Академический Документы

Профессиональный Документы

Культура Документы

Micro Channel Poster-MMc Revision

Загружено:

Emre ÖlçeroğluИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Micro Channel Poster-MMc Revision

Загружено:

Emre ÖlçeroğluАвторское право:

Доступные форматы

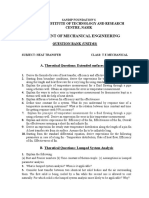

BIOTEMPLATED SUPERHYDROPHILIC COATINGS FOR ENHANCED FLOW BOILING IN MICROCHANNELS

Lara D. Branco, Alison K. Krick, Stephen M. King, Matthew McCarthy

Department of Mechanical Engineering and Mechanics, Drexel University, Philadelphia, PA

Introduction and Motivation

The demand for greater power density in electronic devices drives investigation into more efficient thermal management systems to dissipate the heat associated with them. One method that continues to be explored is two-phase flow in microchannels. Flow-boiling utilizes the latent heat of vaporization of the fluid as a cooling mechanism; this, combined with the increased surface area to volume ratio, is capable of removing higher (roughly 1000x) heat fluxes than in current applications. Surface wettability plays a large role in enhancing two-phase heat transfer. Studies show nanostructured hydrophilic surfaces enable a cyclic flow process which is related to bubble nucleation, growth, and coalescence due to augmented wetting properties [1]. Poor surface wettability leads to excessive superheat and dryout preventing efficient bubble nucleation and detachment [1]. In the present study, the tobacco mosaic virus (TMV) is utilized as nanoscale scaffold to form super-hydrophilic coatings on copper channel walls to improve two-phase heat transfer.

Experimental Set-up

1 mm

Figure 3: (a) Schematic of experimental set-up; pressurized water forces flow through channel while mass flow controller regulates water flow rate. Cartridge and film heaters connected to power supply heats channel while thermocouples track temperature fluctuation along length of channel. A high-speed camera capture flow regimes. (b) Actual experimental set-up. (c) Microchannel test device with five thermocouples equally distributed over channel length.

(a)

(b)

(c)

Results

Flat Copper Channel TMV-coated Copper Channel

(a) 0 s (a)

Dryout vs. Annular Flow

TMV and Device Design

Tobacco mosaic virus is a rod-shaped plant virus, which is stable up to 60C over pH 2-11. The high aspect ratio biomaterial contains a genetic mutation which introduces thiol groups regularly over its coat protein. These thiol groups are capable of complexing with metals, enhancing the surface binding capability of the virus [2]. These properties make TMV an attractive candidate to coat existing surfaces with a bio-template for hydrophilic coatings to aid in surface wetting and increased heat transfer.

(a) 0 s

30 mm (b) 1.4 s (b) 0.19 s

18 mm t (b)

Liquid Boundary Layer

(c) 2.4 s

Elongated bubble 300 nm Coat proteins containing thiols

(c) 0.38 s

(d) 2.7 s

2 m

Slug 18 nm

Figure 6: Comparison of flow at 1 ccm and 25 W on two channels.(a) In the flat copper channel, greater heat eventually leads to a dryout phenomenon, preventing heat removal from the channel. (b) In the TMV-coated channel, the wicking properties keep the walls of the channel wetted; annular flow with a liquid boundary layer is developed, preventing dryout.

Figure 1. Tobacco mosaic virus

Two microchannels, flat copper and nickel coated TMV, are subjected to two-phase flow. The super hydrophilic TMV-coated channel should keep the walls significantly more wetted, promoting the heat removal quality of the device and preventing a dryout phenomenon.

Figure 4: Two-phase flow through flat copper microchannel at 1.5 ccm and 15 W. The flow goes through a cycle described by: (a) Vapor bubble formation growth; (b) Further growth of bubble; (c) Development of elongated bubble; (d) Slug formation. The cycle occurs within 3 s.

Figure 5: Two-phase flow through TMV-coated copper microchannel at 1.5 ccm and 17.4 W. (a) Vapor bubble nucleation; (b) Bubble growth; (c) Bubble coalescence and departure. This cycle occurs much faster than flat copper s, and bubble departure size is significantly smaller.

Copper channel for uniform heat Teflon Case for insulation Polycarbonate cover Cartridge heater inserted in Cu Thin Film Heater under Cu Dimensions:1mm x 1mm x 30mm

TMV

Conclusions and Future Work

Flat copper surfaces promote elongated vapor bubbles that form into slugs and slow down liquid flow leading to instabilities TMV-coated channels keep vapor bubbles constantly mobile and smaller in size than flat copper channel At higher heat, the hydrophilic channel achieves annular flow with a liquid boundary layer, preventing dryout More experiments need to be performed in order to fully characterize temperature behavior difference between channels A new design should be developed to eliminate leak in testing device Study the effect of multiple channels on the flow regimes and instability Quantitatively analyze the heat transfer qualities of channels coated with TMV

References

[1] Ting Y. Liu. Int. J. Heat and Mass Trans. 54 (2011) 126-134 [2] Gerasopoulos, K. J. Micrmech. Microeng. 18 (2008) 104003 (8pp)

Figure 2. Schematic of test device

Вам также может понравиться

- Thermal ScienceДокумент12 страницThermal ScienceMuhammad shehryar wainОценок пока нет

- Alumina Nanoparticle Pre-Coated Tubing Ehancing Subcooled Flow Boiling Cricital Heat FluxДокумент8 страницAlumina Nanoparticle Pre-Coated Tubing Ehancing Subcooled Flow Boiling Cricital Heat FluxChinniRohithaОценок пока нет

- 1 s2.0 S0017931015306037 MainДокумент11 страниц1 s2.0 S0017931015306037 MainJOHNSAN RОценок пока нет

- High-Pressure Pool-Boiling Heat Transfer Mechanism On Sintered-Particle WickДокумент32 страницыHigh-Pressure Pool-Boiling Heat Transfer Mechanism On Sintered-Particle WickJoel Jr Rudinas (Remodulator)Оценок пока нет

- Experimental study on silicon micro-heat pipe arrays for electronic coolingДокумент11 страницExperimental study on silicon micro-heat pipe arrays for electronic coolingshahriar70Оценок пока нет

- Applied Thermal Engineering: Bo Shi, Yi-Biao Wang, Kai ChenДокумент7 страницApplied Thermal Engineering: Bo Shi, Yi-Biao Wang, Kai ChenAbhijit PalОценок пока нет

- 1 s2.0 S0017931020311686 MainДокумент10 страниц1 s2.0 S0017931020311686 MainJOHNSAN RОценок пока нет

- Pool Boiling Heat Transfer and Simpli®ed One-Dimensional Model For Prediction On Coated Porous Surfaces With Vapor ChannelsДокумент9 страницPool Boiling Heat Transfer and Simpli®ed One-Dimensional Model For Prediction On Coated Porous Surfaces With Vapor ChannelsHany Elsawy AbdelrahmanОценок пока нет

- Experimental Investigation of Fluid Flow and Heat Transfer in MicrochannelsДокумент6 страницExperimental Investigation of Fluid Flow and Heat Transfer in MicrochannelsRam MurtyОценок пока нет

- Nanotechnology Materials For Heat Sink: Nathan Otundo OnsareДокумент12 страницNanotechnology Materials For Heat Sink: Nathan Otundo OnsareOtundo OnsareОценок пока нет

- Me52102 - HMT Sheet - Ii - FinsДокумент2 страницыMe52102 - HMT Sheet - Ii - FinsHarshОценок пока нет

- Volume of Fluid Simulation of Boiling Two-Phase Flow in A Vapor-Venting MicrochannelДокумент11 страницVolume of Fluid Simulation of Boiling Two-Phase Flow in A Vapor-Venting MicrochannelDr Mohammed AzharОценок пока нет

- 3 Watkinson Fouling-ConceptДокумент8 страниц3 Watkinson Fouling-ConceptAnonymous AtAGVssJОценок пока нет

- Journal Pre-Proofs: Materials LettersДокумент9 страницJournal Pre-Proofs: Materials LettersjorgeОценок пока нет

- Role of Wickability On The Critical Heat Flux of Structured Superhydrophilic SurfacesДокумент10 страницRole of Wickability On The Critical Heat Flux of Structured Superhydrophilic Surfacesavi0341Оценок пока нет

- Nanotechnology Materials For Heat Sink: Nathan Otundo OnsareДокумент11 страницNanotechnology Materials For Heat Sink: Nathan Otundo Onsarenawinnawmu1026Оценок пока нет

- Micromachines 11 00323Документ18 страницMicromachines 11 00323uygar atesОценок пока нет

- Unit IIIДокумент8 страницUnit IIIPrashant NandanОценок пока нет

- Microstructure and Cavitation Erosion Behavior of WC-Co-Cr Coating On 1Cr18Ni9Ti Stainless Steel by HVOF Thermal Spraying 2012 International Journal of Refractory MetalsДокумент6 страницMicrostructure and Cavitation Erosion Behavior of WC-Co-Cr Coating On 1Cr18Ni9Ti Stainless Steel by HVOF Thermal Spraying 2012 International Journal of Refractory MetalsastronotusОценок пока нет

- A Microreactor For The Nitration of Benzene and TolueneДокумент19 страницA Microreactor For The Nitration of Benzene and TolueneAnna YagodnitsinaОценок пока нет

- PANIMALAR ENGINEERING COLLEGE HEAT AND MASS TRANSFER MODEL EXAMДокумент2 страницыPANIMALAR ENGINEERING COLLEGE HEAT AND MASS TRANSFER MODEL EXAMPoyyamozhi Nadesan RanjithОценок пока нет

- 1 s2.0 S001793101733106X MainДокумент10 страниц1 s2.0 S001793101733106X MainJOHNSAN RОценок пока нет

- Heat Transfer: Code: ME5T5Документ3 страницыHeat Transfer: Code: ME5T5rudresh JmОценок пока нет

- Carbon nanotubes grown and separated in fluidized bedДокумент8 страницCarbon nanotubes grown and separated in fluidized bedtapasdoraОценок пока нет

- 1 s2.0 S2214157X23010948 MainДокумент17 страниц1 s2.0 S2214157X23010948 MainASIST MechОценок пока нет

- SCH2108201612 Transport PhenomenaДокумент5 страницSCH2108201612 Transport PhenomenaAljebre MohmedОценок пока нет

- A Microreactor For In-Situ Hydrogen Production by Catalytic Methanol ReformingДокумент11 страницA Microreactor For In-Situ Hydrogen Production by Catalytic Methanol ReformingramahtamahОценок пока нет

- Applied Thermal EngineeringДокумент13 страницApplied Thermal Engineeringbala subrahmanyamОценок пока нет

- Heat Transfer (MEE - 306) RCS (Makeup) (EngineeringDuniya - Com)Документ3 страницыHeat Transfer (MEE - 306) RCS (Makeup) (EngineeringDuniya - Com)Sanjay ShreeshaОценок пока нет

- 1 s2.0 S129007292100168X MainДокумент16 страниц1 s2.0 S129007292100168X MainLiviu BadeaОценок пока нет

- Thermal Performance of Higher Aspect Ratio Microchannels Using Tio - Water Nano UidsДокумент5 страницThermal Performance of Higher Aspect Ratio Microchannels Using Tio - Water Nano UidsdddОценок пока нет

- Reboiler Case StudyДокумент6 страницReboiler Case StudyamlhrdsОценок пока нет

- Dual DamasceneДокумент21 страницаDual Damascenebisma_waseeqОценок пока нет

- Macroscopic Growth of Carbon Nanotube MatsДокумент4 страницыMacroscopic Growth of Carbon Nanotube MatsBhanuka ThennakoonОценок пока нет

- Enhanced Nucleate Boiling in Microchannels: 0-7803-7185-2/02/$10.00 ©2002 IEEEДокумент4 страницыEnhanced Nucleate Boiling in Microchannels: 0-7803-7185-2/02/$10.00 ©2002 IEEEdenghueiОценок пока нет

- Sensors 20 05533 v2Документ13 страницSensors 20 05533 v2ramvineethkasireddyОценок пока нет

- Transport 2 Sample Final ExamДокумент4 страницыTransport 2 Sample Final Examlcleaveland3Оценок пока нет

- International Journal of Heat and Mass TransferДокумент12 страницInternational Journal of Heat and Mass TransferThao DophuongОценок пока нет

- 10 1016@j Cryogenics 2019 06 004Документ12 страниц10 1016@j Cryogenics 2019 06 004Cristina TamayОценок пока нет

- Lianzhang2002 PDFДокумент8 страницLianzhang2002 PDFRizki TriwulandaОценок пока нет

- Twisted Tube Heat Exchanger TechnologyДокумент8 страницTwisted Tube Heat Exchanger TechnologyhuangjlОценок пока нет

- Kim 1998Документ10 страницKim 1998ahmoudaОценок пока нет

- Composites: Part A: Kai Yang, Mingyuan GuДокумент7 страницComposites: Part A: Kai Yang, Mingyuan Gueid elsayedОценок пока нет

- Yang Et Al. - 2020 - Experimental Study On Single-Phase Hybrid MicrochaДокумент11 страницYang Et Al. - 2020 - Experimental Study On Single-Phase Hybrid Microchamosab.backkupОценок пока нет

- 106 - MPH 34a - 2020110207353660Документ19 страниц106 - MPH 34a - 2020110207353660Eman NasirОценок пока нет

- Krishnamurthy and Peles 2010 Flow Boiling Heat Transfer On Micro Pin Fins Entrenched in A MicrochannelДокумент10 страницKrishnamurthy and Peles 2010 Flow Boiling Heat Transfer On Micro Pin Fins Entrenched in A MicrochannelChong Jen HawОценок пока нет

- A Review of Manufacturing Processes For Microchannel Heat Exchanger FabricationДокумент6 страницA Review of Manufacturing Processes For Microchannel Heat Exchanger Fabricationgyanendra_vatsa4380Оценок пока нет

- Fabrication of Lateral Porous Silicon Membranes For Planar Microfluidic DevicesДокумент4 страницыFabrication of Lateral Porous Silicon Membranes For Planar Microfluidic DevicesTilottama DeoreОценок пока нет

- HMT R04 Nov Dec 2009Документ4 страницыHMT R04 Nov Dec 2009balakaleesОценок пока нет

- Kuznetsov 2018Документ4 страницыKuznetsov 2018Eduardo CastañedaОценок пока нет

- Heat Exchanger - Process DesignДокумент11 страницHeat Exchanger - Process DesignkeziaОценок пока нет

- Cairo University Mechanical Power Heat Transfer ExamДокумент1 страницаCairo University Mechanical Power Heat Transfer ExamHager ArefОценок пока нет

- DB 3 CH 20Документ75 страницDB 3 CH 20JuanJesúsSantosLoeraОценок пока нет

- Liquid-Liquid Two-Phase Flow Patterns in MicrochannelsДокумент9 страницLiquid-Liquid Two-Phase Flow Patterns in MicrochannelsJo JoОценок пока нет

- Heat Transfer Jan2003 NR 320305Документ8 страницHeat Transfer Jan2003 NR 320305Nizam Institute of Engineering and Technology LibraryОценок пока нет

- HEAT TRANSFER 2011 JNTUH Question PaperДокумент8 страницHEAT TRANSFER 2011 JNTUH Question PaperAnil Frivolous AbstemiousОценок пока нет

- Numerical Simulation of Heat Transfer - H.A. MohammedДокумент6 страницNumerical Simulation of Heat Transfer - H.A. MohammedElver GonzalesОценок пока нет

- Characterization of Sputtered Inconel 617Документ5 страницCharacterization of Sputtered Inconel 617rashik072Оценок пока нет

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesОт EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášОценок пока нет

- Heat and Moisture Transfer between Human Body and EnvironmentОт EverandHeat and Moisture Transfer between Human Body and EnvironmentОценок пока нет

- Pop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovalДокумент5 страницPop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovaluserОценок пока нет

- Effect of Preparation Method of Ni Catalyst Using Bentonite As The Support MaterialДокумент8 страницEffect of Preparation Method of Ni Catalyst Using Bentonite As The Support MaterialNastitiОценок пока нет

- PACKAGING OF MEAT AND MEAT PRODUCTSДокумент46 страницPACKAGING OF MEAT AND MEAT PRODUCTSrajesh bethaОценок пока нет

- AAMA Vs Qualicoat 2018Документ12 страницAAMA Vs Qualicoat 2018viet nguyen cao0% (1)

- EP0070932B1Документ5 страницEP0070932B1bayuОценок пока нет

- Activated CarbonДокумент34 страницыActivated CarbonSanjeeva YedavalliОценок пока нет

- OPSS 369 Nov08Документ7 страницOPSS 369 Nov08Muhammad UmarОценок пока нет

- Oths Academic Chemistry Syllabus 2015-2016Документ6 страницOths Academic Chemistry Syllabus 2015-2016api-254514513Оценок пока нет

- Int Esws at Y9 Workbook Answers TTPPДокумент37 страницInt Esws at Y9 Workbook Answers TTPPChrystal GraceОценок пока нет

- Erosion Tecnalia 2016 06Документ17 страницErosion Tecnalia 2016 06FernanОценок пока нет

- COMPACT 99B Inlet Valve ManualДокумент4 страницыCOMPACT 99B Inlet Valve Manualalwill09Оценок пока нет

- Coway water purifiers product collectionДокумент10 страницCoway water purifiers product collectionSyida NaufalОценок пока нет

- MCQ - Question-Paper-11 PDFДокумент16 страницMCQ - Question-Paper-11 PDFMuhammad TauseefОценок пока нет

- MSDS - TD - OIL - 22 For Chimpo GearboxДокумент7 страницMSDS - TD - OIL - 22 For Chimpo GearboxKritbordin RintaОценок пока нет

- Magnetic Susceptibility ReportДокумент13 страницMagnetic Susceptibility Reportsackeynat100% (1)

- Constructing Key Questions for PBL in ScienceДокумент3 страницыConstructing Key Questions for PBL in ScienceJboar TbenecdiОценок пока нет

- Experiment 5Документ30 страницExperiment 5Mags CabelinОценок пока нет

- Method Statement For Installation of Water Recticulation SystemДокумент18 страницMethod Statement For Installation of Water Recticulation SystemRabi'atul Adawiyah Ismail100% (2)

- Indowud Brochure Revised PDFДокумент10 страницIndowud Brochure Revised PDFsurabhi narangОценок пока нет

- 1984 WhiteheadДокумент19 страниц1984 WhiteheadAnita yuliyantiОценок пока нет

- ASTM D 5861-Ensayo de Adhesión FRP A Sustrato MetálicoДокумент2 страницыASTM D 5861-Ensayo de Adhesión FRP A Sustrato MetálicoFernando Alfredo Sepúlveda JiménezОценок пока нет

- Bass String Diameters and TensionsДокумент6 страницBass String Diameters and Tensionsbonruiz100% (1)

- Kerosene: Prepared by Supervisor:-Mr. Shwan Ammar Askandar Waleed AdnanДокумент9 страницKerosene: Prepared by Supervisor:-Mr. Shwan Ammar Askandar Waleed AdnanWalid Adnan100% (1)

- Composition and Stability of Iron and Copper Citrate Complexes in Aqueous SolutionДокумент9 страницComposition and Stability of Iron and Copper Citrate Complexes in Aqueous SolutionNitinPrachiJainОценок пока нет

- PROCESS GAS SOLUTIONS: AERZEN'S RELIABLE COMPRESSORS AND BLOWERSДокумент26 страницPROCESS GAS SOLUTIONS: AERZEN'S RELIABLE COMPRESSORS AND BLOWERSWesley andrade martins100% (1)

- Grammar Files b2 Unit 1Документ7 страницGrammar Files b2 Unit 1Irina Shopova100% (1)

- TestДокумент94 страницыTestmutiaraОценок пока нет

- 3D Printing of Structured Electrodes For Rechargeable BatteriesДокумент22 страницы3D Printing of Structured Electrodes For Rechargeable Batterieskhue tranОценок пока нет

- Group II Cation AnalysisДокумент4 страницыGroup II Cation AnalysisClare CaspeОценок пока нет

- Material Safety Data Sheet - Surgical NeedlesДокумент4 страницыMaterial Safety Data Sheet - Surgical NeedlesAri CleciusОценок пока нет