Академический Документы

Профессиональный Документы

Культура Документы

Shell and Tube Heat Exchanger

Загружено:

Narayan Jaiswal0 оценок0% нашли этот документ полезным (0 голосов)

76 просмотров1 страницаDESIGN OPTIMIZATION HAS BEEN DONE IN PRESENT STUDY TO IMPROVE PERFORMANCE OF SHELL AND TUBE HEAT EXCHANGER.

Оригинальное название

SHELL AND TUBE HEAT EXCHANGER

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документDESIGN OPTIMIZATION HAS BEEN DONE IN PRESENT STUDY TO IMPROVE PERFORMANCE OF SHELL AND TUBE HEAT EXCHANGER.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

76 просмотров1 страницаShell and Tube Heat Exchanger

Загружено:

Narayan JaiswalDESIGN OPTIMIZATION HAS BEEN DONE IN PRESENT STUDY TO IMPROVE PERFORMANCE OF SHELL AND TUBE HEAT EXCHANGER.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Design and Optimization of Shell and Tube Heat Exchanger

Team number : G07

Team Member : Vivek Barot , Hardik Patel , Virpalsinh Raulji , Abhiraj Dhekale

Project Guide : Narayan Jaiswal

Co-Guide : Nimit Patel

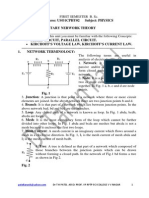

ABSTRACT LITERATURE REVIEW

RESULT

Heat exchangers are one of most P.S Gowthaman and S.Sathish [2]

important heat transfer apparatus analyzed of two different types of In STHX with helical baffle Changes

which are used in a process baffles in a Shell and tube heat in heat transfer & pressure drop

industries, nuclear power station, exchanger. The segmental baffle forces due to change in helix angle .

water reactor power plant etc. the liquid in a Zigzag flow and gives

Shell and tube heat exchanger less heat transfer and a high pressure Helix angle Heat Pressure

(STHX) are one of the most drop and also increases the fouling transfer(W/ drop(Pa)

versatile heat exchanger used in resistance whereas with helical baffle m².K)

industries. In STHX with the comparatively smooth flow over tube 90ᵒ 29185.63 0.0007

segmental baffle, dead zone is surface can be achieved that causes 10ᵒ 51608.91 631.27

created between the baffle end and effective increase in heat transfer

20ᵒ 34643.5 148.16

shell which causes reduction in heat coefficient and lowers the pressure

transfer and at baffle end more drop. The desirable feature of STHX is 30ᵒ 26880.12 58.89

resistance is created which causes to obtain a maximum heat transfer Helix H.T coefficient Pressure Ratio

drop in pressure. To overcome these coefficient and a lower pressure drop. angle (W/m².K) drop (Pa)

problems in present study, From the Numerical Experimentation 15 102.25 36.6 28.4 Improve above table insert your graph

analytical and HTRI analysis is done result the performance of heat

and results. Improve conclusions as our

for conventional segmental baffle exchanger is evaluated and

teletalk.

and helical baffle. Also analytical performance increase is found in 35 604.24 5.23 116.2

optimization for helical baffle is Helical Baffle instead of Segmental

also done. In STHX, the use of Baffle.

helical baffle reduces the pressure 45 403.73 36.72 109.9 CONCLUSIONS

drop due to smooth flow and

increases heat transfer. 1. In helical baffle heat exchanger

change in heat transfer and

INTRODUCTION pressure drop is depended on

helix angle .

2. Heat transfer coefficient are

Heat exchanger is a mechanical MODLING OF STHX

decrease gradually when we

device which transfers heat from incersesing helix angle .

hot fluid to clod fluid with

3. Pressure drop are increase

maximum rate of heat transfer.

gradually when we increasing

Conventional shell and tube heat

helix angle.

exchangers with segmental baffles

have low heat transfer co-efficient

due to the segmental baffle

arrangement causing high REFERENCES

resistance flow bypassing the heat 1. Sadik Kakac, Hongtan Liu, “Heat

transfer surface and high pressure exchangers- selection, rating and

drop that cause big problems for thermal design”, Department of

industries such as increase in Mechanical Engineering,

pumping costs. The hydrodynamic University of Miami, Coral

studies testing the heat transfer Gables, Florida, CRC press, 1998

(mean temperature difference) and

2. P.S.Gowthaman Ȧ and S.Sathish,

the pressure drop; with the help of

“Analysis of Segmental and

research facilities and industrial

Helical Baffle in Shell and

equipment have shown much better

tube Heat Exchanger”,

performance of helical baffle heat

International Journal of Current

exchangers as compared to the

Engineering and Technology

conventional ones. This results in

relatively high value of shell side 3. Edward S. Gaddis a, Volker

heat transfer coefficient, low Gnielinski b, “Pressure drop on

pressure drop, and low shell side the shell side of shell and tube

WORKING MODEL STHX heat exchangers with segmental

fouling [5].

baffle.”

4. H. Lia, V. Kottkeb, “ Analysis of

local shell side heat and mass

transfer in the shell and tube

heat exchanger with disc and

doughnut baffle”

5. Professor Sunilkumar Shinde ,

Mustansir Hatim Pancha

“Comparative Thermal

Performance Analysis Of

Segmental Baffle Heat Exchanger

with Continuous Helical Baffle

Heat Exchanger using Kern

method.”

RESEARCH POSTER PRESENTATION DESIGN © 2012

www.PosterPresentations.com

Вам также может понравиться

- Cutting A GemДокумент18 страницCutting A Gemmobsivac100% (1)

- WWW - Incar.tw-Kobelco SK 75 Service ManualДокумент5 страницWWW - Incar.tw-Kobelco SK 75 Service Manualpurnomo0% (1)

- Trade Skills Assessment GuideДокумент25 страницTrade Skills Assessment GuideRandz Lampa0% (1)

- 2019-Design of Helical Coil Heat Exchanger For A Mini Power Plant PDFДокумент11 страниц2019-Design of Helical Coil Heat Exchanger For A Mini Power Plant PDFAshish AgrawalОценок пока нет

- Ultrasonic TestingДокумент55 страницUltrasonic Testingdhasdj100% (1)

- Infiltration Ventilation LeakageДокумент42 страницыInfiltration Ventilation LeakageBulut YildizОценок пока нет

- 3 Design and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern Method PDFДокумент7 страниц3 Design and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern Method PDFserious96Оценок пока нет

- As 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisДокумент7 страницAs 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisSAI Global - APAC0% (1)

- 882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFДокумент6 страниц882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDavid Alemán Sánchez100% (1)

- Effectof Differenttypesof Baffleson Heat Transfer Pressure DropofДокумент6 страницEffectof Differenttypesof Baffleson Heat Transfer Pressure DropofiffatОценок пока нет

- Effectof Differenttypesof Baffleson Heat Transfer Pressure DropofДокумент6 страницEffectof Differenttypesof Baffleson Heat Transfer Pressure DropofAltamash MunirОценок пока нет

- Helical Baffle Design in Shell and Tube Type Heat Exchanger With CFD AnalysisДокумент6 страницHelical Baffle Design in Shell and Tube Type Heat Exchanger With CFD AnalysispriyabОценок пока нет

- 1 s2.0 S001793101734440X MainДокумент13 страниц1 s2.0 S001793101734440X Mainjaber saketОценок пока нет

- Cryogenics: Seungwhan Baek, Cheonkyu Lee, Sangkwon JeongДокумент13 страницCryogenics: Seungwhan Baek, Cheonkyu Lee, Sangkwon JeongDedi AfandiОценок пока нет

- Heat Transfer Enhancement of Circular Pipe Using Serrated Plate Inserts PG Con1Документ6 страницHeat Transfer Enhancement of Circular Pipe Using Serrated Plate Inserts PG Con1AJIT SHINDEОценок пока нет

- Applied Thermal Engineering: Saeed Mohebbi, Farzad VeysiДокумент12 страницApplied Thermal Engineering: Saeed Mohebbi, Farzad VeysizahiraОценок пока нет

- Wang 2007Документ9 страницWang 2007LỢI NGUYỄN CÔNGОценок пока нет

- Numerical Investigation of Thermal and Hydraulic Performance of Shell andДокумент11 страницNumerical Investigation of Thermal and Hydraulic Performance of Shell andSandro Chuqui PorteroОценок пока нет

- Effect of Baffle Spacing On The Performance of Shell and Tube Heat ExchangerДокумент15 страницEffect of Baffle Spacing On The Performance of Shell and Tube Heat ExchangerAhmed JamilОценок пока нет

- Experimental Thermal and Fluid Science: Bin Gao, Qincheng Bi, Zesen Nie, Jiangbo WuДокумент10 страницExperimental Thermal and Fluid Science: Bin Gao, Qincheng Bi, Zesen Nie, Jiangbo Wuannisa fitriОценок пока нет

- Effects of Baffle Inclination Angle On Flow and Heat Transfer of A Heat Exchanger With Helical BafflesДокумент10 страницEffects of Baffle Inclination Angle On Flow and Heat Transfer of A Heat Exchanger With Helical BafflesAhmad Restian Adi NugrohoОценок пока нет

- Yadav 2021Документ12 страницYadav 2021moontree1990Оценок пока нет

- Mathematical Modeling of Spiral Heat ExcДокумент4 страницыMathematical Modeling of Spiral Heat ExcKaleem UllahОценок пока нет

- 1-s2.0-S1359431123018689-mainДокумент18 страниц1-s2.0-S1359431123018689-mainTrọng HòaОценок пока нет

- International Journal of Heat and Technology: Received: 25 November 2019 Accepted: 6 November 2020Документ8 страницInternational Journal of Heat and Technology: Received: 25 November 2019 Accepted: 6 November 2020ethiopian art2020Оценок пока нет

- Effect of Corrugated Baffles On The Flow and Thermal Fields in A Channel Heat ExchangerДокумент10 страницEffect of Corrugated Baffles On The Flow and Thermal Fields in A Channel Heat Exchangermustafa11dahamОценок пока нет

- BAFFLE 3 in Heat ExchangerДокумент8 страницBAFFLE 3 in Heat ExchangerShariq KhanОценок пока нет

- Artigo 2 PDFДокумент10 страницArtigo 2 PDFIago HenriqueОценок пока нет

- Heat Transfer Analysis of A Helical Coil Heat Exchanger by Using CFD AnalysisДокумент6 страницHeat Transfer Analysis of A Helical Coil Heat Exchanger by Using CFD AnalysisPRAVEEN HОценок пока нет

- Louvre BafflesДокумент10 страницLouvre BafflesAbhishek kumarОценок пока нет

- L06030599107 PDFДокумент9 страницL06030599107 PDFBanksyОценок пока нет

- Ijeeet 0023 192 22 - 2Документ6 страницIjeeet 0023 192 22 - 2میلاد قاسمیОценок пока нет

- Enhancement of Heat Transfer Coefficient Through Helical CoilДокумент5 страницEnhancement of Heat Transfer Coefficient Through Helical CoilNaqqash SajidОценок пока нет

- Experimental Investigation of The Effect of BaffleДокумент5 страницExperimental Investigation of The Effect of BaffleAltamash MunirОценок пока нет

- 1 s2.0 S1359431108004845 MainДокумент6 страниц1 s2.0 S1359431108004845 Main1AdityaPathania1Оценок пока нет

- Processes 09 00939 v2Документ19 страницProcesses 09 00939 v2selisenОценок пока нет

- Baffle6 in A Shell and Tube Heat ExchangerДокумент12 страницBaffle6 in A Shell and Tube Heat ExchangerShariq KhanОценок пока нет

- For NCAIDCAE by AdilДокумент18 страницFor NCAIDCAE by AdilAadil AhmadОценок пока нет

- Mixed Brazed Plate Heat ExchangersДокумент14 страницMixed Brazed Plate Heat ExchangersFurkan YildirimОценок пока нет

- Asymmetric Plate Heat Ex ChangersДокумент4 страницыAsymmetric Plate Heat Ex ChangersfcadavidОценок пока нет

- IRJET Spiral CoilДокумент10 страницIRJET Spiral CoilRithwik pawarОценок пока нет

- Numerical investigation of convective heat transfer and pressure loss in a round tube fitted with circular-ring turbulatorsДокумент6 страницNumerical investigation of convective heat transfer and pressure loss in a round tube fitted with circular-ring turbulatorsGanesh BodakheОценок пока нет

- Improve Exchanger Efficiency with Tube EnhancementДокумент3 страницыImprove Exchanger Efficiency with Tube Enhancementaegean227Оценок пока нет

- Design Optimization of HB-STHEДокумент9 страницDesign Optimization of HB-STHEUsman KhanОценок пока нет

- International Journal of Thermal Sciences: M.A. Akhavan-Behabadi, Ravi Kumar, M.R. Salimpour, R. AzimiДокумент7 страницInternational Journal of Thermal Sciences: M.A. Akhavan-Behabadi, Ravi Kumar, M.R. Salimpour, R. AzimiIrene Lara AbadОценок пока нет

- Applied Thermal Engineering: Orhan Ayd In, Burak Markal, Mete Avc IДокумент7 страницApplied Thermal Engineering: Orhan Ayd In, Burak Markal, Mete Avc IRevian Arief PutraОценок пока нет

- Heat Exchanger ModelingДокумент8 страницHeat Exchanger ModelingwameathОценок пока нет

- 1 s2.0 S1359431122011401 MainДокумент14 страниц1 s2.0 S1359431122011401 MainTanti ArdiyatiОценок пока нет

- AnushaДокумент6 страницAnushaElemental Hero GaiaОценок пока нет

- Heat Exchanger Sample Report 2018manish3Документ39 страницHeat Exchanger Sample Report 2018manish3RahulSrivastavaОценок пока нет

- Design of Shell and Tube Type Heat Exchanger Using CFD ToolsДокумент4 страницыDesign of Shell and Tube Type Heat Exchanger Using CFD Toolsanil kasotОценок пока нет

- Twisted Oval Tube Heat Exchanger PerformanceДокумент10 страницTwisted Oval Tube Heat Exchanger PerformanceRohan PrajapatiОценок пока нет

- Design and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern MethodДокумент7 страницDesign and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern MethodIJAERS JOURNALОценок пока нет

- Experiments On A Crossflow Heat Exchanger With Tubes of Lenticular ShapeДокумент5 страницExperiments On A Crossflow Heat Exchanger With Tubes of Lenticular ShapeNacer ben abbesОценок пока нет

- Numerical Studies of A Double-Pipe Helical Heat Exchanger: Timothy J. Rennie, Vijaya G.S. RaghavanДокумент8 страницNumerical Studies of A Double-Pipe Helical Heat Exchanger: Timothy J. Rennie, Vijaya G.S. Raghavan1AdityaPathania1Оценок пока нет

- Heat Exchanger Design - Part 1Документ26 страницHeat Exchanger Design - Part 1Siddhant SoymonОценок пока нет

- Transformer thermal modelling benchmarkДокумент4 страницыTransformer thermal modelling benchmarkdiogoufrn-1Оценок пока нет

- General Steady State Model for Fin-and-Tube Heat ExchangersДокумент9 страницGeneral Steady State Model for Fin-and-Tube Heat ExchangersLỢI NGUYỄN CÔNGОценок пока нет

- Heat Exchanger With Helical BafflesДокумент8 страницHeat Exchanger With Helical BaffleshuangjlОценок пока нет

- 3D Analysis of LHPДокумент11 страниц3D Analysis of LHPArjun ChaliyathОценок пока нет

- 4 Estudo Do Desenpenho Do Trocador de Calor Via CFDДокумент16 страниц4 Estudo Do Desenpenho Do Trocador de Calor Via CFDMaribel ValverdeОценок пока нет

- Shell and Tube Heat Exchanger - The Heat Transfer Area Design ProcessДокумент12 страницShell and Tube Heat Exchanger - The Heat Transfer Area Design ProcessMuhammadAsimОценок пока нет

- tanimizu2012Документ7 страницtanimizu2012mshah222Оценок пока нет

- Research Article: Thermohydraulic Analysis of Shell-and-Tube Heat Exchanger With Segmental BafflesДокумент6 страницResearch Article: Thermohydraulic Analysis of Shell-and-Tube Heat Exchanger With Segmental BafflesYADAV ANIL KUMARОценок пока нет

- 35.02 21Документ10 страниц35.02 21tesfayОценок пока нет

- 200E ManualДокумент56 страниц200E ManualManoj KrishnanОценок пока нет

- Stop Motion Pre Production - Negotiated BriefДокумент10 страницStop Motion Pre Production - Negotiated Briefp4nd3m0n1c100% (1)

- TASK 1 Physics Class XI: (Do Always Any Five Numerical Problems Related To The Chapter)Документ3 страницыTASK 1 Physics Class XI: (Do Always Any Five Numerical Problems Related To The Chapter)frank 101Оценок пока нет

- Bel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Документ5 страницBel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Palani AppanОценок пока нет

- Earth Gravity and Satellite Orbits CalculationsДокумент9 страницEarth Gravity and Satellite Orbits CalculationsYoobsan Asaffaa FufaaОценок пока нет

- Flow Charts Option: StartДокумент13 страницFlow Charts Option: StartbalabooksОценок пока нет

- 460 (Part-2)Документ16 страниц460 (Part-2)rambinod0% (1)

- Electrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caДокумент9 страницElectrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caTimothy Murray HenleyОценок пока нет

- Wrf736sdam14 - Tech - Sheet - W10811276 - Rev - B Otro Modelo de La Nevera de Oliva OcoaДокумент5 страницWrf736sdam14 - Tech - Sheet - W10811276 - Rev - B Otro Modelo de La Nevera de Oliva OcoaEdison EspinalОценок пока нет

- Dual Band Mobile Phone Service ManualДокумент40 страницDual Band Mobile Phone Service Manualأبو عبد الرحمان زهيرОценок пока нет

- GEC - Sample Resume For StudentsДокумент2 страницыGEC - Sample Resume For StudentsNiketОценок пока нет

- FTS ScaleoEUserManualEN 10 1082177Документ2 044 страницыFTS ScaleoEUserManualEN 10 1082177JОценок пока нет

- Jeepney Demand and Supply in Baguio CityДокумент19 страницJeepney Demand and Supply in Baguio CityJanna CrowОценок пока нет

- Rectify Binary Plate Efficiency BubblesДокумент4 страницыRectify Binary Plate Efficiency BubblesCsaba AndrásОценок пока нет

- Maximum Power Tracking System for Solar Panels Using Automatic ControlДокумент79 страницMaximum Power Tracking System for Solar Panels Using Automatic ControlHarish VarmaОценок пока нет

- Us01cphy02 Unit 1 2014 THPДокумент18 страницUs01cphy02 Unit 1 2014 THPapi-264723824Оценок пока нет

- Hdfs Default XML ParametersДокумент14 страницHdfs Default XML ParametersVinod BihalОценок пока нет

- Structural Analysis of Beams Using Moment Distribution MethodДокумент15 страницStructural Analysis of Beams Using Moment Distribution MethodneetuОценок пока нет

- Whatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Документ6 страницWhatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Kuningan NesiaОценок пока нет

- Physicaltestingofrubberrogerbrown2006 Book 150514103634 Lva1 App6892Документ389 страницPhysicaltestingofrubberrogerbrown2006 Book 150514103634 Lva1 App6892AbdelhamidHarratОценок пока нет

- Vacuum Chill BlockДокумент2 страницыVacuum Chill BlockAditheya Varthan MОценок пока нет

- 3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureДокумент4 страницы3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureMohammed MustafaОценок пока нет

- PactFocus Report - Sample - LPGДокумент27 страницPactFocus Report - Sample - LPGIqbal HussainОценок пока нет

- Strahlenfolter Stalking - TI - Baker - UK Targeted Individuals Activism & Safety Watch - February 2013 - UktargetedindividualsДокумент3 страницыStrahlenfolter Stalking - TI - Baker - UK Targeted Individuals Activism & Safety Watch - February 2013 - UktargetedindividualsKarl-Hans-RohnОценок пока нет