32,L64

L16 OR is found suitable

Taguchi advocates the use of signal to noise ratio.

The SNR is treated as a response of the experiment which is a

measure of the variation.

Taguchi developed over 60 different SNR for various engineering

parameter design.

For this experiment objective is to maximise the flight time so we

choose

SNR related to Larger The Better(LTB)

Where Ni Number of repeats=2

Yu=Each observed value

Normal probability plot helps to identify Significant

Main and Interaction Factors

Plotting the absolute values of the effects (both Main and

interaction) along the X axis and the percentage

probability along Y axis.

Percentage probability can be obtained by using the

following equation:

Where i= Rank in ascending order , n= Total no of

effects=9

Fig . Shows most dominant factor is the wing length followed

by paper type, wing shape and no. of clips

For this experiment none of the interaction effect is

significant

Interaction plots are constructed by plotting the average

SNR values at each factor level combination.

ie:-Interaction of Body length x Body width( BD)

For the paper helicopter experiment ,based on

the highest SNR values, optimal settings have

been determined.

Teaching the taguchi method to industrial

engineers-Fiju Antony and Frenie fiju Antony

Thank you!

Вам также может понравиться

- Ac 2017 16Документ10 страницAc 2017 16karpaga raj aОценок пока нет

- DOE Report XinliShaДокумент16 страницDOE Report XinliShaXinli ShaОценок пока нет

- IPE - 302 Sessional SheetДокумент22 страницыIPE - 302 Sessional SheetzahirrayhanОценок пока нет

- Application of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing OperationДокумент7 страницApplication of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing Operationwww.irjes.comОценок пока нет

- Experimental Investigation of The Plasma Arc Cutting ProcessДокумент6 страницExperimental Investigation of The Plasma Arc Cutting ProcessKevin MaciasОценок пока нет

- Taguchi APPДокумент14 страницTaguchi APPAmey VidvansОценок пока нет

- Taguchi MethodДокумент22 страницыTaguchi MethodsadanalzoubiОценок пока нет

- Taguchi MethoДокумент17 страницTaguchi MethoSaurabh Verma70% (10)

- Design of Experiments - Applications 2013Документ120 страницDesign of Experiments - Applications 2013Daoud IssaОценок пока нет

- Tensile Test Report on Mild Steel SpecimenДокумент16 страницTensile Test Report on Mild Steel SpecimenEngr.Hamid Ismail CheemaОценок пока нет

- A Study On Two Plate and Three Plate Mol PDFДокумент7 страницA Study On Two Plate and Three Plate Mol PDFKamleshVasavaОценок пока нет

- Experimental Analysis of Plasma Arc Cutting Process For SS 316l PlatesДокумент6 страницExperimental Analysis of Plasma Arc Cutting Process For SS 316l PlatesRomy RomanttikoОценок пока нет

- Matheus, 2020Документ34 страницыMatheus, 2020LucasОценок пока нет

- Optimization of Surface Roughness in Turning Operation of Brass Tube Using Taguchi MethodДокумент22 страницыOptimization of Surface Roughness in Turning Operation of Brass Tube Using Taguchi Methodashwani kaushikОценок пока нет

- Wood Compressive Strength Lab ManualДокумент3 страницыWood Compressive Strength Lab ManualMuhammad AmmarОценок пока нет

- Chapter 1 Supplemental Text Material on Planning ExperimentsДокумент179 страницChapter 1 Supplemental Text Material on Planning ExperimentsHanapi AliОценок пока нет

- Tuft Height of Pile Floor Coverings: Standard Test Method ForДокумент5 страницTuft Height of Pile Floor Coverings: Standard Test Method ForJuanОценок пока нет

- Fractional Factorial Designs ExperimentsДокумент23 страницыFractional Factorial Designs ExperimentsKrishnaThakraniОценок пока нет

- Ijaret: ©iaemeДокумент12 страницIjaret: ©iaemeIAEME PublicationОценок пока нет

- Model-Based Experimental Design For Biological Systems ModellingДокумент32 страницыModel-Based Experimental Design For Biological Systems ModellingMarcelo SilvaОценок пока нет

- Ultrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsДокумент10 страницUltrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsPetrОценок пока нет

- 7 PDFДокумент5 страниц7 PDFVirojana TantibadaroОценок пока нет

- Parametric Investigation of FDM Process Parameter On Impact Strength of 3D-Printed PartДокумент8 страницParametric Investigation of FDM Process Parameter On Impact Strength of 3D-Printed PartIJRASETPublicationsОценок пока нет

- Optimization of Rapid Prototyping Parameters For Production of Flexible ABS ObjectДокумент8 страницOptimization of Rapid Prototyping Parameters For Production of Flexible ABS ObjectSachin BanerjiОценок пока нет

- Preliminary Feasibility Torque Mechanical Evaluation For 3D Printed Orthodontic Springs With Different Parameters - in Vitro Study - SpringerLinkДокумент21 страницаPreliminary Feasibility Torque Mechanical Evaluation For 3D Printed Orthodontic Springs With Different Parameters - in Vitro Study - SpringerLinkDr.Prakher SainiОценок пока нет

- MEE20004 Lab1 - 2015 Sem 2Документ9 страницMEE20004 Lab1 - 2015 Sem 2Thilan RathnayakaОценок пока нет

- Tension Test on Mild Steel RodДокумент38 страницTension Test on Mild Steel RodSathis KumarОценок пока нет

- Optimization of Electrical Discharge Machining Process Parameters Using Taguchi MethodДокумент10 страницOptimization of Electrical Discharge Machining Process Parameters Using Taguchi MethodRajapandian TОценок пока нет

- 3tesdДокумент21 страница3tesdGoogle facebookОценок пока нет

- Effect of Spinning Process ParametersДокумент6 страницEffect of Spinning Process ParametersKRISHNA JОценок пока нет

- Tensile TestДокумент9 страницTensile TestDhana KumaranОценок пока нет

- Mel705 15Документ22 страницыMel705 15Rudraksh AgrawalОценок пока нет

- Taguchi MethodДокумент8 страницTaguchi MethodLSARAVANAN91Оценок пока нет

- ATP RevisonДокумент9 страницATP RevisonShlok And gauransh legendОценок пока нет

- High Resolution Phased Array Imaging Using The Total Focusing Method (Kierspel Et Al - 2017)Документ8 страницHigh Resolution Phased Array Imaging Using The Total Focusing Method (Kierspel Et Al - 2017)pjhollowОценок пока нет

- Classification of Signatures of Aircraft Prototypes Using Support Vector MachineДокумент5 страницClassification of Signatures of Aircraft Prototypes Using Support Vector MachinePrabhakarОценок пока нет

- Experimental Investigation Using Taguchi Method To Optimize Process Parameters of Fused Deposition Modeling For ABS and Nylon MaterialsДокумент9 страницExperimental Investigation Using Taguchi Method To Optimize Process Parameters of Fused Deposition Modeling For ABS and Nylon MaterialsArukana KotoОценок пока нет

- Yarn HairinessДокумент35 страницYarn HairinessNikesh SoobdhanОценок пока нет

- The Taguchi Approach to Fractional Factorial DesignДокумент5 страницThe Taguchi Approach to Fractional Factorial DesignKailash C BhosaleОценок пока нет

- Gunay and HinisliogluДокумент10 страницGunay and HinisliogluZriОценок пока нет

- Research Paper Optimization of Mig Welding Parameters For Improving Strength of Welded JointsДокумент3 страницыResearch Paper Optimization of Mig Welding Parameters For Improving Strength of Welded JointsSourabh LoharОценок пока нет

- Taguchi's Design of Experiments and Selection of Orthogonal ArrayДокумент22 страницыTaguchi's Design of Experiments and Selection of Orthogonal ArrayBhavin DesaiОценок пока нет

- User Manual Pro-Fluo en v.1Документ10 страницUser Manual Pro-Fluo en v.1Muhammad Ihsan0% (1)

- An Experimental Study of The Impact of Turning Parameters On Surface Roughness PDFДокумент10 страницAn Experimental Study of The Impact of Turning Parameters On Surface Roughness PDFCuteAssadОценок пока нет

- Film Test ValidationДокумент19 страницFilm Test Validationjerobu100% (1)

- Lab Manual: International Islamic University Malaysia Department of Mechanical EngineeringДокумент36 страницLab Manual: International Islamic University Malaysia Department of Mechanical EngineeringMuhamad HilmiОценок пока нет

- Thesis MelenkaДокумент35 страницThesis MelenkaRafael RodriguezОценок пока нет

- Aet319a Cms Lab RecordДокумент26 страницAet319a Cms Lab Recordhod.aeroОценок пока нет

- Application of Computational Fluid Dynamics To Design of Polymer Extrusion DiesДокумент7 страницApplication of Computational Fluid Dynamics To Design of Polymer Extrusion Dies李庆森Оценок пока нет

- Optimization of Bead Geometry Parameters of Bead-On-Plate Weldments Prepared by Submerged Arc Welding Using Taguchi TechniqueДокумент7 страницOptimization of Bead Geometry Parameters of Bead-On-Plate Weldments Prepared by Submerged Arc Welding Using Taguchi TechniqueIJERDОценок пока нет

- 3level Full Factorial DesignДокумент7 страниц3level Full Factorial DesignKervin B. UntalanОценок пока нет

- Comparative Analysis of Real and Ideal Wire-Slot Play in Square and Rectangular ArchwiresДокумент11 страницComparative Analysis of Real and Ideal Wire-Slot Play in Square and Rectangular ArchwiresKanish AggarwalОценок пока нет

- Destructive R&RДокумент19 страницDestructive R&RKalyan SrinivasОценок пока нет

- Assessing the Single Fiber Fragmentation TestДокумент10 страницAssessing the Single Fiber Fragmentation Testdeathjester1Оценок пока нет

- Fun With Civa Simulation Software for Ultrasonic NDT TrainingДокумент12 страницFun With Civa Simulation Software for Ultrasonic NDT Trainingmusaismail8863Оценок пока нет

- Robust Design Taguchi Module 808Документ17 страницRobust Design Taguchi Module 808moragorОценок пока нет

- Taguchi Method AssignmentДокумент6 страницTaguchi Method AssignmentpuriОценок пока нет

- TQM Tools in MFG and Service IndustriesДокумент29 страницTQM Tools in MFG and Service IndustriesSimantoPreeomОценок пока нет

- Basic Instrumentation for Engineers and Physicists: The Commonwealth and International Library: Applied Electricity and Electronics DivisionОт EverandBasic Instrumentation for Engineers and Physicists: The Commonwealth and International Library: Applied Electricity and Electronics DivisionОценок пока нет

- Design for Testability, Debug and Reliability: Next Generation Measures Using Formal TechniquesОт EverandDesign for Testability, Debug and Reliability: Next Generation Measures Using Formal TechniquesОценок пока нет

- 2 Case StudyДокумент8 страниц2 Case Studysehrish khawerОценок пока нет

- Hotels Cost ModelДокумент6 страницHotels Cost ModelThilini SumithrarachchiОценок пока нет

- 50hz Sine PWM Using Tms320f2812 DSPДокумент10 страниц50hz Sine PWM Using Tms320f2812 DSPsivananda11Оценок пока нет

- UTC awarded contracts with low competitionДокумент2 страницыUTC awarded contracts with low competitioncefuneslpezОценок пока нет

- FRABA - Absolute - Encoder / PLC - 1 (CPU 314C-2 PN/DP) / Program BlocksДокумент3 страницыFRABA - Absolute - Encoder / PLC - 1 (CPU 314C-2 PN/DP) / Program BlocksAhmed YacoubОценок пока нет

- Activity2 Mba 302Документ2 страницыActivity2 Mba 302Juan PasyalanОценок пока нет

- Yamaha RX-A3000 - V3067Документ197 страницYamaha RX-A3000 - V3067jaysonОценок пока нет

- ACM JournalДокумент5 страницACM JournalThesisОценок пока нет

- Programming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduДокумент34 страницыProgramming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduNaruto DragneelОценок пока нет

- 4 DiscussionДокумент2 страницы4 DiscussiondreiОценок пока нет

- Skype Sex - Date of Birth - Nationality: Curriculum VitaeДокумент4 страницыSkype Sex - Date of Birth - Nationality: Curriculum VitaeSasa DjurasОценок пока нет

- Data Validation and Verification - BBC BitsizeДокумент56 страницData Validation and Verification - BBC BitsizeluciferothegoatОценок пока нет

- Unitary Small Air-Conditioners and Air-Source Heat Pumps (Includes Mixed-Match Coils) (RATED BELOW 65,000 BTU/H) Certification ProgramДокумент65 страницUnitary Small Air-Conditioners and Air-Source Heat Pumps (Includes Mixed-Match Coils) (RATED BELOW 65,000 BTU/H) Certification ProgramAmer GaladОценок пока нет

- Carbapenamses in Antibiotic ResistanceДокумент53 страницыCarbapenamses in Antibiotic Resistancetummalapalli venkateswara raoОценок пока нет

- Data Sheet FC SIДокумент2 страницыData Sheet FC SIAndrea AtzeniОценок пока нет

- Teacher Commitment and Dedication to Student LearningДокумент8 страницTeacher Commitment and Dedication to Student LearningElma Grace Sales-DalidaОценок пока нет

- AP World History: Islamic Empires and Scientific AdvancementДокумент55 страницAP World History: Islamic Empires and Scientific AdvancementJa'TasiaОценок пока нет

- Microwave: Microwaves Are A Form ofДокумент9 страницMicrowave: Microwaves Are A Form ofDhanmeet KaurОценок пока нет

- TESTIS PHYSIOLOGY Spermatogenic Cell Syncytium Makela and Toppari 2018Документ10 страницTESTIS PHYSIOLOGY Spermatogenic Cell Syncytium Makela and Toppari 2018LudimilaОценок пока нет

- Cisco Lab 2.2.4.3Документ5 страницCisco Lab 2.2.4.3vcx100100% (6)

- Cypress Enable Basic Rer Erence ManualДокумент2 страницыCypress Enable Basic Rer Erence ManualCarlos RodasОценок пока нет

- Lending Tree PDFДокумент14 страницLending Tree PDFAlex OanonoОценок пока нет

- Plumbing Arithmetic RefresherДокумент80 страницPlumbing Arithmetic RefresherGigi AguasОценок пока нет

- SRS documentation of Virtual Classroom System , SRS documentation of Personal Identity Management ,SRS documentation of EMentoring for women system , SRS Documentation of Employee Performance Management SRS Documentation of Online TicketingДокумент79 страницSRS documentation of Virtual Classroom System , SRS documentation of Personal Identity Management ,SRS documentation of EMentoring for women system , SRS Documentation of Employee Performance Management SRS Documentation of Online Ticketingsaravanakumar1896% (26)

- Solution of Introduction To Many-Body Quantum Theory in Condensed Matter Physics (H.Bruus & K. Flensberg)Документ54 страницыSolution of Introduction To Many-Body Quantum Theory in Condensed Matter Physics (H.Bruus & K. Flensberg)Calamanciuc Mihai MadalinОценок пока нет

- Sci7 Q1 Wk-5 Module-5Документ15 страницSci7 Q1 Wk-5 Module-5Lester Noel RosalesОценок пока нет

- Book 7 More R-Controlled-VowelsДокумент180 страницBook 7 More R-Controlled-VowelsPolly Mark100% (1)

- Insert BondingДокумент14 страницInsert BondingHelpful HandОценок пока нет

- KCL Thesis PrintingДокумент4 страницыKCL Thesis PrintingMelinda Watson100% (2)

- SIO 12 Syllabus 17Документ3 страницыSIO 12 Syllabus 17Paul RobaiaОценок пока нет