Академический Документы

Профессиональный Документы

Культура Документы

Condition Based Monitoring of

Загружено:

Manoj MalladiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Condition Based Monitoring of

Загружено:

Manoj MalladiАвторское право:

Доступные форматы

Condition based monitoring of ball bearing

Project guide : D.V.A.Ramasastry assoc. Professor Team members: P.Karthikeyudu 09101345 Y.Lakshmi pavan 09101349 M.Manoj Kumar 09101353 P.T.N.Malleswar 09101365 N.Ravindra babu 09101381

Ball bearing A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. Purpose The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were rotating on each other.

Common motions permitted by bearings are: Axial rotation e.g. shaft rotation Linear motion e.g. drawer spherical rotation e.g. ball and socket joint hinge motion e.g. door, elbow, knee

Introduction to rolling element bearing A rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing round elements between the two pieces. The relative motion of the pieces causes the round elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them.

A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between the shaft and hole. As the shaft turns, each roller acts as the logs in the above example. However, since the bearing is round, the rollers never fall out from under the load. Rolling-element bearings have the advantage of a good tradeoff between cost, size, weight, carrying capacity, durability, accuracy, friction, and so on. Other bearing designs are often better on one specific attribute, but worse in most other attributes, although fluid bearing scan sometimes simultaneously outperform on carrying capacity, durability, accuracy, friction, rotation rate and sometimes cost. Only plain bearings are used as widely as rolling-element bearings.

General design considerations: Determine the length of bearing by using l/d ratio. bearing pressure ,p=W/(l.d) Determine a lubricant. Determine the operating value of ZN/p . Determine clearance ratio c/d. Determine coefficient of friction ().

Determine the heat generated

Qg= .W.V watts

Determine the heat dissipated

Qd = C.A(tb-ta) watts

Determine the thermal equilibrium to see

that the heat dissipated becomes atleast equal to the heat generated. In case the heat generated is more than the heat dissipated then either the bearing is redesigned or it is cooled artificially.

Types of rollers : Ball Ball bearings use balls instead of cylinders. Ball bearings can support both radial (perpendicular to the shaft) and axial loads (parallel to the shaft). For lightly loaded bearings, balls offer lower friction than rollers. Ball bearings can operate when the bearing races are misaligned. Precision balls are typically cheaper to produce than shapes such as rollers; combined with high-volume use, ball bearings are often much cheaper than other bearings of similar dimensions. Ball bearings may have high point loads, limiting total load capacity compared to other bearings of similar dimensions.

Cylindrical roller Common roller bearings use cylinders of slightly greater length than diameter. Roller bearings typically have higher load capacity than ball bearings, but a lower capacity and higher friction under loads perpendicular to the primary supported direction. If the inner and outer races are misaligned, the bearing capacity often drops quickly compared to either a ball bearing or a spherical roller bearing.

Needle Needle roller bearings use very long and thin cylinders. Often the ends of the rollers taper to points, and these are used to keep the rollers captive, or they may be hemispherical and not captive but held by the shaft itself or a similar arrangement. Since the rollers are thin, the outside diameter of the bearing is only slightly larger than the hole in the middle. However, the small-diameter rollers must bend sharply where they contact the races, and thus

Tapered roller: Tapered roller bearings use conical rollers that run on conical races. Most roller bearings only take radial or axial loads, but tapered roller bearings support both radial and axial loads, and generally can carry higher loads than ball bearings due to greater contact area. Taper roller bearings are used, for example, as the wheel bearings of most wheeled land vehicles. The downsides to this bearing is that due to manufacturing complexities, tapered roller bearings are usually more expensive than ball bearings; and additionally under heavy loads the tapered roller is like a wedge and bearing loads tend to try to eject the roller; the force from the collar which keeps the roller in the bearing adds to bearing friction compared to ball bearings.

Spherical roller: Spherical roller bearings use rollers that are thicker in the middle and thinner at the ends; the race is shaped to match. Spherical roller bearings can thus adjust to support misaligned loads. However, spherical rollers are difficult to produce and thus expensive, and the bearings have higher friction than a comparable ball bearing since different parts of the spherical rollers run at different speeds on the rounded race and thus there are opposing forces along the bearing/race contact.

Bearing failures : Failures of bearing depend on Irregularities in roller element. Oil cooling. Lubrication.

Constraints and tradeoffs : All parts of a bearing are subject to many design constraints. For example, the inner and outer races are often complex shapes, making them difficult to manufacture. Balls and rollers, though simpler in shape, are small; since they bend sharply where they run on the races, the bearings are prone to fatigue. The loads within a bearing assembly are also affected by the speed of operation: rolling-element bearings may spin over 100,000 rpm, and the principal load in such a bearing may be momentum rather than the applied load. Smaller rolling elements are lighter and thus have less momentum, but smaller elements also bend more sharply where they contact the race, causing them to fail more rapidly from fatigue.

There are also many material issues: a harder material may be more durable against abrasion but more likely to suffer fatigue fracture, so the material varies with the application, and while steel is most common for rollingelement bearings, plastics, glass, and ceramics are all in common use. A small defect (irregularity) in the material is often responsible for bearing failure; one of the biggest improvements in the life of common bearings during the second half of the 1900s was the use of more homogeneous materials, rather than better materials or lubricants (though both were also significant). Lubricant properties vary with temperature and load, so the best lubricant varies with application.

Although bearings tend to wear out with use, designers can make tradeoffs of bearing size and cost versus lifetime. A bearing can last indefinitely longer than the rest of the machine if it is kept cool, clean, lubricated, is run within the rated load, and if the bearing materials are sufficiently free of microscopic defects. Note that cooling, lubrication, and sealing are thus important parts of the bearing design.

The needed bearing lifetime also varies with the application. For example, Tedric A. Harris reports in his Rolling Bearing Analysis[2] on an oxygen pump bearing in the U.S. Space Shuttle which could not be adequately isolated from the liquid oxygen being pumped, but all lubricants reacted with the oxygen leading to fires and other failures. The solution was to lubricate the bearing with the oxygen. Although liquid oxygen is a poor lubricant, it was adequate, since the service life of the pump was just a few hours.

The operating environment and service needs are also important design considerations. Some bearing assemblies require routine addition of lubricants, while others are factory sealed, requiring no further maintenance for the life of the mechanical assembly. Although seals are appealing, they increase friction, and a permanently-sealed bearing may have the lubricant contaminated by hard particles, such as steel chips from the race or bearing, sand, or grit that got past the seal. Contamination in the lubricant is abrasive and greatly reduces the operating life of the bearing assembly. Another major cause of bearing failure is the presence of water in the lubrication oil. Online water in oil monitors have been introduced in recent years to monitor the effects of both particles and the presence of water in oil and their combined effect.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 2005 S003 NBPG Rfi 04952 - R00Документ1 страница2005 S003 NBPG Rfi 04952 - R00RPDeshОценок пока нет

- IEC Motor Data CalculatorДокумент6 страницIEC Motor Data Calculatorsabill arasyidОценок пока нет

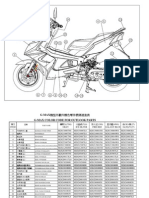

- Bigy 150MX - 2019Документ25 страницBigy 150MX - 2019Kamila KОценок пока нет

- Front Axle Steering Linkage - 2wdДокумент2 страницыFront Axle Steering Linkage - 2wdGiovani FariasОценок пока нет

- G Max150 PartslistДокумент92 страницыG Max150 PartslistKenji BearОценок пока нет

- Fuel Injection Equipment Roos Master John Deere TM1064 TextДокумент100 страницFuel Injection Equipment Roos Master John Deere TM1064 TextjuanОценок пока нет

- AM3K Manual 2019-10-15Документ130 страницAM3K Manual 2019-10-15Roger Pozo AriasОценок пока нет

- Double Piston Single Connecting RodДокумент31 страницаDouble Piston Single Connecting RodMeet Patel100% (2)

- Manual - Belt Air Compressor Series - ENДокумент26 страницManual - Belt Air Compressor Series - ENknjigebook1 knjigebook1Оценок пока нет

- 3 MechanismsДокумент35 страниц3 Mechanismsesham2100% (1)

- CAT D342 Shop Armer Manual PDFДокумент18 страницCAT D342 Shop Armer Manual PDFJhony Soto LoperaОценок пока нет

- Automatic Transmission Service GroupДокумент48 страницAutomatic Transmission Service GroupAndrei Balla100% (3)

- Assembly ProcedureДокумент115 страницAssembly ProcedureAlex Castillo100% (1)

- Bom 8.037733.rДокумент11 страницBom 8.037733.rneid smajicОценок пока нет

- ATLAS COPCO - GA - Gearbox - v01Документ8 страницATLAS COPCO - GA - Gearbox - v01Carlos Perez Isaac100% (5)

- Plugin Chapter16Документ45 страницPlugin Chapter16Akshay GatkalОценок пока нет

- 9AGE BuildInformation2Документ13 страниц9AGE BuildInformation2Danno NОценок пока нет

- Technical Service Bulletin: Excessive Oil Consumption - Nu/Gamma EnginesДокумент13 страницTechnical Service Bulletin: Excessive Oil Consumption - Nu/Gamma EnginesKimberly RamirezОценок пока нет

- Mainero 2330 Grain Handler Parts Manual PDFДокумент26 страницMainero 2330 Grain Handler Parts Manual PDFБондаренко Сергій Миколайович100% (1)

- Automotive TransmissionДокумент146 страницAutomotive TransmissionTony Neal100% (1)

- TC 5000 (FS) - TC 5100 (FS)Документ1 страницаTC 5000 (FS) - TC 5100 (FS)Alfarizqi WijayaОценок пока нет

- Table 2-1 N M KGF M: 2 Inspection Data and Maintenance Period 2.1Документ5 страницTable 2-1 N M KGF M: 2 Inspection Data and Maintenance Period 2.1Gabriel BalcazarОценок пока нет

- BAH Series 6000 Manguard - 113534-91Документ40 страницBAH Series 6000 Manguard - 113534-91AhmedОценок пока нет

- Illustrated Parts List: FS-4005A November 2008Документ16 страницIllustrated Parts List: FS-4005A November 2008Jorge Castillo HdzОценок пока нет

- Monika Alloys & Steel IndustriesДокумент13 страницMonika Alloys & Steel Industriesvelu.gОценок пока нет

- SOR-Vol3 PrintДокумент518 страницSOR-Vol3 PrintSalakati NTPCОценок пока нет

- Operator'S Manual For Models: JG, Jga, JGM, JGP: Heavy Duty Balanced Opposed CompressorsДокумент70 страницOperator'S Manual For Models: JG, Jga, JGM, JGP: Heavy Duty Balanced Opposed CompressorsDjebali MouradОценок пока нет

- S/No C/No PT No Nomenclature A/U QTY Wheel Loader 2021Документ5 страницS/No C/No PT No Nomenclature A/U QTY Wheel Loader 2021Pannalal RajwarОценок пока нет

- GPT Installation Instruction - 12.2018Документ2 страницыGPT Installation Instruction - 12.2018Zool HilmiОценок пока нет

- TAD750VE Spare PartsДокумент100 страницTAD750VE Spare PartsAnonymous I6U56Ib100% (2)