Академический Документы

Профессиональный Документы

Культура Документы

Chemical Engineering Plant Design: Hazards Considerations

Загружено:

Muhammad Bilal0 оценок0% нашли этот документ полезным (0 голосов)

8 просмотров23 страницыОригинальное название

Lecture 3

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

8 просмотров23 страницыChemical Engineering Plant Design: Hazards Considerations

Загружено:

Muhammad BilalАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 23

Chemical Engineering Plant

Design

HAZARDS CONSIDERATIONS

Dr. M. Azam Saeed

HEALTH AND SAFETY HAZARDS

• The potential health hazard to an individual by a material

used in any chemical process is a function of

1. Inherent toxicity of the material

2. Frequency and duration of exposure.

• A highly toxic material that causes immediate injury is

classified as a safety hazard.

• Material whose effect is only apparent after long exposure

at low concentrations is considered as an industrial health

and hygiene hazard.

Assignment:

Health and safety hazards symbols with their

description

Contd..

• The inherent toxicity of a material is measured by tests

on animals.

• The short-term effect is expressed as LD 50.

• Lethal dose at which 50 percent of the test animals do

not survive.

• The permissible limits of concentration for the long-term

exposure of humans to toxic materials is set by the

threshold limit value (TLV).

• TLV is defined as the upper permissible concentration

limit of the material believed to be safe for humans even

with an exposure of 8 hr per day, 5 days per week over a

period of many years.

• Recommended TLV values are published by

1. Occupational Safety and Health Agency(OSHA)

2. American Conference of Governmental Industrial

Hygienists (ACGIH)

3. American Industrial Hygiene Association (AIHA)

4. National Institute for Occupational Safety and Health

(NIOSH)

5. United Kingdom Health and Safety Executive (HSE).

Sources of Exposure:

• The most common and most significant source of

workplace exposure to chemicals and also the most

difficult to control is inhalation.

• Workers become exposed when the contaminant is

picked up by the air they breathe.

• understanding of the sources of contaminants to which

workers are exposed is important for the recognition,

evaluation, and control of occupational health hazards.

For example

1. mechanical abrasions of solid materials by cutting.

2. Liquid aerosols, on the other hand, may be produced by

any process that supplies sufficient energy to overcome

the surface tension of the liquid.

• A significant source of mercury poisoning is from worker

exposure in laboratories where mercury has been spilled,

trapped in cracks, and then evaporates at room

temperature to exceed the TLV of 0.05 m g/m 3.

• Contamination of air with gas occurs from fugitive

emissions (leaks) or from venting.

• High-value and very toxic materials are usually very

tightly controlled.

• Contaminants that are neither valuable nor toxic but that

create an undesirable atmosphere in neighboring

communities are also controlled to maintain good public

relations.

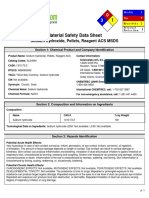

Exposure Evaluation:

• If health hazards are to be controlled, they must be

recognized and evaluated.

• An estimate of the toxicity or intrinsic hazard is needed

for each material identified in the inventory.

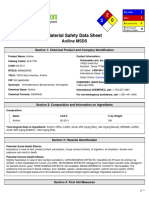

• Such information for many chemicals in the form of a

Material Safety Data Sheet (MSDS).

• To perform a risk assessment and then prioritize the

exposure measurement effort requires an approximate

initial exposure potential assessment.

• It is generally not necessary to make an exposure

estimate for every chemical/exposure source

combination.

• The most commonly used methods for the analysis of

airborne contaminants are listed in Table 2.

Exposure-Hazard Control:

• when exposure problem exists, decisions need to be

made regarding the implementation of hazard-control

measures for the purpose of reducing exposure.

• Decision must be made relative to the degree of risk

reduction that is to be attained.

• series of choices must be made from a wide range of

options available to achieve the desired risk reduction.

• These are three general control principles utilized in

reducing the exposure of workers to occupational health

hazards

Contd..

1. source controls,

2. transmission barriers

3. personal protection

• Basic or detailed changes in the way the process is

permitted to operate can eliminate or reduce exposure.

• The primary purpose of local exhaust ventilation is to

control contaminant exposure by establishing a control

surface or barrier.

• Local exhaust ventilation is cumbersome, inconvenient,

and requires considerable maintenance.

• Dilution ventilation, on the other hand, removes air

containing a contaminant from the workplace.

• The objective of dilution ventilation is not to prevent any

exposure, but to keep the exposure to acceptable levels

by dilution.

• Various control options or combinations of options need

to be selected to reduce the evaluated exposure level to

an acceptable one.

• The best option or combination of options is then

selected by means of a cost analysis.

• Measurements of exposure, for use in comparison with

occupational-exposure limits, need to be made over the

averaging time appropriate to the standard.

Fire and Explosion Hazards:

• Fire and explosion are the two most dangerous events

likely to occur in a chemical plant.

• These two hazards account for the major loss of life and

property in the chemical and petroleum industry.

• For a fire to occur, there must be

1. a fuel

2. an oxidizer

3. an ignition source

• The minimum concentration of fuel in air required for

ignition at ambient temperature is known as the lower

flammable limit (LFL).

Contd..

• Any mixture of fuel and air below the LFL is too lean to burn.

• concentration above which ignition will not occur is labeled

as the upper flammable limit (UFL).

• Concentration of oxidizer that must be present for ignition,

called the limiting oxygen index.

• The temperature at which ignition will occur without the

presence of a spark or flame is designated as the auto

ignition temperature (AIT).

• The liquid temperature at which the concentration of the

fuel in the air becomes large enough to ignite is labeled the

flash-point.

• An explosion is a sudden and generally catastrophic

release of energy, causing a pressure wave.

• An explosion can occur without a fire, such as the failure

through overpressure of a steam boiler.

• In a detonation, the chemical reaction propagates at

supersonic velocity and the principal heating mechanism

is shock compression.

• In a deflagration, the combustion process is the same as

in the normal burning of a flammable mixture with the

reaction propagating at subsonic velocity and

experiencing a slow pressure buildup.

• An explosion can result from a purely

1. physical reaction

2. a chemical

3. a nuclear reaction

• In boiling-liquid-expanding-vapor explosion(BLEVE) heat

leak into a container filled with a boiling liquid results in

an excessive vaporization accompanied with a steady

pressure buildup that ruptures the tank.

• Unconfined-vapor-cloud explosion (UVCE) can result

when a large cloud of gas or vapor forms following

release of a flammable material.

The ignition sensitivity depends on

• the ignition temperature

• the minimum ignition energy

• minimum explosion concentration

The explosion severity, on the other hand, is a function of

• the maximum pressure measured during a test explosion

• maximum rate of pressure rise during the test.

Possible sources of fire are reduced by eliminating all

unnecessary ignition sources.

The installation of sufficient fire alarms, temperature

alarms, fire-fighting equipment, and sprinkler systems

must be specified in the design.

Classification

Fires are classified into four groups

Class A fires are those burning ordinary solids.

Class B fires are those burning liquids or gases.

Class C fires are those that burn either Class A or Class B

fuels in the presence of live electrical circuits.

Class D fires consume metals.

Contd..

Fire-protection systems can be divided into two large

categories

• Passive

Passive fire-protection systems do not require

any action at the time of the fire. They are designed and

installed at the time the plant is built and remain passively

in place until needed.

• Active

Active systems include such agents as water

sprays, foam, and dry chemicals; these require that some

action be taken, either by plant personnel or as a response

by an automatic fire-protection system.

Design

Equipment should be designed to meet the specifications

and codes of recognized authorities such as

• the American Standards Association

• American Petroleum Institute

• American Society for Testing Materials

• Factory Mutual Laboratories

• National Fire Protection Association

• Underwriters’ Laboratories.

• Possible sources of fire are reduced by eliminating all

unnecessary ignition sources, such as flames, sparks, or

heated materials. Matches, smoking, welding and

cutting, static electricity.

Personnel Safety

• Every attempt should be made to incorporate facilities

for health and safety protection of plant personnel in the

original design.

• This includes, but is not limited to, protected walkways,

platforms, stairs, and work areas.

• Physical hazards, if unavoidable, must be clearly defined.

• In such areas, means for egress must be unmistakable.

• All machinery must be guarded with protective devices.

• In all cases, medical services and first-aid must be readily

available for all workers.

• Occupational Safety and Health Act

• Two of the standards directly related to worker health

and important in design work are Toxic Hazardous

Substances and Occupational Noise Exposure.

• The first of these two concerns the normal release of

toxic and carcinogenic substances, carried via vapors,

fumes, dust fibers, or other media.

LOSS PREVENTION

• The phrase loss prevention in the chemical industry is

an insurance term where the loss represents the financial

loss associated with an accident.

• This loss not only represents the cost of repairing or

replacing the damaged facility and taking care of all

damage claims, but also includes the loss of earnings

from lost production during the repair period and any

associated lost sales opportunities.

• Identification and assessment of the major hazards.

• Control of the hazards by the most appropriate means;

for example, containment, substitution, improved

maintenance, etc.

• Control of the process, i.e., prevention of hazardous

conditions in process operating variables by utilizing

automatic control and relief systems, interlocks, alarms,

etc.

• Limitation of the loss when an incident occurs.

Вам также может понравиться

- Control MeasuresДокумент52 страницыControl MeasuresAaron Jhan PerezОценок пока нет

- HAZARDOUS AREA CLASSIFICATION - UpdatedДокумент132 страницыHAZARDOUS AREA CLASSIFICATION - Updatedabdelrahman MohamedОценок пока нет

- Service Manual Hx220Nl: Section 1 GeneralДокумент41 страницаService Manual Hx220Nl: Section 1 Generalsonjisahuri100% (1)

- 1968 US Army Vietnam War Field Fortifications 132pДокумент131 страница1968 US Army Vietnam War Field Fortifications 132pwwwsurvivalebookscom50% (4)

- Ammunition and Explosives Safety Standards August 1997Документ185 страницAmmunition and Explosives Safety Standards August 1997Forum Pompierii100% (1)

- Blast Load of Building StructureДокумент8 страницBlast Load of Building StructurePetr KonupčíkОценок пока нет

- ETP Risk AssesmentДокумент20 страницETP Risk Assesmentvikkas verma0% (1)

- Ambulatory Surgery Center Safety Guidebook: Managing Code Requirements for Fire and Life SafetyОт EverandAmbulatory Surgery Center Safety Guidebook: Managing Code Requirements for Fire and Life SafetyОценок пока нет

- The Chemistry of ExplosionsДокумент7 страницThe Chemistry of ExplosionsJJ Lim100% (1)

- Chapter 5 - The Auto Shop SafetyДокумент10 страницChapter 5 - The Auto Shop Safetypapipapii0% (1)

- Activity 1 - Safety in The Clinical LaboratoryДокумент12 страницActivity 1 - Safety in The Clinical LaboratoryJulliene DadoleОценок пока нет

- Ch2-General Design Considerations Week2Документ61 страницаCh2-General Design Considerations Week2ميثة الغيثيةОценок пока нет

- Technical Advisory For Safe Operation of Lifting EquipmentДокумент22 страницыTechnical Advisory For Safe Operation of Lifting EquipmentErlet ShaqeОценок пока нет

- Section 1 Explosive Atmospheres 07-2017 Rev 3Документ17 страницSection 1 Explosive Atmospheres 07-2017 Rev 3kingmltОценок пока нет

- The Quantitative Assessment of Domino EfДокумент14 страницThe Quantitative Assessment of Domino EfAndrzej BąkałaОценок пока нет

- Chemical Spill ManagementДокумент35 страницChemical Spill ManagementArielen Magno Bismar100% (1)

- Taliban in AfghanistanДокумент9 страницTaliban in AfghanistanMuhammad BilalОценок пока нет

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesОт EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesОценок пока нет

- MSDS NaohДокумент6 страницMSDS NaohNiko yuga ade putraОценок пока нет

- Health Safety & Environmnetal ChallengesДокумент13 страницHealth Safety & Environmnetal ChallengesSantosh Mhatre88% (8)

- AS 2187 - Terminology PDFДокумент29 страницAS 2187 - Terminology PDFkrainaoz2011Оценок пока нет

- Cpde 3aДокумент172 страницыCpde 3aAbdul HaseebОценок пока нет

- General Design ConsiderationsДокумент37 страницGeneral Design ConsiderationsArif AmancioОценок пока нет

- Process Economics: BY Akhilesh GuptaДокумент7 страницProcess Economics: BY Akhilesh GuptaakhileshguptamnreОценок пока нет

- Understanding: Intrinsic SafetyДокумент14 страницUnderstanding: Intrinsic SafetyParidhi GargОценок пока нет

- Ome754 Industrial Safety - Unit III NotesДокумент87 страницOme754 Industrial Safety - Unit III Notesraghul balaОценок пока нет

- Chemical Engineering Plant Design: Process Plant Hazards and SafetyДокумент50 страницChemical Engineering Plant Design: Process Plant Hazards and SafetyAbdul RehmanОценок пока нет

- Chemical Engineering Plant Design: Process Plant Hazards and SafetyДокумент50 страницChemical Engineering Plant Design: Process Plant Hazards and SafetyadnanОценок пока нет

- Lecture 3Документ26 страницLecture 3Anusha DesaiОценок пока нет

- 03 Industrial HygieneДокумент50 страниц03 Industrial HygieneSaniha Aysha AjithОценок пока нет

- Industrial SafetyДокумент23 страницыIndustrial SafetysumitОценок пока нет

- Introduction To Chemical Process Safety: Instructor: Dr. Tamaghna Chakraborti Ph. No.: +91 9892770980Документ44 страницыIntroduction To Chemical Process Safety: Instructor: Dr. Tamaghna Chakraborti Ph. No.: +91 9892770980Ishaat HussainОценок пока нет

- Environmental and Safety Aspects in Process IndustriesДокумент6 страницEnvironmental and Safety Aspects in Process Industriesyadavsuyash007Оценок пока нет

- I Am Sharing 'Industrial Hygiene 1' With YouДокумент27 страницI Am Sharing 'Industrial Hygiene 1' With YouFAISAL DESHPANDEОценок пока нет

- Chapter-2: Industrial Hygiene Prepared by Tarik HisheДокумент44 страницыChapter-2: Industrial Hygiene Prepared by Tarik Hishezinabu weldebrhanОценок пока нет

- Industrial Causes of FireДокумент24 страницыIndustrial Causes of FireMantı BaxisovaОценок пока нет

- 2 Risk Assessment Methodology-1Документ7 страниц2 Risk Assessment Methodology-1Eman fatimaОценок пока нет

- Chapter 23 External Forces TerrorismДокумент30 страницChapter 23 External Forces TerrorismPhilanderGereenPiniliОценок пока нет

- S-Self-Heating Substances Haz Risk MinДокумент3 страницыS-Self-Heating Substances Haz Risk MinSilvi DelaОценок пока нет

- Hazard and Risk Management - Sarika MamДокумент24 страницыHazard and Risk Management - Sarika MamSharon DsouzaОценок пока нет

- INDG254 CHEMICAL REACTION HAZARDS and The Risk of THERMAL Runaway PDFДокумент9 страницINDG254 CHEMICAL REACTION HAZARDS and The Risk of THERMAL Runaway PDFJayaprakasan Koyadan KorothОценок пока нет

- Post Contract Corporate Health, Safety Policy On Respiratory Infections Group One 1.5410 . 2.54 .. 3.54 . 4.54 5.54 .Документ24 страницыPost Contract Corporate Health, Safety Policy On Respiratory Infections Group One 1.5410 . 2.54 .. 3.54 . 4.54 5.54 .E-Lie NarteyОценок пока нет

- 2nd Assignment Progress-HoangThanh (May 31)Документ97 страниц2nd Assignment Progress-HoangThanh (May 31)Nguyễn Hoàng ThànhОценок пока нет

- Control Measures of Chemical Hazard.. Gondaleeya DevangДокумент17 страницControl Measures of Chemical Hazard.. Gondaleeya DevangDevang GondaliyaОценок пока нет

- P Safety Ekc367 - 1pdfДокумент10 страницP Safety Ekc367 - 1pdfAdawiyah Az-zahraОценок пока нет

- Week 1: Che 61403 Safety in Process Plant DesignДокумент31 страницаWeek 1: Che 61403 Safety in Process Plant DesignPorkkodi SugumaranОценок пока нет

- Chemical Hazard and Safety Data SheetДокумент54 страницыChemical Hazard and Safety Data Sheetudemeb93Оценок пока нет

- Group7, BoshДокумент26 страницGroup7, Boshhernandez rayven p.Оценок пока нет

- Industrial HygieneДокумент50 страницIndustrial HygieneNURUL YAHSIFAH SYQELLA BINTI YAHYA BK21110100Оценок пока нет

- Industrial Engineering, Work-Study & Ergonomics: Assignment 1Документ25 страницIndustrial Engineering, Work-Study & Ergonomics: Assignment 1Mard GeerОценок пока нет

- Process Design I General Design ConsiderationДокумент29 страницProcess Design I General Design ConsiderationTowfiq AhmedОценок пока нет

- OME754 INDUSTRIALSAFETY-Unit II NotesДокумент106 страницOME754 INDUSTRIALSAFETY-Unit II Notesraghul balaОценок пока нет

- GHJGHJДокумент37 страницGHJGHJJust TmyОценок пока нет

- Industrial and Environmental Safety Lec 1Документ53 страницыIndustrial and Environmental Safety Lec 1AnnieMalikОценок пока нет

- 6.1 Material-Safety-Data-SheetДокумент5 страниц6.1 Material-Safety-Data-Sheetoussama achouriОценок пока нет

- Topic Six: Health Assessment & SurveillanceДокумент29 страницTopic Six: Health Assessment & Surveillancesrkam100% (1)

- Industrial Hygiene 2 PresentationДокумент19 страницIndustrial Hygiene 2 PresentationYashini DussoyeОценок пока нет

- PROJECTДокумент23 страницыPROJECTMsc StudentsОценок пока нет

- GC 2 Element 7Документ25 страницGC 2 Element 7vidya sagar boddetiОценок пока нет

- Cpe 561Документ19 страницCpe 561Akpan Anthonia AthanasiusОценок пока нет

- Under The GHS, Proper Labeling Is Composed of The Following Elements and Their Respective DefinitionsДокумент19 страницUnder The GHS, Proper Labeling Is Composed of The Following Elements and Their Respective DefinitionsJabin Sta. TeresaОценок пока нет

- Hse Emergency Preparedness and ResponseДокумент6 страницHse Emergency Preparedness and ResponsenagaaОценок пока нет

- 413 Building CosДокумент13 страниц413 Building CosepocyberОценок пока нет

- Chp. 4 - Hazards Identification: Faculty of Chemical Engineering Universiti Teknologi MARAДокумент39 страницChp. 4 - Hazards Identification: Faculty of Chemical Engineering Universiti Teknologi MARACaratsSVTОценок пока нет

- Safety: Student Name: Ismahil Mahmood Ismahil Course: Safety Instructor: Dr. Haval Date: 28/6/2020Документ14 страницSafety: Student Name: Ismahil Mahmood Ismahil Course: Safety Instructor: Dr. Haval Date: 28/6/2020Jameel Gorgees TomaОценок пока нет

- Scope and Background: Environmental Health and SafetyДокумент6 страницScope and Background: Environmental Health and SafetyJedel ReyesОценок пока нет

- SOP Flammable and Combustible Liquids: Doc: AAP/HR/EOHS/SP/FCL/00Документ2 страницыSOP Flammable and Combustible Liquids: Doc: AAP/HR/EOHS/SP/FCL/00Neeraj TomerОценок пока нет

- Safety in LaboratoryДокумент19 страницSafety in LaboratoryasfgegfОценок пока нет

- INDUSTRIAL HAZARDS AND THEIR SAFETY NotesДокумент15 страницINDUSTRIAL HAZARDS AND THEIR SAFETY NotesSimna RamesanОценок пока нет

- Chemical & Industrial Disasters: Prevention, Preparedness & ManagementДокумент23 страницыChemical & Industrial Disasters: Prevention, Preparedness & ManagementAnkur SharmaОценок пока нет

- Hazard CommunicationДокумент57 страницHazard CommunicationClaude De GuzmanОценок пока нет

- Health and Safety HazardsДокумент4 страницыHealth and Safety HazardsAbdullah IshaqОценок пока нет

- Plant For Pakistan DriveДокумент1 страницаPlant For Pakistan DriveMuhammad BilalОценок пока нет

- Eng EveДокумент1 страницаEng EveMuhammad BilalОценок пока нет

- (Revised) Admission To 1ST Year Classes EtcДокумент2 страницы(Revised) Admission To 1ST Year Classes EtcMuhammad BilalОценок пока нет

- Page No. 9, 10 SF.4Документ2 страницыPage No. 9, 10 SF.4Muhammad BilalОценок пока нет

- Math EveДокумент1 страницаMath EveMuhammad BilalОценок пока нет

- Lec 6Документ25 страницLec 6Muhammad BilalОценок пока нет

- Mathematics EveningДокумент1 страницаMathematics EveningMuhammad BilalОценок пока нет

- Eng EveДокумент1 страницаEng EveMuhammad BilalОценок пока нет

- Lec 1Документ21 страницаLec 1Muhammad BilalОценок пока нет

- Lec 2Документ22 страницыLec 2Muhammad BilalОценок пока нет

- Lec 3Документ34 страницыLec 3Muhammad BilalОценок пока нет

- Lec 4Документ21 страницаLec 4Muhammad BilalОценок пока нет

- Again, It's Been A Pleasure Being With You All Today. Thank YouДокумент1 страницаAgain, It's Been A Pleasure Being With You All Today. Thank YouMuhammad BilalОценок пока нет

- 19 - GULSHAN - v22 - 2 - Wint2015Документ14 страниц19 - GULSHAN - v22 - 2 - Wint2015Muhammad BilalОценок пока нет

- Indian Afghanishtan 3Документ40 страницIndian Afghanishtan 3Aadhya ChhabraОценок пока нет

- Afghanistan Post Taliban GovernanceДокумент106 страницAfghanistan Post Taliban GovernanceMuhammad BilalОценок пока нет

- To Whom It May Concern: H.R Cadet College JhangДокумент1 страницаTo Whom It May Concern: H.R Cadet College JhangMuhammad BilalОценок пока нет

- Again, It's Been A Pleasure Being With You All Today. Thank YouДокумент1 страницаAgain, It's Been A Pleasure Being With You All Today. Thank YouMuhammad BilalОценок пока нет

- Politics of Federalism in Pakistan: Problems and Prospects: January 2013Документ16 страницPolitics of Federalism in Pakistan: Problems and Prospects: January 2013Muhammad BilalОценок пока нет

- An Intractable Challenge: Managing Civil Military Relations After The Election 2018Документ7 страницAn Intractable Challenge: Managing Civil Military Relations After The Election 2018Muhammad BilalОценок пока нет

- DraftДокумент11 страницDraftMuhammad BilalОценок пока нет

- FP 20210929 Afghanistan TranscriptДокумент21 страницаFP 20210929 Afghanistan TranscriptMuhammad BilalОценок пока нет

- South Asia Brief.: Women-And-SportДокумент2 страницыSouth Asia Brief.: Women-And-SportMuhammad BilalОценок пока нет

- Ghazi University, D. G. Khan: Administrative/Non Teaching/otherДокумент2 страницыGhazi University, D. G. Khan: Administrative/Non Teaching/otherMuhammad BilalОценок пока нет

- Research Article On AfghanistanДокумент16 страницResearch Article On AfghanistanMuhammad BilalОценок пока нет

- Politics of Federalism in Pakistan: Problems and Prospects: January 2013Документ16 страницPolitics of Federalism in Pakistan: Problems and Prospects: January 2013Muhammad BilalОценок пока нет

- Cultures of PakistanДокумент15 страницCultures of PakistanhassantahirkhanОценок пока нет

- An Intractable Challenge: Managing Civil Military Relations After The Election 2018Документ7 страницAn Intractable Challenge: Managing Civil Military Relations After The Election 2018Muhammad BilalОценок пока нет

- Pols 335: Muslim Political Thought: Course DescriptionДокумент4 страницыPols 335: Muslim Political Thought: Course DescriptionMuhammad BilalОценок пока нет

- DPP (37 To) PCДокумент54 страницыDPP (37 To) PCRaju SinghОценок пока нет

- PMR Motorola T280 User ManualДокумент22 страницыPMR Motorola T280 User Manualpinavi18600% (1)

- rr036 OkДокумент440 страницrr036 OkangeljosОценок пока нет

- Protego 2020 - 21Документ429 страницProtego 2020 - 21jleonclau1Оценок пока нет

- Natural Disasters Prevention, Risk Factors and Management (Biljana Raskovic, Svetomir Mrdja) PDFДокумент374 страницыNatural Disasters Prevention, Risk Factors and Management (Biljana Raskovic, Svetomir Mrdja) PDFMarcio LeãoОценок пока нет

- DOCK Explosive Aspect of Port Emg PlannigДокумент2 страницыDOCK Explosive Aspect of Port Emg PlannigVignesh KmОценок пока нет

- Sodium BorohydrideДокумент7 страницSodium BorohydrideKuat DratОценок пока нет

- Gas Explosion Scale Offshore Modules Using Fuel/air Clouds Experiments in I:33 and 1:5 Separator and Compressor Stoichiometric HomogeneousДокумент9 страницGas Explosion Scale Offshore Modules Using Fuel/air Clouds Experiments in I:33 and 1:5 Separator and Compressor Stoichiometric Homogeneousigor VladimirovichОценок пока нет

- Gasification Guide Check List Final PDFДокумент6 страницGasification Guide Check List Final PDFf.BОценок пока нет

- Confined Spaces: Code of PracticeДокумент40 страницConfined Spaces: Code of PracticeLi ChenОценок пока нет

- Basis of SafetyДокумент2 страницыBasis of SafetyTen Dye MungwadziОценок пока нет

- Triethylamine MSDS: Section 1: Chemical Product and Company IdentificationДокумент6 страницTriethylamine MSDS: Section 1: Chemical Product and Company IdentificationM. Erfan FazriawanОценок пока нет

- Flash Point and Fire PointДокумент30 страницFlash Point and Fire PointMukesh KharbОценок пока нет

- Msds Aniline PDFДокумент6 страницMsds Aniline PDFMika PelagioОценок пока нет

- Selection of Inherently Safer Process Routes: A Case StudyДокумент7 страницSelection of Inherently Safer Process Routes: A Case StudyJames EdwardsОценок пока нет

- August 17 (Tuesday) DiscussionДокумент6 страницAugust 17 (Tuesday) DiscussionYuGenОценок пока нет

- Eudiometry ProblemsДокумент5 страницEudiometry ProblemsHimanshu raj100% (4)

- Albumin, Egg MSDS: Section 1: Chemical Product and Company IdentificationДокумент5 страницAlbumin, Egg MSDS: Section 1: Chemical Product and Company IdentificationSefin Nur AisyahОценок пока нет

- Erratum: Source of SpillДокумент1 страницаErratum: Source of Spillsatnam1979Оценок пока нет