Академический Документы

Профессиональный Документы

Культура Документы

Concentricity and Coaxiality: The Institute For Enhancement of Technology

Загружено:

Mukesh DepthsОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Concentricity and Coaxiality: The Institute For Enhancement of Technology

Загружено:

Mukesh DepthsАвторское право:

Доступные форматы

Concentricity And Coaxiality

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

CONCENTRICITY AND COAXIALITY

Concentricity is a condition in which two or more features, such

as circles, spheres, cylinders, cones, or hexagons, share a common

center or axis.

An example would be a round hole through the center of a cylindrical

part.

Coaxiality is a very similar condition in which two or more

circular or similar features are arranged with their axes in the

same straight line.

Examples might be a counter bored hole or a shaft having parts along its

length turned to different diameters.

Both these terms are often used interchangeably. For geometrical

tolerancing the same symbol is used for both conditions.

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

SYMBOL

The geometric characteristic symbol for both concentricity and

coaxiality consists of two concentric circles, having diameters equal to

75% and 50% respectively of the feature control symbol frame height

CONCENTRICITY SYMBOL

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

CONCENTRICITY TOLERANCING

CONCENTRICITY OF CIRCLES

• Diameter A is the Datum Circle

• Concentricity Tolerance is applied to the outer circle

• The Circle with 0.12 Dia. is the tolerance zone

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

ENLARGED PROFILE OF PART

The datum center is the center of the largest perfect circle, which can be inscribed

within the datum feature.

The tolerance zone is concentric with this datum center.

The center points of the controlled circle are established from the periphery of the

feature and their position will be affected by irregularities or errors of form of the

periphery.

Note : This is illustrated by the enlarged profiles. The center point of diameter A-A is

a point a, and the center point of diameter B-B is point b. These and all other center

points must lie within the tolerance zone.

5

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

CYLINDRICAL PART WITH CYLINDRICITY TOLERANCE

A common type of part where the outer diameter is required to

be concentric with the center bore, which is designated as a

datum feature.

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

MEASURING PRINCIPLE

• To fit a suitable mandrel in the datum feature

• Set two indicators with Master Gages to Zero reading

• Rotate the mandrel with component in V-block

• The difference of the reading gives the concentricity

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

EFFECTS OF ERRORS OF CONCENTRICITY

Figure A theoretical Perfect form

Both indicators read Zero-Zero as the part is revolved

Figure B represents eccentric part

The upper indicator read –0.05 and lower indicator read

+0.05 when revolved by 90deg both indicators return to zero

8

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

EFFECTS OF ERRORS OF CONCENTRICITY

Figure C represents a oval part

Both indicators read 0.12

when revolve by 90deg. Both indicators return to zero

Figure D represents a three lobed part

The upper indicator reads zero While the lower reads 0.1

(center is high by 0.05)

when revolve by 60deg. The upper indicator reads –0.1 and lower one reads

zero (center is 0.05 low)

9

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

TWO-FEATURE DATUM

10

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

MEASURING WITH VEE-BLOCK

MEASURING WITH VEE-BLOCK

11

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

CONCENTRICITY REFERENCED TO DATUM SYSTEM

Tolerance zone is perpendicular to datum A and also concentric with

the axis of datum B in the plane of datum A

The part is mounted on datum A and centered on datum B, and the job is

revolved while the controlled feature is contacted by two opposing

indicators.

It should be noted that this tolerance automatically controls the

straightness of the centerline of the 25mm portion and its

perpendicularity with datum A within the same tolerance.

12

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

Вам также может понравиться

- Concentricity & Coaxiality (GD&T)Документ12 страницConcentricity & Coaxiality (GD&T)Kishor kumar Bhatia88% (8)

- RoundnessДокумент23 страницыRoundnessKumar ChowdaryОценок пока нет

- Engineering Surveying: Theory and Examination Problems for StudentsОт EverandEngineering Surveying: Theory and Examination Problems for StudentsРейтинг: 4.5 из 5 звезд4.5/5 (8)

- ACCRETECH Guide Measuring Forms ENДокумент20 страницACCRETECH Guide Measuring Forms ENpatrikcncОценок пока нет

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionОт EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionРейтинг: 2.5 из 5 звезд2.5/5 (4)

- Cylindricity DefinitionДокумент3 страницыCylindricity DefinitionMuhd Rifdi Che AbRahimОценок пока нет

- Planar Linkage Synthesis: A modern CAD based approachОт EverandPlanar Linkage Synthesis: A modern CAD based approachОценок пока нет

- Roundness - GD&TДокумент23 страницыRoundness - GD&TKishor kumar Bhatia100% (3)

- GD&T Position TolДокумент204 страницыGD&T Position Toldramilt100% (2)

- Contact Lens Design Tables: Tables for the Determination of Surface Radii of Curvature of Hard Contact Lenses to Give a Required Axial Edge LiftОт EverandContact Lens Design Tables: Tables for the Determination of Surface Radii of Curvature of Hard Contact Lenses to Give a Required Axial Edge LiftОценок пока нет

- Drawing PracticesДокумент60 страницDrawing Practicespverma02Оценок пока нет

- METROLOGYДокумент11 страницMETROLOGYarvan singhОценок пока нет

- Updated MQC ManualДокумент29 страницUpdated MQC ManualssselvaОценок пока нет

- Angular MeasumentДокумент51 страницаAngular MeasumentVinay PanditОценок пока нет

- RoundnessДокумент7 страницRoundnessjacobian1810Оценок пока нет

- CH 3 Describing DataДокумент25 страницCH 3 Describing DataATHAYAОценок пока нет

- Geometric Dimensioning and Tolerancing, Concentricity, Runout Tolerances, Circular Runout, Total RunoutДокумент3 страницыGeometric Dimensioning and Tolerancing, Concentricity, Runout Tolerances, Circular Runout, Total Runoutmick.pride81Оценок пока нет

- Differentiate Between Line Standard and End Standard of Measurement 1Документ19 страницDifferentiate Between Line Standard and End Standard of Measurement 1ghghgОценок пока нет

- Fig.1.23 The Generation of Involute Profile On Right Side Fig.1.24 The Generation of Involute Profile On Left SideДокумент12 страницFig.1.23 The Generation of Involute Profile On Right Side Fig.1.24 The Generation of Involute Profile On Left SideBalvinderОценок пока нет

- Comparators NotesДокумент16 страницComparators NotesSrinivasulu GoliОценок пока нет

- Presentation Shared On Tolerance Stackup PDFДокумент40 страницPresentation Shared On Tolerance Stackup PDFSiva MareesanОценок пока нет

- PDF 20230731 022616 0000Документ10 страницPDF 20230731 022616 0000godwinayamga123Оценок пока нет

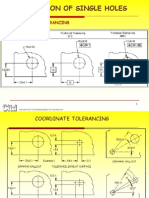

- Location of Single HolesДокумент8 страницLocation of Single HolesKumar ChowdaryОценок пока нет

- Experiment 4Документ3 страницыExperiment 4Arvind BhosaleОценок пока нет

- Measurements and Metrology Laboratory ManualДокумент20 страницMeasurements and Metrology Laboratory Manualbossanand05100% (3)

- CYLINDRICITYДокумент10 страницCYLINDRICITYKumar ChowdaryОценок пока нет

- Content TheodoliteДокумент23 страницыContent TheodoliteDdeqz Elina Bueno IОценок пока нет

- National Institute of Technology Warangal Department of Mechanical Engineering Warangal - 506 004Документ50 страницNational Institute of Technology Warangal Department of Mechanical Engineering Warangal - 506 004Venu Gopal AnneОценок пока нет

- MECHANICAL DESIGN ENGINEERING - Geometrical Dimensioning and Tolerancing - What Is The CYLINDRICITY Tolerance?Документ7 страницMECHANICAL DESIGN ENGINEERING - Geometrical Dimensioning and Tolerancing - What Is The CYLINDRICITY Tolerance?Sathya DharanОценок пока нет

- Module 1:tacheometric SurveyДокумент29 страницModule 1:tacheometric SurveyveereshОценок пока нет

- The Misunderstanding of Concentricity The Misunderstanding of ConcentricityДокумент3 страницыThe Misunderstanding of Concentricity The Misunderstanding of ConcentricityNisha NtaОценок пока нет

- Practice 000 250 2015 Date 11feb00 Page 1 of 7Документ11 страницPractice 000 250 2015 Date 11feb00 Page 1 of 7mengelito almonteОценок пока нет

- Squareness Measurement: Unit-Iv Module-IДокумент9 страницSquareness Measurement: Unit-Iv Module-ITommyVercettiОценок пока нет

- Brochure Roundness BookletДокумент12 страницBrochure Roundness BookletImm Yoon-AhОценок пока нет

- Engineering Drawings - ThayerДокумент39 страницEngineering Drawings - Thayermaran.suguОценок пока нет

- Geometrical TolerancingДокумент12 страницGeometrical TolerancingKumar Chowdary100% (1)

- Roundness and CircularityДокумент16 страницRoundness and CircularityKiran MadhavanОценок пока нет

- GD&T (Mechanical Engineers)Документ228 страницGD&T (Mechanical Engineers)Suman Ramsagar89% (19)

- MECH3002Y METROLOGY NotesДокумент9 страницMECH3002Y METROLOGY NotesBenoit J. AyoungОценок пока нет

- Circularity Measurement Using Electronic, Mechanical ComparatorДокумент7 страницCircularity Measurement Using Electronic, Mechanical Comparatorविशाल पुडासैनीОценок пока нет

- Plate 6Документ8 страницPlate 6Sleepy SpettoОценок пока нет

- CH 6 - Straightness, Flatness and Roundness-P2Документ13 страницCH 6 - Straightness, Flatness and Roundness-P2إحسان خالد جودة الشحات ٣٥٧٣Оценок пока нет

- A Brief Introduction To The Measurement of Roundness and Spindle Error SeparationДокумент12 страницA Brief Introduction To The Measurement of Roundness and Spindle Error SeparationaralvoiОценок пока нет

- Acceptance of MC Tool 123 PDFДокумент24 страницыAcceptance of MC Tool 123 PDFakshayОценок пока нет

- Angular Measurements: MEGR 6181 Engineering MetrologyДокумент14 страницAngular Measurements: MEGR 6181 Engineering MetrologyNarasimha ReddyОценок пока нет

- Leica Surveying Made EasyДокумент36 страницLeica Surveying Made EasyVali ComanОценок пока нет

- Experiment No. 3: Angle Measurement Metrology & Instrumentation (3341905)Документ7 страницExperiment No. 3: Angle Measurement Metrology & Instrumentation (3341905)T.MОценок пока нет

- Understanding Optical Specifications Edmund OpticsДокумент7 страницUnderstanding Optical Specifications Edmund OpticsYorche AlternoОценок пока нет

- Metrology Laboratory: Experiment No. 1Документ5 страницMetrology Laboratory: Experiment No. 1Mitesh KumarОценок пока нет

- MMMДокумент34 страницыMMMVaibhav Vithoba NaikОценок пока нет

- Metro20152 CH3Документ30 страницMetro20152 CH3Ba BuОценок пока нет

- Lab ReportДокумент20 страницLab ReportJoshua Reynolds67% (3)

- Linear MeasurementДокумент79 страницLinear MeasurementRht BrdОценок пока нет

- Chapter 4 - Angular Measurements PDFДокумент11 страницChapter 4 - Angular Measurements PDFIbrahim AlghoulОценок пока нет

- CE245 - Module 3Документ36 страницCE245 - Module 3Benmark JabayОценок пока нет

- GD&T Form and Position TolerancesДокумент1 страницаGD&T Form and Position TolerancesSaulo TrejoОценок пока нет

- Form TolerancesДокумент4 страницыForm Tolerancesvskumar4uОценок пока нет

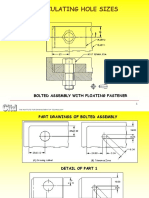

- Calculating Hole Sizes: Bolted Assembly With Floating FastenerДокумент16 страницCalculating Hole Sizes: Bolted Assembly With Floating FastenerMukesh DepthsОценок пока нет

- SymmetryДокумент14 страницSymmetryKumar ChowdaryОценок пока нет

- SymmetryДокумент14 страницSymmetryKumar ChowdaryОценок пока нет

- Projected Tolerance Zone GDNTДокумент23 страницыProjected Tolerance Zone GDNTMukesh DepthsОценок пока нет

- Aircraft Cruise 1Документ1 страницаAircraft Cruise 1Mukesh DepthsОценок пока нет

- Runout: The Institute For Enhancement of TechnologyДокумент14 страницRunout: The Institute For Enhancement of TechnologyChauhan HiteshkumarОценок пока нет

- Aircraft Control - Wright 1907 2Документ2 страницыAircraft Control - Wright 1907 2Mukesh DepthsОценок пока нет

- Naca Tn3781Документ108 страницNaca Tn3781Mukesh DepthsОценок пока нет

- Bezier CurvesДокумент22 страницыBezier CurvesATUL CHAUHANОценок пока нет

- AbstractДокумент1 страницаAbstractMukesh DepthsОценок пока нет

- Mukesh ResumeДокумент1 страницаMukesh ResumeMukesh DepthsОценок пока нет

- BeeeДокумент1 страницаBeeeMukesh DepthsОценок пока нет

- Modeling and Fuzzy Logic Control of A Quadrotor UAVДокумент5 страницModeling and Fuzzy Logic Control of A Quadrotor UAVAnonymous kw8Yrp0R5rОценок пока нет

- Sem 4 - Minor 2Документ6 страницSem 4 - Minor 2Shashank Mani TripathiОценок пока нет

- Attachment BinaryДокумент5 страницAttachment BinaryMonali PawarОценок пока нет

- Usha Unit 1 GuideДокумент2 страницыUsha Unit 1 Guideapi-348847924Оценок пока нет

- Lps - Config Doc of Fm-BcsДокумент37 страницLps - Config Doc of Fm-Bcsraj01072007Оценок пока нет

- Black BookДокумент28 страницBlack Bookshubham50% (2)

- Harga H2H Pula-Paket Data - Saldo EWallet v31012022Документ10 страницHarga H2H Pula-Paket Data - Saldo EWallet v31012022lala cemiОценок пока нет

- Fortigate Fortiwifi 40F Series: Data SheetДокумент6 страницFortigate Fortiwifi 40F Series: Data SheetDiego Carrasco DíazОценок пока нет

- Common OPCRF Contents For 2021 2022 FINALE 2Документ21 страницаCommon OPCRF Contents For 2021 2022 FINALE 2JENNIFER FONTANILLA100% (30)

- Giuliani Letter To Sen. GrahamДокумент4 страницыGiuliani Letter To Sen. GrahamFox News83% (12)

- SCHEDULE OF FEES - FinalДокумент1 страницаSCHEDULE OF FEES - FinalAbhishek SunaОценок пока нет

- China Ve01 With Tda93xx An17821 Stv9302a La78040 Ka5q0765-SmДокумент40 страницChina Ve01 With Tda93xx An17821 Stv9302a La78040 Ka5q0765-SmAmadou Fall100% (1)

- Ambient Lighting Vol 6 CompressedДокумент156 страницAmbient Lighting Vol 6 Compressedadvait_etcОценок пока нет

- Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Документ28 страницSelf-Instructional Manual (SIM) For Self-Directed Learning (SDL)Monique Dianne Dela VegaОценок пока нет

- Typical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpДокумент2 страницыTypical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpSabrinadeFeraОценок пока нет

- MSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)Документ10 страницMSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)ANNaОценок пока нет

- SPIE Oil & Gas Services: Pressure VesselsДокумент56 страницSPIE Oil & Gas Services: Pressure VesselsSadashiw PatilОценок пока нет

- ACC403 Week 10 Assignment Rebecca MillerДокумент7 страницACC403 Week 10 Assignment Rebecca MillerRebecca Miller HorneОценок пока нет

- LR Format 1.2Документ1 страницаLR Format 1.2Ch.Suresh SuryaОценок пока нет

- Finaniial AsceptsДокумент280 страницFinaniial AsceptsKshipra PrakashОценок пока нет

- Labor Law 1Документ24 страницыLabor Law 1Naomi Cartagena100% (1)

- Irrig in AfricaДокумент64 страницыIrrig in Africaer viОценок пока нет

- MOL Breaker 20 TonДокумент1 страницаMOL Breaker 20 Tonaprel jakОценок пока нет

- MMMДокумент6 страницMMMReet KanjilalОценок пока нет

- Risk and Uncertainty in Estimating and TenderingДокумент16 страницRisk and Uncertainty in Estimating and TenderingHaneefa ChОценок пока нет

- Enumerator ResumeДокумент1 страницаEnumerator Resumesaid mohamudОценок пока нет

- Computer System Sevicing NC Ii: SectorДокумент44 страницыComputer System Sevicing NC Ii: SectorJess QuizzaganОценок пока нет

- 19-2 Clericis LaicosДокумент3 страницы19-2 Clericis LaicosC C Bờm BờmОценок пока нет

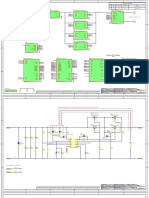

- Scheme Bidirectional DC-DC ConverterДокумент16 страницScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaОценок пока нет

- A Study On Effective Training Programmes in Auto Mobile IndustryДокумент7 страницA Study On Effective Training Programmes in Auto Mobile IndustrySAURABH SINGHОценок пока нет