Академический Документы

Профессиональный Документы

Культура Документы

Ref: M.R. Riazi, Characterization and Properties of Petroleum Fractions, ASTM, 2005

Загружено:

sterling100%(1)100% нашли этот документ полезным (1 голос)

82 просмотров42 страницыPetroleum Properties

Оригинальное название

Petroleum Properties

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPetroleum Properties

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

82 просмотров42 страницыRef: M.R. Riazi, Characterization and Properties of Petroleum Fractions, ASTM, 2005

Загружено:

sterlingPetroleum Properties

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 42

Ref: M.R.

Riazi, Characterization and Properties of Petroleum

Fractions, ASTM, 2005

Petroleum Definitions

Petroleum is a complex mixture of hydrocarbons that

occur in the sedimentary rocks in the form of gases

(natural gas), liquids (crude oil), semisolids (bitumen), or

solids (wax or asphaltite).

An underground reservoir that contains hydrocarbons is

called petroleum reservoir and its hydrocarbon contents

that can be recovered through a producing well is called

reservoir fluid.

Petroleum Definitions

Paraffins

Generally, hydrocarbons are divided into four groups:

paraffins, olefins, naphthenes and aromatics.

Paraffins are also called alkanes and have the general

formula of CnH2n+2, where n is the number of carbon

atoms. Paraffins from C1 to C40 usually appear in crude oil

and represent up to 20% of crude by volume. Since

paraffins are fully saturated (no double bond), they are

stable and remain unchanged over long periods of

geological time.

Petroleum Definitions

Olefins

Olefins are another series of noncyclic hydrocarbons but

they are unsaturated and have at least one double bond

between carbon-carbon atoms. Compounds with one

double bond are called monoolefins or alkenes.

Monoolefins have a general formula of CnH2n.

Olefins are uncommon in crude oils due to their reactivity

with hydrogen that makes them saturated; however, they

can be produced in refineries through cracking reactions.

Petroleum Definitions

Naphthenes

Naphthenes or cycloalkanes are ring or cyclic saturated

hydrocarbons with the general formula of CnH2n.

Cyclopentane (C5H10), cyclohexane (C6H12), and their

derivatives such as n-alkylcyclopentanes are normally

found in crude oils.

Thermodynamic studies show that naphthene rings with

five and six carbon atoms are the most stable naphthenic

hydrocarbons. The content of cycloparaffins in petroleum

may vary up to 60%.

Petroleum Definitions

Aromatics

Aromatics are an important series of hydrocarbons found

in almost every petroleum mixture from any part of the

world. Aromatics are cyclic but unsaturated hydrocarbons

that begin with benzene molecule (C6H6) and contain

carbon-carbon double bonds.

Some of the common aromatics found in petroleum and

crude oils are benzene and its derivatives with attached

methyl, ethyl, propyl, or higher alkyl groups. This series

of aromatics is called alkylbenzenes and have a general

formula of CnH2n-6 (where n ≥ 6).

Petroleum Definitions

Sulfur content

Sulfur is the most important heteroatom in petroleum and

it can be found in cyclic as well as noncyclic compounds

such as mercaptanes (R-S-H) and sulfides (R-S-R’), where

R and R’ are alkyl groups.

Sulfur in natural gas is usually found in the form of

hydrogen sulfide (H2S). Some natural gas contain H2S as

high as 30% by volume. The amount of sulfur in a crude

may vary from 0.05 to 6% by weight.

Petroleum Definitions

Gas-to-Oil Ratio

The most important characteristic of a reservoir fluid in

addition to specific gravity (or API gravity) is its gas-to-

oil ratio (GOR), which represents the amount of gas

produced at SC in standard cubic feet (scf) to the amount

of liquid oil produced at the SC in stock tank barrel (stb).

Generally, reservoir fluids are black oil, volatile oil, gas

condensate, wet gas, and dry gas.

Petroleum Definitions

Crude Oil

The crude oil produced from the atmospheric separator

has a composition different from the reservoir fluid from a

producing well. Two important characterisitics of a crude

that determine its quality are the API gravity (specific

gravity) and the sulfur content.

Generally, a crude with the API gravity of less than 20-22

is called heavy crude and with API gravity of greater than

33-40 is called light crude. Similarly, if the sulfur content

of a crude is less than 0.5 wt% it is called a sweet oil.

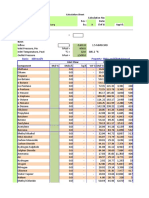

Petroleum Fractions

Some of the petroleum fractions produced from

distillation columns with their boiling point ranges are

given in Table below. These fractions may go through

further processes to produce desired products.

Petroleum Standards

There are a number of international standard organizations

that recommend specific characteristics or standard

measuring techniques for various petroleum products.

Some of these organizations are as follows:

1. ASTM (American Society for Testing and Materials) in

the United States

2. ISO (International Organization for Standardization),

which is at the international level

3. IP (Institute of Petroleum) in the United Kingdom

4. API (American Petroleum Institute) in the United States

Petroleum Properties

Distillation curves

For a crude oil or a petroleum fraction of unknown

composition, the boiling point may be presented by a curve

of temperature versus vol% (or fraction) of mixture

vaporized.

There are several methods of measuring and reporting

boiling points curves of crude oil and petroleum fractions:

1- ASTM D 86

2- True Boiling Point (TBP)

3- Simulated Distillation by GC (ASTM D 2887)

4- Equilibrium Flash Vaporization (EFV)

5- Distillation at Reduced Pressures (ASTM D 1160)

Petroleum Properties

ASTM D 86

ASTM D 86 is one of the simplest and oldest methods of

measuring and reporting boiling points of crude oil and

petroleum fractions. The test is conducted at atmospheric

pressure with 100 mL of sample and the result is shown as

a distillation curve with temperatures at 0, 5, 10, 20, 30,

40, 50, 60, 70, 80, 90, 95, and 100% volume vaporized.

For crudes and heavy products, temperatures are reported

at maximum of 90, 70, or even 50% volume vaporized.

This is due to the cracking of heavy hydrocarbons at high

temperatures.

Petroleum Properties

ASTM D 86

Petroleum Properties

True Boiling Point

ASTM D 86 distillation data do not represent actual

boiling point of components in a petroleum fraction.

Atmospheric true boiling point (TBP) data are obtained

through distillation of a petroleum mixture using a

distillation column with 15-100 theoretical plates at

relatively high reflux ratios (1-5 or greater).

The high degree of fractionation in these distillations gives

accurate component distributions for mixtures. The lack of

standardized apparatus and operational procedure is a

disadvantage, but variations between TBP data reported by

different laboratories for the same sample are small.

Petroleum Properties

True Boiling Point

The IBP from TBP curve is less than the IBP from ASTM

D 86 curve, while the FBP of TBP curve is higher than that

of ASTM curve. Therefore, the boiling range based on

ASTM D 86 is less than the actual true boiling range.

Petroleum Properties

ASTM D 2887

A distillation curve produced by GC is called a simulated

distillation (SD) and the method is described in ASTM D

2887 test method. Simulated distillation method is simple,

consistent, and reproducible and can represent the boiling

range of a petroleum mixture without any ambiguity.

Distillation curves by SD are presented in terms of boiling

point versus wt% of mixture vaporized because in gas

chromatography composition is measured in terms of wt%

or weight fraction. SD curves are very close to actual

boiling points shown by TBP curves.

Petroleum Properties

ASTM D 1160

For products such as heavy gas oils that contain heavy

compounds and may undergo a cracking process during

vaporization at atmospheric pressure, distillation data are

measured at reduced pressures, 1, 2, 10, or 50 mmHg. The

experimental procedure is described in ASTM D 1160 test

method.

ASTM D 1160 distillation data are measured more

accurately than ASTM D 86 since it is conducted at low

pressure. For this reason ASTM D 1160 curves are closer

to TBP curves at the same pressure base.

Petroleum Properties

The Watson characterization factor (Kw) is one of the

oldest characterization factors originally defined by

Watson et al. of the Universal Oil Products (UOP) in mid

1930s. For this reason the parameter is sometimes called

UOP characterization factor and is defined as

Tb1/ 3

Kw where Tb normal boiling point oR

SG

The naphthenic hydrocarbons have Kw values between

paraffinic and aromatic compounds. In general, aromatics

have low Kw values while paraffins have high values.

Petroleum Properties

Reid vapor pressure (RVP) is the absolute pressure exerted

by a mixture at 100 oF and a vapor-to-liquid volume ratio of

4. The RVP is one of the important properties of gasolines

and jet fuels. The standard test of RVP is ASTM D 323.

For a pure compound the freezing point is the temperature

at which liquid solidifies at 1 atm pressure. Similarly the

melting point is the temperature that a solid substance

liquefies at 1 atm. A pure substance has the same freezing

and melting points; however, for petroleum mixtures, there

are ranges of melting and freezing points versus percent of

the mixture melted or frozen.

Petroleum Properties

Pour point of a petroleum fraction is the lowest

temperature at which the oil will pour or flow when it is

cooled without stirring under standard cooling conditions.

Pour point represents the lowest temperature at which an

oil can be stored and still capable of flowing under

gravity. When temperature is less than pour point of a

petroleum product it cannot be stored or transferred

through a pipeline. Test procedures for measuring pour

points of petroleum fractions are given under ASTM D 97

and ASTM D 5985 methods.

Petroleum Properties

Cloud point is the lowest temperature at which wax crystals

begin to form by a gradual cooling under standard conditions.

At this temperature the oil becomes cloudy and the first

particles of wax crystals are observed. The standard procedure

to measure the cloud point is ASTM D 2500.

Low cloud point products are desirable under low-temperature

conditions. Wax crystals can plug the fuel system lines and

filters, which could lead to stalling aircraft and diesel engines

under cold conditions. Cloud points are measured for oils that

contain paraffins in the form of wax and therefore for light

fractions (naphtha or gasoline) no cloud point data are reported.

Petroleum Properties

Flash point for a hydrocarbon or a fuel is the minimum

temperature at which vapor pressure of the hydrocarbon is

sufficient to produce the vapor needed for spontaneous

ignition of the hydrocarbon with the air with the presence

of an external source, i.e., spark or flame. The standard

procedure to measure the Flash point is ASTM D 93.

Flash point is an important parameter for safety

considerations, especially during storage and transportation

of volatile petroleum products (i.e., LPG, light naphtha,

gasoline). The surrounding temperature around a storage

tank should always be less than the flash point of the fuel to

avoid possibility of ignition.

Petroleum Properties

Flash point should not be mistaken with fire point, which

is defined as the minimum temperature at which the

hydrocarbon will continue to burn for at least 5 s after

being ignited by a flame.

Autoignition temperature is the minimum temperature at

which hydrocarbon vapor when mixed with air can

spontaneously ignite without the presence of any external

source. Values of autoignition temperature are generally

higher than flash point. This is particularly important

from a safety point of view when hydrocarbons are

compressed. Standard test is ASTM D 2155.

Petroleum Properties

To have a combustion, three elements are required: fuel

(hydrocarbon vapor), oxygen (i.e., air), and a spark to

initiate the combustion. One important parameter to have

a good combustion is the ratio of air to hydrocarbon fuel.

The combustion does not occur if there is too much air

(little fuel) or too little air (too much fuel). This suggests

that combustion occurs when hydrocarbon concentration

in the air is within a certain range. This range is called

flammability range and is usually expressed in terms of

lower and upper volume percent in the mixture of

hydrocarbon vapor and air.

Petroleum Properties

Octane number is a parameter defined to characterize

antiknock characteristic of a fuel (gasoline and jet fuel)

for spark ignition engines. Octane number is a measure

of fuel's ability to resist auto-ignition during compression

and prior to ignition. Higher octane number fuels have

better engine performance.

The octane number of a fuel is measured based on two

reference hydrocarbons of n-heptane with an assigned

octane number of zero and isooctane (2,2,4-

trimethylpentane) with assigned octane number of 100.

Petroleum Properties

There are two methods of measuring octane number of a

fuel in the laboratory; motor octane number (MON) and

research octane number (RON). The MON is indicative

of high-speed performance (900 rpm) and is measured

under heavy road conditions (ASTM D 357). The RON is

indicative of normal road performance under low engine

speed (600 rpm) city driving conditions (ASTM D 908).

The arithmetic average value of RON and MON is known

as posted octane number (PON).

Isoparaffins and aromatics have high octane numbers while

n-paraffins and olefins have low octane numbers.

Petroleum Properties

Generally there are three kinds of gasolines: regular,

intermediate, and premium with PON of 87, 90, and 93,

respectively. Improving the octane number of fuel would

result in reducing power loss of the engine, improving fuel

economy, and a reduction in environmental pollutants and

engine damage. There are a number of additives that can

improve octane number of gasoline or jet fuels. These

additives are tetra-ethyl lead (TEL), alcohols, and ethers.

Petroleum Properties

For diesel engines, the fuel must have a characteristic

that favors auto-ignition. The ignition delay period can

be evaluated by the fuel characterization factor called

cetane number (CN). The shorter the ignition delay

period the higher CN value.

The cetane number is defined as:

CN = vol% n-cetane + 0.15(vo1% HMN)

Where n-cetane (n-C16H34) has a CN of 100, and

heptamethylnonane (HMN) has a CN of 15. The cetane

number of a diesel fuel can be measured by the ASTM D

613 test method.

Petroleum Properties

Higher cetane number fuels reduce combustion noise and

permit improved control of combustion resulting in

increased engine efficiency and power output. Higher

cetane number fuels tend to result in easier starting and

faster warm-up in cold weather and can cause reduction in

air pollution.

The product distributed in France and Europe have CN in

the range of 48-55. In the United States and Canada the

cetane number of diesel fuels are most often less than 50.

Cetane number of diesel fuels can be improved by adding

additives such as 2-ethyl-hexyl nitrate or other types of

alkyl nitrates.

Petroleum Properties

Aniline point for a hydrocarbon or a petroleum fraction is

defined as the minimum temperature at which equal

volumes of liquid hydrocarbon and aniline are miscible.

The aniline point is important in characterization of

petroleum fractions and analysis of molecular type. The

aniline point is also used as a characterization parameter

for the ignition quality of diesel fuels. It is measured by the

ASTM D 611 test method. Aromatics have very low

aniline points in comparison with paraffins, since aniline

itself is an aromatic compound (C6H5-NH2) and it has

better miscibility with aromatic hydrocarbons.

Petroleum Properties

When a petroleum fraction is vaporized in the absence of

air at atmospheric pressure, the nonvolatile compounds

have a carbonaceous residue known as carbon residue

(CR). Therefore, heavier fractions with more aromatic

contents have higher carbon residues while volatile and

light fractions such as naphthas and gasolines have no

carbon residues.

There are three different test methods to measure carbon

residues, Ramsbottom (ASTM D 524), the Conradson

(ASTM D 189) and microcarbon (ASTM D 4530). In

most cases carbon residues are reported in wt%.

Petroleum Properties

The smoke point (SP) is a maximum flame height at

which a fuel can be burned in a standard wick-fed lamp

without smoking. It is expressed in millimeters and a high

smoke point indicates a fuel with low smoke-producing

tendency. Measurement of smoke point is described under

ASTM D 1322.

Smoke point is a characteristic of aviation turbine fuels

and kerosenes and indicates the tendency of a fuel to burn

with a smoky flame. Higher amount of aromatics in a fuel

causes a smoky characteristic for the flame and energy

loss due to thermal radiation.

Quality of Petroleum Products

The quality of a petroleum product depends on certain

specifications or properties of the fuel to satisfy required

criteria set by the market demand. These characteristics

are specified for best use of a fuel (i.e., highest engine

performance) or for cleaner environment.

These specifications vary from one product to another and

from one country to another. Standard organizations such

as ASTM give such specifications for various products.

For example: ASTM D 4814 for gasoline, ASTM D 975

for diesel fuel, ASTM D 3699 for kerosene and ASTM D

6615 for jet fuel.

Crude Oil Distillation

Ref: R. Smith, Chemical Process Design and Integration, Wiley, 2005.

In the first stage of processing crude oil, it is distilled

under conditions slightly above atmospheric pressure. A

range of petroleum fractions are taken from the crude oil

distillation.

Designs are normally thermally coupled. Most

configurations follow the thermally coupled indirect

sequence as shown in Figure (a). However, rather than

build the configuration in Figure (a), the configuration of

Figure (b) is the one normally constructed. Notice that the

two arrangements are equivalent.

Crude Oil Distillation

Crude Oil Distillation

Unfortunately, a practical crude oil distillation cannot be

operated in quite the way shown in Figure (b), because:

Extremely high temperature sources of heat would be

required. Steam is usually not distributed for process

heating at such high temperatures.

High temperatures in the reboilers would result in

significant fouling of the reboilers from decomposition of

the hydrocarbons to form coke.

Therefore, in practice, some or all of the reboiling is

substituted by the direct injection of steam into the

distillation. The steam is condensed in the overhead and is

separated in a decanter from the hydrocarbons.

Crude Oil Distillation

Another problem with the

arrangement in Figure (b) is that

as the vapor rises up the main

column, its flow rate increases

significantly.

This problem can be solved by

removing heat from the main

column at intermediate points by

pumparound. This corresponds

with introducing some

condensation of the vapor at the

top of intermediate columns.

Crude Oil Distillation

Pumparound

In a pumparound, liquid is taken from the column, sub

cooled and returned to the column at a higher point.

By choosing the most appropriate flow rate and temperature

for the pumparound, the heat load to be removed can be

adjusted to whatever is desired.

The trays between the liquid draw and return in a

pumparound have more to do with heat transfer than mass

transfer. In addition to returning a sub cooled liquid to the

column, mixing occurs as material is introduced to a higher

point in the column.

Crude Oil Distillation

Furnace

The crude oil entering the main column needs to be

preheated to around 400 ◦C. This is down by a furnace

(fired heater). Note that this temperature is higher than

decomposition limit, but a high temperature can be tolerated

in the furnace if it is only for a short residence time.

All of the material that needs to leave as product above the

feed point must vaporize as it enters the column. In addition

to this, some extra vapor over and above this flowrate must

be created that will be condensed and flow back down

through the column as reflux. This extra vaporization to

create reflux is known as overflash.

Crude Oil Distillation

The distillation of crude oil under conditions slightly

above atmospheric pressure is limited by the maximum

temperature that can be tolerated by the materials being

distilled, otherwise there would be decomposition.

The residue from the atmospheric crude oil distillation is

usually reheated to a temperature around 400◦C or

slightly higher and fed to a vacuum column, which

operates under a high vacuum (about 50 mmHg) to

allow further recovery of material from the atmospheric

residue, as shown in the next Figure.

Crude Oil Distillation

Вам также может понравиться

- Crude Assay - Lecture NotesДокумент18 страницCrude Assay - Lecture Notessam joseph100% (1)

- Petroleum PropertiesДокумент28 страницPetroleum PropertiesRathish RagooОценок пока нет

- DistillationДокумент25 страницDistillationMohammadAslam100% (1)

- Assay of Crude OilsДокумент8 страницAssay of Crude OilsGilberto Pires100% (1)

- Crude Petroleum analysis handbook: Crude oil Quality control, #1От EverandCrude Petroleum analysis handbook: Crude oil Quality control, #1Рейтинг: 4 из 5 звезд4/5 (1)

- Crude OilДокумент5 страницCrude OilSyed Bakhtyar AhmedОценок пока нет

- PRPP 2013 Crude Oil PropertiesДокумент7 страницPRPP 2013 Crude Oil PropertiesMohamed AlaaОценок пока нет

- Chapter 1: IntroductionДокумент5 страницChapter 1: IntroductionRahul PantОценок пока нет

- May Karl-FischerДокумент82 страницыMay Karl-Fischerhoang hai100% (1)

- Fluid Properties: PVT Properties of Crude Oils: 1. Oil Formation Volume Factor, BДокумент6 страницFluid Properties: PVT Properties of Crude Oils: 1. Oil Formation Volume Factor, BAli HijaziОценок пока нет

- Crude Oil Properties AnalysisДокумент54 страницыCrude Oil Properties AnalysisNur AmalinaОценок пока нет

- Crude Oil and Product Catalog PropertiesДокумент24 страницыCrude Oil and Product Catalog PropertiesToapanta FredyОценок пока нет

- 03 Blending PowerpointДокумент70 страниц03 Blending PowerpointNinhHoàngHải100% (4)

- Gasoline SpecificationsДокумент2 страницыGasoline SpecificationsvikasbadhanОценок пока нет

- CRUDE OIL CHARACTERIZATION METHODSДокумент8 страницCRUDE OIL CHARACTERIZATION METHODSAbhinav JoshiОценок пока нет

- Gasoline FAQ 3Документ20 страницGasoline FAQ 3Claudia MmsОценок пока нет

- Unit 1 Crude Oil Properties PDFДокумент38 страницUnit 1 Crude Oil Properties PDFmehtab hussain100% (4)

- Crude Assay vs. HTSDДокумент0 страницCrude Assay vs. HTSDmahmoudmakladОценок пока нет

- Blending of Gasolin PDFДокумент14 страницBlending of Gasolin PDFAakanksha RaulОценок пока нет

- Finger Print - Crude OilДокумент8 страницFinger Print - Crude OilSladjana TeslićОценок пока нет

- Measurement ManualДокумент83 страницыMeasurement ManualJavier Marcelo Sandoval BozoОценок пока нет

- Gasoline FAQ 4Документ25 страницGasoline FAQ 4Claudia MmsОценок пока нет

- SASO FDS 30127 2016 E Gasoline SpecДокумент13 страницSASO FDS 30127 2016 E Gasoline SpecZiauddeen NoorОценок пока нет

- Source Rock Evaluation Parameters (Nippon)Документ3 страницыSource Rock Evaluation Parameters (Nippon)RamLy SinaGaОценок пока нет

- Fundamentals of Oil RefineryДокумент12 страницFundamentals of Oil RefineryMarie SaundersОценок пока нет

- Q and A Refinery ProcessesДокумент9 страницQ and A Refinery ProcessesnishilgeorgeОценок пока нет

- Classifying Crude Oil by CompositionДокумент14 страницClassifying Crude Oil by Compositiondana mohammedОценок пока нет

- Refinery BasicsДокумент34 страницыRefinery BasicsashtaxОценок пока нет

- Assay of Crude OilДокумент1 страницаAssay of Crude OilabdsalОценок пока нет

- Flow Measurement: - Introduced By: Taha Safi Ahmad Habbas Essa Qaisi Abdel Rahman AlnatourДокумент29 страницFlow Measurement: - Introduced By: Taha Safi Ahmad Habbas Essa Qaisi Abdel Rahman AlnatourAbd Al-NatourОценок пока нет

- Mini Oil Refinery Plants Technotrade LtdДокумент3 страницыMini Oil Refinery Plants Technotrade LtdrudiandriesОценок пока нет

- 16 - Upgrading Olefins For Gasoline BlendingДокумент21 страница16 - Upgrading Olefins For Gasoline BlendingAbhimanyu SharmaОценок пока нет

- ZZ 1207573397 IsoFraction LNG Sampling SystemR2Документ3 страницыZZ 1207573397 IsoFraction LNG Sampling SystemR2kaysb786133Оценок пока нет

- AnilineДокумент6 страницAnilineMUHAMMAD AKRAM0% (1)

- Physicochemical Characterization and Applications of NaphthaДокумент7 страницPhysicochemical Characterization and Applications of NaphthaCherie AdamsОценок пока нет

- What is Gasoline? Key details on production, octane number, knocking, and additivesДокумент11 страницWhat is Gasoline? Key details on production, octane number, knocking, and additivesAayush PandeyОценок пока нет

- Gas Chromatographic Methods For Oil AnalysisДокумент37 страницGas Chromatographic Methods For Oil AnalysisDurvel de la CruzОценок пока нет

- Gasoline FAQ 1Документ9 страницGasoline FAQ 1Claudia MmsОценок пока нет

- Crude Oil Chemistry PDFДокумент410 страницCrude Oil Chemistry PDFJesse Haney IIIОценок пока нет

- Measuring Salinity in Crude Oils Evaluation of MetДокумент9 страницMeasuring Salinity in Crude Oils Evaluation of Metarmando fuentesОценок пока нет

- Petroleum Refining & PetrochemicalsДокумент32 страницыPetroleum Refining & PetrochemicalsprasoonОценок пока нет

- Properties of Petroleum (Oil and Gas) and Petroleum ProductsДокумент21 страницаProperties of Petroleum (Oil and Gas) and Petroleum ProductsHadi H. HussenОценок пока нет

- Khor2016Khor, C. S., & Varvarezos, D. (2016) - Petroleum Refinery Optimization. Optimization and EngineeringДокумент47 страницKhor2016Khor, C. S., & Varvarezos, D. (2016) - Petroleum Refinery Optimization. Optimization and EngineeringKhaled BeheryОценок пока нет

- Amspec Techtalk Hydrogen Sulfide - h2s 4Документ3 страницыAmspec Techtalk Hydrogen Sulfide - h2s 4Javier Gomez TorregrosaОценок пока нет

- Base Oil Technology EvolutionДокумент14 страницBase Oil Technology EvolutionsalleyОценок пока нет

- Electrostatic Treater Principles for Emulsion BreakingДокумент20 страницElectrostatic Treater Principles for Emulsion BreakingRicardo BecОценок пока нет

- Chemical and Physical Prop of PetroleumДокумент35 страницChemical and Physical Prop of Petroleumshivam tiwari100% (1)

- SARA Method D4124Документ9 страницSARA Method D4124mahamuninaresh1Оценок пока нет

- 05 - Shale AssessmentДокумент88 страниц05 - Shale AssessmentAdriana RezendeОценок пока нет

- Fluid Movement in A SAGD ProcessДокумент13 страницFluid Movement in A SAGD ProcessmandersonОценок пока нет

- Understanding Crude Oil and Product Markets Primer Low PDFДокумент39 страницUnderstanding Crude Oil and Product Markets Primer Low PDFrohanpujari100% (1)

- Refining crude oil into gasolineДокумент4 страницыRefining crude oil into gasolineAngel Anne AlcantaraОценок пока нет

- Application of Organic Petrology in Oil ExplorationДокумент6 страницApplication of Organic Petrology in Oil ExplorationKrantikari KishorОценок пока нет

- Crude Oil ProcessingДокумент19 страницCrude Oil ProcessingYinka OlatunjiОценок пока нет

- Fuel Field ManualДокумент26 страницFuel Field ManualFREDIELABRADORОценок пока нет

- List of Gasoline Additives - Wikipedia, The Free EncyclopediaДокумент3 страницыList of Gasoline Additives - Wikipedia, The Free EncyclopediaMukesh BohraОценок пока нет

- 1b - Characteristics, Classification and Properties of Petroleum 5Документ8 страниц1b - Characteristics, Classification and Properties of Petroleum 5THE TERMINATORОценок пока нет

- Introduction To Petroleum PropertiesДокумент28 страницIntroduction To Petroleum PropertiesMichael MedinaОценок пока нет

- 06 PP PGP Lecture 6 2014-2015Документ34 страницы06 PP PGP Lecture 6 2014-2015anmarОценок пока нет

- Report For The Design and Simulation of Benzene Recovery PlantДокумент32 страницыReport For The Design and Simulation of Benzene Recovery PlantsterlingОценок пока нет

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataДокумент6 страницCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingОценок пока нет

- Pump sizing spreadsheet calculates performanceДокумент26 страницPump sizing spreadsheet calculates performancesterling100% (1)

- Chapter 3&4&5Документ24 страницыChapter 3&4&5sterlingОценок пока нет

- Higher Institutions in Rivers State and Their Locations - Ekky BlogДокумент7 страницHigher Institutions in Rivers State and Their Locations - Ekky BlogsterlingОценок пока нет

- Basis: Basis: 100 Mol/h Property: GPSA and Elliott ManualДокумент6 страницBasis: Basis: 100 Mol/h Property: GPSA and Elliott ManualsterlingОценок пока нет

- Control Valve Specification SheetДокумент1 страницаControl Valve Specification SheetsterlingОценок пока нет

- Optimal Production Planning and Scheduling in Breweries: Journal Pre-ProofДокумент61 страницаOptimal Production Planning and Scheduling in Breweries: Journal Pre-ProofsterlingОценок пока нет

- Chapter Three: 3.1 MaterialsДокумент24 страницыChapter Three: 3.1 MaterialssterlingОценок пока нет

- Chapter 3&4&5Документ24 страницыChapter 3&4&5sterlingОценок пока нет

- H&MBДокумент1 страницаH&MBsterlingОценок пока нет

- Two Phase Line Sizing Calculation - Case AДокумент1 страницаTwo Phase Line Sizing Calculation - Case AsterlingОценок пока нет

- Consumption of Cooking GasДокумент5 страницConsumption of Cooking GassterlingОценок пока нет

- Ealant EquipmentДокумент1 страницаEalant EquipmentsterlingОценок пока нет

- Serck Audco Valves: Sealants and Injection EquipmentДокумент21 страницаSerck Audco Valves: Sealants and Injection EquipmentsterlingОценок пока нет

- Temporarypermanent Pipe Repair - GuidelinesДокумент70 страницTemporarypermanent Pipe Repair - Guidelinesqinaip100% (1)

- NVABR1014-Sealant SealantEquipment PDFДокумент8 страницNVABR1014-Sealant SealantEquipment PDFsterlingОценок пока нет

- Orbit Valves Brochure PDFДокумент28 страницOrbit Valves Brochure PDFHendi RofiansyahОценок пока нет

- Gas Chromatographic Analysis ResultsДокумент3 страницыGas Chromatographic Analysis ResultssterlingОценок пока нет

- Consumption of Cooking GasДокумент5 страницConsumption of Cooking GassterlingОценок пока нет

- 4662022Документ40 страниц4662022sterlingОценок пока нет

- Sample Conf LetterДокумент2 страницыSample Conf LettersterlingОценок пока нет

- Hazop Training GuideДокумент9 страницHazop Training GuideAdyBorsosОценок пока нет

- MysepДокумент16 страницMysepsterlingОценок пока нет

- MySep Vessel Motion - White Paper PDFДокумент12 страницMySep Vessel Motion - White Paper PDFsterlingОценок пока нет

- Equipment TroubleshootДокумент13 страницEquipment TroubleshootManel Montesinos100% (1)

- Level MeasurementДокумент31 страницаLevel MeasurementMalik MuchamadОценок пока нет

- Energy BalanceДокумент29 страницEnergy BalancesterlingОценок пока нет

- Material Balance NotesДокумент108 страницMaterial Balance Notesapi-3709413100% (4)

- Air Conditioning and Refrigeration: Muhammad Bilal KhanДокумент25 страницAir Conditioning and Refrigeration: Muhammad Bilal KhanMuzammalRehmanОценок пока нет

- Total Internal Reflection at a Single Curved SurfaceДокумент30 страницTotal Internal Reflection at a Single Curved SurfaceIlakkiyaa KPОценок пока нет

- Industrial FRP Tank Water Media FilterДокумент4 страницыIndustrial FRP Tank Water Media FilterT Nagaraju AF VetaranОценок пока нет

- Making A Standrad SolutionДокумент2 страницыMaking A Standrad SolutionFaridaОценок пока нет

- Underground Power Transmission Insulation MaterialsДокумент31 страницаUnderground Power Transmission Insulation MaterialsnandhakumarmeОценок пока нет

- 2.0 Electric FieldsДокумент4 страницы2.0 Electric FieldsEdAnОценок пока нет

- Iare RRS Notes PDFДокумент588 страницIare RRS Notes PDFmohan reddyОценок пока нет

- Brchembase LRДокумент4 страницыBrchembase LRRavindra PawarОценок пока нет

- Condensation of Acetophenone To (Dypnone) Over Solid Acid CatalystsДокумент9 страницCondensation of Acetophenone To (Dypnone) Over Solid Acid CatalystsLutfiah Nur HidayatiОценок пока нет

- Slug Catcher Conceptual DesignДокумент8 страницSlug Catcher Conceptual Designfanziskus100% (1)

- Starting With Zero: Create Your Own Topographic Map ProjectДокумент4 страницыStarting With Zero: Create Your Own Topographic Map ProjectVinujah SukumaranОценок пока нет

- Introduction to MEMS Etching TechniquesДокумент16 страницIntroduction to MEMS Etching TechniquesArjit GoswamiОценок пока нет

- 01 StudyGuide (2021) ChemДокумент157 страниц01 StudyGuide (2021) ChemYzakRVОценок пока нет

- ConductorsДокумент19 страницConductorsNavdeep KaurОценок пока нет

- Biological MoleculesДокумент98 страницBiological MoleculesSuyashОценок пока нет

- Applied Metallurgy and CorrosionДокумент2 страницыApplied Metallurgy and Corrosiongetavijit.asheshОценок пока нет

- ESAS-Lindeburg Terms (Dreamforce)Документ14 страницESAS-Lindeburg Terms (Dreamforce)e5865domingoascotbaguioОценок пока нет

- Adiabatic Operation of A Tubular Reactor For Cracking of Acetone (Prob. 4.3)Документ10 страницAdiabatic Operation of A Tubular Reactor For Cracking of Acetone (Prob. 4.3)ahmed ubeedОценок пока нет

- 9th Class Science Mid-Term AssessmentДокумент6 страниц9th Class Science Mid-Term AssessmentAshish GambhirОценок пока нет

- Circulation Rates in Thermosiphon ReboilerДокумент7 страницCirculation Rates in Thermosiphon ReboilersОценок пока нет

- Mechanism and kinetics of oxygen reduction on porous La 12x Sr x CoO 32d electrodesДокумент10 страницMechanism and kinetics of oxygen reduction on porous La 12x Sr x CoO 32d electrodessinytellsОценок пока нет

- Light PPT 120108205852 Phpapp01Документ13 страницLight PPT 120108205852 Phpapp01padmja4purohit100% (1)

- Evaluation of Microhardness and PDFДокумент7 страницEvaluation of Microhardness and PDFVictor SabОценок пока нет

- Blast furnace burden calculation methods and parametersДокумент2 страницыBlast furnace burden calculation methods and parametersJaymart Hernandez Mojica75% (4)

- Cimiracemates A-D, Phenylpropanoid Esters From The Rhizomes of Cimicifuga RacemosaДокумент5 страницCimiracemates A-D, Phenylpropanoid Esters From The Rhizomes of Cimicifuga RacemosaLarisa CatautaОценок пока нет

- Weathering of RocksДокумент2 страницыWeathering of Rocksvee propagandaОценок пока нет

- List of Baryons - WikipediaДокумент8 страницList of Baryons - WikipediaSallyy SpitownОценок пока нет

- Water Analysis: SolidsДокумент14 страницWater Analysis: SolidsCy CruzОценок пока нет

- Mas and e PDFДокумент5 страницMas and e PDFtulasi saladiОценок пока нет

- 45DAYCHECKLIST DexterChemДокумент1 страница45DAYCHECKLIST DexterChemroyalassassinking2020Оценок пока нет