Академический Документы

Профессиональный Документы

Культура Документы

Marine HVAC Systems

Загружено:

Siti Aishah HussienИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Marine HVAC Systems

Загружено:

Siti Aishah HussienАвторское право:

Доступные форматы

Marine Auxiliary Support System

HVAC

By: Mr. Anuar Bin Bero

Marine Auxiliary Support System

How does it work?

High Temperature Reservoir

Heat Rejected R Work Input

Heat Absorbed Low Temperature Reservoir

2

Marine Auxiliary Support System How does it work?

Thermal energy moves from left to right through five loops of heat transfer:

1) Indoor air loop 2) 3) 4) 5)

Chilled water loop

Refrigerant loop

Condenser water loop

Cooling water loop

(Bureau of Energy Efficiency, 2004)

Marine Auxiliary Support System

AC Systems

AC options / combinations:

Air Conditioning (for comfort / machine) Split air conditioners

Fan coil units in a larger system

Air handling units in a larger system

4

Marine Auxiliary Support System Refrigeration and Air Conditioning Systems

Vapour Compression Refrigeration (VCR): uses mechanical energy Vapour Absorption Refrigeration (VAR): uses thermal energy Gas Refrigeration System:used to cool aircraft and to obtain very low temperatures after it is modified with regeneration.

Marine Auxiliary Support System

Vapour Compression Refrigeration

Refrigeration cycle (Primary System)

Condenser 4 3

High Pressure Side Expansion Device

Compressor

1 Evaporator

Low Pressure Side

Marine Auxiliary Support System

Low pressure liquid refrigerant Vapour Compression in evaporator absorbs heat and changes to a gas Refrigeration cycle

Condenser 4

Refrigeration

3

High Pressure Side Expansion Device

Compressor

1 Evaporator

Low Pressure Side

Marine Auxiliary Support System

The superheated vapour enters the compressor Vapour Compression where its pressure is raised Refrigeration cycle

Condenser 4

Refrigeration

3

High Pressure Side Expansion Device

Compressor

1 Evaporator

Low Pressure Side

Marine Auxiliary Support System

The high pressure superheated gas is cooled Vapour Compression in several stages in the condenser

Refrigeration

3

Refrigeration cycle

Condenser 4

High Pressure Side Expansion Device

Compressor

1 Evaporator

Low Pressure Side

Type of Refrigeration Marine Auxiliary Support System

Liquid passes through expansion device, which reduces its pressure Vapour and controls the flow into the Compression Refrigeration evaporator

Refrigeration cycle

Condenser 4

High Pressure Side Expansion Device

Compressor

1 Evaporator

Low Pressure Side

10

Marine Auxiliary Support System

Vapour Compression Refrigeration

Choice of compressor, design of condenser, evaporator determined by

Refrigerant

Required cooling Load

Ease of maintenance

Physical space requirements Availability of utilities (water, power)

11

Marine Auxiliary Support System

Assessment of Air Conditioning

Measure

Airflow Q (m3/s) at Fan Coil Units (FCU) or Air Handling Units (AHU): anemometer

Air density (kg/m3)

Dry bulb and wet bulb temperature: psychrometer Enthalpy (kCal/kg) of inlet air (hin) and outlet air (Hout): psychrometric charts

Q h in h out TR 3024

12

Calculate TR

Marine Auxiliary Support System

Assessment of Air Conditioning

Indicative TR load profile

Small office cabins : 0.1 TR/m2 Medium size office (10 30 people occupancy) with central A/C: 0.06 TR/m2 Large multistoried office complexes with central A/C: 0.04 TR/m2

13

Basic HVAC Calculations

Applying Thermodynamics to HVAC Processes Looking at a simplified (but complete) air-conditioning system. Terminology: qsensible, mwater, qL, hw, solar gains. First law of thermodynamics (energy) and conservation of mass. Air is removed from the room, returned to the air-conditioning apparatus where it is reconditioned, and then supplied again to the room. Many cases, it is mixed with outside air required for ventilation Outdoor air (o) is mixed with return air (r) from the room and enters the apparatus at condition (m). Air flows through the conditioner & is supplied to the space (s). The air supplied to the space absorbs heat qs and moisture mw, and the cycle continues.

Applying Thermodynamics to HVAC Processes

Figure 1: Working Principle of Air Conditioning System

Marine Auxiliary Support System

Exhaust Return air Air Handling Unit

Supply air To Comp. Space

Fan Mixed Outside air air

Chiller Out

Chiller In

Primary System

16

Figure 2

Figure 3

Absorption of Space Heat and Moisture Gains AC usually reduces to determining the quantity of moist air that must supplied and the condition it must have to remove given amounts of energy and water Sensible heat gain addition of energy only

Figure 4

Heating or Cooling of Air without moisture gain or loss straight line on psychrometric chart since humidity ratio is constant

Figure 5

Cooling and Dehumidifying Air Moist air brought down below its dew point temperature some of the water will condense and leaves the air stream Assume condensed water is cooled to the final air temperature before draining from the system

Figure 6 Cooling and Dehumidifying Air

Cooling and Dehumidifying Air Moist air brought down below its dew point temperature some of the water will condense and leaves the air stream Assume condensed water is cooled to the final air temperature before draining from the system Cooling and dehumidifying process involves both sensible heat transfer and latent heat transfer where sensible heat transfer is associated with the decrease in dry-bulb temperature and the latent heat transfer is associated with the decrease in humidity ratio.

Figure 7

Figure 8

Figure 9 Adiabatic Mixing of Moist Air with Injected Water

Figure 10

Approximate Equations Using Volume Flow Rates Since volumes of air change need to make calculations with mass of dry air instead of volume. But volumetric flow rates define selection of fans, ducts, coils, etc. Use volume while still considering mass by using volume rates based on standard air conditions Dry air at 20 oC and 101.325 kPa (68 oF and 14.7 psia) Density is 1.204 kg/m3 (0.075 lb/ft3) dry air Specific volume is 0.83 m3/kg (13.3 ft3/lb) dry air Saturated air at 15 oC has about same density and volume Need to convert actual volumetric flow conditions to standard Say you need 1,000 cfm outside air rate at standard conditions Outside measured at 35 oC dry bulb and 23.8 oC wet bulb corresponding to a specific volume of 14.3 ft3/lb. The actual flow rate would be 1,000 (14.3/13.3) = 1,080 cfm 1,000/13.3 = 1,080/14.3 = mass rate (lb/min) of moist air

Sensible heat gain corresponding to the change of drybulb temperature for a given airflow (at standard ASHRAE conditions) qs = Q(1.204)(1.00+1.872) t Where: qs = Sensible Heat Gain (Watt) Q = Airflow (L/s) 1.204 = Density of standard dry air. Kg/m3 1.00 = Specific Heat of dry air kJ/(kg.K) 1.872 = Specific Heat of water vapor kJ/(kg.K) W = Humidity ratio, mass of water per mass of dry t = Temperature difference

Latent heat gain corresponding to the change of humidity ratio W for a given airflow (at standard conditions). The latent heat gain in Watts (Btu/h) as a result of a difference in humidity ratio W between the incoming and leaving air flowing at standard conditions.

Total heat gain corresponding to the change of dry-bulb temperature and humidity ratio W for a given airflow (at standard conditions). The total heat gain in Watts (Btu/h) as a result of a difference in enthalpy h between the incoming and leaving air flowing at standard conditions.

Single-Path Systems Simplest form of all-air HVAC system serving a single temperature control zone Responds to one set of space conditions, where conditions vary uniformly and the load is stable. Schematic of system return fan necessary under certain conditions of p. Need for reheat necessary to control humidity independent of the temperature requirements. Equations for single-path systems air supplied must be adequate to take care of each rooms peak load conditions. Peak loads may be governed by sensible or latent room cooling loads, heating loads, outdoor air requirements, air motion, and exhaust. let us look at each of these loads and what air volume is required to satisfy these demands.

Single-Path Systems - schematic

Figure 11

Single-Path Systems equations for supply air

Single-Path Systems supply air for ventilation 1. Supply air for ventilation needed when the amount of outside air is not adequate 2. Supply air not adequate for the amount of exhaust makeup required no return air comes from the room and entire volume of make-up ventilation air becomes an outside air burden to system 3. Desired air exchange rate not satisfied supply air is determined 4. Desired air movement not satisfied, based on area index parameter, K. Each of the above conditions are used at different times Case 1 when outside air governs, Cases 3 and 4 when air movement governs, and Case 2 when exhaust governs.

Each state point is identified both in summer and winter Change of t is result of sensible heat loss or gain, qS Change in W is result of latent heat loss or gain, gL All return air is assumed to pass from the room through a hung-ceiling return air plenum Supply air CFMS at the fan discharge temperature tsf (summer mode) absorbs the transmitted supply duct heat qsd and supply air fan velocity pressure energy qsf,vp thereby raising the temperature to ts

Room supply air absorbs room sensible and latent heat qSR and qLR along the room sensible heat factor (SHR) line sR, reaching the desired room state, tR and WR.

Room (internal) sensible loads which determine the CFMs consist of:

Single-Path Systems Psychrometric Representation

Single-Path Systems Psychrometric Representation

Single-Path Systems Psychrometric Representation

Single-Path System Sensible Heat Factor (Ratio) Sensible heat factor (ratio), SHF or SHR=ratio of sensible heat for a process to the total of sensible and latent heat for the process. The sensible and latent combined is referred to as the total heat On psychrometric chart, the protractor provides this ratio and may be used to establish the process line for changes in the conditions of the air across the room or the conditioner on the chart The supply air to a conditioned space must have the capability to offset both the rooms sensible and latent heat loads. Connecting the room and supply points with a straight line provides the sensible heat factor condition. The conditioner provides the simultaneous cooling and dehumidifying that occurs. Horizontal line would be SHF = 0.0 (only sensible) Line with SHF = 0.5 would be half sensible and half latent

Single-Path System Example 2

Single-Path System Example 2 Sensible and latent loads given Room Conditions: (75 oF and 55% RH) Supply at 58 oF Outside Conditions: 96 oF DB, 77 oF WB and 20% of total flow

Single-Path System Psyc

b.

Marine Auxiliary Support System

THANK YOU

FOR YOUR ATTENTION

58

Вам также может понравиться

- Rac Lab ManualДокумент30 страницRac Lab ManualPrakharGupta100% (1)

- Air Conditioning System On ShipsДокумент18 страницAir Conditioning System On ShipsAzym Azizi100% (3)

- Ship Air Conditioning SystemДокумент9 страницShip Air Conditioning SystemMEET PATEL100% (1)

- Air Filling and SoundingДокумент20 страницAir Filling and Soundingsathish_sbit100% (2)

- Marine Boiler Question AnswersДокумент9 страницMarine Boiler Question AnswersSumeet SawantОценок пока нет

- Provision Cooling GuideДокумент13 страницProvision Cooling Guideedo100% (1)

- Ek GeneralДокумент24 страницыEk GeneralPRASHANT SAWANTОценок пока нет

- Guidelines For Engine-Room Layout, Design & ArrangementДокумент38 страницGuidelines For Engine-Room Layout, Design & Arrangement123habib123fikri100% (1)

- 1 Piping Systems On ShipsДокумент9 страниц1 Piping Systems On ShipsBang NielОценок пока нет

- Starting Air SystemДокумент55 страницStarting Air SystemLTE002Оценок пока нет

- Marine SystemsДокумент44 страницыMarine Systemsvikrantgulhane83% (6)

- Marine Auxiliary Machinery PDFДокумент7 страницMarine Auxiliary Machinery PDFMahmoud ElNaggar50% (2)

- General Engineering Knowledge For Marine EngineersДокумент31 страницаGeneral Engineering Knowledge For Marine EngineersSrini VasanОценок пока нет

- Marine BoilersДокумент16 страницMarine BoilersPawan Beniwal100% (1)

- Marine Bilge and Ballast SystemsДокумент17 страницMarine Bilge and Ballast SystemsRyanОценок пока нет

- Ship piping systems design and componentsДокумент74 страницыShip piping systems design and componentsNguyen Anh Tung82% (11)

- General Engineering KnowlegeДокумент63 страницыGeneral Engineering KnowlegeMicheal O Muiris100% (3)

- Marine Air Compressor Maintenance - Things You Must Know About PDFДокумент15 страницMarine Air Compressor Maintenance - Things You Must Know About PDFHope Ikue-JohnОценок пока нет

- Ship Machineries GuideДокумент54 страницыShip Machineries GuideWilfred Joseph T. Casas100% (1)

- R06 - 31SI. Marine RefrigerationДокумент8 страницR06 - 31SI. Marine RefrigerationWilliam Ruiz100% (1)

- 2-Stroke vs 4-Stroke Marine Diesel EnginesДокумент19 страниц2-Stroke vs 4-Stroke Marine Diesel EnginesAnonymous GFrM6XAОценок пока нет

- Engine Room Systems and Layout PDFДокумент3 страницыEngine Room Systems and Layout PDFRENGANATHAN P33% (3)

- Marine HVAc EquipmentsДокумент15 страницMarine HVAc EquipmentsMohammed JassimОценок пока нет

- Coaling Load HVAC PDFДокумент10 страницCoaling Load HVAC PDFIntan Luruh LarasatiОценок пока нет

- Basic Principles of RefrigerationДокумент16 страницBasic Principles of Refrigerationgenas7265Оценок пока нет

- Carrier Cold Room Calculaton PDFДокумент28 страницCarrier Cold Room Calculaton PDFMohammad Amer93% (60)

- Marine Gas TurbineДокумент34 страницыMarine Gas TurbineAllesandraОценок пока нет

- E.5 Engine Room Ventilation SystemДокумент5 страницE.5 Engine Room Ventilation Systemednsmn100% (1)

- Ships Refrigeration Plant221928Документ8 страницShips Refrigeration Plant221928Bagas AbhimanyuОценок пока нет

- RefrigerationДокумент84 страницыRefrigerationGeorge AbrahamОценок пока нет

- AALBORG ThermalFluidSystemДокумент10 страницAALBORG ThermalFluidSystemrafiradityaОценок пока нет

- Marine Engineering PracticeДокумент159 страницMarine Engineering PracticeRemisius Corera100% (1)

- DNV Marpol Annex VI Guide Lines LSHFO PositionsДокумент32 страницыDNV Marpol Annex VI Guide Lines LSHFO Positionsch3g44Оценок пока нет

- AHU ManualДокумент17 страницAHU ManualwolfzemunОценок пока нет

- How To Synchronize Generators On A ShipДокумент115 страницHow To Synchronize Generators On A Shipandriea03100% (1)

- Double Skin Modular Air HAndling Unit AHUДокумент43 страницыDouble Skin Modular Air HAndling Unit AHUDinh Nguyen Dao100% (1)

- Safety Devices in Air Conditioning and Refrigeration PlantsДокумент11 страницSafety Devices in Air Conditioning and Refrigeration PlantsQOBITОценок пока нет

- Essential Fire Safety Equipment ShipsДокумент6 страницEssential Fire Safety Equipment ShipsBeng Kiong NeoОценок пока нет

- Trane 4 Chiller Plant ControlsДокумент28 страницTrane 4 Chiller Plant ControlsEdward Siu100% (3)

- Marine Boilers by G.T.H Flanagan 3rd EditionДокумент123 страницыMarine Boilers by G.T.H Flanagan 3rd EditionRicky Chua100% (8)

- Created by Ankur Sharma, Gurudayal Srivastava, Vikram Singh, Sanket TamhaneДокумент7 страницCreated by Ankur Sharma, Gurudayal Srivastava, Vikram Singh, Sanket TamhaneSankash Sood100% (2)

- Refrigeration System DiagramДокумент7 страницRefrigeration System DiagramNama Saya ZulОценок пока нет

- TC Manual Air ConditionersДокумент27 страницTC Manual Air ConditionersvickersОценок пока нет

- Chiller Plant Room VentilationДокумент8 страницChiller Plant Room VentilationQaz Zaq100% (2)

- College Project MakersДокумент2 страницыCollege Project MakersShahzad Saif0% (1)

- Refrigeration SystemsДокумент100 страницRefrigeration SystemsRay RavelОценок пока нет

- Marine Frequency ConvertersДокумент20 страницMarine Frequency Convertersrajee7Оценок пока нет

- Proposal Document For HVAC Equipment Design, Installation and Maintenance Services For Offshore Oil & Gas FacilitiesДокумент35 страницProposal Document For HVAC Equipment Design, Installation and Maintenance Services For Offshore Oil & Gas FacilitiesIB Ismady100% (1)

- Refrigeration CycleДокумент5 страницRefrigeration CycleLiezel Quijada LicupОценок пока нет

- HVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerryДокумент29 страницHVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerrySuresh KumarОценок пока нет

- The Basics of Heating, Ventilation and Air ConditioningДокумент96 страницThe Basics of Heating, Ventilation and Air Conditioningsakshi1405Оценок пока нет

- Psychrometric ChartДокумент63 страницыPsychrometric ChartCutekarthik Subramanian100% (1)

- HVAC Systems Analysis and DesignДокумент67 страницHVAC Systems Analysis and DesignSidd SalОценок пока нет

- 05 RefrigerationДокумент17 страниц05 RefrigerationApostolos AvraamidesОценок пока нет

- Fundamentals of AC and All Air SystemДокумент36 страницFundamentals of AC and All Air Systemnareshbv749Оценок пока нет

- EME PPT (For 32 To 35) by DivyeshДокумент24 страницыEME PPT (For 32 To 35) by DivyeshDivyesh ParmarОценок пока нет

- Gas Refrigeration System (Air Refrigeration)Документ30 страницGas Refrigeration System (Air Refrigeration)Ruturaj UmaranikarОценок пока нет

- CH 3Документ33 страницыCH 3beila.amu.22Оценок пока нет

- REFRIGERATION & AIR-CONDITIONING SYSTEMSДокумент35 страницREFRIGERATION & AIR-CONDITIONING SYSTEMSlanikhilОценок пока нет

- Refrigeration System: An OverviewДокумент37 страницRefrigeration System: An OverviewDaniel HillОценок пока нет

- Cold Facts Buyers Guide (2017) PDFДокумент41 страницаCold Facts Buyers Guide (2017) PDFBinh Thanh LeОценок пока нет

- Chapter 24: Torsional Vibrations: (A) Shaft of Varying Diameters. (B) Torsionally Equivalent ShaftДокумент8 страницChapter 24: Torsional Vibrations: (A) Shaft of Varying Diameters. (B) Torsionally Equivalent ShaftNazmus Sakib100% (1)

- Biomechanics of CartilageДокумент14 страницBiomechanics of CartilageEric Urbina SantibañezОценок пока нет

- KIRAN PPT-unit 3Документ54 страницыKIRAN PPT-unit 3RED EYEОценок пока нет

- Sae Technical Paper Series: Alan P. Druschitz, Thomas E. Prucha, Adam E. Kopper and Thomas A. ChadwickДокумент9 страницSae Technical Paper Series: Alan P. Druschitz, Thomas E. Prucha, Adam E. Kopper and Thomas A. ChadwickAliakbar SaifeeОценок пока нет

- 1st Presentation - Analyzing Dynamic Line Rating of Distribution Tower LineДокумент19 страниц1st Presentation - Analyzing Dynamic Line Rating of Distribution Tower LineMohamed Nihaj100% (1)

- A Predictive Approach To Fitness-For-Service Assessment of Pitting CorrosionДокумент9 страницA Predictive Approach To Fitness-For-Service Assessment of Pitting CorrosionMaría Vaquero TxapartegiОценок пока нет

- 2Документ13 страниц2VNSAramakiОценок пока нет

- Boilers & FurnacesДокумент88 страницBoilers & Furnacesnrnak0% (1)

- 2 - 3D4D On ARIETTA V70 and ARIETTA V60Документ40 страниц2 - 3D4D On ARIETTA V70 and ARIETTA V60AlexОценок пока нет

- Daikin Air Cooled Liquid Screw Chiller EWAD400D-XS-CUALДокумент4 страницыDaikin Air Cooled Liquid Screw Chiller EWAD400D-XS-CUALBibin VijayakumarОценок пока нет

- FM - PW-MT Fhi - UPFДокумент75 страницFM - PW-MT Fhi - UPFarnoldОценок пока нет

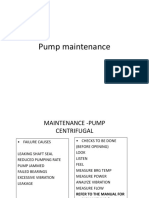

- Pump Maintenance PDFДокумент9 страницPump Maintenance PDFkamelОценок пока нет

- AZ nLOF 2000 Series Technical DatasheetДокумент8 страницAZ nLOF 2000 Series Technical DatasheetSwarnava SanyalОценок пока нет

- Lecture 2Документ12 страницLecture 2Sima KumariОценок пока нет

- Offshore Fabrication NDT TestingДокумент1 страницаOffshore Fabrication NDT TestingRudolph RednoseОценок пока нет

- TIMBERДокумент13 страницTIMBERAbigail FababaerОценок пока нет

- Elements of Gating SystemДокумент44 страницыElements of Gating SystemNemani RaghuОценок пока нет

- Process Control FundamentalsДокумент59 страницProcess Control Fundamentalsaanouar77Оценок пока нет

- Visible Spectra of Soft DrinksДокумент6 страницVisible Spectra of Soft Drinksfatin harris100% (1)

- Air Crew Radiation Exposure - An OverviewДокумент8 страницAir Crew Radiation Exposure - An OverviewStarxteelОценок пока нет

- Boiling Heat Transfer FundamentalsДокумент11 страницBoiling Heat Transfer FundamentalsOtto Heinrich WehmannОценок пока нет

- SCIE 10 - Chapter 1Документ3 страницыSCIE 10 - Chapter 1Crishia joy J. EstrellaОценок пока нет

- Geology Lab ReportДокумент2 страницыGeology Lab ReportSteve100% (1)

- Crack Control for Concrete Slabs GuideДокумент28 страницCrack Control for Concrete Slabs GuideChandu CKОценок пока нет

- Lab # 5. Collision Experiment: Trajectory of The Object IsДокумент4 страницыLab # 5. Collision Experiment: Trajectory of The Object IsClaraSintaОценок пока нет

- SOP For Boiler PassivationДокумент2 страницыSOP For Boiler PassivationSAKTHIVEL MОценок пока нет

- Calculated installed flux and lighting layoutДокумент4 страницыCalculated installed flux and lighting layoutdarshaniОценок пока нет

- 1.solid StateДокумент4 страницы1.solid StateChemGuru 4 U0% (1)

- (DIN 28082-2 - 1996-06) - Standzargen Fã R Apparate - Teil 2 - Fuà - Ring Mit Pratzen Oder Doppelring Mit Stegen - Maà - e - 0001.de - enДокумент6 страниц(DIN 28082-2 - 1996-06) - Standzargen Fã R Apparate - Teil 2 - Fuà - Ring Mit Pratzen Oder Doppelring Mit Stegen - Maà - e - 0001.de - enNaveen Suresh KumarОценок пока нет