Академический Документы

Профессиональный Документы

Культура Документы

Prestressing and Post Tensioning

Загружено:

Bharat Gouripur0 оценок0% нашли этот документ полезным (0 голосов)

36 просмотров9 страницPrestressing and Post Tensioning

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPrestressing and Post Tensioning

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

36 просмотров9 страницPrestressing and Post Tensioning

Загружено:

Bharat GouripurPrestressing and Post Tensioning

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 9

Principles - the well known

properties of concrete are that it

has high compressive strength and

low tensile strength. the basic

concept of reinforced concrete is

to include a designated amount of

steel bars in a predetermined

pattern to give concrete a

reasonable amount of tensile

strength. In pre stressed concrete

a pre compression is induced into

the member to make full use of its

own inherent compressive

strength when loaded the design

aim is to achieve a balance of

tensile and compressive forces so

that the end result is a concrete

member which is resisting only

stresses which are compressive. In

practice a small amount of tension

may be present but providing this

does not exceed the tensile

strength of the concrete being

used tensile failure will not occur.

PRE STRESSING AND POST TENSIONING IN CONCRETE

Pre-tensioning - This method is used

mainly in the factory production of precast

concrete components such as lintels, floor

units and small beams. Many of these units

are formed by the long line method where

precision steel mould up to 12000 long are

used with spacer or dividing plates to form

the various lengths requires. In pre-

tensioning the wires are stressed within the

mould before the concrete is placed around

them. Steam curing is often used to

accelerate the curing process. Stressing of

the wires is carried out by using hydraulic

jacks operating from both ends of the mould

to achieve an initial 10% overstress to

counteract expected losses. After curing the

wires are released or cut and the bond

between the stressed wires and the concrete

prevents the tendons from regaining their

original length thus maintaining the pre-

compression or pre-stress.

PRE TENSIONING IN CONCRETE

PRE TENSIONING IN CONCRETE

Post - tensioning - this method

is usually employed where

stressing is to be carried out on

site after casting an in-situ

component or where a series of

precast concrete units are to be

joined together to form the

required member. It can also be

used where curved tendons are to

be used to overcome negative

bending moments. In post-

tensioning the concrete is cast

around ducts or sheeting in which

the tendons are to be housed.

Stressing is carried out after the

concrete has cured by means f

hydraulic jacks operating from one

or both the ends of the member.

The anchorages which form part

of the complete components

prevent the stressed tendons from

regaining its original length thus

maintaining the pre-compression

or pre-stress.

POST TENSIONING IN CONCRETE

After stressing the annular

spaces in the tendons ducts

should be filled with grout to

prevent corrosion of the

tendons due to any

entrapped moisture and to

assist in stress distribution.

Due to the high local stresses

at the anchorage positions it

is usual for a reinforcing spiral

to be included in the design.

POST TENSIONING IN CONCRETE

POST TENSIONING IN CONCRETE

PRE STRESSING AND POST TENSIONING IN CONCRETE

PRE STRESSING AND POST TENSIONING IN CONCRETE

PRE STRESSING AND POST TENSIONING IN CONCRETE

Вам также может понравиться

- 15 Day Detox ChallengeДокумент84 страницы15 Day Detox ChallengeDanii Supergirl Bailey100% (4)

- ChatGpt PDFДокумент19 страницChatGpt PDFsanx2014100% (1)

- Basement Water ProofingДокумент35 страницBasement Water ProofingSCOA crewОценок пока нет

- Apexi Powerfc Instruction ManualДокумент15 страницApexi Powerfc Instruction ManualEminence Imports0% (2)

- Construction of Post Tension Slab System.: MaterialsДокумент13 страницConstruction of Post Tension Slab System.: Materialsdindo lauron100% (1)

- Basements and Retaining WallДокумент49 страницBasements and Retaining WallSakshi Rawat100% (1)

- 1.1 Purpose Behind Project:: "Prestressing Technique"Документ6 страниц1.1 Purpose Behind Project:: "Prestressing Technique"MayankMehrotraОценок пока нет

- Pre Cast ConcreteДокумент88 страницPre Cast ConcreteMudit JainОценок пока нет

- Specification - Reinforcement BarsДокумент23 страницыSpecification - Reinforcement BarsShishupal SinghОценок пока нет

- Curing of ConcreteДокумент11 страницCuring of ConcreteNeeraj VashistОценок пока нет

- Construction Technology 2Документ27 страницConstruction Technology 2SamZa ChiewОценок пока нет

- Joints in Construction PracticeДокумент10 страницJoints in Construction PracticeCyril LongtonОценок пока нет

- Pre Stressed ConcreteДокумент47 страницPre Stressed ConcreteBurakku Rōzu100% (2)

- Hollow CoreДокумент15 страницHollow CoreBassem Muhanna100% (2)

- Properties of Precast Concrete ConstructionДокумент6 страницProperties of Precast Concrete ConstructionMaryGraceDelaCruzОценок пока нет

- Pre StressingДокумент5 страницPre StressingAakriti VermaОценок пока нет

- Construction JointsДокумент4 страницыConstruction JointsAvelino De Leon Jr100% (1)

- LEC01 - Reinforced Concrete Design Introduction V02Документ51 страницаLEC01 - Reinforced Concrete Design Introduction V02Migs David100% (1)

- Post Tensioning SystemДокумент32 страницыPost Tensioning SystemAnurag Pandey100% (1)

- Advantages of Precast ConcreteДокумент124 страницыAdvantages of Precast ConcreteVladimir SimeunovicОценок пока нет

- Reinforced Concrete Design - I (CE 320) : Course ContentsДокумент19 страницReinforced Concrete Design - I (CE 320) : Course ContentsAbdul basitОценок пока нет

- Prestensioning & Post-Tensioning: Methods of Prestressing in ConcreteДокумент32 страницыPrestensioning & Post-Tensioning: Methods of Prestressing in Concreteindian royalОценок пока нет

- Implosion of StructuresДокумент14 страницImplosion of StructuresKiran GhorpadeОценок пока нет

- Method Statement of Utracon Post TensioningДокумент7 страницMethod Statement of Utracon Post TensioningIrshad Khan0% (1)

- Precast Concrete Manufacturing Techniques and InstallationДокумент21 страницаPrecast Concrete Manufacturing Techniques and InstallationVIgneshОценок пока нет

- What Are The Methods of Concrete Crack RepairДокумент10 страницWhat Are The Methods of Concrete Crack RepairsadanandОценок пока нет

- Prestressing Concrete: Neda Shakil 4 Year, BДокумент8 страницPrestressing Concrete: Neda Shakil 4 Year, BNeda ShakilОценок пока нет

- Precast PanelsДокумент57 страницPrecast PanelsNilesh MistryОценок пока нет

- Total Precast BrochureДокумент32 страницыTotal Precast BrochureashihomohodОценок пока нет

- Illustrating An Experiment, Outcome, Sample Space and EventДокумент9 страницIllustrating An Experiment, Outcome, Sample Space and EventMarielle MunarОценок пока нет

- Prestressed Concrete: By: Lois B. BernarinoДокумент27 страницPrestressed Concrete: By: Lois B. BernarinoloisОценок пока нет

- Prestressed ConcreteДокумент14 страницPrestressed ConcretekomalОценок пока нет

- Production of Hollow Core SlabsДокумент13 страницProduction of Hollow Core SlabsAziz AhmedОценок пока нет

- PrestressingДокумент44 страницыPrestressingPravin100% (1)

- PrecastДокумент35 страницPrecastalyssa0% (1)

- Lecture 1 - Prestressed ConcreteДокумент15 страницLecture 1 - Prestressed ConcreteHasini KadaruОценок пока нет

- Circular PrestressingДокумент18 страницCircular Prestressingbemd_ali69900% (1)

- Plastering and PaintingДокумент55 страницPlastering and PaintingTanvir ShovonОценок пока нет

- Why Pre-Stressing?: Prestressed Concrete Is A Method For Overcoming Concrete's NaturalДокумент14 страницWhy Pre-Stressing?: Prestressed Concrete Is A Method For Overcoming Concrete's NaturalAfifa yasinОценок пока нет

- Long Span Concrete StructureДокумент18 страницLong Span Concrete StructureDevvrat Chowdhary100% (1)

- Flat Slab - Types of Flat Slab Design and Its AdvantagesДокумент7 страницFlat Slab - Types of Flat Slab Design and Its AdvantagesnandanaОценок пока нет

- 2-Batching, Mixing, Transporting and Handling ConcreteДокумент57 страниц2-Batching, Mixing, Transporting and Handling ConcreteMa ThiОценок пока нет

- Specification Note 02Документ3 страницыSpecification Note 02Anonymous etk4fCHОценок пока нет

- Pre Tensioning and Post TensioningДокумент13 страницPre Tensioning and Post TensioningBal Krishna Rajput100% (1)

- Prestressed Concrete StructureДокумент9 страницPrestressed Concrete StructurepreetiОценок пока нет

- Pre Stressed ConcreteДокумент46 страницPre Stressed ConcreteChhun SeaklengОценок пока нет

- Prestress Presentation SAB4323 OCW Topic 1Документ50 страницPrestress Presentation SAB4323 OCW Topic 1dasdhjhkjОценок пока нет

- Precast Concrete SlabДокумент55 страницPrecast Concrete SlabKimberly LoОценок пока нет

- Pre Stressed BeamsДокумент127 страницPre Stressed BeamsjaffnaОценок пока нет

- Advantages of Using Filler Slab RoofДокумент4 страницыAdvantages of Using Filler Slab Roofanjana susan johnОценок пока нет

- Approved by AICTIE, New Delhi & Affiliated by BTER, Jodhpur (Raj)Документ33 страницыApproved by AICTIE, New Delhi & Affiliated by BTER, Jodhpur (Raj)Jay KothariОценок пока нет

- Retrofitting and Strengthening of Structures: Dr.P.Rathish Kumar Department of Civil Engineering NIT WarangalДокумент64 страницыRetrofitting and Strengthening of Structures: Dr.P.Rathish Kumar Department of Civil Engineering NIT Warangalabcd efgh100% (1)

- Moment® Post Tensioning System Brochure - Ver2Документ12 страницMoment® Post Tensioning System Brochure - Ver2mdkmlОценок пока нет

- Shoring and UnderpinningДокумент14 страницShoring and UnderpinningShraddha KaushikОценок пока нет

- Pre-Tensioning and Post-Tensioning in Prestressed Concrete DesignДокумент3 страницыPre-Tensioning and Post-Tensioning in Prestressed Concrete Designp i n k y p a n t sОценок пока нет

- Retrofitting of BridgesДокумент30 страницRetrofitting of Bridgesmanu_696Оценок пока нет

- GUNITINGДокумент11 страницGUNITINGPavithravasu100% (1)

- What Is Cold Joint in ConcreteДокумент2 страницыWhat Is Cold Joint in ConcretearuanОценок пока нет

- 02-05 Climbing Formwork Xclimb 60Документ62 страницы02-05 Climbing Formwork Xclimb 60Jae Min HwangОценок пока нет

- Pre StressingДокумент10 страницPre Stressingvinita thakurОценок пока нет

- 2.CHAPTER Prestreesed Concrete StructuresДокумент10 страниц2.CHAPTER Prestreesed Concrete StructuresMohammed AhmedОценок пока нет

- Reinforced and Prestressed ConcreteДокумент34 страницыReinforced and Prestressed ConcretecutespyierОценок пока нет

- MMBC Prestressed ConcreteДокумент1 страницаMMBC Prestressed ConcreteNiveditha jОценок пока нет

- Chapter 4 Pre-Stressed ConcreteДокумент23 страницыChapter 4 Pre-Stressed ConcreteDdeqz Elina Bueno IОценок пока нет

- RESUME and Work Experience 080723Документ9 страницRESUME and Work Experience 080723Bharat GouripurОценок пока нет

- Class - Section - Wise - ATSEC AДокумент1 страницаClass - Section - Wise - ATSEC ABharat GouripurОценок пока нет

- MT Handbook GrainДокумент250 страницMT Handbook GrainBharat GouripurОценок пока нет

- Aluminium Glass Shutter Profile 2Документ2 страницыAluminium Glass Shutter Profile 2Bharat GouripurОценок пока нет

- Practice F.stone-Walls FinalДокумент5 страницPractice F.stone-Walls FinalBharat GouripurОценок пока нет

- Enrolment Numbers 2018-19 BatchДокумент2 страницыEnrolment Numbers 2018-19 BatchBharat GouripurОценок пока нет

- Class Section WiseДокумент1 страницаClass Section WiseBharat GouripurОценок пока нет

- Parent LetterДокумент38 страницParent LetterBharat GouripurОценок пока нет

- CIE - MIS Architecture Architecture Semester6 SECBДокумент2 страницыCIE - MIS Architecture Architecture Semester6 SECBBharat GouripurОценок пока нет

- Avalanche 2020Документ1 страницаAvalanche 2020Bharat GouripurОценок пока нет

- CIE - MIS Architecture Architecture Semester6 SECBДокумент2 страницыCIE - MIS Architecture Architecture Semester6 SECBBharat GouripurОценок пока нет

- Quiz GuideДокумент18 страницQuiz GuideBharat GouripurОценок пока нет

- BrochureДокумент44 страницыBrochureBharat GouripurОценок пока нет

- Auditorium PlanДокумент1 страницаAuditorium PlanBharat GouripurОценок пока нет

- School RequirementsДокумент3 страницыSchool RequirementsBharat GouripurОценок пока нет

- CIE - MIS Architecture Architecture Semester6 SECAДокумент2 страницыCIE - MIS Architecture Architecture Semester6 SECABharat GouripurОценок пока нет

- CIE - MIS Architecture Architecture Semester2 SECBДокумент1 страницаCIE - MIS Architecture Architecture Semester2 SECBBharat GouripurОценок пока нет

- Lec 1Документ14 страницLec 1Bharat GouripurОценок пока нет

- LibraryДокумент5 страницLibraryBharat GouripurОценок пока нет

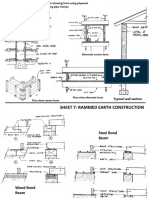

- Sheet 7Документ3 страницыSheet 7Bharat GouripurОценок пока нет

- Sheet 8Документ8 страницSheet 8Bharat GouripurОценок пока нет

- Lec 2Документ17 страницLec 2Bharat GouripurОценок пока нет

- Master PlanДокумент1 страницаMaster PlanBharat GouripurОценок пока нет

- Sheet 6Документ4 страницыSheet 6Bharat GouripurОценок пока нет

- Resource Center N Exibitin ZoningДокумент1 страницаResource Center N Exibitin ZoningBharat GouripurОценок пока нет

- Section AaДокумент1 страницаSection AaBharat GouripurОценок пока нет

- M.arch Ground FloorДокумент1 страницаM.arch Ground FloorBharat GouripurОценок пока нет

- Zoning LibraryДокумент1 страницаZoning LibraryBharat GouripurОценок пока нет

- B.arch ZoningДокумент1 страницаB.arch ZoningBharat GouripurОценок пока нет

- B.arch Class Room First FloorДокумент1 страницаB.arch Class Room First FloorBharat GouripurОценок пока нет

- Julia Dito ResumeДокумент3 страницыJulia Dito Resumeapi-253713289Оценок пока нет

- Genetics Icar1Документ18 страницGenetics Icar1elanthamizhmaranОценок пока нет

- Physics Blue Print 1 Class XI Half Yearly 23Документ1 страницаPhysics Blue Print 1 Class XI Half Yearly 23Nilima Aparajita SahuОценок пока нет

- SASS Prelims 2017 4E5N AДокумент9 страницSASS Prelims 2017 4E5N ADamien SeowОценок пока нет

- Chapter 4 Achieving Clarity and Limiting Paragraph LengthДокумент1 страницаChapter 4 Achieving Clarity and Limiting Paragraph Lengthapi-550339812Оценок пока нет

- Shakespeare Sonnet EssayДокумент3 страницыShakespeare Sonnet Essayapi-5058594660% (1)

- 8051 NotesДокумент61 страница8051 Notessubramanyam62Оценок пока нет

- Dwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFДокумент35 страницDwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFmirthafoucault100% (8)

- Modlist - Modlist 1.4Документ145 страницModlist - Modlist 1.4Tattorin vemariaОценок пока нет

- Microsmart GEODTU Eng 7Документ335 страницMicrosmart GEODTU Eng 7Jim JonesjrОценок пока нет

- Neonatal Mortality - A Community ApproachДокумент13 страницNeonatal Mortality - A Community ApproachJalam Singh RathoreОценок пока нет

- LM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorДокумент21 страницаLM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorcgmannerheimОценок пока нет

- John L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiДокумент12 страницJohn L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiDivya AggarwalОценок пока нет

- FuzzingBluetooth Paul ShenДокумент8 страницFuzzingBluetooth Paul Shen许昆Оценок пока нет

- Unsuccessful MT-SM DeliveryДокумент2 страницыUnsuccessful MT-SM DeliveryPitam MaitiОценок пока нет

- Week 4 - Theoretical Framework - LectureДокумент13 страницWeek 4 - Theoretical Framework - LectureRayan Al-ShibliОценок пока нет

- 1 in 8.5 60KG PSC Sleepers TurnoutДокумент9 страниц1 in 8.5 60KG PSC Sleepers Turnoutrailway maintenanceОценок пока нет

- Topic 3Документ21 страницаTopic 3Ivan SimonОценок пока нет

- Chapter 13 (Automatic Transmission)Документ26 страницChapter 13 (Automatic Transmission)ZIBA KHADIBIОценок пока нет

- Cooperative Learning: Complied By: ANGELICA T. ORDINEZAДокумент16 страницCooperative Learning: Complied By: ANGELICA T. ORDINEZAAlexis Kaye GullaОценок пока нет

- KsДокумент5 страницKsnurlatifahОценок пока нет

- Hướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangДокумент4 страницыHướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangHưng Quân VõОценок пока нет

- Ra 9272Документ6 страницRa 9272janesamariamОценок пока нет

- Miguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Документ22 страницыMiguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Immigrant & Refugee Appellate Center, LLCОценок пока нет

- 7TH Maths F.a-1Документ1 страница7TH Maths F.a-1Marrivada SuryanarayanaОценок пока нет

- Man As God Created Him, ThemДокумент3 страницыMan As God Created Him, ThemBOEN YATORОценок пока нет