Академический Документы

Профессиональный Документы

Культура Документы

Low Volume Esp Application

Загружено:

Alisha BasukiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Low Volume Esp Application

Загружено:

Alisha BasukiАвторское право:

Доступные форматы

Low Volume ESP Application

Chevron Permian Basin

October 2005 to October 2006

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Reason Applications Were Chosen

Repeat rod failures

Progressing cavity pump costs and daily monitoring

Progressing cavity pump could not be chemically

treated

Low profile required to avoid agricultural watering

systems

Production range from 40 – 480 BFPD

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Design Of Applications

Motor temperature targeted below 250oF due to scaling

and chemical limitations

– Motor de-rate

– Recirculation pump

– Motor shroud

#2 cable for reliable motor starting with low

horsepower / low voltage motors

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Application Confidence

Concerns:

– Pump wear

• Low Flow Causing Downthrust

– Motor temperature

• Conductive Cooling Lessened by Low Flow Past Motor

Resolutions:

– Analyzed thrust curves - maximum possible downthrust is

negligible

– Motor de-rate, recirculation pump, or motor shroud used to aid

cooling

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Flow Rate and Depth Range Application Count

Chevron Permian Low Volume ESP Application - October 2005 to October 2006

8,001

to 3 1

10,000

6,001

to 4 1

Pump Set Depth [FT]

8,000

5,001

to 1

6,000

4,001

to 5 3 1 3 4 3

5,000

2,500

to 1

4,000

30 to 60 61 to 100 101 to 120 121 to 150 151 to 250 251 to 500

Flow Rate [BFPD]

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Case Studies

Deloache 11

– 59 BFPD

– 372 run days (As Of 10/10/2006)

– Prior issues:

• Progressing cavity pump high failure rate

• Progressing cavity pump needs daily fluid shots to prevent pump-

off

• Chemical treatment difficult with PC pump due to stator elastomer

break down

• Cost comparison of low volume ESP vs. strap-jacks

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Case Studies

Wharton Jr 10

– 41 BFPD

– 357 Run Days (As Of 10/10/2006)

– Prior Issues:

• Low profile required for crop watering

• ESP over sizing

• Scale plugged pumps

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Problems Found

Minimal clearance between impeller and diffuser

susceptible to scaling

– Solution: Reviewed chemical treatment

program

Increased pump horsepower requirement due to thrust

washer material

– Solution: Modified material selection for

increased durability

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Root Cause Of Pull

Chevron Permian Low Volume ESP Application - October 2005 to October 2006

180 4

166

160

154

3 139

140 3

3

120

Average Run Time [Days]

111

109

Number of Pulls

100 94

2

77

80

60

1 1 1 1 1 1

1

40

40

20

0 0

Scale Plugged Operating Cable Defect Improper Drive Electrical Damaged Work Over

Temperature Setup Supply Recirc Tube

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Average Run Time Number of Pulls

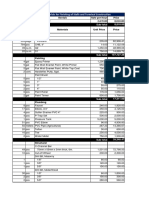

Run Stage Set Depth Production

Well Name Install Date Days Count [FT] [BFPD]

AB COATES C22 4/8/2006 186 408 6,091 488

AB WHARTON JR A-10 10/19/2005 357 210 4,727 52

Current Low AB WHARTON JR A-14

AB WHARTON JR JOA 13

10/11/2005

10/17/2005

365

359

240

228

4,727

4,792

128

156

Volume ESP AN STATE 5

CDU 152

CRIER MCELROY 439

6/14/2006

2/13/2006

4/7/2006

119

240

187

412

273

129

8,794

6,417

2,699

238

205

436

Installations CVU 75

CVU 280

CVU 286

1/24/2006

4/26/2006

2/17/2006

260

168

236

242

204

204

4,679

4,314

4,288

259

391

162

(As Of 10/10/2006) DELOACHE 11 10/4/2005 372 210 4,708 59

DELOACHE 12 9/1/2006 40 202 4,614 55

DELOACHE 25 1/28/2006 256 198 4,648 128

DELOACHE 26 1/25/2006 259 198 4,674 39

DELOACHE 35 9/7/2005 399 204 4,649 155

DELOACHE 60 9/10/2005 396 210 4,666 76

DELOACHE 86 2/2/2006 251 186 4,621 100

FRISTO B2-18 6/1/2006 132 412 9,274 207

INVESTORS ROYALTY 36 2/23/2006 230 315 7,715 151

MED NCT 2 128 11/18/2005 327 204 4,614 34

MED NCT 2 164 3/2/2006 223 223 4,726 148

MEDARBY 27 9/7/2006 34 242 4,646 353

MONUMENT STATE 15 7/19/2006 84 296 7,255 161

NLU 502 7/19/2006 84 204 4,669 111

NLU 601 9/16/2005 390 216 4,744 185

Copyright 2006 Baker Hughes, Inc. All rights reserved.

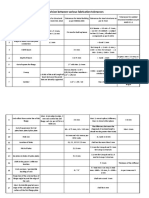

Pulled Low Volume ESPs

Run Stage Failed Failed Set Depth Production

Well Name Install Date Pull Date Days Count PIT Pull Reason Component Root Cause [FT] [BFPD]

LOW / NO Damaged

CVU 175 1/27/2006 5/1/2006 94 257 Yes Pump 4,751 79

PRODUCTION Recirc Tube

HIGH AMPS / NO

DELOACHE 12 12/31/2005 5/24/2006 144 203 Yes Pump Scale 4,614 55

START

LOW / NO

DELOACHE 12 5/26/2006 8/30/2006 96 202 Yes Pump Scale 4,614 55

PRODUCTION

LOW / NO

DELOACHE 26 1/7/2006 1/24/2006 17 198 Yes Pump Plugged 4,674 39

PRODUCTION

GROUNDED Electrical

FRISTO B2-18 2/10/2006 5/30/2006 109 390 Yes Motor 9,274 207

DOWNHOLE Supply

GROUNDED Operating

INVESTORS ROYALTY 45 11/17/2005 5/2/2006 166 343 Yes MLE 7,686 214

DOWNHOLE Temperature

GROUNDED Improper Drive

INVESTORS ROYALTY 45 5/4/2006 9/20/2006 139 Yes Motor 7,686 214

350 DOWNHOLE Setup

LOW / NO

MONUMENT STATE 15 1/20/2006 7/17/2006 178 296 Yes Pump Plugged 7,255 161

PRODUCTION

GROUNDED

NLU 502 2/14/2006 7/18/2006 154 204 No Cable Cable Defect 4,669 111

DOWNHOLE

CONVERT TO OTHER

NM STATE AB-9 3/30/2006 5/9/2006 40 409 No None Work Over 8,357 203

LIFT METHOD

LOW / NO

STATE AN 1 7/12/2006 8/18/2006 37 353 Yes Pump Plugged 8,444 130

PRODUCTION

LOW / NO

STATE AN 1 4/4/2006 7/7/2006 94 353 Yes Pump Scale 8,444 130

PRODUCTION

VGWU 55 9/11/2006 9/26/2006 15 279 No WELL TEST ENDED None None 5,752 180

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Number of Systems and Average Runtimes

Chevron Permian Low Volume ESP Application - October 2005 to October 2006

30 9

8

25

7

Average Runtime [Months]

20 6

Number of Systems

5

15

4

10 3

2

5

1

0 0

Oct-05 Nov-05 Dec-05 Jan-06 Feb-06 Mar-06 Apr-06 May-06 Jun-06 Jul-06 Aug-06 Sep-06 Oct-06

Avg Running Runtime Avg Pulled Runtime Number of Units Running Number of Units Pulled

Copyright 2006 Baker Hughes, Inc. All rights reserved.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- TrainingManual PDFДокумент234 страницыTrainingManual PDFJuan José Matos Ch100% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- (Logistics Team) PDO Oilfield Transport & Interior Based Vehicle SpecificationsДокумент22 страницы(Logistics Team) PDO Oilfield Transport & Interior Based Vehicle SpecificationsVenkatesha HebbarОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 3 Hrs Motor Grader 2,670.00 8,010.00: Detailed Bill of Materials For Finishing of Stalls and Terminal ConstructionДокумент2 страницы3 Hrs Motor Grader 2,670.00 8,010.00: Detailed Bill of Materials For Finishing of Stalls and Terminal ConstructionKris Aileen CortezОценок пока нет

- Comparision of Fabrication TolerancesДокумент4 страницыComparision of Fabrication TolerancesSatish Keskar100% (1)

- Alfa Laval LKH Pump ManualДокумент62 страницыAlfa Laval LKH Pump ManualAristoteles CarreñoОценок пока нет

- Howard B (1) - Petroleum Engineers Handbook, Part 4Документ331 страницаHoward B (1) - Petroleum Engineers Handbook, Part 4yayОценок пока нет

- Thermowell InstallationДокумент8 страницThermowell Installationprasoon_eilОценок пока нет

- JD - Field Service EngineerДокумент2 страницыJD - Field Service EngineerRajesh PotluriОценок пока нет

- Flexible Design - Geo Synthetic LCR MethodДокумент14 страницFlexible Design - Geo Synthetic LCR MethodartiОценок пока нет

- Tensile Test Lab Report MAE 361Документ3 страницыTensile Test Lab Report MAE 361mrm3zaОценок пока нет

- Cornell Pump Company Refrigerant Pump 1.5CBHДокумент2 страницыCornell Pump Company Refrigerant Pump 1.5CBHJavier AffifОценок пока нет

- Válvula de Seguridad Anderson Greenwood Crosby - La Rosita - Jos-EДокумент66 страницVálvula de Seguridad Anderson Greenwood Crosby - La Rosita - Jos-EJose Flores100% (2)

- Wa5471ab SeriesДокумент41 страницаWa5471ab SeriesJahangir JinguОценок пока нет

- Fea 2 Marks and AnswersДокумент20 страницFea 2 Marks and AnswerssnvijayanОценок пока нет

- FD100 分Документ17 страницFD100 分Hadi FaisalОценок пока нет

- Cdo CalcДокумент3 страницыCdo CalcJeric FarinОценок пока нет

- Me401A Lab Report: Experiment Number: 5 Group Number: B2Документ9 страницMe401A Lab Report: Experiment Number: 5 Group Number: B2Rishu KatiyarОценок пока нет

- Automobile Workshop PracticeДокумент2 страницыAutomobile Workshop PracticeSachi MensiОценок пока нет

- Updated Summary of Alignment Soils Mpemba-Isongole Road From CML - 03102012Документ35 страницUpdated Summary of Alignment Soils Mpemba-Isongole Road From CML - 03102012david karasilaОценок пока нет

- Review On Comparative Analysis of PSC Box Girder Bridge and PSC Precast I Girder Bridge StructureДокумент11 страницReview On Comparative Analysis of PSC Box Girder Bridge and PSC Precast I Girder Bridge StructureIJRASETPublicationsОценок пока нет

- Chapter1 Intro ME651Документ93 страницыChapter1 Intro ME651Sahastranshu KomalangamОценок пока нет

- Boiler Starting Operating ProcedureДокумент2 страницыBoiler Starting Operating ProcedureRoopeshОценок пока нет

- Rover 75 ATF Fluid ChangeДокумент11 страницRover 75 ATF Fluid ChangeRichardОценок пока нет

- Thermodynamics-1 Semester AssignmentДокумент9 страницThermodynamics-1 Semester AssignmentShahZaib AnwarОценок пока нет

- 456895431585387343213$5 1refnoapplied MechanicsДокумент1 страница456895431585387343213$5 1refnoapplied MechanicsKumar SaurabhОценок пока нет

- 05 - Engine Removal-Installation PDFДокумент7 страниц05 - Engine Removal-Installation PDFJhon J AcevedoОценок пока нет

- Solved ProblemДокумент35 страницSolved ProblemTroy BaongОценок пока нет

- Dbatu Scheme - New & OldДокумент9 страницDbatu Scheme - New & OldDeepak BhopeОценок пока нет

- Ur P2feb2021Документ40 страницUr P2feb2021nafrisqsОценок пока нет

- Aluminum Crane Systems 1110701Документ32 страницыAluminum Crane Systems 1110701aidixon CAD designОценок пока нет