Академический Документы

Профессиональный Документы

Культура Документы

Ceramic Whitewares (Lecture 2)

Загружено:

Mhxz See0 оценок0% нашли этот документ полезным (0 голосов)

597 просмотров25 страницОригинальное название

Ceramic Whitewares (Lecture 2).pptx

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

597 просмотров25 страницCeramic Whitewares (Lecture 2)

Загружено:

Mhxz SeeАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 25

Whiteware

any of a broad class of ceramic products that

are white to off-white in appearance and

frequently contain a significant vitreous, or

glassy, component. Including products as

diverse as fine china dinnerware, lavatory

sinks and toilets, dental implants, and spark-

plug insulators.

Raw materials: clay, flint, and

feldspar

Whitewares are often referred to

as triaxial bodies, owing to the

three mineral types—clay, silica,

and feldspar—consistently found

in their makeup.

• Clay is the plastic component, giving shaping

abilities to the unfired product and also

serving as a glass former during firing. Flint

(the common name used in the industry for all

forms of silica) serves as a filler, lending

strength to the shaped body before and

during firing. Feldspar serves as a fluxing

agent, lowering the melting temperatures of

the mixture.

Clay is the most important of the ingredients,

and the most important clay used in fine

whiteware products is kaolin, also known as

china clay.

Kaolin is the only type of clay from which a

white, translucent, vitreous ceramic can be

made.

It is a refractory clay, meaning that it can be

fired at high temperatures without deforming,

and it is white-burning, meaning that it

imparts whiteness to the finished ware.

Whiteware products are often differentiated

into three main classes—porous,

semivitreous, and vitreous—according to

their degree of vitrification (and resulting

porosity). Proceeding from porous to

vitreous, more particular product categories

include earthenware, stoneware, china, and

technical porcelains.

Earthenware is non-vitreous and of

medium porosity. It is often glazed to

provide fluid impermeability and an

attractive finish. Specific products

include tableware and decorative tile

ware.

Whitewares all depend for their utility upon a

relatively small set of properties:

imperviousness to fluids, low conductivity of

electricity, chemical inertness, and an ability to

be formed into complex shapes. These

properties are determined by the mixture of raw

materials chosen for the products, as well as by

the forming and firing processes employed in

their manufacture.

the raw materials, properties, and

applications of whiteware ceramics at a

certain points in the article there are

references to specific industrial processes

employed in the manufacture of whiteware

products.

For more detailed description of these

processes, see industrial ceramics.

Raw materials: clay, flint, and feldspar

• Kaolin is formed principally of the

mineral kaolinite, a hydrous

aluminosilicate with a fine, platy

structure; its ideal chemical

formula is Al2(Si2O5)(OH)4.

China clays are composed mostly of well-

ordered kaolinite, with no impurities. Lower-

grade whitewares are usually made of ball

clays, which incorporate ordered and

disordered kaolinite plus other clay minerals

and impurities. These impurities—particularly

iron oxides—render the fired ware off-white

to gray or tan in colour.

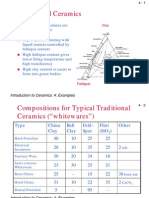

Whiteware Products

• Stoneware is a semivitreous or

vitreous whiteware with a fine

microstructure (that is, a fine

arrangement of solid phases and

glass on the micrometre level).

Products include tableware,

cookware, chemical ware, and

sanitary ware (e.g., drainpipe).

All vitreous whitewares are often

referred to as porcelains, but in the

ceramics industry a distinction is

maintained between the true

porcelains (or technical porcelains)

and china.

• China is vitreous whiteware for

nontechnical applications. Because of its

high glass content, it can be used

unglazed, though it also can be glazed for

aesthetic appeal. China is known for high

strength and impact resistance and also

for low water absorption—all deriving

from the high glass content.

Typical products include hotel china, a

lower grade of china tableware with a

strength and impact resistance suiting

it to commercial use; fine china

(including bone china), a highly

vitreous, translucent tableware; and

sanitary plumbing fixtures.

Technical porcelains, like china, are

vitreous and nonporous. They are

similarly strong and impact-resistant,

but they are also chemically inert in

corrosive environments and are

excellent insulators against electricity.

Applications include chemical ware,

dental implants, and electric

insulators, including spark-plug

insulators in automobile engines.

Processing

• The forming and firing processes

employed in the manufacture of

whiteware products are outlined in

the article industrial ceramics.

Typically, pressing is employed in the

forming of tiles, chemical ware, and

technical porcelains; extrusion in the

forming of tiles and sanitary ware

(including pipe); and slip casting in the

forming of plumbing fixtures and some

tableware. In addition to these

standard processes, jiggering is

employed in the manufacture of

tableware.

Jiggering involves the mixing of a

plastic mass and turning it on a wheel

beneath a template to a specified size

and shape.

Most whitewares are fired in continuous tunnel

kilns. The porous varieties are fired at lower

temperatures (1,100–1,250 °C, or approximately

2,000–2,300 °F), whereas china and true

porcelains are fired at 1,250 to 1,300 °C (2,300

to 2,400 °F).

Porous and semivitreous whitewares may be

glazed in a second firing to produce an

impermeable glass coating for decorative or

functional purposes.

One of the great advantages of the triaxial

composition of whitewares is that it makes

the formed piece relatively insensitive to

minor changes in composition and in firing

time or temperature. This stability is a

result of the wide range of temperatures

over which the three ingredients melt to

form glass.

As an example, in a typical feldspar-clay-silica

composition for porcelain, a whiteware with a

particularly high glassy component, small grains

of feldspar would begin to form liquid at

temperatures as low as 990 °C (1,810 °F), and

large feldspar grains would be molten by 1,140

°C (2,080 °F). Because of the high viscosity of the

liquid formed, there would be no change in the

shape of the ceramic piece until approximately

1,200 °C (2,200 °F).

Above this temperature the feldspar grains

would react with surrounding clay particles

to form glass, and “needles” of mullite (a

crystalline aluminosilicate mineral formed

during the firing of clay-silica mixtures)

would grow into the liquid regions. In

addition, the surfaces of silica particles

would begin to dissolve and form solution

rims, or envelopes of glass surrounding the

crystalline particle.

As more and more of the silica

particles dissolved, the resulting glass

would become increasingly viscous,

helping to maintain the integrity of the

piece.

Вам также может понравиться

- 2 Ceramics - WhitewaresДокумент5 страниц2 Ceramics - WhitewaresTristan James Sim100% (1)

- Firing of Porcelain TilesДокумент5 страницFiring of Porcelain TilesRajarshi Dionysus BhattacharyyaОценок пока нет

- Chapter#04 CeramicsДокумент19 страницChapter#04 CeramicsAfif Ajjan 210012101Оценок пока нет

- Glass IndustryДокумент40 страницGlass IndustrynОценок пока нет

- White Wares by K-H SchullerДокумент17 страницWhite Wares by K-H SchullerChuff123Оценок пока нет

- Effect of Soaking On Phase Composition and Topography and Surface MicrostructureДокумент9 страницEffect of Soaking On Phase Composition and Topography and Surface MicrostructureRafaelОценок пока нет

- Pozzolans PPT (Meghna)Документ63 страницыPozzolans PPT (Meghna)Meghna Prateek BhardwajОценок пока нет

- Group Members: Anjali Patwardhan Rajlaxmi Mandge Sakshi Kothari Dikshita Mutha Wahid Devra Sagar PardesiДокумент39 страницGroup Members: Anjali Patwardhan Rajlaxmi Mandge Sakshi Kothari Dikshita Mutha Wahid Devra Sagar PardesiDevyani TotlaОценок пока нет

- 7discuss Different Methods of Strengthening Ceramics1Документ74 страницы7discuss Different Methods of Strengthening Ceramics1Nallaiah venkatraman100% (1)

- CeramicsДокумент18 страницCeramicsMark William Almero Geron100% (1)

- Introduction To Glaze CalculationДокумент4 страницыIntroduction To Glaze CalculationThongMaVanОценок пока нет

- Innovative Building Materials: Presented byДокумент19 страницInnovative Building Materials: Presented byMuhamet AhmetiОценок пока нет

- 5 Ceramic and CementДокумент13 страниц5 Ceramic and CementAmzar MuhammadОценок пока нет

- Ceramics: Windows To The FutureДокумент75 страницCeramics: Windows To The FuturevishwanathanskОценок пока нет

- Chinese Ceramics Final DraftДокумент60 страницChinese Ceramics Final DraftEliezer HabaОценок пока нет

- The Recent Developments in Ceramic Glazes: September 2020Документ14 страницThe Recent Developments in Ceramic Glazes: September 2020SAMUEL PSALMОценок пока нет

- Charu Ceramics Industry LTDДокумент8 страницCharu Ceramics Industry LTDZareen Rashid ChoudhuryОценок пока нет

- Processing of CeramicsДокумент17 страницProcessing of CeramicsVikrant SharmaОценок пока нет

- Low Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewДокумент20 страницLow Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewMeiliza HastutiОценок пока нет

- G314 06 Prac2 Calculating CIPW NormsДокумент5 страницG314 06 Prac2 Calculating CIPW NormsTilahun MershaОценок пока нет

- Basic Slip CastingДокумент3 страницыBasic Slip Castingnataliebuffalo100% (1)

- Deformations in CeramicsДокумент6 страницDeformations in Ceramicsashutoshgoel100% (1)

- Slip CastingДокумент15 страницSlip CastingLuciano MagalhãesОценок пока нет

- Ceramics & Glass STUDENTS, 2018Документ20 страницCeramics & Glass STUDENTS, 2018aviОценок пока нет

- STA Decorating SlipДокумент2 страницыSTA Decorating SlipmohanОценок пока нет

- FeldsparДокумент7 страницFeldsparRiChy KantuОценок пока нет

- Silicate IndustryДокумент40 страницSilicate IndustryTamiru DerejeОценок пока нет

- Instructions CIPW NormДокумент6 страницInstructions CIPW NormJuanJo Ordoñez BolañosОценок пока нет

- Firing Without Signup and A Kiln Chart May Be Turned Off! Plan To Unload Your Kiln by 2Документ5 страницFiring Without Signup and A Kiln Chart May Be Turned Off! Plan To Unload Your Kiln by 2stueferОценок пока нет

- TOPIC 11 Composite Materials (Notes)Документ16 страницTOPIC 11 Composite Materials (Notes)Kaynine KikoОценок пока нет

- Curvature Evolution in Porcelain Tile During FiringДокумент12 страницCurvature Evolution in Porcelain Tile During Firingمحمد رمضانОценок пока нет

- Bubble Control in Ceramic GlazesДокумент17 страницBubble Control in Ceramic Glazesppaba30Оценок пока нет

- Business Plan Competition - VIJAY GДокумент11 страницBusiness Plan Competition - VIJAY GPraveen kumarОценок пока нет

- Fire More For Less PDFДокумент5 страницFire More For Less PDFJose Vicente Nuguid ErictaОценок пока нет

- Clay Packet GuideДокумент4 страницыClay Packet Guideapi-290985916100% (1)

- Raw Material PreperationДокумент6 страницRaw Material PreperationMuhammed EmamiОценок пока нет

- SeminarДокумент21 страницаSeminarsoukhya100% (1)

- Mixing Slip, Plaster Mold Fabrication, Slip-CastingДокумент4 страницыMixing Slip, Plaster Mold Fabrication, Slip-CastingLauraОценок пока нет

- Introduction To CeramicsДокумент29 страницIntroduction To CeramicsShrikrishna BirajdarОценок пока нет

- Properties Processing and Application ofДокумент20 страницProperties Processing and Application ofTushar AneyraoОценок пока нет

- Cement 2Документ106 страницCement 2CBIT CIVIL A1100% (1)

- Ceramics 1 MCG2361 2016Документ42 страницыCeramics 1 MCG2361 2016Jessica BarhomaОценок пока нет

- CIPW Norm Hollacher Norm4Документ2 страницыCIPW Norm Hollacher Norm4Lucas CabelierОценок пока нет

- Sintering of Ceramics-Overview PDFДокумент83 страницыSintering of Ceramics-Overview PDFEstelle Maurice-ArgentОценок пока нет

- Bricks and Shapes 2Документ6 страницBricks and Shapes 2nay den100% (1)

- Ceramic FritsДокумент2 страницыCeramic Fritslaklain100% (1)

- Analysis of Drying Process in Ceramic Tiles Industries Ijariie2063Документ10 страницAnalysis of Drying Process in Ceramic Tiles Industries Ijariie2063map vitcoОценок пока нет

- Engineering Ceramics - IntroductionДокумент62 страницыEngineering Ceramics - IntroductionPhilmona Samuel100% (1)

- Basic Info About Glaze FormulationsДокумент3 страницыBasic Info About Glaze FormulationsThongMaVanОценок пока нет

- CERAMICSДокумент25 страницCERAMICSKawaii SamaОценок пока нет

- Ceramic Tile Manufacturing Process PDFДокумент9 страницCeramic Tile Manufacturing Process PDFamirq4100% (2)

- Stoneware MaturityДокумент3 страницыStoneware MaturityLОценок пока нет

- CeramicsДокумент31 страницаCeramicsMuhammad FakhruddinОценок пока нет

- Chapter 1 Glass IndustryДокумент32 страницыChapter 1 Glass Industryد.حاتممرقه100% (1)

- IckДокумент22 страницыIckshahidul islamОценок пока нет

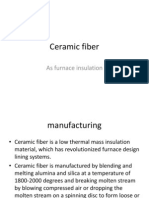

- Ceramic FiberДокумент9 страницCeramic FiberPriyatham GangapatnamОценок пока нет

- Slip CastingДокумент7 страницSlip CastingPradyumna PadukoneОценок пока нет

- Firing Defects: Home Education Glazes Materials Video Publications Software Links Main IndexДокумент1 страницаFiring Defects: Home Education Glazes Materials Video Publications Software Links Main IndexMainul Islam RafiОценок пока нет

- Dr. Rizwan ThesisДокумент168 страницDr. Rizwan ThesisSufian AhmadОценок пока нет

- WhitewareДокумент2 страницыWhitewareAngga Buledhbuledh PerdanaОценок пока нет

- All Ceramic1Документ15 страницAll Ceramic1Shu NserОценок пока нет

- Rocks Gems MineralsДокумент10 страницRocks Gems MineralsOwen CooperОценок пока нет

- 7 Grade 7 Art T G QTR 1 Mindanao Module 3 Les 1 and 2 AapДокумент8 страниц7 Grade 7 Art T G QTR 1 Mindanao Module 3 Les 1 and 2 AapSheilaBenavente100% (1)

- Islamic ArchitectureДокумент4 страницыIslamic ArchitectureseamajorОценок пока нет

- Test Admitere Cls 5 20201Документ2 страницыTest Admitere Cls 5 20201mihail cucurezeanuОценок пока нет

- Henri Matisse Egg Project Power Point 3-20-17Документ13 страницHenri Matisse Egg Project Power Point 3-20-17api-218373666Оценок пока нет

- Boegh Manual de Intaglio No ToxicoДокумент108 страницBoegh Manual de Intaglio No ToxicoJuan Carlos Bermúdez100% (2)

- Netherlands Art HistoryДокумент40 страницNetherlands Art HistoryIrina DamascanОценок пока нет

- EmbroideryStudio E2 Brochure English A4 Lowres v2Документ6 страницEmbroideryStudio E2 Brochure English A4 Lowres v2Harry SunrizeОценок пока нет

- National Artists of The PhilippinesДокумент36 страницNational Artists of The PhilippinesCharmaine MagnoОценок пока нет

- Module 4 Art AppreciationДокумент11 страницModule 4 Art Appreciationfrederick liponОценок пока нет

- Hammering Art To Save EarthДокумент7 страницHammering Art To Save EarthDrinu CamilleriОценок пока нет

- Batak Architecture 1Документ8 страницBatak Architecture 1Deebak TamilmaniОценок пока нет

- ARTSДокумент3 страницыARTSJudith MagnayeОценок пока нет

- Naram-Sin of AkkadДокумент4 страницыNaram-Sin of AkkadValentin MateiОценок пока нет

- Comisión Gestora de Las Pruebas de Acceso A La UniversidadДокумент6 страницComisión Gestora de Las Pruebas de Acceso A La UniversidadSanti Entre ParentesisОценок пока нет

- Capitol ComplexДокумент5 страницCapitol ComplexPrabhjot SinghОценок пока нет

- Muzharul Islam Archive - Fine Arts Institute, Dhaka University, BangladeshДокумент2 страницыMuzharul Islam Archive - Fine Arts Institute, Dhaka University, BangladeshAditya Niloy100% (2)

- With The Issuance of The Sedition Law.: The City Beautiful MovementДокумент7 страницWith The Issuance of The Sedition Law.: The City Beautiful MovementJane RicardelОценок пока нет

- Quantusum ExcerptДокумент120 страницQuantusum ExcerptAndrei Iacob100% (1)

- The Dezeen Guide To Contemporary Cemetery ArchitectureДокумент22 страницыThe Dezeen Guide To Contemporary Cemetery ArchitectureMarina RochaОценок пока нет

- Sir Christopher Wren: Presented byДокумент10 страницSir Christopher Wren: Presented byAnuj SomaniОценок пока нет

- LAS in Mapeh Week 1-2Документ2 страницыLAS in Mapeh Week 1-2Janrey Catuday ManceraОценок пока нет

- London Artefact Series: Clay Tobaco PipesДокумент4 страницыLondon Artefact Series: Clay Tobaco PipesUrban Archaeology: Chiz Harward71% (7)

- Cpar Week 1-20Документ72 страницыCpar Week 1-20Jamaica Minandang94% (18)

- CPAR PPT 3Документ26 страницCPAR PPT 3Wendy L. Gomez100% (1)

- AdjectivesДокумент1 страницаAdjectivessmiksОценок пока нет

- 1913-Butler-Ancient ArchitectureДокумент84 страницы1913-Butler-Ancient ArchitecturePaolo Bianchi100% (1)

- Seigniorage Charges PDFДокумент3 страницыSeigniorage Charges PDFAnand Kumar PandiriОценок пока нет

- DPS Quarterly Exam Grade 9Документ3 страницыDPS Quarterly Exam Grade 9Michael EstrellaОценок пока нет