Академический Документы

Профессиональный Документы

Культура Документы

EFICAAKERJABAGUS

Загружено:

Cim sastroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EFICAAKERJABAGUS

Загружено:

Cim sastroАвторское право:

Доступные форматы

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

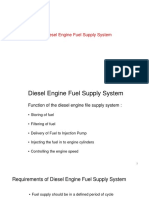

OBJECTIVES

After studying Chapter 17, the reader should be

able to:

1. Prepare for ASE Engine Performance (A8) certification test

content area “C” (Fuel, Air Induction, and Exhaust Systems

Diagnosis and Repair).

2. Describe how a port fuel-injection system works.

3. Discuss the purpose and function of the fuel-pressure

regulator.

4. List the types of fuel injection.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

ELECTRONIC FUEL-

INJECTION OPERATION

Most electronic fuel-injection systems

share the following:

Electric fuel pump (usually located inside the

fuel tank)

Fuel-pump relay (usually controlled by the

computer)

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Fuel-pressure regulator (mechanically

operated spring loaded rubber diaphragm

maintains proper fuel pressure)

Fuel-injector nozzle or nozzles

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Most electronic fuel injection systems use

the computer to control these aspects of

their operation:

Pulsing the fuel injectors on and off. The

longer the injectors are held open, the greater

the amount of fuel injected into the cylinder.

Operating the fuel-pump relay circuit. The

computer uses signals from the ignition switch

and RPM signals from the ignition module or

system to energize the fuel-pump relay circuit.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

There are two types of electronic fuel-

injection systems:

Throttle-body-injection (TBI) type. A TBI

system delivers fuel from a nozzle(s) into the

air above the throttle plate.

Port fuel-injection-type. A port fuel-injection

design uses a nozzle for each cylinder and

the fuel is squirted into the intake manifold

about 2 to 3 inches (70 to 100 mm) from the

intake valve.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Fuel-injection computer systems require a

method for measuring the amount of air

the engine is breathing in, in order to

match the correct fuel delivery. There are

two basic methods used:

Speed density

Mass air flow

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

The speed density method does not

require an air quantity sensor, but rather

calculates the amount of fuel required by

the engine. The computer uses

information from sensors such as the MAP

and TP to calculate the needed amount of

fuel.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

MAP sensor. The value of the intake (inlet)

manifold pressure (vacuum) is a direct

indication of engine load.

TP sensor. The position of the throttle plate

and its rate of change are used as part of the

equation to calculate the proper amount of

fuel to inject.

Temperature sensors. Both engine coolant

temperature (ECT) and intake air temperature

(IAT) are used to calculate the density of the

air and the need of the engine for fuel.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

The formula used to determine the injector

pulse width (PW) in milliseconds (ms) is:

Injector pulse width = MAP/BARO x

RPM/MAXIMUM RPM

The formula is modified by values from other

sensors, including:

• Throttle position (TP)

• Engine coolant temperature (ECT)

• Intake air temperature (IAT)

• Oxygen sensor voltage (O2S)

• Adaptive memory (Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-1 Typical port fuel-injection system, indicating the location of various components. Notice that the fuel-

pressure regulator is located on the fuel return side of the system. The computer does not control fuel pressure, but does

control the operation of the electric fuel pump (on most systems) and the pulsing on and off of the injectors.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-2 A dual-nozzle TBI unit on a Chevrolet 4.3-L V-6 engine.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-3 A typical port fuel-injection system squirts fuel into the low pressure (vacuum) of the intake manifold,

about 3 in. (70 to 100 mm) from the intake valve.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

MASS AIR FLOW FUEL-

INJECTION SYSTEMS

The formula used by fuel-injection systems

that use a mass air flow (MAF) sensor to

calculate the injection base pulse width is:

Injector pulse width = air flow/RPM

The formula is modified by other sensor

values such as:

Throttle position

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Engine coolant temperature

Barometric pressure

Adaptive memory

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

THROTTLE-BODY INJECTION

The computer controls injector pulses in

one of two ways:

Synchronized

Nonsynchronized

The strength of the spring inside the

regulator determines at what pressure the

valve is unseated, sending the fuel back to

the tank and lowering the pressure.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

The PCM commands a variety of pulse

widths to supply the amount of fuel that an

engine needs at any specific moment.

A long pulse width delivers more fuel.

A short pulse width delivers less fuel.

A stuck shuttle valve, a part of many

Chrysler TBI systems used to close off the

fuel return to the tank.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-4 The tension of the spring in the fuel-pressure regulator determines the operating pressure on a throttle-

body fuel-injection unit.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-5 (a) Removing the fuel-pressure regulator from a Chrysler brand TBI unit. (b) A shuttle valve (if equipped)

is located in this fuel return passage.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-5 (continued) (a) Removing the fuel-pressure regulator from a Chrysler brand TBI unit. (b) A shuttle valve

(if equipped) is located in this fuel return passage.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

PORT FUEL INJECTION

The advantages of port fuel injection

design also are related to characteristics

of intake manifolds:

Fuel distribution is equal to all cylinders

because each cylinder has its own injector.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

The fuel is injected almost directly into the

combustion chamber, so there is no chance

for it to condense on the walls of a cold intake

manifold.

Because the manifold does not have to carry

fuel to properly position a TBI unit, it can be

shaped and sized to tune the intake air flow to

achieve specific engine performance

characteristics.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

An EFI injector is simply a specialized

solenoid.

Electronic fuel-injection systems use a

solenoid-operated injector to spray

atomized fuel in timed pulses into the

manifold or near the intake valve.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Domestic systems use one of three ways

to trigger the injectors:

Grouped double-fire

Simultaneous double-fire

Sequential

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Grouped Double-Fire

This system divides the injectors into two

equalized groups. The groups fire alternately;

each group fires once each crankshaft

revolution, or twice per 4-stroke cycle. The

fuel injected remains near the intake valve

and enters the engine when the valve opens.

This method of pulsing injectors in groups is

sometimes called gang fired.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Simultaneous Double-Fire

This design fires all of the injectors at the

same time once every engine revolution: two

pulses per 4-stroke cycle. Many port fuel-

injection systems on 4-cylinder engines use

this pattern of injector firing.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Sequential

In this system, the injectors are timed and

pulsed individually, much like the spark plugs

are sequentially operated in firing order of the

engine. This system is often called sequential

fuel injection or SFI.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

The major advantage of using port

injection instead of the simpler throttle-

body injection is that the intake manifolds

on port fuel injected engines only contain

air, not a mixture of air and fuel.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

This allows the engine design engineer the

opportunity to design long, "tuned" intake-

manifold runners that help the engine

produce increased torque at low engine

speeds.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-6 The injectors receive fuel and are supported by the fuel rail.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-7 Cross-section of a typical port fuel-injection nozzle assembly. These injectors are serviced as an

assembly only; no part replacement or service is possible except for replacement of external O-ring seals.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-8 Port fuel injectors spray atomized fuel into the intake manifold about 3 inches (75 mm) from the intake

valve.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-9 A port fuel-injected engine that is equipped with long-tuned intake manifold runners.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

GASOLINE DIRECT

INJECTION

Gasoline direct injection (GDI) systems

inject fuel directly into the combustion

chamber just before the spark. The fuel,

under very high pressure, is injected in a

fine mist into the closely packed air

molecules.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Gasoline direct injection systems, like

diesel systems, require very high fuel

pressures to overcome the combustion

chamber pressures during injection.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-10 A gasoline direct-injection system.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

FUEL-PRESSURE

REGULATOR

The pressure regulator and fuel pump

work together to maintain the required

pressure drop at the injector tips. The

fuel-pressure regulator typically consists of

a spring-loaded, diaphragm-operated

valve in a metal housing.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

The pressure regulator used in a port fuel-

injection system has an intake manifold

vacuum line connection on the regulator

vacuum chamber. This allows fuel

pressure to be modulated by a

combination of spring pressure and

manifold vacuum acting on the diaphragm.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Port fuel-injection systems generally

operate with pressures at the injector of

about 30 to 55 psi (207 to 379 kPa), while

TBI systems work with injector pressures

of about 10 to 20 psi (69 to 138 kPa).

Some fuel-pressure regulators contain a

10-micron filter. If this filter becomes

clogged, a lack of fuel flow would result.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-11 A typical port fuel-injected system showing a vacuum-controlled fuel-pressure regulator.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-12 A typical fuel-pressure regulator that has a spring that exerts 46 pounds of force against the fuel. If 20

inches of vacuum are applied above the spring, the vacuum reduces the force exerted by the spring on the fuel, allowing

the fuel to return to the tank at a lower pressure.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-13 Note the filter screen in this cutaway fuel pressure regulator. A lack of fuel flow could be due to a

restricted fuel-pressure regulator.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

VACUUM-BIASED FUEL-

PRESSURE REGULATOR

The primary reason why many port fuel-

injected systems use a vacuum-controlled

fuel-pressure regulator is to ensure that

there is a constant pressure drop across

the injectors.

Engine Operating Intake Manifold Fuel Pressure

Condition Vacuum

Idle or cruise High Lower

Heavy load Low Higher

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Intake Manifold Fuel Difference

Pressure

Idle: 20 in. Hg (-10 psi) 35 psi 45 psi

WOT: 0 in. Hg (0 psi) 45 psi 45 psi

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

ELECTRONIC RETURNLESS

FUEL SYSTEM

Fuel pressure at the rail is sensed by a

pressure transducer, which sends a low-

level signal to a controller. The controller

contains logic to calculate a signal to the

pump power driver.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

The power driver contains a high-current

transistor that controls the pump speed

using pulse width modulation (PWM). This

system is called the electronic returnless

fuel system (ERFS).

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-14 The fuel-pressure sensor and fuel-temperature sensor are often constructed together in one assembly

to help give the PCM the needed data to control the fuel-pump speed.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

MECHANICAL RETURNLESS

FUEL SYSTEM

The first production returnless systems

employed the mechanical returnless fuel

system (MRFS) approach. This system

has a bypass regulator to control rail

pressure that is located in close proximity

to the fuel tank. Fuel is sent by the in-tank

pump to a chassis-mounted inline filter

with excess fuel returning to the tank

through a short return line. (Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-15 A mechanical returnless fuel system. The bypass regulator in the fuel tank controls fuel-line pressure.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

DEMAND DELIVERY SYSTEM

(DDS)

A different form of demand pressure

regulator has been applied to the fuel rail.

It mounts at the head or port entry and

regulates the pressure downstream at the

injectors by admitting the precise quantity

of fuel into the rail as consumed by the

engine.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Having demand regulation at the rail

improves pressure response to flow

transients and provides rail pulsation

damping. A fuel pump and a low-cost,

high-performance bypass regulator are

used within the appropriate fuel sender.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

A port fuel-injection system uses a pipe or

tubes to deliver fuel from the fuel line to

the intended fuel injectors. This pipe or

tube is called the fuel rail. Some vehicle

manufacturers construct the fuel rail in a

rectangular cross-section.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

See Figure 17-17. The sides of the fuel

rail are able to move in and out slightly,

thereby acting as a fuel pulsator evening

out the pressure pulses created by the

opening and closing of the injectors to

reduce underhood noise. A round cross-

section fuel rail is not able to deform and,

as a result, some manufacturers have had

to use a separate dampener.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-17 A rectangular-shaped fuel rail is used to help dampen fuel system pulsations and noise caused by the

injector opening and closing.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-16 A demand delivery system uses an in-tank regulator.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

FUEL INJECTORS

EFI systems use solenoid-operated

injectors.

The armature is pulled off of its seat

against spring force, allowing fuel to flow

through the inlet filter screen to the spray

nozzle, where it is sprayed in a pattern

that varies with application.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-18 A multiport fuel injector. Notice that the fuel flows straight through and does not come in contact with

the coil windings.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-19 Each of the eight injectors shown are producing a correct spray pattern for the applications. While all

throttle-body injectors spray a conical pattern, most port fuel-injectors do not.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

CENTRAL PORT INJECTION

A cross between port fuel injection and

throttle-body injection, CPI was introduced

in the early 1990s by General Motors. The

CPI assembly consists of a single fuel

injector, a pressure regulator, and six

poppet nozzle assemblies with nozzle

tubes.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

When the injector is energized, its

armature lifts off of the six fuel tube seats

and pressurized fuel flows through the

nozzle tubes to each poppet nozzle.

Newer versions use six individual

solenoids to fire one for each cylinder.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-20 A central port fuel-injection system.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-21 A view of a sequential central fuel-injection unit showing the electrical connections for the six individual

solenoids.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

FUEL-INJECTION MODES OF

OPERATION

These modes of operation include:

Starting (cranking) Acceleration enrichment

Clear flood Deceleration enleanment

Idle (run) Fuel shut-off

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Starting Mode

When the ignition is turned to the start (on)

position, the engine cranks and the PCM

energizes the fuel-pump relay.

The colder the engine is, the greater the pulse

width. Cranking mode air-fuel ratio varies

from about 1.5:1 at -40 degrees F (-40

degrees C) to 14.7:1 at 200 degrees F (93

degrees C).

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Clear Flood Mode

If the engine becomes flooded with too much

fuel, the driver can depress the accelerator

pedal to greater than 80% to enter the clear

flood mode.

Open-Loop Mode

Open-loop operation occurs during warm-up

before the oxygen sensor can supply accurate

information to the PCM.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Closed-Loop Mode

Closed-loop operation is used to modify the

base injector pulse width as determined by

feedback from the oxygen sensor to achieve

proper fuel control.

Acceleration Enrichment Mode

During acceleration, the throttle-position (TP)

voltage increases, indicating that a richer air-

fuel mixture is required.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Deceleration Enleanment Mode

When the engine decelerates, a leaner air-

fuel mixture is required to help reduce

emissions and to prevent deceleration

backfire.

Fuel Shut-Off Mode

Besides shutting off fuel entirely during

periods of rapid deceleration, PCM also shuts

off the injector when the ignition is turned off

to prevent the engine from continuing to run.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

IDLE CONTROL

Port fuel-injection systems generally use

an auxiliary air bypass.

Most PFI systems use an idle air control

(IAC) motor to regulate idle bypass air.

The idle air control valve is also called an

electronic air control (EAC) valve.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

When the engine is warm and restarted,

the idle speed should momentarily

increase, then decrease to normal idle

speed. This increase and then decrease

in engine speed is often called an engine

flare. If the engine speed does not flare,

then the IAC may not be working (it may

be stuck in one position).

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-22 The small arrows indicate the air bypassing the throttle plate in the closed throttle position. This air is

called minimum air. The air flowing through the IAC is the air flow that determines the idle speed.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

STEPPER MOTOR

OPERATION

A digital output is used to control stepper

motors.

A common use for stepper motors is as an

idle air control (IAC) valve, which controls

engine idle speeds and prevents stalls due

to changes in engine load.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

The computer pulses the windings and

changes the polarity of the windings to

cause the armature of the stepper motor to

rotate 90 degrees at a time. Each 90-

degree pulse is recorded by the computer

as a “count” or “step;” therefore, the name

given to this type of motor.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

In some applications, an externally

mounted permanent magnet motor called

the idle speed control (ISC) motor

mechanically advances the throttle linkage

to advance the throttle opening.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-23 Most stepper motors use four wires, which are pulsed by the computer to rotate the armature in steps.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

INJECTOR SPRAY PATTERNS

Injector Spray Patterns

All injectors produce the same shape of

spray pattern.

Each engine design requires the specified

injector spray pattern. Do not use a

substitute injector unless specified by the

vehicle manufacturer or injection supplier.

(Continued)

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Figure 17-24 Not all fuel injectors create a hollow cone discharge because the pattern depends on the design.

Copyright ©2007 by Pearson Education, Inc.

Automotive Engine Performance, Second Edition

Upper Saddle River, New Jersey 07458

James D. Halderman

All rights reserved.

Вам также может понравиться

- Truck Selection J688 SAEДокумент34 страницыTruck Selection J688 SAEGM Maquinaria100% (1)

- Overall Requirements 1. Scope: Applicable Gazette Notification Under CMVRДокумент23 страницыOverall Requirements 1. Scope: Applicable Gazette Notification Under CMVRsingh_ranveerОценок пока нет

- 2013 Cummins ISX New Valve Camshaft Roller and Rocker LeversTSB - 100551Документ1 страница2013 Cummins ISX New Valve Camshaft Roller and Rocker LeversTSB - 100551juanОценок пока нет

- Instruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionДокумент42 страницыInstruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionVladimirОценок пока нет

- Sanden LTD - Automobile Air-Conditioning - Mechanical Engg. (ME) Summer Training Project ReportДокумент29 страницSanden LTD - Automobile Air-Conditioning - Mechanical Engg. (ME) Summer Training Project ReportRITESH ROHILLAОценок пока нет

- Pump Goveror Class OneДокумент38 страницPump Goveror Class OneEolo RojasОценок пока нет

- Surface Vehicle Recommended PracticeДокумент4 страницыSurface Vehicle Recommended Practicewilian_coelho3309Оценок пока нет

- Diesel Engine Vs Petrol EngineДокумент5 страницDiesel Engine Vs Petrol EngineAshutosh SinghОценок пока нет

- Fuel RecommendationsДокумент7 страницFuel RecommendationsLaiqОценок пока нет

- EPA GuideДокумент65 страницEPA GuideArr KaraszОценок пока нет

- Exhaust Gas After TreatmentДокумент32 страницыExhaust Gas After TreatmentMajid KhanОценок пока нет

- QSK38 MCRSДокумент2 страницыQSK38 MCRSsomplaklgОценок пока нет

- FR92154 Busu Isb4.5 PDFДокумент4 страницыFR92154 Busu Isb4.5 PDFJuan Diego SarangoОценок пока нет

- Aeb 02138Документ33 страницыAeb 02138Bosko KalicaninОценок пока нет

- "Camless Engine": A Technical Seminar Report OnДокумент29 страниц"Camless Engine": A Technical Seminar Report OnVinayKumarОценок пока нет

- KAYO EFI Instructions: 1 Operating PrincipleДокумент16 страницKAYO EFI Instructions: 1 Operating Principlekenny nieuwenwegОценок пока нет

- CI Engine CombustionДокумент14 страницCI Engine CombustionRahul MeenaОценок пока нет

- Delphi Heavy Duty Emissions Brochure 2011 2012Документ100 страницDelphi Heavy Duty Emissions Brochure 2011 2012Younwoo NamОценок пока нет

- UNIT1L3S - Engine Performance TerminologyДокумент10 страницUNIT1L3S - Engine Performance TerminologyEbied Yousif AlyОценок пока нет

- Electric: VehicleДокумент18 страницElectric: VehicleSarthak JoshiОценок пока нет

- Mechanic Diesel: Syllabus of Semester SystemДокумент28 страницMechanic Diesel: Syllabus of Semester Systempradeep100% (1)

- Wiring DiagramДокумент93 страницыWiring DiagramAggrey-Anthony DuncanОценок пока нет

- 64L Fuel Supply SystemДокумент5 страниц64L Fuel Supply SystemMurray ServiceОценок пока нет

- Fuel Flow MetersДокумент7 страницFuel Flow MetersAMIYA SHANKAR PANDAОценок пока нет

- Introduction To Automobile EngineeringДокумент8 страницIntroduction To Automobile EngineeringSaurabh AwacharОценок пока нет

- Aeb09202 PDFДокумент16 страницAeb09202 PDFCesar G.Оценок пока нет

- Engine Design ClassificationДокумент76 страницEngine Design ClassificationLuis NunesОценок пока нет

- Constant-Pressure Turbocharger Matching by Michael M. W. de SilvaДокумент32 страницыConstant-Pressure Turbocharger Matching by Michael M. W. de SilvaMichael M. W. de Silva100% (1)

- Lecture 2 - Internal CombussionДокумент67 страницLecture 2 - Internal Combussionchoongwenkang100% (2)

- Air Fuel Ratio ControlДокумент6 страницAir Fuel Ratio Controlmiguel oswaldo gonzalez benitezОценок пока нет

- Engine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyДокумент61 страницаEngine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyZain Ul AbideenОценок пока нет

- Electronic Diesel Control (Edc)Документ9 страницElectronic Diesel Control (Edc)SUNIL TОценок пока нет

- Engine TestДокумент20 страницEngine TestTUMELOОценок пока нет

- Effect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsДокумент9 страницEffect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsNgocTinhPhamОценок пока нет

- Cummins Guidanz Mobile User TrainingДокумент56 страницCummins Guidanz Mobile User TrainingP.p. Arul IlancheeranОценок пока нет

- 01 Fuel Filters FW Seps v3 - 0 PDFДокумент118 страниц01 Fuel Filters FW Seps v3 - 0 PDFJOAOОценок пока нет

- Multi Point Fuel InjectionДокумент15 страницMulti Point Fuel Injectionಶಿವರಾಜ್ ಎನ್Оценок пока нет

- Automotive ACДокумент19 страницAutomotive ACJijish RAОценок пока нет

- Engine Performance With Variable Valve TimingДокумент4 страницыEngine Performance With Variable Valve TimingWilliam KibbeОценок пока нет

- Powerpoint Fuel Injection SystemsДокумент17 страницPowerpoint Fuel Injection Systemsanitadas19Оценок пока нет

- Diesel Engine Development TENERGYДокумент86 страницDiesel Engine Development TENERGYddi11100% (1)

- Viva Questions - Internal Combustion Engine - Liquefied Petroleum GasДокумент4 страницыViva Questions - Internal Combustion Engine - Liquefied Petroleum Gasmailsk123Оценок пока нет

- 08 Fuel Supply System 2Документ122 страницы08 Fuel Supply System 2ramalingeswarao annamdevulaОценок пока нет

- QSX15 System DiagramДокумент12 страницQSX15 System Diagramnavid cheungОценок пока нет

- Basic Tools 1Документ48 страницBasic Tools 1palaniОценок пока нет

- Gasoline Direct InjectionДокумент21 страницаGasoline Direct InjectionhoangОценок пока нет

- Fuel SystemДокумент7 страницFuel SystemখালিদহাসানОценок пока нет

- Edexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginesДокумент9 страницEdexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginescataiceОценок пока нет

- Simulation of A Heavy-Duty Diesel Engine With ElectricalДокумент13 страницSimulation of A Heavy-Duty Diesel Engine With ElectricalBertalan Gyuszi Kristóf100% (1)

- Understanding The Mack MP8 - Engine Builder MagazineДокумент5 страницUnderstanding The Mack MP8 - Engine Builder MagazineEslam MansourОценок пока нет

- Hydro Pneumatic Braking SytemДокумент11 страницHydro Pneumatic Braking Sytempramo_dass100% (1)

- CRDI Seminar ReportДокумент19 страницCRDI Seminar ReportBharadwaj PradhanОценок пока нет

- 1-MS-Module 1-Diesel Engine FundamentalsДокумент43 страницы1-MS-Module 1-Diesel Engine FundamentalsSamehОценок пока нет

- Theary of Operation - STC Fuel SystemДокумент5 страницTheary of Operation - STC Fuel SystemMohamed MohamedОценок пока нет

- I C Engine TestingДокумент87 страницI C Engine TestingLove Reloaded100% (1)

- High-Pressure Common-Rail Fuel InjectionДокумент6 страницHigh-Pressure Common-Rail Fuel InjectionAndi Anzar0% (1)

- HEUI Hydraulic Electronically Unit InjectorДокумент43 страницыHEUI Hydraulic Electronically Unit InjectorMahmoud Elsayed100% (1)

- Engine BreathingДокумент18 страницEngine BreathingNimalanОценок пока нет

- Turbocharger - SuperchargerДокумент32 страницыTurbocharger - SuperchargerTegar LanangОценок пока нет

- Containers On A Train: Lecture ObjectivesДокумент3 страницыContainers On A Train: Lecture ObjectivesKarlos EstévezОценок пока нет

- UML Class Diagram NotationsДокумент9 страницUML Class Diagram Notationsshiva0909Оценок пока нет

- Java Lab FileДокумент38 страницJava Lab Filehimanshu agarwalОценок пока нет

- Online Shopping SystemДокумент31 страницаOnline Shopping SystemDapborlang Marwein86% (7)

- Network Security Revised-EricДокумент3 страницыNetwork Security Revised-EricJojo CansinoОценок пока нет

- Cloud Computing ServicesДокумент25 страницCloud Computing ServicesSakshi KakadeОценок пока нет

- Module 2 - Technologies Behind Iot: 2.1 Challenges and Issues, Security Control UnitsДокумент21 страницаModule 2 - Technologies Behind Iot: 2.1 Challenges and Issues, Security Control UnitsAdarsh AjОценок пока нет

- E190 Type Training APU Reviwe Questions PDFДокумент5 страницE190 Type Training APU Reviwe Questions PDFcollinsОценок пока нет

- Yourstore Major Project (Sampada Verma)Документ88 страницYourstore Major Project (Sampada Verma)Ravi SinghОценок пока нет

- Kunal Samant: Cum LaudeДокумент1 страницаKunal Samant: Cum LaudegsndharavkatyalОценок пока нет

- Top Business Analyst Interview QuestionsДокумент7 страницTop Business Analyst Interview QuestionsAkshay MalhotraОценок пока нет

- AbcdДокумент7 страницAbcdRichard Neil CudiasОценок пока нет

- Celso Alos - Senior DeveloperДокумент8 страницCelso Alos - Senior DeveloperChristianettm86Оценок пока нет

- Question Bank Cloud SecurityДокумент4 страницыQuestion Bank Cloud SecurityKurulus Osman English subtitlesОценок пока нет

- Maintenance Engineering (CH: 2,0) : Instructors: Dr. M. Zeeshan Zahir Engr. Adnan RasheedДокумент13 страницMaintenance Engineering (CH: 2,0) : Instructors: Dr. M. Zeeshan Zahir Engr. Adnan RasheedAltamash MunirОценок пока нет

- Betting Documentation 1 3Документ70 страницBetting Documentation 1 3robel ragoОценок пока нет

- Optimal Control System Company Profile PDFДокумент9 страницOptimal Control System Company Profile PDFkarna patelОценок пока нет

- Delphi Language Guide 10.3Документ391 страницаDelphi Language Guide 10.3josentavarez31Оценок пока нет

- Engine Mechanical SpecificationsДокумент17 страницEngine Mechanical SpecificationsAzip ShabariОценок пока нет

- Test Plan DocumentДокумент7 страницTest Plan DocumentNyambura Kinyua100% (1)

- World Class Automation Training: PLC Scada Dcs VFD Hmi Control PanelsДокумент20 страницWorld Class Automation Training: PLC Scada Dcs VFD Hmi Control PanelsPronadeep BoraОценок пока нет

- Check Engine CodesДокумент5 страницCheck Engine CodesazaharОценок пока нет

- SCADA Systems: Zhu Kun 2012-4-17Документ28 страницSCADA Systems: Zhu Kun 2012-4-17gabriel galvez figueroaОценок пока нет

- Sce 020 100 Process Description Sorting Station Intro r1709 enДокумент10 страницSce 020 100 Process Description Sorting Station Intro r1709 enJoachimОценок пока нет

- To The Development of Web Applications (Core) MVC: Razvan Alexandru MezeiДокумент321 страницаTo The Development of Web Applications (Core) MVC: Razvan Alexandru Mezeijerry.voldoОценок пока нет

- PBN FOR ATC SimplifiedДокумент96 страницPBN FOR ATC SimplifiedBaskara SenoajiОценок пока нет

- How To Write SecureДокумент6 страницHow To Write Securemijat99180Оценок пока нет

- OOSE Chapter 3 Req Elici Present ConciseДокумент95 страницOOSE Chapter 3 Req Elici Present ConciseLemi TuroОценок пока нет

- Copia de Trabajo Autónomo Introducción Python - Ipynb - ColaboratoryДокумент3 страницыCopia de Trabajo Autónomo Introducción Python - Ipynb - Colaboratorygaluisby9Оценок пока нет

- Multiple AdmisiónДокумент2 страницыMultiple AdmisiónRamón ManglesОценок пока нет

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestОт EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestРейтинг: 4 из 5 звезд4/5 (28)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]От EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Рейтинг: 5 из 5 звезд5/5 (2)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVОт EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVРейтинг: 5 из 5 звезд5/5 (2)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyОт EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyРейтинг: 5 из 5 звезд5/5 (1)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceОт EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceОценок пока нет

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)От EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Оценок пока нет

- The Official Highway Code: DVSA Safe Driving for Life SeriesОт EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesРейтинг: 3.5 из 5 звезд3.5/5 (25)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WОт EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WРейтинг: 4.5 из 5 звезд4.5/5 (6)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideОт EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Automotive Master Technician: Advanced Light Vehicle TechnologyОт EverandAutomotive Master Technician: Advanced Light Vehicle TechnologyРейтинг: 5 из 5 звезд5/5 (1)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsОт EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsРейтинг: 5 из 5 звезд5/5 (4)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)