Академический Документы

Профессиональный Документы

Культура Документы

Boiler Commissioning Activities

Загружено:

Aanchal SharmaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Boiler Commissioning Activities

Загружено:

Aanchal SharmaАвторское право:

Доступные форматы

BASICS OF COMMISSIONING

Before putting any auxiliary or system in operation, following points are to be ensured, System is installed fully as per drg./scheme. It is free from any debris/foreign materials. Emergency shut-off/activity suspending arrangements are available.

Contd

All interlock/ protections are incorporated. All the system forming part of closed cycle of main power plant are cleaned, such that pure steam is produced for admission to turbine.

VARIOUS SYSTEMS IN THERMAL POWER STATION

Feed water system. Condensate and drip system. Steam and water system of boiler. Air and flue gas system. MS, CRH, HRH & HP/LP bypass system. Fuel Firing system. Coal milling system. ACW/BCW system.

Pre- boiler system alkali flushing. Chemical cleaning of boiler, consisting of alkali boil-out, acid cleaning, passivation. Steam blowing. Steam dumping. Safety valve floating. Coal firing and full loading.

COMMISSIONING SEQUENCE OF SYSTEMS FOR BOILER

Pre- boiler system alkali flushing

Boiler is fed with water from pre-boiler system, consisting of condenser, CEP, LP Heaters, Deaerator, feed pump suction, feed pump, HP Heaters, Feed control system. For cleaning purpose the system is divided in two systems viz. condensate & drip system and feed water system. For circulation of alkali solution the system is connected suitably with temporary pumping / circulation set up.

Contd

The system is filled/ pressure tested and leakages are attended. First flushed with cold water followed by hot water, alkali solution and then rinsing with hot water and DM water till system is cleaned. Normally cleanliness is declared by physical inspection. PH, turbidity, oil ppm etc. of inlet and outlet.

Chemical cleaning of boiler, alkali boil-out, acid cleaning, passivation.

The circuit from economiser inlet isolation valve to boiler outlet MS stop valve are the the boundary points of boiler. The drains, vents, safety valves, chemical dosing points are all connected to boiler pressure part system. After completion of system it is hydro tested and then flushed two three times for clearing major debris/ muck

Contd

Boiler is made ready for light up by making initial commissioning of all auxiliaries viz. ID Fan, FD Fan, Air & Flue Gas system, fuel oil firing system etc. Boiler drum is filled slightly below normal level and then alkali solution is added in required quantity and then boiler is lighted for alkali boilout.

Acid Cleaning

Acid cleaning is done after the Alkali Boil out is complete After acid cleaning is complete, the system is passivated and preserved with Nitrogen gas till it is used for generation of steam.

Steam Blowing

Steam blowing is done mainly to clean the pipelines that carry steam to the Turbines. The pressure is raised to a fixed value and the steam is let out through temporary pipelines. The debris and scales formed in the pipeline gets cleaned in the process. The completion of the steam blowing process is decided by inspecting the targets plates placed in the pipeline

Safety Valve Floating

This is a mandatory requirement of the Boiler For safety of the operating personnel and Boiler, the safety valve operation is tested againsted actual pressure in the boiler. The boiler pressure is raised and the operation of the safety valve is tested. With the completion of the safety valve floating, the boiler is ready of

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Dual Draw/Dual Return Fuel System TroubleshootingДокумент4 страницыDual Draw/Dual Return Fuel System Troubleshootinginformer techОценок пока нет

- YesДокумент80 страницYesRonnie TorresОценок пока нет

- Pre Check: 1. Vgrs System DescriptionДокумент8 страницPre Check: 1. Vgrs System DescriptionNickОценок пока нет

- Quest CCS ProjectДокумент10 страницQuest CCS ProjecttruehemingwayОценок пока нет

- TDG11Документ100 страницTDG11Splycho GoranОценок пока нет

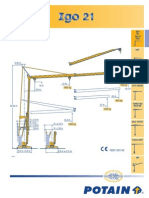

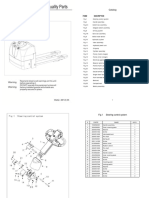

- Potain Igo 21 PDFДокумент4 страницыPotain Igo 21 PDFMarco CruzОценок пока нет

- RISC Vs CISCДокумент13 страницRISC Vs CISCBehin SamОценок пока нет

- Sidewall Framing Elevation @GL.K: Gutter DetailДокумент1 страницаSidewall Framing Elevation @GL.K: Gutter DetailLUUVANDONG48XFОценок пока нет

- Li-Fi Industries Communication Using Laser Media in Open SpaceДокумент61 страницаLi-Fi Industries Communication Using Laser Media in Open SpaceVinothKumar100% (1)

- "Part - I - General Central Services Group B'Документ13 страниц"Part - I - General Central Services Group B'NarayanaОценок пока нет

- GC120 Outline Rev SGДокумент2 страницыGC120 Outline Rev SGsong perezОценок пока нет

- Refrigerator: Service ManualДокумент44 страницыRefrigerator: Service ManualBetileno QuadAlexОценок пока нет

- Tps 53014Документ27 страницTps 53014nebiyu mulugetaОценок пока нет

- Catalog: Ningbo Liftstar Material Handling Equipment Co., LTDДокумент27 страницCatalog: Ningbo Liftstar Material Handling Equipment Co., LTDKiều Văn TrungОценок пока нет

- NEOCLASSICAL CITY PlanningДокумент10 страницNEOCLASSICAL CITY PlanningAfrahОценок пока нет

- MSM Carbon FibreДокумент35 страницMSM Carbon FibrelokeshkrkushwahaОценок пока нет

- Chapter 1 Introduction: U V U U V X y yДокумент56 страницChapter 1 Introduction: U V U U V X y ywithyou100% (1)

- Safety in The Kitchen - 1Документ36 страницSafety in The Kitchen - 1Roxanne OquendoОценок пока нет

- Repair Kit Hitachi PlasmaДокумент4 страницыRepair Kit Hitachi Plasmacolman123456789100% (1)

- A Simulation of Attempts To Influence Crowd Dynamics'Документ6 страницA Simulation of Attempts To Influence Crowd Dynamics'KhairulОценок пока нет

- Polylux WebkatalogДокумент96 страницPolylux WebkatalogNesil Abiera50% (2)

- Brilliance - 64 - (ct101) - Site - Guidefor TrailerДокумент19 страницBrilliance - 64 - (ct101) - Site - Guidefor Trailerbody2030Оценок пока нет

- Annex A - Technical SpecificationsДокумент52 страницыAnnex A - Technical SpecificationsNikko MontoyaОценок пока нет

- OHT Estimates 50000 LtrsДокумент59 страницOHT Estimates 50000 LtrsSandgrouse RajОценок пока нет

- (GUNSMITHING) The .22 PistolДокумент18 страниц(GUNSMITHING) The .22 PistolMago Invisivel88% (25)

- NextCloud OnlyOffice PDFДокумент89 страницNextCloud OnlyOffice PDFOmar Gallegos Vazquez100% (1)

- Noise and VibrationДокумент14 страницNoise and VibrationABHISHEK V GOWDAОценок пока нет

- Yousif Alotaibi 01 CVДокумент3 страницыYousif Alotaibi 01 CVyousefx20Оценок пока нет

- Six Sigma Report Out TemplateДокумент55 страницSix Sigma Report Out Templatevijayasarathy201325350% (2)

- TN 1473Документ63 страницыTN 1473Meisam TabrizОценок пока нет