Академический Документы

Профессиональный Документы

Культура Документы

Bcas Compact

Загружено:

Sehana Rajapaksha0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров19 страницОригинальное название

bcas-compact.pptx

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров19 страницBcas Compact

Загружено:

Sehana RajapakshaАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 19

BY

Eng SAM Hilmy

Soil Compaction

-Soil compaction is defined as the method of

mechanically increasing the density of soil.

- In construction, this is a significant part of the

building process. If performed improperly,

settlement of the soil could occur and result in

unnecessary maintenance costs or structure

failure.

-Almost all types of building sites and

construction projects utilize mechanical

compaction techniques.

Following are important elements in soil compaction:

- Soil type

- Soil moisture content

- Compaction effort required

• These different types of effort are found in the two principle types of

compaction force: static and vibratory.

Static force

– Static force is simply the deadweight of the machine, applying downward

force on the soil surface, compressing the soil particles.

– The only way to change the effective compaction force is by adding or

subtracting the weight of the machine. Static compaction is confined to

upper soil layers and is limited to any appreciable depth. Kneading and

pressure are two examples of static compaction.

Vibratory force

- Vibratory force uses a mechanism, usually engine-driven, to create a

downward force in addition to the machine's static weight.

-The vibrating mechanism is usually a rotating eccentric weight or

piston/spring combination (in rammers). The compactors deliver a rapid

sequence of blows (impacts) to the surface, thereby affecting the top layers

as well as deeper layers.

-Vibration moves through the material, setting particles in motion and

moving them closer together for the highest density possible. Based on the

materials being compacted, a certain amount of force must be used to

overcome the cohesive nature of particular particles.

Static mechanism

Static Roller

Vibrating Roller – Double Drum

Vibratory mechanism

Vibrating Roller – Single Drum

Pneumatic Roller

• Initial compaction of the surfaces is done using a pneumatic-

tyred roller, where instead the single- or double-drum is

replaced by two rows (front and back) of pneumatically filled

tyres. The flexibility of the tyres, with a certain amount of

vertical movement of the wheels, enables the roller to

operate effectively on uneven ground. The finish is done using

metal-drum rollers to ensure a smooth, even result.

Pneumatic Roller

Sheep’s Foot Rollers

• Rollers are also used in land fill compaction. Such compactors

typically have knobbed ('sheep’s-foot') wheels and do not

attempt to achieve a smooth surface. The knobs aid in

compression due to a smaller surface area being in contact

with the ground

Standard proctor test

Moisture-Density (Compaction) Relationship

(Standard Proctor)

• When additives such as Portland cement, lime, or fly

ash are used to determine the maximum density of

mixed compacted soils in the laboratory, care should

be taken to duplicate the expected delay period

between mixing and compaction in the field.

• It should be kept in mind that these chemical additives

start reacting as soon as they are added to the wet soil.

• They cause substantial changes in soil properties,

including densities achievable by compaction.

• If in the field the period between mixing and

compaction is expected to be three hours, for example,

then in the laboratory the compaction of the soil

should also be delayed three hours after mixing the

stabilizing additives.

Optimum moisture content

Poor Compaction results

Soil Compaction test ( In situ)

Thank you

Вам также может понравиться

- Operational Devices For Compaction Optimization and Quality ControlДокумент10 страницOperational Devices For Compaction Optimization and Quality ControlcannonlicaОценок пока нет

- How to Build a Global Model Earthship Operation I: Tire WorkОт EverandHow to Build a Global Model Earthship Operation I: Tire WorkОценок пока нет

- SENR33120001 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)Документ2 страницыSENR33120001 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)CEVegaOОценок пока нет

- Typical Exam Questions With Answers 2Документ17 страницTypical Exam Questions With Answers 2Khadem Nuristani100% (1)

- Caterpillar Compaction ManualДокумент25 страницCaterpillar Compaction ManualSiegfred RaccaОценок пока нет

- Djj10022 Fitting ReportДокумент7 страницDjj10022 Fitting ReportTamil passang songОценок пока нет

- Compaction Equipments FinalДокумент37 страницCompaction Equipments FinalVageesha Shantha Veerabhadra Swamy100% (1)

- New PPT Presentation-1Документ25 страницNew PPT Presentation-1ICEMAN MAHOHOMAОценок пока нет

- The Amendments To Increase Soil DensityДокумент27 страницThe Amendments To Increase Soil Densityخلدون مهند الحديثيОценок пока нет

- Ground Improvement Techniques ME 3rd Sem PPT FileДокумент57 страницGround Improvement Techniques ME 3rd Sem PPT FileArham Sheikh100% (6)

- 5-Soil Stabilization and CompactionДокумент7 страниц5-Soil Stabilization and CompactionSafaaОценок пока нет

- Compacting and FinishingДокумент48 страницCompacting and FinishingLhaie Balasbas100% (1)

- Methods of Soil CompactionДокумент4 страницыMethods of Soil CompactionLyka Isabel TanОценок пока нет

- Various Types of Compaction EquipmentДокумент14 страницVarious Types of Compaction EquipmentJohn Mareos QuidezОценок пока нет

- CH 5Документ45 страницCH 5debas dessieОценок пока нет

- Describe The Purpose of Soil Stabilization and Discuss at Least Three Methods of Achieving Soil StabilizationДокумент6 страницDescribe The Purpose of Soil Stabilization and Discuss at Least Three Methods of Achieving Soil StabilizationhaileyyyОценок пока нет

- COMPACTIONДокумент4 страницыCOMPACTIONSarah MarieОценок пока нет

- Field EquipmentsДокумент3 страницыField EquipmentsRobert Malusher MwandoeОценок пока нет

- Civl3501 - Soil Mechanics: CompactionДокумент66 страницCivl3501 - Soil Mechanics: CompactionBazimya DixonОценок пока нет

- Compaction & Types of CompactorsДокумент28 страницCompaction & Types of CompactorsYALAMANCHILI NIKHILОценок пока нет

- Compacion and Diff Types of Comp Action EquipmentДокумент16 страницCompacion and Diff Types of Comp Action EquipmentAtish KumarОценок пока нет

- HuhuhuhuДокумент3 страницыHuhuhuhuCedricJohndelLeolaОценок пока нет

- CIVL2810 - Trigger Words Week 4 - 6Документ4 страницыCIVL2810 - Trigger Words Week 4 - 6Khaled AttarОценок пока нет

- Soil Compaction - UKM - Joint LectureДокумент23 страницыSoil Compaction - UKM - Joint LectureINDRAN A/L SELVAMОценок пока нет

- CIVL 392 - Chapter 5 - Compacting and GradingДокумент59 страницCIVL 392 - Chapter 5 - Compacting and Gradingweston chegeОценок пока нет

- Part 1 - Soil CompactionДокумент38 страницPart 1 - Soil CompactionAlex Ferreira80% (5)

- CompactionДокумент24 страницыCompactionzubair-scribdОценок пока нет

- Compacting Equipments CemДокумент20 страницCompacting Equipments CemAnmol ChaniОценок пока нет

- DPWH Standard Specification on:COMPACTION AND STABILIZATIONДокумент7 страницDPWH Standard Specification on:COMPACTION AND STABILIZATIONAldever BretanaОценок пока нет

- ch-10 Ground Improvement TechniqueДокумент14 страницch-10 Ground Improvement TechniqueRJ JordanОценок пока нет

- Compaction and FinishingДокумент3 страницыCompaction and FinishingneilgumataОценок пока нет

- CompactionДокумент10 страницCompactionmohsen.911.mkОценок пока нет

- Assigned To: Dr. Sawsan By: Mohammed Thamer Lafta MS.C Construction Management StudentДокумент25 страницAssigned To: Dr. Sawsan By: Mohammed Thamer Lafta MS.C Construction Management StudentMohammed AlmusawiОценок пока нет

- Soil Mechanics-II: Soil Stabilization and ImprovementДокумент16 страницSoil Mechanics-II: Soil Stabilization and ImprovementShivpreet SharmaОценок пока нет

- Cet 423 - Mod 2Документ100 страницCet 423 - Mod 2Shreyas ManuОценок пока нет

- Beng-Soil Mechanics IB-Slides 89-117Документ31 страницаBeng-Soil Mechanics IB-Slides 89-117Tom WhanОценок пока нет

- Soil Improvement MethodsДокумент5 страницSoil Improvement Methodstouqeer Abro100% (3)

- Soil Compaction: Expert TipsДокумент3 страницыSoil Compaction: Expert TipsPratik BadaveОценок пока нет

- Machine MouldingДокумент3 страницыMachine MouldingDr.S.Ravi CITОценок пока нет

- Plant and EquipmentДокумент6 страницPlant and EquipmentpiusОценок пока нет

- V.bbachilor of Main ProjetДокумент65 страницV.bbachilor of Main Projetsaladin nasirОценок пока нет

- Unh T Center Technical Note: Achieving and Measuring Proper Road CompactionДокумент4 страницыUnh T Center Technical Note: Achieving and Measuring Proper Road Compactionnorasyikin nordinОценок пока нет

- Foundation Soil ImprovementsДокумент44 страницыFoundation Soil ImprovementsTej Chaulagain100% (1)

- Assignment 6 - Somesh Siddharth - A1988520002Документ9 страницAssignment 6 - Somesh Siddharth - A1988520002Somesh SiddharthОценок пока нет

- CVE 131 - CompactionДокумент109 страницCVE 131 - CompactionZxeroОценок пока нет

- Jet GroutingДокумент4 страницыJet GroutingB RAMUОценок пока нет

- Lecture 11 - Ground Improvement TechniquesДокумент42 страницыLecture 11 - Ground Improvement TechniquesH. DaasОценок пока нет

- Roller Compactor: Vibrating Roller Compaction MethodДокумент3 страницыRoller Compactor: Vibrating Roller Compaction Method04 ChetanChimateОценок пока нет

- Compaction Part2 SM Students Total 15 Feb 16Документ13 страницCompaction Part2 SM Students Total 15 Feb 16VidyaSagarSinghОценок пока нет

- CompactorДокумент6 страницCompactorMohammed AlmusawiОценок пока нет

- Ground Improvement PDFДокумент31 страницаGround Improvement PDFGeorge KinaОценок пока нет

- CompactionДокумент56 страницCompactionkritizasharmaОценок пока нет

- CIVL354 Notes 1 Soil CompactionДокумент20 страницCIVL354 Notes 1 Soil Compactionmusiomi2005Оценок пока нет

- 608 P2 Lec1 CompactionEquipmentДокумент30 страниц608 P2 Lec1 CompactionEquipmentMohammad RaeisiОценок пока нет

- Field CompactionДокумент5 страницField CompactionG-ann DatarioОценок пока нет

- Soil ImprovementДокумент2 страницыSoil ImprovementlamyuwangОценок пока нет

- Soil Stabilisation & Compaction MethodsДокумент44 страницыSoil Stabilisation & Compaction MethodsKURUBA SARAN RAJ SamОценок пока нет

- Construction of AP (New Ver.) .Документ60 страницConstruction of AP (New Ver.) .sfsdgdfngfm esefsgОценок пока нет

- Pavement DesignДокумент92 страницыPavement Designpankaj_mbm100% (1)

- Pacting and Finishing - Construction MethodsДокумент18 страницPacting and Finishing - Construction Methodspaijo klimpritОценок пока нет

- Compaction of Subgrade SoilsДокумент28 страницCompaction of Subgrade SoilsSaeed KhawamОценок пока нет

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsОт EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsОценок пока нет

- Chapter - 7 Part I STDДокумент75 страницChapter - 7 Part I STDBelkacem Achour100% (1)

- PARKER TGK/THK MotorДокумент36 страницPARKER TGK/THK MotorgugiОценок пока нет

- Instruction Manual Shinva 45litre Autoclave240V With PrinterДокумент21 страницаInstruction Manual Shinva 45litre Autoclave240V With PrinterEnfant Perdu100% (3)

- Steam and Oil Flushing Procedure of LDO & HFOДокумент10 страницSteam and Oil Flushing Procedure of LDO & HFOislamfarag2Оценок пока нет

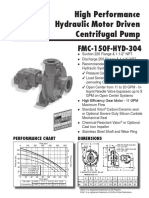

- FMC-150F-HYD-304 - 04-13 Bomba AceДокумент2 страницыFMC-150F-HYD-304 - 04-13 Bomba AceEmerson GomesОценок пока нет

- Installation, Operation, Maintenance, Repair and Troubleshooting Instructions For THE ZSE Fire PumpДокумент119 страницInstallation, Operation, Maintenance, Repair and Troubleshooting Instructions For THE ZSE Fire PumpKashif MasudОценок пока нет

- Armature Controlled DCMotors Fedfrom HWRectifierДокумент20 страницArmature Controlled DCMotors Fedfrom HWRectifierTejas Sharma 2K20EE281Оценок пока нет

- Angular GripperДокумент12 страницAngular GripperAman RajОценок пока нет

- Manufacturing Processes Ch.4 (10 and 11) CastingДокумент143 страницыManufacturing Processes Ch.4 (10 and 11) Castingashoku24007Оценок пока нет

- SchifflerisedДокумент17 страницSchifflerisedJitendraОценок пока нет

- Example 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Документ6 страницExample 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Imran SaikatОценок пока нет

- Block Die Positioning and Pre-ProcessingДокумент18 страницBlock Die Positioning and Pre-ProcessingAndres CaizaОценок пока нет

- Flat Wakaf Mek Zainab P1Документ1 страницаFlat Wakaf Mek Zainab P1Nur NaziraОценок пока нет

- Datasheet (API 610 - 1 Page)Документ8 страницDatasheet (API 610 - 1 Page)Rudin Fahrudin RahmanОценок пока нет

- Bomba A2fo Bosch RexrothДокумент3 страницыBomba A2fo Bosch RexrothHIDRAFLUIDОценок пока нет

- Air Cleaner and Air Intake Parts Models With Turbocharged EngineДокумент2 страницыAir Cleaner and Air Intake Parts Models With Turbocharged EngineNeftali FuentesОценок пока нет

- Workshop 2 DaumДокумент25 страницWorkshop 2 DaumAqsha QОценок пока нет

- Levers in Musculoskeletal SystemДокумент22 страницыLevers in Musculoskeletal SystemGlenn JohnstonОценок пока нет

- Overall DimensionДокумент1 страницаOverall DimensionjanetОценок пока нет

- Pford 2Документ7 страницPford 2primavera1969Оценок пока нет

- 02 110 BPS Foam Pump Skid With Foam Pump and RC ControllerДокумент8 страниц02 110 BPS Foam Pump Skid With Foam Pump and RC Controllerarachman297988Оценок пока нет

- Air Cylinder: Series A03 COMPACT CYLINDERS MAGNETIC Double Acting (Ø12 - 100) MM FeaturesДокумент4 страницыAir Cylinder: Series A03 COMPACT CYLINDERS MAGNETIC Double Acting (Ø12 - 100) MM FeaturesBiswanath LenkaОценок пока нет

- Ductulator: S.P. Loss (Per 100 FT.) (In. of W.C.) Width (In.) X Duct Velocity Height (In.) (FPM)Документ8 страницDuctulator: S.P. Loss (Per 100 FT.) (In. of W.C.) Width (In.) X Duct Velocity Height (In.) (FPM)joabjim8392Оценок пока нет

- 4011b PDFДокумент46 страниц4011b PDFlungu mihaiОценок пока нет

- Ford Expedition 2017 Ecobost 3.5 V6Документ9 страницFord Expedition 2017 Ecobost 3.5 V6Gaston YTОценок пока нет

- BTD SyllabusДокумент3 страницыBTD SyllabusSubuddhi DamodarОценок пока нет

- Retentor Din 3760Документ13 страницRetentor Din 3760Marcelo Godinho BatistaОценок пока нет