Академический Документы

Профессиональный Документы

Культура Документы

Material Science and Mettalurgy

Загружено:

SR-71 BLACKBIRDАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Material Science and Mettalurgy

Загружено:

SR-71 BLACKBIRDАвторское право:

Доступные форматы

Introduction to Materials Science, Chapter 9, Phase Diagrams

How to calculate the total amount of

phase (both eutectic and primary)?

Fraction of phase determined by application of

the lever rule across the entire + phase field:

W = (Q+R) / (P+Q+R) ( phase)

W = P / (P+Q+R) ( phase)

University of Virginia, Dept. of Materials Science and Engineering 1

Introduction to Materials Science, Chapter 9, Phase Diagrams

Intermediate Phases

So far only two solid phases ( and )

Terminal solid solutions

Some binary systems have intermediate

solid solution phases.

Cu-Zn: and h are terminal solid solutions,

, ’, g, d, e are intermediate solid solutions.

University of Virginia, Dept. of Materials Science and Engineering 2

Introduction to Materials Science, Chapter 9, Phase Diagrams

Intermetallic Compounds

Intermetallic compounds

precise chemical compositions exist in some systems.

Using the lever rules, intermetallic compounds are

treated like any other phase,

They appear as a vertical line.

intermetallic

compound

Two eutectic diagrams: Mg-Mg2Pb and Mg2Pb-Pb.

Intermetallic compound Mg2Pb is considered a

component.

University of Virginia, Dept. of Materials Science and Engineering 3

Introduction to Materials Science, Chapter 9, Phase Diagrams

Eutectoid Reactions (I)

Eutectoid (eutectic-like in Greek) reaction

similar to eutectic reaction

One solid phase to two new solid phases

Invariant point (the eutectoid)

Three solid phases in equilibrium

Upon cooling, a solid phase transforms into

two other solid phases (d g + e below)

Cu-Zn

Eutectoid

University of Virginia, Dept. of Materials Science and Engineering 4

Introduction to Materials Science, Chapter 9, Phase Diagrams

Eutectoid Reactions (II)

Contains an eutectic reaction

and an eutectoid reaction

University of Virginia, Dept. of Materials Science and Engineering 5

Introduction to Materials Science, Chapter 9, Phase Diagrams

Peritectic Reactions

Peritectic solid phase + liquid phase will

together form a second solid phase at a particular

temperature and composition upon cooling

L+

Reactions are slow as product phase will form at

boundary between two reacting phases separating

them

Peritectics are not as common as eutectics

and eutectiods. There is one in Fe-C system

University of Virginia, Dept. of Materials Science and Engineering 6

Introduction to Materials Science, Chapter 9, Phase Diagrams

Congruent Phase Transformations

Congruent transformation no change in

composition

(e.g, allotropic transformation such as -Fe to g-Fe

or melting transitions in pure solids)

Incongruent transformation, at least one phase

changes composition (eutectic, eutectoid, peritectic).

Congruent Ni-Ti

melting of g

University of Virginia, Dept. of Materials Science and Engineering 7

Introduction to Materials Science, Chapter 9, Phase Diagrams

The Iron–Iron Carbide (Fe–Fe3C) Phase Diagram

Steels: alloys of Iron (Fe) and Carbon (C).

Fe-C phase diagram is complex. Will only consider the

steel part of the diagram, up to around 7% Carbon.

University of Virginia, Dept. of Materials Science and Engineering 8

Introduction to Materials Science, Chapter 9, Phase Diagrams

Phases in Fe–Fe3C Phase Diagram

-ferrite - solid solution of C in BCC Fe

• Stable form of iron at room temperature.

• The maximum solubility of C is 0.022 wt%

• Transforms to FCC g-austenite at 912 C

g-austenite - solid solution of C in FCC Fe

• The maximum solubility of C is 2.14 wt %.

• Transforms to BCC d-ferrite at 1395 C

• Is not stable below the eutectic temperature

(727 C) unless cooled rapidly (Chapter 10)

d-ferrite solid solution of C in BCC Fe

• The same structure as -ferrite

• Stable only at high T, above 1394 C

• Melts at 1538 C

Fe3C (iron carbide or cementite)

• This intermetallic compound is metastable, it

remains as a compound indefinitely at room T, but

decomposes (very slowly, within several years)

into -Fe and C (graphite) at 650 - 700 C

Fe-C liquid solution

University of Virginia, Dept. of Materials Science and Engineering 9

Introduction to Materials Science, Chapter 9, Phase Diagrams

Comments on Fe–Fe3C system

C is an interstitial impurity in Fe. It forms a solid

solution with , g, d phases of iron

Maximum solubility in BCC -ferrite is 0.022 wt%

at727 C. BCC:relatively small interstitial positions

Maximum solubility in FCC austenite is 2.14 wt%

at 1147 C - FCC has larger interstitial positions

Mechanical properties: Cementite (Fe3C is hard

and brittle: strengthens steels. Mechanical

properties also depend on microstructure: how

ferrite and cementite are mixed.

Magnetic properties: -ferrite is magnetic below

768 C, austenite is non-magnetic

Classification. Three types of ferrous alloys:

Iron: < 0.008 wt % C in -ferrite at room T

Steels: 0.008 - 2.14 wt % C (usually < 1 wt % )

-ferrite + Fe3C at room T (Chapter 12)

Cast iron: 2.14 - 6.7 wt % (usually < 4.5 wt %)

University of Virginia, Dept. of Materials Science and Engineering 10

Introduction to Materials Science, Chapter 9, Phase Diagrams

Eutectic and eutectoid reactions in Fe–Fe3C

Eutectic: 4.30 wt% C, 1147 C

L g + Fe3C

Eutectoid: 0.76 wt%C, 727 C

g(0.76 wt% C) (0.022 wt% C) + Fe3C

Eutectic and Eutectoid reactions are important in

heat treatment of steels

University of Virginia, Dept. of Materials Science and Engineering 11

Introduction to Materials Science, Chapter 9, Phase Diagrams

Microstructure in Iron - Carbon alloys

Microstructure depends on composition (carbon

content) and heat treatment.

Assume slow cooling equilibrium maintained

Microstructure of eutectoid steel (I)

University of Virginia, Dept. of Materials Science and Engineering 12

Introduction to Materials Science, Chapter 9, Phase Diagrams

Microstructure of eutectoid steel (II)

Pearlite, layered structure of two phases: -ferrite

and cementite (Fe3C)

Alloy of eutectoid composition (0.76 wt % C)

Layers formed for same reason as in eutectic:

Atomic diffusion of C atoms between ferrite (0.022

wt%) and cementite (6.7 wt%)

Mechanically, properties intermediate to

soft, ductile ferrite and hard, brittle cementite.

In the micrograph, the dark areas

are Fe3C layers, the light phase is

-ferrite

University of Virginia, Dept. of Materials Science and Engineering 13

Introduction to Materials Science, Chapter 9, Phase Diagrams

Microstructure of hypoeutectoid steel (I)

Compositions to the left of eutectoid (0.022 - 0.76

wt % C) hypoeutectoid (less than eutectoid -Greek)

alloys.

g + g + Fe3C

University of Virginia, Dept. of Materials Science and Engineering 14

Introduction to Materials Science, Chapter 9, Phase Diagrams

Microstructure of hypoeutectoid steel (II)

Hypoeutectoid contains proeutectoid ferrite

formed above eutectoid temperature and eutectoid

perlite that contains ferrite and cementite.

University of Virginia, Dept. of Materials Science and Engineering 15

Introduction to Materials Science, Chapter 9, Phase Diagrams

Microstructure of hypereutectoid steel (I)

Compositions to right of eutectoid (0.76 - 2.14 wt

% C) hypereutectoid (more than eutectoid -Greek)

alloys. g g + Fe3C + Fe3C

University of Virginia, Dept. of Materials Science and Engineering 16

Introduction to Materials Science, Chapter 9, Phase Diagrams

Microstructure of hypereutectoid steel (II)

Hypereutectoid contains proeutectoid cementite

(formed above eutectoid temperature) plus perlite

that contains eutectoid ferrite and cementite.

University of Virginia, Dept. of Materials Science and Engineering 17

Introduction to Materials Science, Chapter 9, Phase Diagrams

How to calculate the relative amounts of

proeutectoid phase ( or Fe3C) and pearlite?

Lever rule + tie line that extends from the eutectoid

composition (0.75 wt% C) to – ( + Fe3C)

boundary (0.022 wt% C) for hypoeutectoid alloys

and to ( + Fe3C) – Fe3C boundary (6.7 wt% C) for

hipereutectoid alloys.

Fraction of phase determined by application of

lever rule across

University theDept.

of Virginia, entire ( +Science

of Materials Fe3C) phase field 18

and Engineering

Introduction to Materials Science, Chapter 9, Phase Diagrams

Example: hypereutectoid alloy, composition C1

Fraction of pearlite:

WP = X / (V+X) = (6.7 – C1) / (6.7 – 0.76)

Fraction of proeutectoid cementite:

WFe3C = V / (V+X) = (C1 – 0.76) / (6.7 – 0.76)

University of Virginia, Dept. of Materials Science and Engineering 19

Introduction to Materials Science, Chapter 9, Phase Diagrams

Summary

Make sure you understand language and concepts:

Austenite Microconstituent

Cementite Pearlite

Component Peritectic reaction

Congruent transformation Phase

Equilibrium Phase diagram

Eutectic phase Phase equilibrium

Eutectic reaction Primary phase

Eutectic structure Proeutectoid

Eutectoid reaction cementite

Ferrite Proeutectoid ferrite

Hypereutectoid alloy Solidus line

Hypoeutectoid alloy Solubility limit

Intermediate solid solution Solvus line

Intermetallic compound System

Invariant point Terminal solid

Isomorphous solution

Lever rule Tie line

Liquidus line

Metastable

University of Virginia, Dept. of Materials Science and Engineering 20

Introduction to Materials Science, Chapter 9, Phase Diagrams

Reading for next class:

Chapter 10: Phase Transformations in Metals

Kinetics of phase transformations

Multiphase Transformations

Phase transformations in Fe-C alloys

Isothermal Transformation Diagrams

Mechanical Behavior

Tempered Martensite

Optional reading (Parts that are not covered / not tested):

10.6 Continuous Cooling Transformation Diagrams

University of Virginia, Dept. of Materials Science and Engineering 21

Вам также может понравиться

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Plastic Deformation, Flow Stress and FormabilityДокумент35 страницPlastic Deformation, Flow Stress and FormabilityAnna100% (1)

- Metallography PDFДокумент185 страницMetallography PDFTunjung Harry MuktiОценок пока нет

- A Metallographic Examination of Fracture Splitting C70S6 Steel Used in Connecting RodsДокумент14 страницA Metallographic Examination of Fracture Splitting C70S6 Steel Used in Connecting RodsSujay NahaldeОценок пока нет

- Porosity in Castings AFS Transactions 2005Документ28 страницPorosity in Castings AFS Transactions 2005jlplazaolaОценок пока нет

- An Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesОт EverandAn Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesОценок пока нет

- COE-101.01, Corrosion PrinciplesДокумент133 страницыCOE-101.01, Corrosion PrinciplesJhonattan BarruetaОценок пока нет

- Corrosion of SS in Nitric Acid ServiceДокумент23 страницыCorrosion of SS in Nitric Acid ServiceAdriaan de Witt100% (1)

- How Dislocations Enable Plastic Deformation in MetalsДокумент33 страницыHow Dislocations Enable Plastic Deformation in MetalsKate Lynn PabelicoОценок пока нет

- Development and Processing of Low Carbon Bainite SteelДокумент486 страницDevelopment and Processing of Low Carbon Bainite Steelpaimpilly100% (1)

- Cast IronДокумент15 страницCast IronJohnОценок пока нет

- Interpretation of The Microstructure of SteelsДокумент61 страницаInterpretation of The Microstructure of SteelsCiresica Sanda Cocindau100% (1)

- Plot displacement curves from position diagramsДокумент9 страницPlot displacement curves from position diagramsReyner LozaОценок пока нет

- Chapter 7 - Dislocations and Strengethening MechanismsДокумент50 страницChapter 7 - Dislocations and Strengethening MechanismsmikeengineeringОценок пока нет

- Stainless Steel Microstructure, Mechanical Properties and Methods of Application - 2015Документ291 страницаStainless Steel Microstructure, Mechanical Properties and Methods of Application - 2015Ariel NemcoОценок пока нет

- Sub-Zero Treatment of Steels - Technology, Processes, Equipment (Final Artwork) PDFДокумент20 страницSub-Zero Treatment of Steels - Technology, Processes, Equipment (Final Artwork) PDFBinh Thanh LeОценок пока нет

- Iron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiДокумент41 страницаIron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiAmrit MallickОценок пока нет

- Welding Metallurgy and Weldability of Nickel-Base AlloysОт EverandWelding Metallurgy and Weldability of Nickel-Base AlloysРейтинг: 5 из 5 звезд5/5 (1)

- Chromate Conversion Coatings and Their Current AppДокумент5 страницChromate Conversion Coatings and Their Current AppDeni HermawanОценок пока нет

- ASM-Powder Metallurgy Stainless Steels - Processing, Microstructures, and PropertiesДокумент227 страницASM-Powder Metallurgy Stainless Steels - Processing, Microstructures, and PropertiesAldin Bubic100% (2)

- Fastener FailuresДокумент3 страницыFastener FailuresWylliam Diel WagnerОценок пока нет

- SpecialEdition3 - Gas Nitriding and Nitrocarburising138 - 177074Документ48 страницSpecialEdition3 - Gas Nitriding and Nitrocarburising138 - 177074ABRAHAM SILVA HERNANDEZОценок пока нет

- Two-Stage Ball Milling of Recycled Machining Chips To Create An Alternative Feedstock Powder For Metal Additive ManufacturingДокумент40 страницTwo-Stage Ball Milling of Recycled Machining Chips To Create An Alternative Feedstock Powder For Metal Additive ManufacturingJazmínARОценок пока нет

- The Study of Metal Structures and Their Mechanical Properties: Pergamon Unified Engineering SeriesОт EverandThe Study of Metal Structures and Their Mechanical Properties: Pergamon Unified Engineering SeriesОценок пока нет

- Welding CoatingДокумент69 страницWelding CoatingphillipskincaidОценок пока нет

- Handbook For Machining GuidelinesДокумент135 страницHandbook For Machining GuidelinesSyed NawazОценок пока нет

- MicrostructuresДокумент10 страницMicrostructuresErin BarryОценок пока нет

- Iron-carbon phase diagram guideДокумент9 страницIron-carbon phase diagram guideNagamuthu PandianОценок пока нет

- SA210 A1 Engg - Failure Analysis - Rajat PDFДокумент8 страницSA210 A1 Engg - Failure Analysis - Rajat PDFShoaib AhmedОценок пока нет

- NCERT Physics STD 12 Part 1Документ311 страницNCERT Physics STD 12 Part 1Yash MaheshwariОценок пока нет

- UNIT 1-LN The Materials and Process UniverseДокумент27 страницUNIT 1-LN The Materials and Process UniverseSEPОценок пока нет

- Brazing Allloy Cusil ABAДокумент12 страницBrazing Allloy Cusil ABADheeraj SharmaОценок пока нет

- Modern Metallography: The Commonwealth and International Library: Metallurgy DivisionОт EverandModern Metallography: The Commonwealth and International Library: Metallurgy DivisionРейтинг: 5 из 5 звезд5/5 (1)

- Metallographic Principles 200-860Документ44 страницыMetallographic Principles 200-860marian111100% (4)

- Microstructural Changes in The Forge Weld Area During HF-ERWДокумент4 страницыMicrostructural Changes in The Forge Weld Area During HF-ERWilze86Оценок пока нет

- MetallographyДокумент480 страницMetallographypawoe3064100% (2)

- AHДокумент114 страницAHReyza PrasetyoОценок пока нет

- Podfa AluminumДокумент8 страницPodfa AluminumAnonymous TfZRkQYОценок пока нет

- Steel CleanlinessДокумент22 страницыSteel CleanlinessfondershellОценок пока нет

- Development of Coarse-Grained Structure During RecrystallizationДокумент20 страницDevelopment of Coarse-Grained Structure During Recrystallizationsivajirao70100% (1)

- Physical Metallurgy Laboratory Manual PDFДокумент83 страницыPhysical Metallurgy Laboratory Manual PDFafnene1100% (1)

- Case HardeningДокумент28 страницCase Hardeningdramilt100% (1)

- Effect of Forging Surface On Fatigue Behavior of Steels A Literature ReviewДокумент56 страницEffect of Forging Surface On Fatigue Behavior of Steels A Literature ReviewCan ERTANОценок пока нет

- Material Selection Guide for DesignДокумент5 страницMaterial Selection Guide for DesignIwan SurachwantoОценок пока нет

- Microstructure Properties: I Sensitivity of Properties To Thermal History?Документ35 страницMicrostructure Properties: I Sensitivity of Properties To Thermal History?MadhusudanОценок пока нет

- Cleaning, Casting Defects and Die Castings. CleaningFettling of CastingsДокумент70 страницCleaning, Casting Defects and Die Castings. CleaningFettling of Castingsmecaunidos7771Оценок пока нет

- Phase Transformation in AISI 410 Stainless Steel PDFДокумент10 страницPhase Transformation in AISI 410 Stainless Steel PDFirajfarjiОценок пока нет

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsДокумент7 страницWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalОценок пока нет

- Copper Casting Alloys - Foundry TechnologyДокумент16 страницCopper Casting Alloys - Foundry TechnologyOnilio Firmino de MedeirosОценок пока нет

- Selection Process Overview: - at Concept (Preliminary) LevelДокумент23 страницыSelection Process Overview: - at Concept (Preliminary) LevelSudheer Kumar PetetiОценок пока нет

- Module OrderДокумент2 страницыModule OrderhreerОценок пока нет

- Rheocasting of Aluminum 201Документ56 страницRheocasting of Aluminum 201Nahid LatonaОценок пока нет

- Metal Structure and Metallography TechniqueДокумент11 страницMetal Structure and Metallography TechniqueLilian RoseОценок пока нет

- CH 3 PDFДокумент20 страницCH 3 PDFHassaan SajidОценок пока нет

- Engineering Failure Analysis of Low Carbon Steels in Deep DrawingДокумент7 страницEngineering Failure Analysis of Low Carbon Steels in Deep DrawingPaul RosiahОценок пока нет

- Gmaw Cladding PDFДокумент20 страницGmaw Cladding PDFMurad AlamОценок пока нет

- Welding Metallurgy-2Документ9 страницWelding Metallurgy-2Nur SyahroniОценок пока нет

- Foundry ProceduresДокумент25 страницFoundry Procedureskumar21081968Оценок пока нет

- Reducing Gear Distortion with Simple FixtureДокумент7 страницReducing Gear Distortion with Simple FixtureVireshVerma100% (1)

- NitridingДокумент13 страницNitridingShashidhar Ks KadamaОценок пока нет

- Guidelines for Specification, Welding and Inspection of Stainless Alloy PipingДокумент19 страницGuidelines for Specification, Welding and Inspection of Stainless Alloy Pipingafr5364Оценок пока нет

- Valery Marinov, Manufacturing TechnologyДокумент168 страницValery Marinov, Manufacturing TechnologyAbir Roy100% (3)

- Practical Data MetallurgistsДокумент78 страницPractical Data MetallurgistsrtgeorgeОценок пока нет

- Metallurgy GATE SolutionsДокумент24 страницыMetallurgy GATE SolutionsSaurabh ShashankОценок пока нет

- MEM560 Manufacturing Processes - Metal Forming & Shaping ProcessesДокумент115 страницMEM560 Manufacturing Processes - Metal Forming & Shaping ProcessesNabilah MustafaОценок пока нет

- TM23 - Heat Treatment of Metals PDFДокумент32 страницыTM23 - Heat Treatment of Metals PDFAlessio NotariОценок пока нет

- Cold Rolling and Annealing Textures in Low Carbon and Extra Low Carbon SteelsДокумент44 страницыCold Rolling and Annealing Textures in Low Carbon and Extra Low Carbon SteelsZhiyong JiaОценок пока нет

- An Overview On Types of White Cast Irons and HighДокумент13 страницAn Overview On Types of White Cast Irons and HighThanhluan NguyenОценок пока нет

- Metallographic Printing Methods for Detecting ImpuritiesДокумент3 страницыMetallographic Printing Methods for Detecting ImpuritiesAnup Tigga100% (1)

- Gating & RiserДокумент8 страницGating & Riserhegdemahesh1Оценок пока нет

- PART TEST-4 (PT-4) : Subject: ChemistryДокумент25 страницPART TEST-4 (PT-4) : Subject: ChemistrySR-71 BLACKBIRDОценок пока нет

- G Codes PDFДокумент1 страницаG Codes PDFSR-71 BLACKBIRDОценок пока нет

- Tension Test CharacteristicДокумент1 страницаTension Test CharacteristicSR-71 BLACKBIRDОценок пока нет

- Smith CH 01Документ20 страницSmith CH 01Chan Hyun ParkОценок пока нет

- HW7Документ6 страницHW7SR-71 BLACKBIRDОценок пока нет

- Smith CH 01Документ20 страницSmith CH 01Chan Hyun ParkОценок пока нет

- Chemistry CBSE 2014 Sample Paper - 2Документ13 страницChemistry CBSE 2014 Sample Paper - 2kaniska156Оценок пока нет

- Nokia E71-1 UG enДокумент149 страницNokia E71-1 UG enrboxwellОценок пока нет

- 15-8-2015, Junior IIT Answers.Документ19 страниц15-8-2015, Junior IIT Answers.SR-71 BLACKBIRDОценок пока нет

- Free Pick 1 3Документ1 страницаFree Pick 1 3SR-71 BLACKBIRDОценок пока нет

- Viteee Physics 2007Документ5 страницViteee Physics 2007SR-71 BLACKBIRDОценок пока нет

- Solution of DPP # 5Документ11 страницSolution of DPP # 5SR-71 BLACKBIRDОценок пока нет

- NIT Seat Vacancy Report After Round 4Документ2 страницыNIT Seat Vacancy Report After Round 4SR-71 BLACKBIRDОценок пока нет

- For PlayДокумент2 страницыFor PlaySR-71 BLACKBIRDОценок пока нет

- 1-8-2015, Junior IIT Answers, 2015-P1Документ15 страниц1-8-2015, Junior IIT Answers, 2015-P1SR-71 BLACKBIRDОценок пока нет

- Improve Memory PowerДокумент3 страницыImprove Memory PowerSR-71 BLACKBIRDОценок пока нет

- Group Work: Organizing The GroupsДокумент1 страницаGroup Work: Organizing The GroupsSR-71 BLACKBIRDОценок пока нет

- Lenovo Vibe P1ma40 Dual Sim QSG en For India v1.1 201510Документ17 страницLenovo Vibe P1ma40 Dual Sim QSG en For India v1.1 201510SR-71 BLACKBIRDОценок пока нет

- GTA San Andreas: Weapons, Health, Armor & MoneyДокумент3 страницыGTA San Andreas: Weapons, Health, Armor & MoneySR-71 BLACKBIRDОценок пока нет

- Lecture Summary ReportДокумент1 страницаLecture Summary ReportSR-71 BLACKBIRDОценок пока нет

- Lecturer's 12 - Point Compliance ChecklistДокумент1 страницаLecturer's 12 - Point Compliance ChecklistSR-71 BLACKBIRDОценок пока нет

- Preparing An Examination Paper: Good Practice ChecklistДокумент1 страницаPreparing An Examination Paper: Good Practice ChecklistSR-71 BLACKBIRDОценок пока нет

- Team PlayerДокумент6 страницTeam PlayerSR-71 BLACKBIRDОценок пока нет

- Team PlayerДокумент6 страницTeam PlayerSR-71 BLACKBIRDОценок пока нет

- Laila MajjunuДокумент48 страницLaila MajjunuSR-71 BLACKBIRDОценок пока нет

- TeamworkДокумент11 страницTeamworkSR-71 BLACKBIRDОценок пока нет

- Advanced Metal Casting Technology (MAT515) Assignment One Part OneДокумент51 страницаAdvanced Metal Casting Technology (MAT515) Assignment One Part OneBizuayehu Tadesse100% (1)

- Module06 NewДокумент206 страницModule06 NewMiltiadis Zabelas0% (1)

- Sub Module-1 Aircraft-Ferrous Materials 1.1 Ferrous Aircraft MetalsДокумент22 страницыSub Module-1 Aircraft-Ferrous Materials 1.1 Ferrous Aircraft MetalsDeepak Choudhary DCОценок пока нет

- Case Studies in Engineering Failure Analysis: W. Geary, J. HobbsДокумент8 страницCase Studies in Engineering Failure Analysis: W. Geary, J. HobbsCarlosDanielClavijoGranadosОценок пока нет

- Closed-Book Practice-Ch 11 (2015!03!16)Документ17 страницClosed-Book Practice-Ch 11 (2015!03!16)Juan100% (1)

- TTT DiagramДокумент41 страницаTTT Diagramsatish_trivediОценок пока нет

- Chapter 10 Phase TransformationДокумент26 страницChapter 10 Phase TransformationEffendy AdipratamaОценок пока нет

- 7B Microstructure of Iron Carbon AlloysДокумент14 страниц7B Microstructure of Iron Carbon AlloysAhmed AliОценок пока нет

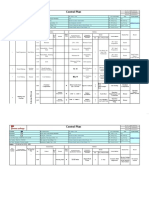

- Control Plan for Flywheel Assembly CastingДокумент24 страницыControl Plan for Flywheel Assembly CastingSuraj RawatОценок пока нет

- PTHT End SemДокумент11 страницPTHT End SemCh PrasadОценок пока нет

- Damping Properties of Selected Steels and Cast Irons: Bureau of Mines Report of Investigations/1987Документ20 страницDamping Properties of Selected Steels and Cast Irons: Bureau of Mines Report of Investigations/1987Luis Alberto Silva NavarroОценок пока нет

- Development of Ductile Iron Over Fifty YearsДокумент36 страницDevelopment of Ductile Iron Over Fifty YearsDenis Yasmin AlineОценок пока нет

- Effect of Chill On Ni Cast Iron PDFДокумент18 страницEffect of Chill On Ni Cast Iron PDFsachinguptachdОценок пока нет

- Engineering Materials and Metallurgy: 2017 Solved Question (Apr/May) and (Nov/Dec)Документ62 страницыEngineering Materials and Metallurgy: 2017 Solved Question (Apr/May) and (Nov/Dec)abdur rahmanОценок пока нет

- Report On Civil EngineeringДокумент48 страницReport On Civil EngineeringArmaan GuptaОценок пока нет

- Optimization of Mechanical Properties of High-Carbon Pearlitic Steels with SI and V AdditionsДокумент14 страницOptimization of Mechanical Properties of High-Carbon Pearlitic Steels with SI and V Additionsceyhun kilicОценок пока нет

- Iron-Carbide DiagramДокумент6 страницIron-Carbide DiagramAbhijit GhanwatОценок пока нет

- DiplomaManufacturingProcessImportant2 3MarksQuestions AnswersEnglish PDFДокумент36 страницDiplomaManufacturingProcessImportant2 3MarksQuestions AnswersEnglish PDFSathya NarayananОценок пока нет

- Subject:-Paper Code: Branch/Sem.: - : - Mechanical/IVДокумент22 страницыSubject:-Paper Code: Branch/Sem.: - : - Mechanical/IVKaran KushwahaОценок пока нет

- Fe-C Equilibrium Diagram PhasesДокумент2 страницыFe-C Equilibrium Diagram Phasesروشان فاطمة روشانОценок пока нет