Академический Документы

Профессиональный Документы

Культура Документы

Aircraft Material

Загружено:

Reza Fahlevi0 оценок0% нашли этот документ полезным (0 голосов)

44 просмотров29 страницОригинальное название

Aircraft Material.pptx

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

44 просмотров29 страницAircraft Material

Загружено:

Reza FahleviАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 29

STRUCTURAL METAL

• Pengetahuan dan pemahaman terhadap

penggunaan, kekuatan, pembatasan, dan

karakteristik lain dari pada Structural Metals

adalah sangat vital untuk suatu konstruksi yang

tepat dan perawatan berbagai peralatan

khususnya AIRFRAME.

• Pemilihan material yang tepat untuk pekerjaan

perbaikan tertentu sangat membutuhkan

pengenalan terhadap sifat-sifat yang paling

umum daripada berbagai macam metal.

10/20/2010 Aircraft Material 1

Stress

4 basic stress

• Tensional stress

• Compression stress

• Shear stress

• Torsion stress

Two or more stress applied

together

• Bending :

10/20/2010 Aircraft Material 2

HARDNESS

• Ability of a metal to resist abrasion,

penetration, cutting action or permanent

distortion.

• Metal hardness may be increased by cold

working

• Aluminum Alloys increased the hardness by

heat-treatment

10/20/2010 Aircraft Material 3

BRITTLENESS

• Property of the metal which allows little

bending or deformation without shattering

• This is not a very desirable property because

structural metal are often subjected to shocks

loads

• cast iron, cast aluminum, very hard steel are

brittle metals

10/20/2010 Aircraft Material 4

MALLEABLE

• Metal which can be hammered, rolled or

pressed into various shapes without cracking,

breaking, or having some other detrimental

effect.

• Copper is an example of malleable metal

10/20/2010 Aircraft Material 5

DUCTILITY

• Is the property of metal which permits to be permanently

drawn, bent, or twisted into various shapes without

breaking.

• Ductility is similar to malleability.

• Ductile metal are greatly preferred for aircraft use because

of their ease of forming and resistant to failure under shock

loads.

• Aluminum alloys used for cowling, fuselage, and wing skin.

• Aluminum extruded or formed such as ribs, spars, and

bulkheads.

• Chrome molybdenum steel is also easily formed into

desired shape.

10/20/2010 Aircraft Material 6

ELASTICITY

• Property of metal which enables a metal to

return to its original shape when the force

which causes the change of shape is removed.

• Spring steel is part which has elasticity.

10/20/2010 Aircraft Material 7

TOUGHNESS

• Property material which withstand tearing or

shearing and may be stretched or otherwise

deformed without breaking.

• Toughness is desirable property in aircraft

metals

10/20/2010 Aircraft Material 8

DENSITY

• Weight of unit volume of a material

• Density is an important consideration when

choosing a material to be used in the design of

a part in order to maintain the proper weight

and balance of the aircraft.

10/20/2010 Aircraft Material 9

FUSIBILITY

• The ability of a metal to become liquid by the

application of heat.

• Steel fuse around 2600°F and aluminum alloys

at approximately 1100°F

10/20/2010 Aircraft Material 10

CONDUCTIVITY

• Property which enables a metal to carry heat

or electricity.

• In Aircraft, electrical conductivity must also be

considered in conjunction with bonding, to

eliminate radio interference.

10/20/2010 Aircraft Material 11

CONTRACTION AND EXPANSION

• Reactions produced in metal as the result of

heating or cooling.

• Heat applied to a metal will causes it to

expand or become larger

10/20/2010 Aircraft Material 12

Selection Factor

• Strength

• Weight

• Reliability

Airframes must be strong and yet as light in

weight as possible.

There are very definite limits to which increases

in strength can be accompanied by increases

in weight

10/20/2010 Aircraft Material 13

Tension Strength

• Resistance to a force which tend to

pull it apart

• Measured in P.S.I.

• Tension strength = load in pounds

cross sectional

10/20/2010 Aircraft Material 14

The compression strength

• Metal resistance to a crushing

force which is the opposite of

tension strength

• Also measured in P.S.I

10/20/2010 Aircraft Material 15

Shear strength

• Shear = tendency on the part of

parallel members to slide in opposite

direction.

• Shear strength = shear force in P.S.I.

10/20/2010 Aircraft Material 16

Torsion Strength

• Torsion = twisting force

• Torsion strength of the material is

resistance to twisting.

10/20/2010 Aircraft Material 17

Strength-weight ratio

• The relationship between the

strength of material and weight

per cubic inch.

10/20/2010 Aircraft Material 18

Corrosion resistance

• Corrosion = is the eating away or

pitting of the surface or the internal

structure of metals.

• The selection metal’s properties

which ignored the corrosion

resistance characteristics is very

dangerous.

10/20/2010 Aircraft Material 19

Heat Treatment

Any process which involves controlled

heating and cooling of metals to

develop certain desirable

characteristics such as hardness,

softness, ductility, tensile strength or

refine grain structure.

10/20/2010 Aircraft Material 20

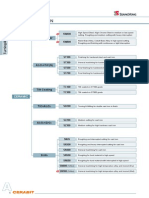

Heat treatment

STEELS ALLUMINUM ALLOYS

• Annealing • HEAT TREATING

• Normalizing The hardening and

toughening process

• Hardening

• ANNEALING

• Tempering The softening process

10/20/2010 Aircraft Material 21

Metal Working Process

• Hot working

• Cold working

• Extruding

10/20/2010 Aircraft Material 22

Hot working

• Steel is hot worked from the ingot

• The Finishing shape by hot- or cold-working

• Bloom = finished metal which have section

dimension > 6x6 inches and app. square

• Billet = finished metal which have section

dimension < 6x6 inches and app. Square

• Slabs = rectangular section which have a

width greater than twice their thickness

10/20/2010 Aircraft Material 23

Cold working

• Cold working applies to mechanical

working performed at temperatures

below the critical range.

• It results in a strain hardening of the

metal.

• In fact, the metal often becomes so hard

that it is difficult to continue the forming

process without softening the metal by

annealing.

10/20/2010 Aircraft Material 24

FORGING

PRESSING HAMMERING

• Used when the parts to be • Used only on relatively

forged are large and heavy small pieces

• Replaces the hammering • To obtain high grade steel is

where high grade steel is used very heavy hammer or

required. subjected the part to

repeated blows

• It is used extensively where

only a small number of

parts are needed.

10/20/2010 Aircraft Material 25

Advantage of both forging process

PRESSING HAMMERING

• The force is uniformly • Operator can control over

transmitted to the center of both the amount of

the section, since a press is pressure applied and the

slow acting. finishing temperature.

• Force affecting the interior • It is able to produce small

grain structure as well as parts of the highest grade

the exterior to give the best steel.

possible structure

throughout.

10/20/2010 Aircraft Material 26

Tempering

• To relieve such strain and reduce brittleness.

• Metal is always tempered after being

hardened.

Tempered consist of heating the steel in a furnace to a specified

temperature under critical point and then cooling it in air, water or

a special solution

• Tempering differs from annealing, normalizing

or hardening which require temperature

above critical point

10/20/2010 Aircraft Material 27

Annealing

PURPOSE PROCESSES

• To relieve internal stresses • Heating the metal to

• Soften the metal prescribed temperature.

• Make it more ductile • Holding it there for a

• Refine grain structure specified length of time.

• Cooling the metal back to

room temperature

To produced maximum softness metal must be cooled very

slowly. Some metal must be furnace cooled, others may be

cooled in air

10/20/2010 Aircraft Material 28

NORMALIZING

• To relieve stresses in metals.

• Applies to iron base metals only.

Consists of :

a. Heating the part to the proper temperature

b. Holding it at that temperature until it is uniformly heated

c. Then cooling it in still air

10/20/2010 Aircraft Material 29

Вам также может понравиться

- Metal Forming and Heat Treatment GuideДокумент21 страницаMetal Forming and Heat Treatment GuideDinesh Killada50% (2)

- Lecture 04-CCT and TemperingДокумент17 страницLecture 04-CCT and TemperingRudy Dwi PrasetyoОценок пока нет

- Report On Heat Treatment of Plain Carbon Steel Kuet MeДокумент11 страницReport On Heat Treatment of Plain Carbon Steel Kuet MeAhmed JishanОценок пока нет

- Heat TreatmentДокумент21 страницаHeat TreatmentChernet MerknehОценок пока нет

- Rotor Manufacturing Report: Heat Treatment ProcessesДокумент3 страницыRotor Manufacturing Report: Heat Treatment Processessumukha nadigОценок пока нет

- Casting Process Advantages and LimitationsДокумент3 страницыCasting Process Advantages and LimitationsaОценок пока нет

- Thermal Processing of MetalsДокумент63 страницыThermal Processing of MetalsNagaVenkateshGОценок пока нет

- Tempcore ProcessДокумент23 страницыTempcore ProcessKumaran 1987Оценок пока нет

- Aisi 305Документ3 страницыAisi 305Aditya PratapОценок пока нет

- TMT ProcesesДокумент39 страницTMT ProcesesVikrant HanwatОценок пока нет

- Metals Classification and Properties GuideДокумент40 страницMetals Classification and Properties Guideaman sudiОценок пока нет

- 06-Fatigue and Creep of Materials - F17 PDFДокумент23 страницы06-Fatigue and Creep of Materials - F17 PDFsabavoonОценок пока нет

- Casting MetallurgyДокумент53 страницыCasting MetallurgyShanmugam BalasubramaniamОценок пока нет

- Tungsten Carbide Rolls Drive Precision & ProductivityДокумент12 страницTungsten Carbide Rolls Drive Precision & Productivitydesetek100% (1)

- CONTINUOUS CASTING ColloquiumДокумент18 страницCONTINUOUS CASTING ColloquiumakritiОценок пока нет

- Continuous Casting ReportДокумент9 страницContinuous Casting ReportAkriti KumariОценок пока нет

- Heat Treatment ProcessesДокумент4 страницыHeat Treatment ProcessesMuhammad Zohaib Ali100% (1)

- Riview On Cold Drawing Process PDFДокумент7 страницRiview On Cold Drawing Process PDFAmandeep Singh GujralОценок пока нет

- 08 - Advanced Metal FormingДокумент12 страниц08 - Advanced Metal FormingAdityaRamaОценок пока нет

- 1st Module BceДокумент49 страниц1st Module BceSvr SОценок пока нет

- Heat Treatment Processes Powerpoint PresentationДокумент14 страницHeat Treatment Processes Powerpoint PresentationDaniel Dowding100% (1)

- Pomina Steel enДокумент2 страницыPomina Steel enrazen_in0% (1)

- A PPT On NBC TrainingДокумент17 страницA PPT On NBC Traininggourav_nama_2150% (2)

- Forging Rolling DefectsДокумент14 страницForging Rolling DefectsRavichandran GОценок пока нет

- Importance of Material Selection in Engineering DesignДокумент2 страницыImportance of Material Selection in Engineering DesignMuhammad UmairОценок пока нет

- Unit 2: Heat Treatment of Iron and SteelsДокумент24 страницыUnit 2: Heat Treatment of Iron and SteelsRahul kumarОценок пока нет

- Combo Bag 1379 RFM Skim Dam E4Документ1 страницаCombo Bag 1379 RFM Skim Dam E4MeteusОценок пока нет

- Powder Metallurgy: Basics & Applications Powder MetallurgyДокумент11 страницPowder Metallurgy: Basics & Applications Powder MetallurgyVivek BajpaiОценок пока нет

- Chapter 4Документ119 страницChapter 4razlan ghazaliОценок пока нет

- AE2253 Unit 2Документ15 страницAE2253 Unit 2Jones Jones Jr.Оценок пока нет

- The effect of annealing on aluminum clad steel sheet propertiesДокумент6 страницThe effect of annealing on aluminum clad steel sheet propertiesRina OktapianiОценок пока нет

- Rolling (Metalworking) : Roller MillДокумент45 страницRolling (Metalworking) : Roller MilldnyaneshwarОценок пока нет

- Annex 1 CCM ProcessДокумент16 страницAnnex 1 CCM ProcessehsanОценок пока нет

- Forging of MetalsДокумент31 страницаForging of MetalsSaiful IslamОценок пока нет

- 23 - Toughened Ceramics 1Документ28 страниц23 - Toughened Ceramics 1Md. Rafiqul IslamОценок пока нет

- PRODUCTION OF STEEL-Lecture 2Документ68 страницPRODUCTION OF STEEL-Lecture 2Nyanda MalashiОценок пока нет

- Metals & Alloys - 2012Документ16 страницMetals & Alloys - 2012Diong Kok HuiОценок пока нет

- Electroflux - The Success Factor in Electroslag Remelting (Esr)Документ18 страницElectroflux - The Success Factor in Electroslag Remelting (Esr)Pradeep DahiyaОценок пока нет

- Continuous Casting Solidification PhenomenaДокумент20 страницContinuous Casting Solidification PhenomenaSyed HasniОценок пока нет

- Manufacturing Unit 1Документ53 страницыManufacturing Unit 1vikas sharma50% (2)

- Engine Block Manufacturing ProcessДокумент5 страницEngine Block Manufacturing ProcessDavid U. AnyegwuОценок пока нет

- The TEMPCORE ProcessДокумент15 страницThe TEMPCORE ProcessShanna Lee100% (1)

- MM223 Manufacturing Process of a Claw HammerДокумент10 страницMM223 Manufacturing Process of a Claw Hammerdipanshil100% (1)

- Development of a new hydraulic mold oscillator model for continuous casting processesДокумент5 страницDevelopment of a new hydraulic mold oscillator model for continuous casting processesM M HossainОценок пока нет

- Proses Manufaktur - Fundamental of Metal FormingДокумент35 страницProses Manufaktur - Fundamental of Metal FormingAnatolium IrgrandeОценок пока нет

- Fast and flexible heat exchanger for heatingДокумент8 страницFast and flexible heat exchanger for heatingtyberius7Оценок пока нет

- What Are Cermets PDFДокумент5 страницWhat Are Cermets PDFAnonymous Inwmu7iEvM100% (1)

- Forging and Its TypesДокумент9 страницForging and Its TypesHarinath GowdОценок пока нет

- Electric Arc Furnace Steelmaking by Jeremy A. T. Jones, Nupro CorporationДокумент9 страницElectric Arc Furnace Steelmaking by Jeremy A. T. Jones, Nupro CorporationGilson JuniorОценок пока нет

- 2 Grade InformationДокумент17 страниц2 Grade InformationAndres Alejandro RoblesОценок пока нет

- On And: Hypereutectoid Transf Ormation BehaviorДокумент8 страницOn And: Hypereutectoid Transf Ormation BehaviorSmruti Ranjan PattanayakОценок пока нет

- Gujarat SORДокумент67 страницGujarat SORbnarendrababu19Оценок пока нет

- Risers Design Unit-IДокумент24 страницыRisers Design Unit-IQUAZI ADYAN AHMAD 160419736049Оценок пока нет

- Friction Stir WeldingДокумент23 страницыFriction Stir WeldingNallappan Rajj AОценок пока нет

- Aircraft MaterialsДокумент44 страницыAircraft MaterialsIan100% (2)

- Unit-2 (1) MPДокумент70 страницUnit-2 (1) MPVishvas SinghhОценок пока нет

- Part 1Документ46 страницPart 1mori.theresya.aer22Оценок пока нет

- Metal Forming Guide on Strain Hardening, Annealing & WorkingДокумент65 страницMetal Forming Guide on Strain Hardening, Annealing & WorkingAli M. ElghawailОценок пока нет

- Aircraft Material SelectionДокумент32 страницыAircraft Material SelectionnishankОценок пока нет

- Lecture 2 Structural SteelДокумент21 страницаLecture 2 Structural SteelLhee Ann GarboОценок пока нет

- Aircraft MetalsДокумент10 страницAircraft MetalsReza FahleviОценок пока нет

- Aircraft MetalsДокумент10 страницAircraft MetalsReza FahleviОценок пока нет

- HelicopterДокумент2 страницыHelicopterReza FahleviОценок пока нет

- Types of Rivets and Riveting Tools ExplainedДокумент2 страницыTypes of Rivets and Riveting Tools ExplainedReza FahleviОценок пока нет

- HelicopterДокумент2 страницыHelicopterReza FahleviОценок пока нет

- Low WingДокумент1 страницаLow WingReza FahleviОценок пока нет

- Gmail - Payment Confirmation and Proof of Race Pack Acquisition Rcti Reds Run 2017 No Reg - Offline-R123Документ1 страницаGmail - Payment Confirmation and Proof of Race Pack Acquisition Rcti Reds Run 2017 No Reg - Offline-R123Reza FahleviОценок пока нет

- 15CDV6 Air 9160c-DatasheetДокумент4 страницы15CDV6 Air 9160c-DatasheetAnil Kumar KammariОценок пока нет

- PMRC Mar Va 122 PDFДокумент26 страницPMRC Mar Va 122 PDFMohamadIbnuHassan100% (1)

- 10 Effect ofДокумент6 страниц10 Effect ofMada PerwiraОценок пока нет

- Material Technology IInd SemДокумент262 страницыMaterial Technology IInd SemvinayakОценок пока нет

- Copper-Nickel-Tin Spinodal Alloy Strip: Standard Specification ForДокумент6 страницCopper-Nickel-Tin Spinodal Alloy Strip: Standard Specification ForDanZel DanОценок пока нет

- Induction Hardening PDFДокумент9 страницInduction Hardening PDFkapilparyaniОценок пока нет

- Control Plan H.TДокумент1 страницаControl Plan H.TABHISHEK PANDEYОценок пока нет

- Spring Project PPT Final Year ProjectДокумент24 страницыSpring Project PPT Final Year Projectumairismail100% (2)

- Asme 437 Sa-437mДокумент6 страницAsme 437 Sa-437mAnonymous GhPzn1xОценок пока нет

- Safety Relief Valves - Spring Loaded - Specification: Indiavz StandardДокумент47 страницSafety Relief Valves - Spring Loaded - Specification: Indiavz StandardShubham DhupkarОценок пока нет

- 05 - Titanium and Titanium AlloysДокумент78 страниц05 - Titanium and Titanium AlloysMiaCat100% (1)

- JIS G 3141 Oos: StripsДокумент28 страницJIS G 3141 Oos: StripsNorberto A. GhiggiОценок пока нет

- Chapter - 15 Boiler Metallurgy DefinitionsДокумент12 страницChapter - 15 Boiler Metallurgy DefinitionsRavi ShankarОценок пока нет

- Heat Treatment Effects on Material PropertiesДокумент5 страницHeat Treatment Effects on Material PropertiesArgha DasОценок пока нет

- 23MnB4 - 1.5535 - SteelNumber - Chemical Composition, Equivalent, PropertiesДокумент2 страницы23MnB4 - 1.5535 - SteelNumber - Chemical Composition, Equivalent, PropertiesSergiОценок пока нет

- Steel Bolts and Nuts and Similar Norm 2377: ObjectiveДокумент9 страницSteel Bolts and Nuts and Similar Norm 2377: ObjectiveanhthoОценок пока нет

- Minimum Pressurization Temperature 7Документ2 страницыMinimum Pressurization Temperature 7Ronald MesinaОценок пока нет

- Aceros y Aleaciones - TUBOSДокумент170 страницAceros y Aleaciones - TUBOSmvicentemОценок пока нет

- Asme Section Ii A-2 Sa-815 Sa-815mДокумент10 страницAsme Section Ii A-2 Sa-815 Sa-815mdavid perezОценок пока нет

- Damage Mechanism in Refinery AreaДокумент83 страницыDamage Mechanism in Refinery AreaKevin PradanaОценок пока нет

- 6 - HiAce - Acidic WearДокумент2 страницы6 - HiAce - Acidic WearNguyên NguyễnОценок пока нет

- Quenched and Tempered Low-Alloy Structural Steel Plate With 70 Ksi (485 Mpa) Minimum Yield Strength To 4 In. (100 MM) ThickДокумент2 страницыQuenched and Tempered Low-Alloy Structural Steel Plate With 70 Ksi (485 Mpa) Minimum Yield Strength To 4 In. (100 MM) ThickJerry BeanОценок пока нет

- 3822 (Eye Hooks For Chain) PDFДокумент9 страниц3822 (Eye Hooks For Chain) PDFAnil BiswalОценок пока нет

- Boiler Materials For USC Plants IJPGC 2000Документ22 страницыBoiler Materials For USC Plants IJPGC 2000pawanumarji1100% (1)

- Aluminum Armor Plate SpecificationДокумент28 страницAluminum Armor Plate SpecificationRobertОценок пока нет

- The Effects of Alloying Elements On SteelsДокумент36 страницThe Effects of Alloying Elements On SteelsRahul PandeyОценок пока нет

- Mechanical Properties For Stainless Steel FastenersДокумент3 страницыMechanical Properties For Stainless Steel FastenersGonzalo MazaОценок пока нет

- Aluminum Bronze Rod, Bar, and Shapes: Standard Specification ForДокумент7 страницAluminum Bronze Rod, Bar, and Shapes: Standard Specification ForraulОценок пока нет

- Stainless Steel GuideДокумент22 страницыStainless Steel Guideasfarjee67% (6)

- Extruded Alloy 6063Документ0 страницExtruded Alloy 6063Lasantha DadallageОценок пока нет