Академический Документы

Профессиональный Документы

Культура Документы

Turbine Control

Загружено:

scribdhas20060 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров44 страницыОригинальное название

Turbine control.pptx

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров44 страницыTurbine Control

Загружено:

scribdhas2006Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 44

DONE BY:

Marthad abdolmonem 044065

Mohammed ahmed osman 054054

Suhail mohammed khairi 044035

Rughem osman karfis 014026

TURBINE CONTROL

At power plants with fossil fuel coordination

working mode consist several hierarchical

organized regulation levels.

Main purpose of coordination control is to secure

that system boiler-turbine-generator in

automatic pressure control behave like one

entity. For that purpose is necessary to integrate

multitude different regulation circuit into one

structure called main controller. This regulator

must control two main control signals:

• steam pressure at boiler output (boiler

following mode)

• electrical power at generator output

(turbine following mode)

Main regulator is containing

two regulation contour

Dependency which regulation contour

(boiler or turbine load) control substantial

control signals (steam pressure or electrical

power) we determine two coordinated

working mode:

• boiler load control – control boiler thermal

load, that is coal quantity which have to

distribute over mills and convey to boiler

burning place.

• turbine load control – controlled value is

turbine valve position, placed between super

heaters and turbine height pressure chamber

and determine steam flow to turbine moving

blade.

Which of these two mode will be in use

depend of many parameters, but in basic

starts from idea: for control value (pressure

or power) which have to change quickly and

frequently usually using turbine load

controller. Boiler load regulation is more

required than turbine load controller by

reason of complicated combustion process in

boiler.

Combustion process in burning place have

big time constants and many disturbances:

coal or air shortage in burning place,

failure equipment in plant, inferior water

supply at boiler,...

From that reasons boiler load control usually

used for values which needed stay constant

for a long time without frequent set point

changing. Turbine is relative fast executive

object related to boiler and that characteristic

determine turbine usage possibility this

objects in coordinated working mode.

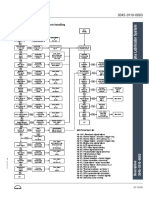

Main controller in boiler coordination mode

(figure 1) contain pressure regulator, which

generate thermal load as output and power

regulator which control position of turbine

valves.

Pressure regulator have to preserve reference

pressure during disturbance such as

changing coal calorific value or changing

position of turbine valves.

Coal calorific value representing quantity of

thermal energy released during complete

combusting a unit mass of fuel. This value is

variable and depend of fuel grade

Operation mode of steam turbine depends on the

control concept that is implemented on steam

power plant. Unit's power is generally controlled

by manipulating of steam flow through turbine.

Turbine's steam flow depends on steam pressure

and size of input area through which steam

enters turbine. This area is manipulated (control)

by position of turbine's control valves. Therefore,

there are two operational modes (in general):

- mode with constant pressure in front of

turbine where turbine's pressure is controlled

by changing control valves position and

mode with sliding pressure in front of

turbine, where control valves are maintained

at some constant position (for example 80 or

100% opened). In such case steam pressure is

controlled by boiler control loops (by

manipulating coal feeders).

Very closely related to this operational modes

are so called "control concepts"

Concept of "boiler leading" means that steam

pressure in front of turbine is controlled by

control valves (constant) while power output

setpoint is associated with boiler controller

that manipulate coal firing.

On the other side, there is "turbine leading"

concept in which, power output setpoint is

associated by control valves and therefore

every demand in power is immediately

followed by changing of control valves

position. Then, steam pressure is controlled

by boiler.

*note that this concept is not fully "sliding

mode" because, control valve position is not

constant, but this concept is usually called

sliding pressure mode, because steam

pressure is changing and boiler pressure

controller needs to adapt to these changes.

Constant pressure implies stable pressure

of the steam generator and main steam line

over the unit’s load range. Meanwhile, the

basic nature of a simple, rotating turbine is to

require less pressure as load and flow rate

are reduced, and if the main steam pressure

is limited to only that required for each load,

this mode is referred to as pure sliding

pressure.

However, when we speak generally of

“sliding pressure,” we often mean modified

sliding pressure, as shown in Figure 2. This

mode has a limited amount of pressure

throttling to provide a modest amount of

fast-response load reserve. A unit under

constant pressure will have significant load

reserve at any reduced load, due to its

significant pressure throttling or the

availability of admission valve(s).

By opening the throttle valve or an admission

valve, the pressure in the turbine and steam

generator move toward equalization. The sudden

reduction of pressure in the steam generator

prompts an instantaneous expulsion of steam

mass due to the increase in a specific volume of

steam within the confines of the system, and it

provides a temporary load increase even before

the fuel-handling and -firing system can be

loaded to support any sustained higher load.

Pure sliding-pressure operation does not offer

this kind of load or frequency response and is

therefore generally not practiced.

AUTOMATIC VOLTAGE REGULATOR (AVR)

A voltage regulator is an electrical regulator

designed to automatically maintain a

constant voltage level.

It may use an electromechanical mechanism,

or passive or active electronic components.

Depending on the design, it may be used to

regulate one or more AC or DC voltages.

With the exception of passive shunt

regulators, all modern electronic voltage

regulators operate by comparing the actual

output voltage to some internal fixed

reference voltage.

Any difference is amplified and used to

control the regulation element in such a way

as to reduce the voltage error. This forms a

negative feedback control loop; increasing

the open-loop gain tends to increase

regulation accuracy but reduce stability

(avoidance of oscillation, or ringing during

step changes).

There will also be a trade-off between

stability and the speed of the response to

changes. If the output voltage is too low

(perhaps due to input voltage reducing or

load current increasing), the regulation

element is commanded, up to a point, to

produce a higher output voltage - by

dropping less of the input voltage, if the

output voltage is too high, the regulation

element will normally be commanded to

produce a lower voltage.

However, many regulators have over-current

protection, so that they will entirely stop

sourcing current (or limit the current in some

way) if the output current is too high, and

some regulators may also shut down if the

input voltage is outside a given range.

Operation of AVR linked to Generators:

AVR is linked with the main stator windings and

the exciter field windings to provide closed loop

control of the output voltage with load

regulation.

In addition to being powered from the main

stator, the AVR also derives a sample voltage

from the output windings for voltage control

purposes. In response to this sample voltage, the

AVR controls the power fed to the exciter field,

and hence the main field, to maintain the

machine output voltage within the specified

limits, compensating for load, speed,

temperature and power factor of the generator.

A frequency measuring circuit continually

monitors the generator output and provides

output under-speed

protection of the excitation system, by

reducing the output voltage proportionally

with speed below a pre-settable threshold.

Potential Divider and Rectifier takes a

proportion of the generator output voltage

and attenuates it. This input chain of

resistors includes the range potentiometer

and hand trimmer which adjust the generator

voltage. A rectifier converts the a.c. into d.c.

for further processing.

The Amplifier (Amp) compares the sensing

voltage to the Reference Voltage and

amplifies the difference (error) to

provide a controlling signal for the power

devices. The Ramp Generator and Level

Detector and Driver infinitely control the

conduction period of the Power Control

Devices and hence provides the excitation

system with the required

power to maintain the generator voltage

within specified limits.

The Stability Circuit provides adjustable

negative ac feedback to ensure good steady

state and transient performance of the

control system.

The Low Hz Detector measures the period of

each electrical cycle and causes the reference

voltage to be reduced approximately linearly

with speed below a presettable threshold.

The Synchronising circuit is used to keep the

Ramp Generator and Low Hz Detector locked

to the generator waveform period.

The Low Pass Filter prevents distorted

waveforms affecting the operation of the

AVR.

Power Control Devices vary the amount of

exciter field current in response to the error

signal produced by the Amplifier.

Suppression components are included to

prevent sub cycle voltage spikes damaging

the AVR components and also to reduce the

amount of conducted noise on the generator

terminals.

The Power Supply provides the required

voltages for the AVR circuitry.

THE END

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Fault Code 599 Auxiliary Commanded Dual Output Shutdown - Special InstructionsДокумент2 страницыFault Code 599 Auxiliary Commanded Dual Output Shutdown - Special InstructionsAhmedmah100% (1)

- Combined Gas (Turbine) and Steam (Turbine) : (COGAS)Документ28 страницCombined Gas (Turbine) and Steam (Turbine) : (COGAS)scribdhas2006100% (1)

- Marshalling KioskДокумент4 страницыMarshalling KioskThant Zin100% (1)

- Li Fi TechnologyДокумент34 страницыLi Fi TechnologyAmit Kumar MauryaОценок пока нет

- Gas Manifolds CPДокумент1 страницаGas Manifolds CPscribdhas2006Оценок пока нет

- Revised Affinity LawsДокумент13 страницRevised Affinity Lawsscribdhas2006Оценок пока нет

- Greater Amman Water SCADA Project (GASS) - TECO GROUPДокумент2 страницыGreater Amman Water SCADA Project (GASS) - TECO GROUPscribdhas2006Оценок пока нет

- Treating Hard Water Using Water Softener or Antiscalant InjectionДокумент1 страницаTreating Hard Water Using Water Softener or Antiscalant Injectionscribdhas2006Оценок пока нет

- Mod 502 WДокумент2 страницыMod 502 Wscribdhas2006Оценок пока нет

- How To Correctly Size A Steam BoilerДокумент2 страницыHow To Correctly Size A Steam Boilerscribdhas2006Оценок пока нет

- Chlor 12Документ1 страницаChlor 12scribdhas2006Оценок пока нет

- Mod T202Документ2 страницыMod T202scribdhas2006Оценок пока нет

- Vacuum Regulator CPДокумент1 страницаVacuum Regulator CPscribdhas2006Оценок пока нет

- 3115C AДокумент2 страницы3115C Ascribdhas2006Оценок пока нет

- Gas Chlorination Equipment Series 3000Документ2 страницыGas Chlorination Equipment Series 3000hfguavitaОценок пока нет

- Data Boiler CFB PB#16Документ61 страницаData Boiler CFB PB#16scribdhas2006Оценок пока нет

- Mod 502 WДокумент2 страницыMod 502 Wscribdhas2006Оценок пока нет

- Nozzles 40kg - MetricДокумент1 страницаNozzles 40kg - Metricscribdhas2006Оценок пока нет

- AutoCAD Electrical Tips Tricks 0618 No2.Docx v2Документ5 страницAutoCAD Electrical Tips Tricks 0618 No2.Docx v2scribdhas2006Оценок пока нет

- WRAS Certificate EPDMДокумент1 страницаWRAS Certificate EPDMscribdhas2006Оценок пока нет

- WRAS Certificate EUROKOTEДокумент2 страницыWRAS Certificate EUROKOTEscribdhas2006Оценок пока нет

- Steel Tetra PakДокумент15 страницSteel Tetra Pakscribdhas2006Оценок пока нет

- TestДокумент1 страницаTestscribdhas2006Оценок пока нет

- WRAS Certificate 90-01Документ1 страницаWRAS Certificate 90-01scribdhas2006Оценок пока нет

- 4500 South Waterline Improvements Bid PackageДокумент1 страница4500 South Waterline Improvements Bid Packagescribdhas2006Оценок пока нет

- 4500 South Waterline Improvements Bid Package PDFДокумент291 страница4500 South Waterline Improvements Bid Package PDFscribdhas2006Оценок пока нет

- 2014.2.7 Rev.2 en Cleaning Method of JA Solar ModulesДокумент3 страницы2014.2.7 Rev.2 en Cleaning Method of JA Solar Modulesscribdhas2006Оценок пока нет

- 3.1B Certificat - ModèleДокумент1 страница3.1B Certificat - Modèlescribdhas2006Оценок пока нет

- Utility TurbinesДокумент67 страницUtility TurbinesBapu612345Оценок пока нет

- CCPPДокумент173 страницыCCPPscribdhas2006Оценок пока нет

- SAMSUNG SEM-3069E Compressor & Turbine Piping Design StandardДокумент124 страницыSAMSUNG SEM-3069E Compressor & Turbine Piping Design Standardscribdhas2006Оценок пока нет

- Pe Scaling PDFДокумент69 страницPe Scaling PDFscribdhas2006Оценок пока нет

- Appendix 7 - TOR ESCO Hot Charging PDFДокумент127 страницAppendix 7 - TOR ESCO Hot Charging PDFscribdhas2006Оценок пока нет

- EE124 Lecture 12 Source Follower Cascode Amplifier and Current Source Mar 9 Spring 2020 Annotated PDFДокумент13 страницEE124 Lecture 12 Source Follower Cascode Amplifier and Current Source Mar 9 Spring 2020 Annotated PDFSabeeq KarimОценок пока нет

- Electronic Circuit AnalysisДокумент7 страницElectronic Circuit AnalysisIshansi AgrawalОценок пока нет

- Gujarat Technological University: 1 Year, Subject Code: 3110018Документ4 страницыGujarat Technological University: 1 Year, Subject Code: 3110018saler71625Оценок пока нет

- PDF Sanken 882276Документ13 страницPDF Sanken 882276Moises CelosoОценок пока нет

- Artist Series: 1001RB-II/700RB-II Owner's ManualДокумент16 страницArtist Series: 1001RB-II/700RB-II Owner's ManualmaxОценок пока нет

- Electrical and Electronics EngineeringДокумент4 страницыElectrical and Electronics EngineeringPrithaBanerjeeОценок пока нет

- Product Overview: Data Sheet - H665GR GPON Gigabit ONT With Video ServiceДокумент7 страницProduct Overview: Data Sheet - H665GR GPON Gigabit ONT With Video ServiceTuấn minh DuongОценок пока нет

- DC Machines1.1 1Документ19 страницDC Machines1.1 1Janaka Chathuranga AbeywardenaОценок пока нет

- Design of Low Noise Amplifier For Microwave Circuits: July 2017Документ5 страницDesign of Low Noise Amplifier For Microwave Circuits: July 2017Jamal NasirОценок пока нет

- Release Note For IPASOLINK 08 May 2014Документ2 страницыRelease Note For IPASOLINK 08 May 2014Haytham Abdel-hadyОценок пока нет

- Electrical Installation Booklet Shipyard Standards: Marine Institute of Memorial University of NewfoundlandДокумент81 страницаElectrical Installation Booklet Shipyard Standards: Marine Institute of Memorial University of NewfoundlandHoangОценок пока нет

- Groundfos - SP 9-48Документ10 страницGroundfos - SP 9-48suwono radukОценок пока нет

- Crouse Hinds Eic Combination Starter BrochureДокумент8 страницCrouse Hinds Eic Combination Starter Brochurejvaldivia82Оценок пока нет

- NEC Article 728 Fire Resistive Cable Systems - No Concrete For Us We Are Fire RatedДокумент4 страницыNEC Article 728 Fire Resistive Cable Systems - No Concrete For Us We Are Fire Ratedthanna9783Оценок пока нет

- ORBIKДокумент96 страницORBIKNizarОценок пока нет

- EN Datasheet Copper SB RevCДокумент1 страницаEN Datasheet Copper SB RevCRoger Valenzuela HuamanОценок пока нет

- Jndal Power ResumeДокумент2 страницыJndal Power ResumeRahul Kumar YadavОценок пока нет

- 63 Sequence Diagram For Alarm HandlingДокумент1 страница63 Sequence Diagram For Alarm HandlingNick SkiadasОценок пока нет

- Agolar PCB Catalogue 2022-23Документ41 страницаAgolar PCB Catalogue 2022-23Karthikeyan .NОценок пока нет

- It8000 Indicator: Industrial Programmable Analog / Digital Controller, IP65Документ6 страницIt8000 Indicator: Industrial Programmable Analog / Digital Controller, IP65Leandro CamargoОценок пока нет

- GB38031-2020EN Electric Vehiles Traction Battery Safety RequerimentsДокумент15 страницGB38031-2020EN Electric Vehiles Traction Battery Safety RequerimentsMarianoОценок пока нет

- The Electrical Resistivity of Ultra-Thin Copper FilmsДокумент6 страницThe Electrical Resistivity of Ultra-Thin Copper FilmsJordan SantosОценок пока нет

- A Bridgeless Single-Stage Half-Bridge AC DC ConverterДокумент12 страницA Bridgeless Single-Stage Half-Bridge AC DC ConverterSaravana Prakash PОценок пока нет

- HT 306PD (sm-AFN75354522)Документ65 страницHT 306PD (sm-AFN75354522)Roberd MihailovОценок пока нет

- AN11740-PM5180 Antenna DesignДокумент62 страницыAN11740-PM5180 Antenna DesignTao TsaiОценок пока нет

- Pioneer PDP-S12-LR ManualДокумент40 страницPioneer PDP-S12-LR ManualAnonymous jnRlH5Оценок пока нет

- Qcells Installation Manual Q.PEAK DUO ML-G10.X Modules Series 2022-10 Rev04 ENДокумент13 страницQcells Installation Manual Q.PEAK DUO ML-G10.X Modules Series 2022-10 Rev04 ENMarko Maky ZivkovicОценок пока нет