Академический Документы

Профессиональный Документы

Культура Документы

Diaphragm Wall Methodology

Загружено:

Devendra SharmaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Diaphragm Wall Methodology

Загружено:

Devendra SharmaАвторское право:

Доступные форматы

Click to edit Master subtitle style

TOP DOWN METHOD OF CONSTRUCTION

Service Corridor in Middle Circle

3/31/12

TOP DOWN METHOD OF CONSTRUCTION

Service Corridor, being made in Middle Circle of Connaught Place is a tunnel of box section of size (6.3 x 7 mtrs)

Top Down Method of excavation adopted for the project as deep excavation was to be carried out very near to existing buildings

Work being carried out by M/s Afcons

3/31/12

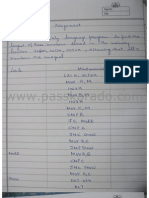

STEPS OF TOP DOWN METHOD

Identification of Existing Utilities Shifting of Utilities & Making of Guide Wall Boring for Diaphragm Wall up to the required depth Lowering of R/F cage in the Bored Area Concreting of the Diaphragm Wall Panel Excavation & Chipping of Concrete up to the cut-off level RCC Top Slab for the Service Tunnel Excavation up to the Bottom Slab

3/31/12

Identification of Existing Utilities

Making of Pre-trench across the road at regular intervals to identify the utilities running along the Proposed Service Tunnel

After the utilities were identified, methodology for shifting of these utilities were finalized

Pre Trench showing the existing utilities

3/31/12

Shifting of Utilities & Making of Guide Wall

The identified utilities were diverted temporarily so as to keep the utilities running & also to make a guide wall for the boring

A Guide Wall was constructed for a depth of 1.6 m along the alignment of Service Corridor to assist in boring for Diaphragm Wall & to shift any 3/31/12unforeseen utilities

Boring for Diaphragm Wall

Boring done up to a depth of 14 m

Boring done with the help of bentonite slurry to help stabilize the walls of the boring till concreting is done

The grab is tied to the body of the crane as a safety 3/31/12 aspect to prevent it from

Lowering of R/F Cage

R/F Cage for Diaphragm Wall Panels of Size (5.0 M) made ready before Each R/F cage boring is weighs commenced approximately 10.5 MT

3/31/12

Concreting for Diaphragm Wall

Tremie Concreting done for Diaphragm Wall

Each Diaphragm Wall Panel is 56 cum

3/31/12

Excavation up to Bottom of Top Slab

After the Diaphragm Wall is casted, Excavation for bottom of top slab is taken up, so that the inconvenience to the public is minimum.

3/31/12

Top Slab

A top slab of 600 mm is casted, leaving openings at regular intervals, so that excavation inside the tunnel can be carried out

3/31/12

Excavation for Base Slab

After the top slab is casted, excavation inside the tunnel is started for base slab works

3/31/12

The identified utilities were diverted temporarily so as to keep the utilities running & also to make a guide wall for the boring ,these included electrical cables, communication cables, drainage sewerage etc.

Click to edit Master subtitle style

3/31/12

FACILITIES INSIDE SERVICE TUNNEL

HT cables LT cables Telecommunication cables Water supply pipe Fire water pipes -one for hydrant network system and another for

water sprinkler systems; tapping to be taken from the latter for providing water spray protection inside the trench.

Irrigation pipeline Gas pipeline. Air conditioning pipes (chilled water) one for supply & one for

return to the entire Connaught Place areas including P Block, Regal Block & Scindia House Block. Secondary pumping system (one working & one standby) and two heat exchangers required for individual blocks are to be provided in the tunnel

3/31/12

Click to edit Master subtitle style

THANKING YOU

3/31/12

Вам также может понравиться

- Diaphragm Wall Method StatementДокумент67 страницDiaphragm Wall Method Statementulhas_nakashe100% (3)

- Secant PilesДокумент14 страницSecant PilesAndrew JacobsОценок пока нет

- DESIGN OF DIaphragm WALLДокумент2 страницыDESIGN OF DIaphragm WALLManan Parikh100% (1)

- CCT AsqДокумент12 страницCCT Asqlcando100% (1)

- Turbo Generators PDFДокумент54 страницыTurbo Generators PDFDevendra Sharma94% (33)

- Retaining Structures and Special Foundations at The Platinum Tower, in MaputoДокумент6 страницRetaining Structures and Special Foundations at The Platinum Tower, in MaputoRuiFPTОценок пока нет

- Soldier Pile WallsДокумент4 страницыSoldier Pile WallsMasar Abdul RakmanОценок пока нет

- Six Lan Road ConstructionДокумент25 страницSix Lan Road ConstructionDevendra SharmaОценок пока нет

- ASME Y14.6-2001 (R2007), Screw Thread RepresentationДокумент27 страницASME Y14.6-2001 (R2007), Screw Thread RepresentationDerekОценок пока нет

- BAUER Diaphragm and Cut Off WallsДокумент16 страницBAUER Diaphragm and Cut Off Wallsshahramk80100% (1)

- Method Statement FOR Construction of Diaphragm Walls (With BAUER BC Trench Cutter System)Документ24 страницыMethod Statement FOR Construction of Diaphragm Walls (With BAUER BC Trench Cutter System)sagar badheОценок пока нет

- Technical Note-Water Seepage Through PilesДокумент5 страницTechnical Note-Water Seepage Through PilesLijo Joseph100% (2)

- Concrete diaphragm slurry walls PA conferenceДокумент18 страницConcrete diaphragm slurry walls PA conferenceJosé Chávez100% (3)

- Diaphragm Wall ConstructionДокумент14 страницDiaphragm Wall ConstructionAkshay Kumar Sahoo100% (5)

- Retaining WallДокумент20 страницRetaining WallCharlesОценок пока нет

- Req 4 Diaphragm WallsДокумент72 страницыReq 4 Diaphragm WallsMohamed ElfawalОценок пока нет

- Deep ExcavationsДокумент29 страницDeep ExcavationsBatu GajahОценок пока нет

- HK Soil Nail DesignДокумент20 страницHK Soil Nail DesignDaltonWong100% (1)

- Diaphragm Wall Construction SequenceДокумент10 страницDiaphragm Wall Construction Sequencedanzy89100% (2)

- Top Down Method of ConstructionДокумент15 страницTop Down Method of ConstructionDevendra Sharma67% (3)

- Prediction of Transmission Line Overloading Using Intelligent TechniqueДокумент18 страницPrediction of Transmission Line Overloading Using Intelligent TechniqueDevendra SharmaОценок пока нет

- Diaphragm Wall TechniquesДокумент28 страницDiaphragm Wall TechniquesMohan ManickamОценок пока нет

- Bob Wright's Declaration of BeingДокумент1 страницаBob Wright's Declaration of BeingBZ Riger100% (2)

- Slope Stabilization & Erosion ControlДокумент53 страницыSlope Stabilization & Erosion ControlSachin Pawar100% (2)

- Digital Booklet - Bach ConcertosДокумент14 страницDigital Booklet - Bach Concertosppopgod33% (3)

- 4 Phases Involved in Bored Cast inДокумент3 страницы4 Phases Involved in Bored Cast inRajesh KhadkaОценок пока нет

- 04-Dr Yet-Managing Adverse ImpactДокумент68 страниц04-Dr Yet-Managing Adverse ImpactfreezefreezeОценок пока нет

- Soldier Piles and Lagging SystemsДокумент7 страницSoldier Piles and Lagging SystemsArjun RajaОценок пока нет

- Basha Diaphragm WallДокумент43 страницыBasha Diaphragm Wallletuananhb100% (4)

- Diaphragm Wall IS CodeДокумент23 страницыDiaphragm Wall IS CodeSudhanshu TrivediОценок пока нет

- Diaphragm Wall PresentationДокумент52 страницыDiaphragm Wall PresentationGagan Goswami100% (11)

- Diaphragm WallДокумент5 страницDiaphragm WallChandra Prakash Khatri0% (1)

- Method Statement For Installation of Soil Nails With For Slope StabilizationДокумент11 страницMethod Statement For Installation of Soil Nails With For Slope StabilizationDelon Yau100% (2)

- South Beach Development-IstructE Conference Singapore 2012Документ20 страницSouth Beach Development-IstructE Conference Singapore 2012blithevincentОценок пока нет

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageДокумент29 страницMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- An 11001 Diaphragm WallДокумент20 страницAn 11001 Diaphragm Wallgahsoon100% (4)

- Gannon - Primary Firm Secant Pile Concrete Specification - April 2016Документ11 страницGannon - Primary Firm Secant Pile Concrete Specification - April 2016muhammad ismailОценок пока нет

- Tunnel Engineering-1Документ26 страницTunnel Engineering-1Ankit PatelОценок пока нет

- Voltage StabilityДокумент27 страницVoltage StabilityDevendra SharmaОценок пока нет

- Bentonite cavities in diaphragm walls case studiesДокумент113 страницBentonite cavities in diaphragm walls case studiesrasanavaneethan100% (1)

- Soil Nailing Design: Presenter Name: Su'aidi Bin Che Su Politeknik Tuanku Sultanah Bahiyah Geotechnical Forensic UnitsДокумент44 страницыSoil Nailing Design: Presenter Name: Su'aidi Bin Che Su Politeknik Tuanku Sultanah Bahiyah Geotechnical Forensic Unitsjumapx100% (1)

- Residential Development Diaphragm Wall WorkДокумент41 страницаResidential Development Diaphragm Wall Workjodemode100% (2)

- Rotating Biological ContactorsДокумент11 страницRotating Biological ContactorsDevendra SharmaОценок пока нет

- Diaphragm WallsДокумент15 страницDiaphragm WallsWan Eira100% (1)

- Secant Pile Wall Design For Deep ExcavationsДокумент1 страницаSecant Pile Wall Design For Deep ExcavationsHorace Prophetic DavisОценок пока нет

- Design & Construction Guidelines For A Soil Nail Wall SystemДокумент27 страницDesign & Construction Guidelines For A Soil Nail Wall Systemgabby80Оценок пока нет

- D-Wall Practice in UkДокумент39 страницD-Wall Practice in Ukwnsrzf100% (1)

- Two Case Histories of Basement Excavation With Influence On Groundwater-Kl - 02Документ19 страницTwo Case Histories of Basement Excavation With Influence On Groundwater-Kl - 02Hoo Yen How100% (1)

- Slope Protection PDFДокумент88 страницSlope Protection PDFSandeep Kumar DangdaОценок пока нет

- Top Down Construction MethodДокумент2 страницыTop Down Construction MethodJoe A. CagasОценок пока нет

- Tunnel Boring MachinesДокумент58 страницTunnel Boring MachinesAliArababadiОценок пока нет

- Diaphragm Wall Paper Hershey2005-Rev - NicholsonДокумент18 страницDiaphragm Wall Paper Hershey2005-Rev - NicholsonTargetRockОценок пока нет

- Eurocode in Geotechnical Engineering: Ground Investigation & Deep Foundation DesignДокумент76 страницEurocode in Geotechnical Engineering: Ground Investigation & Deep Foundation DesignLordM00nОценок пока нет

- Long-Run Incremental Cost Pricing For Negative Growth RateДокумент21 страницаLong-Run Incremental Cost Pricing For Negative Growth RateDevendra SharmaОценок пока нет

- Long-Run Incremental Cost Pricing For Negative Growth RateДокумент21 страницаLong-Run Incremental Cost Pricing For Negative Growth RateDevendra SharmaОценок пока нет

- Offshore Bored Piles Using Permanent CasingsДокумент19 страницOffshore Bored Piles Using Permanent CasingsMohamedAbdelnasser100% (1)

- Challenges To Quality Control in Bored Cast In-Situ Piling in Growing Urban Environment by Karandikar (PPR) PDFДокумент17 страницChallenges To Quality Control in Bored Cast In-Situ Piling in Growing Urban Environment by Karandikar (PPR) PDFsandip0002Оценок пока нет

- Construction Techniques GuideДокумент88 страницConstruction Techniques GuideRON SAMUEL 401935Оценок пока нет

- Diaphargm Wall Construction DetailsДокумент48 страницDiaphargm Wall Construction DetailsAkshay Joshi100% (1)

- Main Presentation Ground Anchors and Anchor SystemsДокумент31 страницаMain Presentation Ground Anchors and Anchor SystemsMirza Waqar BaigОценок пока нет

- Diaphragm Wall SpecificationsДокумент8 страницDiaphragm Wall SpecificationsaomareltayebОценок пока нет

- Plant & Guide Wall ConstructionДокумент10 страницPlant & Guide Wall ConstructionAnonymous S7Cq7ZDgPОценок пока нет

- BAR Digest MenuДокумент4 страницыBAR Digest MenuFloila Jane YmasОценок пока нет

- Diaphragm Walls Construction and DesignДокумент18 страницDiaphragm Walls Construction and DesignShirley Munoz100% (1)

- Diaphragm WallДокумент1 страницаDiaphragm WallliumaoОценок пока нет

- Diaphragm WallДокумент4 страницыDiaphragm Wallリムスィギャン瑞娴Оценок пока нет

- 13 Dewatering of FoundationsДокумент65 страниц13 Dewatering of FoundationsZahoor AhmadОценок пока нет

- Expansive Cements PDFДокумент33 страницыExpansive Cements PDFbardha50% (2)

- Construction of Slurry WallsДокумент22 страницыConstruction of Slurry WallsJOE G PHILIP CEОценок пока нет

- Pressure Calculation Sheet For Locking Load: 20% of 13.8 TonsДокумент3 страницыPressure Calculation Sheet For Locking Load: 20% of 13.8 TonsKrushna RamaОценок пока нет

- Ground AnchorsДокумент31 страницаGround AnchorsHammer HeadОценок пока нет

- CP Unit 2Документ184 страницыCP Unit 2Dhanashri Patil100% (1)

- Tunnel EngineeringДокумент53 страницыTunnel EngineeringshankaregowdaОценок пока нет

- Long-Run Incremental Cost Pricing For Negative Growth RateДокумент22 страницыLong-Run Incremental Cost Pricing For Negative Growth RateDevendra SharmaОценок пока нет

- Urgent Opportunities For Transmission System EnhacementДокумент36 страницUrgent Opportunities For Transmission System EnhacementDevendra SharmaОценок пока нет

- World Trade Park JaipurДокумент3 страницыWorld Trade Park JaipurDevendra SharmaОценок пока нет

- Measurement LabДокумент40 страницMeasurement LabDevendra SharmaОценок пока нет

- Machine Lab 1Документ25 страницMachine Lab 1Devendra SharmaОценок пока нет

- Microprocessor AssignmentДокумент33 страницыMicroprocessor AssignmentDevendra SharmaОценок пока нет

- Water Resource ManagementДокумент34 страницыWater Resource ManagementDevendra SharmaОценок пока нет

- World Trade ParkДокумент33 страницыWorld Trade ParkDevendra Sharma67% (3)

- Training Report Rajasthan Housing BoardДокумент13 страницTraining Report Rajasthan Housing BoardDevendra SharmaОценок пока нет

- NTPC Badarpur TrainingДокумент50 страницNTPC Badarpur TrainingDevendra SharmaОценок пока нет

- WreДокумент21 страницаWreDevendra SharmaОценок пока нет

- Voltage Stability Enhancement in Contingency Conditions Using Shunt DevicesДокумент17 страницVoltage Stability Enhancement in Contingency Conditions Using Shunt DevicesDevendra SharmaОценок пока нет

- Sustainable Energy Strategy and ImplementationДокумент21 страницаSustainable Energy Strategy and ImplementationDevendra SharmaОценок пока нет

- Voltage StabilityДокумент26 страницVoltage StabilityDevendra SharmaОценок пока нет

- Report of Composite StructureДокумент21 страницаReport of Composite StructureDevendra SharmaОценок пока нет

- SewersДокумент13 страницSewersDevendra SharmaОценок пока нет

- Training Report - Khasa KothiДокумент33 страницыTraining Report - Khasa KothiDevendra SharmaОценок пока нет

- Transmission System Application Requirement For Facts ControllersДокумент26 страницTransmission System Application Requirement For Facts ControllersDevendra SharmaОценок пока нет

- Project Report Burj DubaiДокумент14 страницProject Report Burj DubaiDevendra Sharma100% (4)

- Road Light Management System Using EmbeddedДокумент8 страницRoad Light Management System Using EmbeddedDevendra SharmaОценок пока нет

- Reduction in Induction Motor Heating Fed by A New PWM TechniqueДокумент18 страницReduction in Induction Motor Heating Fed by A New PWM TechniqueDevendra SharmaОценок пока нет

- Presentation On 132 KV Chambal G.S.S., JaipurДокумент23 страницыPresentation On 132 KV Chambal G.S.S., JaipurDevendra Sharma100% (6)

- Prediction of Transmission Line Overloading UsingДокумент23 страницыPrediction of Transmission Line Overloading UsingDevendra SharmaОценок пока нет

- Theme Meal ReportДокумент10 страницTheme Meal Reportapi-434982019Оценок пока нет

- 6vortex 20166523361966663Документ4 страницы6vortex 20166523361966663Mieczysław MichalczewskiОценок пока нет

- Tech Letter-NFPA 54 To Include Bonding 8-08Документ2 страницыTech Letter-NFPA 54 To Include Bonding 8-08gl lugaОценок пока нет

- Internship Report Recruitment & Performance Appraisal of Rancon Motorbikes LTD, Suzuki Bangladesh BUS 400Документ59 страницInternship Report Recruitment & Performance Appraisal of Rancon Motorbikes LTD, Suzuki Bangladesh BUS 400Mohammad Shafaet JamilОценок пока нет

- Resume Ajeet KumarДокумент2 страницыResume Ajeet KumarEr Suraj KumarОценок пока нет

- Sample Property Management AgreementДокумент13 страницSample Property Management AgreementSarah TОценок пока нет

- Difference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsДокумент2 страницыDifference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDharma Teja TanetiОценок пока нет

- SAP PS Step by Step OverviewДокумент11 страницSAP PS Step by Step Overviewanand.kumarОценок пока нет

- Code Description DSMCДокумент35 страницCode Description DSMCAnkit BansalОценок пока нет

- Case Study 2 F3005Документ12 страницCase Study 2 F3005Iqmal DaniealОценок пока нет

- 1990-1994 Electrical Wiring - DiagramsДокумент13 страниц1990-1994 Electrical Wiring - Diagramsal exОценок пока нет

- Discretionary Lending Power Updated Sep 2012Документ28 страницDiscretionary Lending Power Updated Sep 2012akranjan888Оценок пока нет

- 9 QP - SSC - MOCK EXAMДокумент5 страниц9 QP - SSC - MOCK EXAMramОценок пока нет

- Milwaukee 4203 838a PB CatalogaciónДокумент2 страницыMilwaukee 4203 838a PB CatalogaciónJuan carlosОценок пока нет

- 3 Course Contents IIIBДокумент5 страниц3 Course Contents IIIBshahabОценок пока нет

- Programme Report Light The SparkДокумент17 страницProgramme Report Light The SparkAbhishek Mishra100% (1)

- Planning For Network Deployment in Oracle Solaris 11.4: Part No: E60987Документ30 страницPlanning For Network Deployment in Oracle Solaris 11.4: Part No: E60987errr33Оценок пока нет

- RTL8316C GR RealtekДокумент93 страницыRTL8316C GR RealtekMaugrys CastilloОценок пока нет

- CCS PDFДокумент2 страницыCCS PDFАндрей НадточийОценок пока нет

- Management Pack Guide For Print Server 2012 R2Документ42 страницыManagement Pack Guide For Print Server 2012 R2Quang VoОценок пока нет

- BS EN 364-1993 (Testing Methods For Protective Equipment AgaiДокумент21 страницаBS EN 364-1993 (Testing Methods For Protective Equipment AgaiSakib AyubОценок пока нет

- Chapter 1 Qus OnlyДокумент28 страницChapter 1 Qus OnlySaksharОценок пока нет

- Engine Controls (Powertrain Management) - ALLDATA RepairДокумент4 страницыEngine Controls (Powertrain Management) - ALLDATA Repairmemo velascoОценок пока нет

- An Overview of Tensorflow + Deep learning 沒一村Документ31 страницаAn Overview of Tensorflow + Deep learning 沒一村Syed AdeelОценок пока нет