Академический Документы

Профессиональный Документы

Культура Документы

Strength of Materials (HE 306)

Загружено:

Anu ParameswaranИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Strength of Materials (HE 306)

Загружено:

Anu ParameswaranАвторское право:

Доступные форматы

7/12/12

WAVE DAMAGE. November 19, 2002

The leaking oil tanker Prestige sinks some 240km off Spain's north-

western coast, taking more than 70,000 tonnes of fuel to the seabed

4 km below.

Click to edit Master subtitle style

7/12/12

Strength of Materials (HE

306)

Prof. Dr. R. Chandra Sekaran Ph.D (C.Engg)

7/12/12

7/12/12

7/12/12

7/12/12

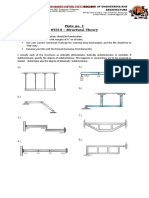

INTRODUCTIONCONCEPT OF STRESS

2 STRESS AND STRAINAXIAL LOADING

3 TORSION

4 PURE BENDING

5 ANALYSIS AND DESIGN OF BEAMS FOR BENDING

In the experiment, a wire of a given

thickness and length was used to

suspend a basket. The

basket was filled slowly with sand, fed

from an adjacently suspended hopper

(Figure). When the wire suspending

the basket breaks, a spring closes the

hopper opening, and the basket falls a

short distance into a hole, so as not to

upset the basket. The sand in the

basket was then weighed to establish

the tensile strength of the wire.

7/12/12

What is Mechanics?

Mechanics is the science which describes and predicts

the conditions of rest or motion of bodies under the

action of forces.

Categories of Mechanics:

- Rigid bodies Statics and Dynamics

- Deformable bodies Strength of Materials

- Fluids

Mechanics is an applied science - it is not an abstract

or pure science but does not have the empiricism found

in other engineering sciences.

Mechanics is the foundation of most engineering

sciences and is an indispensable prerequisite to their

study.

7/12/12

Fundamental Concepts

Space - associated with the notion of the position of a point P given in

terms of three coordinates measured from a reference point or origin.

Time - definition of an event requires specification of the time and

position at which it occurred.

Mass - used to characterize and compare bodies, e.g., response to

earths gravitational attraction and resistance to changes in translational

motion.

Force - represents the action of one body on another. A force is

characterized by its point of application, magnitude, and direction, i.e.,

a force is a vector quantity.

In Newtonian Mechanics, space, time, and mass are absolute concepts,

independent of each other. Force, however, is not independent of the

other three. The force acting on a body is related to the mass of the body

and the variation of its velocity with time.

7/12/12

EQUILIBRIUM

This section will be limited to one- or two-dimensional systems, where all the forces and

couples will be acting in on plane; such a system of forces is called a copl anar system.

In two dimensions, equilibrium is achieved when the following laws are satisfied:

upward forces = downward forces ,

forces to the l eft = forces to the ri ght and

cl ockwi se coupl es = counter cl ockwi se coupl es.

Taki ng moments about B

cl ockwi se coupl es =

counter cl ockwi se coupl es

RAx4 = 3 x 6 + 1 0 x 2

RA = (18 + 20 )/4 RA =

9.5 kN

Resol vi ng forces verti cal l y,

RA+RB = (3+10)

or RB = (13 - 9.5) = 3.5

kN

Determi ne the reacti ons of RA and RB for the si mpl y-supported beam

7/12/12

Tension and compression: direct

stresses

One of the simplest loading conditions of a material is that of tensi on, in which the fibres

of the material are stretched.

Consider, for example, a long steel wire held rigidly at its upper end and loaded by a mass

hung from the lower end. If vertical movements of the lower end are observed during

loading it will be found that the wire is stretched by a small, but measurable,

amount from its original unloaded length. The material of the wire is composed of a large

number of small crystals which are only visible under a microscopic study; these crystals

have irregularly shaped boundaries, and largely random orientations with respect to each

other; as loads are applied to the wire, the crystal structure of the metal is distorted.

For small loads it is found that

the extension of the wire is

roughly proportional to the

applied load. This linear

relationship between load

and extension was first

discovered by Robert

Hooke in 1678; a material

showing this characteristic is

said to obey Hooke's law.

7/12/12

As the tensile load in the wire is increased, a stage is reached where the material ceases

to show this linear characteristic; the corresponding point on the load-extension curve is

known as the l i mi t of proporti onal i ty.

If the wire is made from a high-strength steel then the l oad-extensi on curve up to the

breaking point has the form shown.

Beyond the limit of proportionality the extension of the wire increases non-linearly up to

the elastic limit and, eventually, the breaking point.

Elastic limit is important because it divides the load-extension curve into two regions. For

loads up to the elastic limit, the wire returns to its original un-stretched length on removal

of the loads; this properly of a material to recover its original form on removal of the

loads is known as el asti ci ty; the steel wire behaves as a still elastic spring.

When loads are applied above the el asti c l i mi t, and are then removed, it is found that

the wire recovers onl y part of its extension and is stretched permanently;

in this condition the wire is said to have undergone an i nel asti c, or pl asti c extension.

For most materials, the limit of proportionality and the elastic limit are assumed to have the same value.

In the case of elastic extensions, work performed in stretching the wire is stored as strain energy in

the material; this energy is recovered when the loads are removed. During inelastic extensions,

work is performed in making permanent changes in the internal structure of the material. Not all

the work can be recovered : balance of this energy reappears in other forms, mainly as

heat.

7/12/12

When tensile tests are carried out on steel wires of the same material, but of di fferent

cross secti onal area, the breaking loads are found to be proporti onal approximately

to the respecti ve cross-secti onal areas of the wires.

This is so because the tensile strength is governed by the intensity of force on a normal

cross-section of a wire, and not by the total force.

This intensity of force is known as stress, denoted by .

Suppose A is an element of area of the cross section of

the bar, if the normal force acting on this element is P ,

then the tensile stress at this point of the cross-section is

defined as the limiting value of the ratio ( P/ A) as A

becomes infinitesimally small. Thus,

When the forces P in Figure are reversed in direction at each end of

the bar they tend to compress the bar; the loads then give rise to

compressive stresses.

Tensile and compressive stresses are together referred to as direct

(or normal) stresses, because they act perpendicularly to the surface.

7/12/12

A steel bar of rectangular cross-section, 3 cm by 2 cm, carries an axial load of 30 kN.

Estimate the average tensile stress over a normal cross-section of the bar.

7/12/12

A steel bolt, 2.50 cm in diameter, carries a tensile load of 40 kN. Estimate the

average tensile stress at the section a and at the screwed section b, where the

diameter at the root of the thread is 2.10 cm.

7/12/12

Tensi l e and compressi ve strai ns

In the steel wire experiment we discussed the extension of the whole wire.

If we measure the extension of, say, the lowest quarter-length of the wire we find that

for a gi ven l oad i t i s equal to a quarter of the extensi on of the whol e wi re.

In general we find that, at a given load, the ratio of the extension of any length to that

length is constant for all parts of the wire; this ratio is known as the tensi l e strai n.

Suppose the initial unstrained length of the wire is Lo, and e is the extension due to

straining; the tensile strain is defined as

This definition of strain is useful only for small distortions, in which the extension e is

small compared with the original length Lo;

this definition is adequate for the study of most engineering problems, where we are

concerned with values of of the order 0.001, or so.

If a material is compressed the resulting strain is defined in a similar way, except that

e is the contraction of a length.

We note that strai n i s a non-di mensi onal quanti ty, being the ratio of the extension,

or contraction, of a bar to its original length.

7/12/12

A cylindrical block is 30 cm long and has a circular cross-section 10 cm in

diameter. It carries a total compressive load of 70 kN, and under this load it

contracts by 0.02 cm. Estimate the average compressive stress over a normal

cross-section and the compressive strain.

7/12/12

Stress-strai n curves for bri ttl e materi al s

Many of the characteristics of a material can be deduced from the tensile test.

In the experiment we measured the extensions of the wire for increasing loads; it is more

convenient to compare materials in terms of stresses and strains, rather than loads and

extensions of a particular specimen of a material.

The tensile stress-strain curve for a high-strength steel has the form shown. The stress at

any stage is the ratio of the load of the original cross-sectional area of the test specimen;

the strain is the elongation of a unit length of the test specimen.

For stresses up to about 750 MN/m2 the stress-

strain curve i s l i near, showing that the material

obeys Hooke s l aw in this range; the material is

also elastic in this range, and no permanent

extensions remain after removal of the stresses.

The ratio of stress to strain for this linear region is

usually about 200 GN/m2 for steels;

this ratio is known as Young s modul us and is

denoted by E.

Similarly, the strain at the limit of proportionality is

of the order 0.003, and is small compared with

strains of the order 0.100 at fracture.

7/12/12

We note that Youngs modulus has the units of a stress; the value of E defines the

constant in the linear relation between stress and strain in the elastic range of the

material.

We have, for the linear-elastic range.

If P is the total tensile load in a bar, A its cross-sectional area, and Lo its length,

e is the extension of the length Lo, then

Thus the expansion is given by

If the material is stressed beyond the linear-elastic range, the limit of proportionality is

exceeded, and the strains increase non-linearly with the stresses.

Moreover, removal of the stress leaves the

material with some permanent extension; this

range is then both non-linear and inelastic. The

maximum stress attained may be of the order of

1500 MN/m2, and the total extension, or

elongation, at this stage may be of the order of

10%.

When a material is stressed beyond the limit of

proportionality and is then unloaded,permanent

deformations of the material take place.

Unloading and reloading of a material in the inelastic range; the paths

bc and cd are approximately parallel to the linear-elastic line oa.

7/12/12

Suppose the tensile test-specimen is stressed beyond the limit of proportionality, in figure,

point a, to a point b on the stress-strain diagram. If the stress is now removed, the

stress-strain relation follows the curve bc ; when the stress is completely removed there

is a residual strain given by the intercept Oc on the -axis.

If the stress is applied again, the stress-strain relation follows the curve cd initially, and

finally the curve df to the breaking point.

Both the unloading curve bc and the reloading curve cd are approximately parallel to the

elastic line Oa; they are curved slightly in opposite directions.

The process of unloading and reloading, bcd, had little or no effect on the stress at the

breaking point, the stress-strain curve being interrupted by only a small amount bd.

The stress-strain curves of brittle materials for

tension and compression are usually similar in

form, although the stresses at the limit of

proportionality and at fracture may be very

different for the two loading conditions.

Typical tensile and compressive stress-strain

curves for concrete are shown in Figure; the

maximum stress attainable in tension is only

about one-tenth of that in compression,

although the slopes of the stress-strain curves

in the region of zero stress are nearly equal.

7/12/12

Ducti l e materi al s

A brittle material is one showing relatively little elongation at fracture in the tensile test;

but some materials, such as mild steel, copper, and synthetic polymers, may be stretched

appreciably before breaking. These latter materials are ductile in character.

If tensile and compressive tests are made on a mild steel, the resulting stress-strain

curves are different in form from those of a brittle material, such as a high-strength steel.

If a tensile test specimen of mild steel is loaded axially, the stress-strain curve is linear

and elastic up to a point a, refer figure 1.

(The smal l strai n regi on of Fi gure 1, i s reproduced to a l arger scal e i n Fi gure 2).

The ratio of stress to strain, or Youngs modulus, for the linear portion Oa is usually about

200 GN/m2, ie, 200 x109 N/m2.

The tensile stress at the point a is of order 300 MN/m2, i.e. 300 x 106 N/m2.

The stress for a tensile specimen attains a maximum value at d if the stress is evaluated

on the basis of the original cross-sectional area of the bar; the stress corresponding to

the point d is known as the ul ti mate stress, (ul t) of the material.

From d to f there is a reduction in the nominal stress until fracture occurs at f. The

ultimate stress in tension is attained at a stage when necking begins; this is a reduction of

area at a relatively weak cross-section of the test specimen.

7/12/12

Tensile stress-strain curve for

an annealed mild steel,

showing the drop in stress at

yielding from the upper yield

point a to the lower yield

point b.

Upper and lower yield points of a mild

steel.

7/12/12

If the test specimen is strained beyond the point a, figures 1 and 2, the stress must be

reduced almost immediately to maintain equilibrium.

The reduction of stress, ab, takes place rapidly, and the form of the curve ab is difficult

to define precisely.

Continued straining proceeds at a roughly constant stress along bc.

In the range of strains from a to c the material is said to yield;

Please note: a is the upper yield point, and b the lower yield point.

Yielding at constant stress along bc proceeds usually to a strain about 40 times greater

than that at a.

Beyond the point c the material strain-hardens, and stress again increases with strain

where the slope from c to d is about 1/50th that from 0 to a.

Compressive tests of mild steel give stress-strain curves similar to those for tension. If we

consider tensile stresses and strains as positive, and compressive stresses and strains as

negative, we can plot the tensile and compressive stress-strain curves on the same

diagram.

In determining the stress-strain curves experimentally, it is important to ensure that the

bar is loaded axially;

7/12/12

The figure shows the stress-strain curves for an

annealed mild steel. In the annealed condition

the yield stresses in tension and

Compression are approximately equal.

The lower yield point stress is taken usually as a more realistic definition of yielding of the

material. Some ductile materials show no clearly defined upper yield stress; for these

materials the limit of proportionality may be lower than the stress for continuous yielding.

The term yield stress refers to the stress for continuous yielding of a material; this implies

the lower yield stress for a material in which an upper yield point exists; the yield stress is

denoted by .

Tensile failures in steel specimens

showing necking in mild steel, (i)

and (iii), and brittle fracture in

high-strength steel, (ii).

7/12/12

Defi ni ti on of Stress

The concept of stress originated from the study of strength and failure of solids. The

stress field is the distribution of internal "tractions" that balance a given set of external

tractions and body forces. First, we look at the external traction T that represents the

force per unit area acting at a given location on the body's surface. Traction T is a bound

vector, which means T cannot slide along its line of action or translate to another location

and keep the same meaning.

In other words, a traction vector cannot be fully described unless both the force and the

surface where the force acts on has been specified. Given both F and s, the traction T

can be defined as

7/12/12

The internal traction within a solid, or stress, can be defined in a similar manner. Suppose

an arbitrary slice is made across the solid shown in the above figure, leading to the free

body diagram shown at right. Surface tractions would appear on the exposed surface,

similar in form to the external tractions applied to the body's exterior surface. The stress

at point P can be defined using the same equation as was used for T.

Stress therefore can be interpreted as internal tractions that act on a defined internal

datum plane. One cannot measure the stress without first specifying the datum plane.

Surface tractions, or stresses acting on an

internal datum plane, are typically

decomposed into three mutually

orthogonal components.

One component is normal to the surface

and represents di rect stress. The other

two components are tangential to the

surface and represent shear stresses.

What is the distinction between normal and

tangential tractions, or equivalently, direct

and shear stresses?

The Stress Tensor (or Stress

Matri x)

7/12/12

7/12/12

Di rect stresses tend to change the volume of the material (e.g. hydrostatic pressure)

and are resisted by the body's bulk modulus (which depends on the Young's modulus and

Poisson ratio). Shear stresses tend to deform the material without changing its volume,

and are resisted by the body's shear modulus.

For example, the stress state at point P can be

represented by an infinitesimal cube with three

stress components on each of its six sides

(one direct and two shear components).

Since each point in the body is under static

equilibrium (no net force in the absence of any

body forces), only nine stress components from

three planes are needed to describe the

stress state at a point P.

These nine components can be

Organised into the matrix:

where shear stresses across the diagonal are identical (i.e. xy = yx, yz = zy, and

zx = xz) as a result of static equilibrium (no net moment). This grouping of the nine

stress components is known as the stress tensor (or stress matrix).

The subscript notation used for the

nine stress components have the

following meaning:

7/12/12

Note: The stress state is a second order tensor since it is a quantity associated with

two directions. As a result, stress components have 2 subscripts.

A surface traction is a fi rst order tensor (i.e. vector) since it a quantity associated with

only one direction. Vector components therefore require only 1 subscript.

Mass would be an example of a zero-order tensor (i.e. scalars), which have no

relationships with directions (and no subscripts).

Consider the static equilibrium of a solid subjected to the body force vector field b.

Applying Newton's first law of motion results in the following set of differential equations

which govern the stress distribution within the solid,

In the case of two dimensional stress, the above equations reduce to,

7/12/12

7/12/12

7/12/12

7/12/12

Consider a rod with initial length L which is stretched to a

length L'. The strain measure , a dimensionless ratio, is

defined as the ratio of elongation with respect to the original

length,

Gl obal 1D

Strai n

Consider an arbitrary point in the bar P, which has a

position vector x, and its infinitesimal neighbour dx.

Point P shifts to P' , which has a position vector x' ,

after the stretch. In the meantime, the small "step" dx

is stretched to dx' .

The strain at point p can be defined

Since the displacement ,

the strain can hence be rewritten as,

Infi ni tesi mal 1D

Strai n

The above strain measure is defined in a global sense. The

strain at each point may vary dramatically if the bar's elastic

modulus or cross-sectional area changes.

7/12/12

There are a total of 6

strain measures which

can be organised into

a matrix.

3D Strai n

Matri x

Engi neeri ng Shear

Strai n

Focus on the strain xy for a moment. The expression inside the parentheses can be

rewritten as, where called the

engi neeri ng shear strai n, xy is a total measure of shear strain in the x-y plane.

In contrast, the shear strain xy is the average of the shear strain on the x face along the

y direction, and on the y face along the x direction.

Engineering shear strain is commonly used in engineering reference books. However, please

beware of the difference between shear strain and engineering shear strain, so as to avoid errors

in mathematical manipulations.

7/12/12

In the strain-displacement relationships, there are six strain measures but only three

independent displacements. That is, there are 6 unknowns for only 3 independent

variables. As a result there exist 3 constraint, or compatibility, equations. These

compatibility conditions for infinitesimal strain referred to rectangular Cartesian

coordinates are,

In two dimensional problems (e.g. plane strain), all z terms are set to zero. The

compatibility equations reduce to,

Note that some references use engineering shear strain ( ) when

referencing compatibility equations.

Compati bi l i ty Condi ti ons

7/12/12

General Definition of 3D Strain

As in the one dimensional strain

derivation, suppose that point P in a

body shifts to point P after deformation.

The infinitesimal strain-displacement

relationships can be summarised as,

where u is the displacement vector,

x is coordinate, and the two indices i

and j can range over the three

coordinates {1, 2, 3} in three

dimensional space.

Expanding the above equation for each

coordinate direction gives,

where u, v, and w are the displacements in

the x, y, and z directions respectively

(i.e. they are the components of u).

7/12/12

Bul k El asti c Properti es

The bulk elastic properties of a material determine how much it will compress under a

given amount of external pressure. The ratio of the change in pressure to the fractional

volume compression is called the bul k modul us of the materi al .

A representative value for the bulk modulus for steel is and that for water is

The reciprocal of the bulk modulus is called the compressi bi l i ty of the substance. The

amount of compression of solids and liquids is seen to be very small.

The bulk modulus of a solid influences the speed

of sound and other mechanical waves in the

material. It also is a factor in the amount of

energy stored in solid material.

A common statement is that water is an incompressible fluid.

This is not strictly true, as indicated by its finite bulk modulus,

but the amount of compression is very small.

At the bottom of the Pacific Ocean at a depth of about 4000

meters, the pressure is about 4 x 107 N/m2. Even under this

enormous pressure, the fractional volume compression is only

about 1.8% and that for steel would be only about 0.025%.

So it is fair to say that water is nearly incompressible.

7/12/12

Young' s Modul us

In solid mechanics, Young' s modul us (E) is a measure of the stiffness of an isotropic

elastic material. It is also known as the Young modul us, modul us of el asti ci ty,

el asti c modul us (though Young's modulus is actually one of several elastic moduli such as the bul k

modul us and the shear modul us) or tensi l e modul us.

It is defined as the ratio of the uni-axial stress over the uni-axial strain in the range of

stress in which Hooke' s Law holds.

Young's modulus is named after Thomas Young, the 18th century British scientist. However, the concept was

developed in 1727 by Leonhard Euler.

For the description of the elastic properties of linear objects like wires, rods, columns

which are either stretched or compressed, a convenient parameter is the rati o of the

stress to the strai n, or Young' s modul us of the material. Young's modulus can be

used to predict the elongation or compression of an object as long as the stress is less

than the yield strength of the material.

This can be experimentally determined from the slope of a stress-strain curve created during tensile tests

conducted on a sample of the material.

Material

Densit

y

(kg/m3

)

Young's

Modulus

109

N/m2

Ultimate

Strength

Su

106

N/m2

Yield

Strength

Sy

106

N/m2

Steela 7860 200 400 250

Aluminum 2710 70 110 95

a Structural steel

7/12/12

shear modul us or modul us of ri gi di ty, denoted by G, or sometimes S or , is defined as the

ratio of shear stress to the shear strain:

Where = shear stress;

F is the force which acts and

A is the area on which the force acts

= shear strain;

x is the transverse displacement ,

I is the initial length

Shear modulus is usually measured in GPa (giga pascal)

The shear modulus is concerned with the deformation of a solid when it experiences a force

parallel to one of its surfaces while its opposite face experiences an opposing force (such as

friction). In the case of an object that's shaped like a rectangular prism, it will deform into a

parallelepiped.

Anisotropic materials such as wood and paper exhibit differing material response to stress or strain

when tested in different directions. In this case, when the deformation is small enough so that the

deformation is linear, the elastic moduli, including the shear modulus, will then be a tensor, rather

than a single scalar value. In homogeneous and isotropic solids, there are two kinds of waves, pressure waves and shear

waves. The velocity of a shear wave, (vs) is controlled by the shear modulus,

where

G is the shear modulus

is the solid's density.

shear modul us describes the material's response to shearing strains.

7/12/12

Hooke' s l aw

Hooke's law is named after the 17th century British physicist Robert Hooke.

He first stated this law in 1676 as a Latin anagram, whose solution he published in 1678 as Ut tensi o, si c vi s,

meaning: As the extension, so the force.

Objects that quickly regain their original shape after being deformed by a force, with the

molecules or atoms of their material returning to the initial state of stable equilibrium,

often obey Hooke's law. We may view a rod of any elastic material as a linear spring. The

rod has length L and cross-sectional area A. Its extension (strain) is linearly proportional

to its tensile stress by a constant factor, the inverse of its modulus of elasticity E,

hence, or

Hooke's law only holds for some materials under certain loading conditions. Steel exhibits linear-elastic behavior

in most engineering applications; Hooke's law is valid for it throughout its el asti c range (i.e., for stresses below

the yield strength). For some other materials, such as aluminium, Hooke's law is only valid for a portion of the

elastic range. For these materials a proportional limit stress is defined, below which the errors associated with the

linear approximation are negligible.

For systems that obey Hooke's law, the extension produced is directly proportional to the

load: where:

is the distance that the spring has been stretched or compressed away from the equilibrium

position, (meters),

is the restoring force exerted by the material (Newtons), and

is the force constant (or spri ng constant). The constant has units of force per unit length

(newtons per meter). When this holds, we say that the behavior is linear.

negative sign on the right hand side of the equation because the restoring force always acts in the opposite

direction of the x displacement.

7/12/12

Poi sson' s rati o ( ), named after Simeon Poisson, is the rati o of the rel ati ve contracti on

strai n, or transverse strai n (normal to the appl i ed l oad), to the rel ati ve extensi on

strai n, or axi al strai n (i n the di recti on of the appl i ed l oad).

When a sample of material is stretched in one direction,

it tends to contract (or rarely, expand) in the other two directions.

Conversely, when a sample of material is compressed in one direction,

it tends to expand (or rarely, contract) in the other two directions.

Poi sson' s rati o ( ) i s a measure of thi s tendency.

The Poisson's ratio of a stable material cannot be

less than 1.0 nor greater than 0.5 due to the

requirement that the elastic modulus,

the shear modulus and bulk modulus

have positive values.

Assuming that the material is compressed along the axial direction:

where, is the resulting Poisson's ratio,

is transverse strain (negative for axial tension, positive for axial compression)

is axial strain (positive for axial tension, negative for axial compression).

On the molecular level, Poissons effect is caused by slight movements between molecules and the stretching of

molecular bonds within the material lattice to accommodate the stress. When the bonds elongate in the stress

direction, they shorten in the other directions. This behavior multiplied millions of times throughout the material

lattice is what drives the phenomenon.

Most materials have between 0.0 and 0.5. Cork is close to 0.0, showing almost no Poisson contraction, most

steels are around 0.3, and rubber is nearly incompressible and so has a Poisson ratio of nearly 0.5. A perfectly

incompressible material deformed elastically at small strains would have a Poisson's ratio of exactly 0.5. Some

materials, mostly polymer foams, have a negative Poisson's ratio; if these auxeti c materials are stretched in one

direction, they become thicker in perpendicular directions.

7/12/12

Generalised Hooke's law : For an isotropic material, the deformation of a material in the

direction of one axis will produce a deformation of the material along the other axes in three

dimensions. Thus it is possible to generalise Hooke's Law into three dimensions:

Where , and are strain in the direction of x, y and z axis

x , y and z are stress in the direction of x, y and z axis

E is Young's modulus (the same in all directions: x, y and z for isotropic materials)

is Poisson's ratio (the same in all directions: x, y and z for isotropic materials)

Vol umetri c change: The relative change of volume V /V due to the stretch of the

material can be calculated using a simplified formula (only for small deformations):

Where V is material volume

V is material volume change

L is original length, before stretch

L is the change of length: L = Lnew Lold

If a rod with diameter (or width, or thickness) d and length L is subject to tension so that its length will change

by L then its diameter d will change by (the value is negative, because the diameter will decrease with

increasing length):

The above formula is true only in the case of small deformations; if deformations are large then the following

(more precise) formula can be used

For Orthotropic material, such as wood in which Poisson's ratio is different in each direction (x, y and z axis) the

relation between Young's modulus and Poisson's ratio is described as

Ei is a Young's modulus along axis i and jk is a Poisson's ratio in plane jk

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

A 2.5 cm diameter steel bolt passes through a steel tube 5 cm internal diameter, 6.25cm external

diameter, and 40 cm long. The bolt is then tightened up onto the tube through rigid end blocks

until the tensile force in the bolts is 40 kN. The distance between the head of the bolt and the nut

is 50 cm. If an external force of 30 kN is applied to the end blocks, tending to pull them apart,

estimate the resulting tensile force in the bolt.

7/12/12

A cylindrical block is 30 cm long and has a circular cross-section 10 cm in

diameter. It carries a total compressive load of 70 kN, and under this load it

contracts by 0.02 cm. Estimate the average compressive stress over a normal

cross-section and the compressive strain.

7/12/12

The pressure on the back of the piston acts

on a net area

The load on the piston is then

Area of the piston rod is

The average tensile stress in the rod is then

From equation , the elongation of a length

of 1 m is,

7/12/12

The cross-sectional area is

The tensile stress is then

The measured tensile strain is

Then Youngs modulus is defined by

7/12/12

1.4

7/12/12

7/12/12

7/12/12

a

)

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

Composi te bars i n tensi on or compressi on

A composite bar is one made of two materials, such as steel rods embedded in concrete. The

construction of the bar is such that constituent components extend or contract equally under load.

To illustrate the behaviour of such bars consider a rod made of two materials, 1 and 2, Figure ;

A1, A2, are the cross-sectional areas of the bars, and E1, E2 are the values of Young's modulus.

We imagine the bars to be rigidly connected together at the ends; then for compati bi l i ty, the

longitudinal strains to be the same when the composite bar is stretched

we must have

7/12/12

Stati cal l y Determi nate Structures:

Figure shows a rigid beam BD supported by two vertical wires BF and

DG; the beam carries a force of 4W at C. We suppose the wires extend by

negligibly small amounts, so that the geometrical configuration of the

structure is practically unaffected; then for equilibrium the forces in the

wires must be 3 W in BF and W in DG. As the forces in the wires are

known, it is a simple matter to calculate their extensions and hence to

determine the displacement of any point of the beam.

The calculation of the forces in the wires and structure of Figure is said to

be stati cal l y determi nate.

If, however, the rigid beam be supported by three wires,

with an additional wire, say, between H and J, then

the forces in the three wires cannot be solved by

considering statical equilibrium alone;

such a structure is stati cal l y i ndetermi nate.

If the frame has just sufficient bars or rods to prevent collapse without the application of external

forces, it is said to be si mpl y-sti ff, when there are more bars or rods than this, the frame is said

to be redundant.

If m be the total number of members and j is the total number of

joints, we must have m = 2j 3, if the frame is to be simply-

stiff or statically determinate.

7/12/12

A type of stress analysis problem in which internal stresses are not calculable on considering

statical equilibrium alone; such problems are statically indeterminate. Consider the rigid beam BD

of Figure which is supported on three wires; suppose the tensions in the wires are T1 , T2 and

T3. Then by resolving forces vertically, we have T 1 + T 2 + T 3 = 4W .. (1)

and by taking moments about the point C, T 1 T 2 3 T 3 = 0 .. (2)

From these equilibrium equations alone we cannot derive the values of the three tensile forces;

a third equation is found by discussing the extensions of the wires or considering compatibility.

If the wires extend by amounts e 1 , e 2 , e 3 we must have from Figure (ii) that

e 1 + e 3 = 2e 2 . (3) because the beam BD is rigid.

Suppose the wires are all of the same material and

cross-sectional area, and that they remain elastic.

Then we may write , , .

Where is a constant common to the three wires.

Then equation (3) becomes T 1 + T 3 = 2 T 2 .. (4)

The three equations (1), (2) and (4) then give

Equation (3) is a condition which the extensions of the wires must satisfy.

It is called a strai n compati bi l i ty condi ti on.

Statically indeterminate problems are soluble if strai n compati bi l i ti es are consi dered as wel l as stati cal

equi l i bri um.

Stati cal l y Indetermi nate Structures:

7/12/12

Temperature stresses

Temperature stresses i n composi te bars:

Suppose the bar and tube are quite free of each other;

if Lo is the original length of each bar, the extensions

due to a temperature increase

Difference in lengths of the two members is

Refer Figure (iii),this is now eliminated by compressing

the inner bar with a force P, and pulling the outer tube

with an equal force P.

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

7/12/12

Di rect stresses tend to change the volume of the material (e.g.

hydrostatic pressure) and are resisted by the body's bulk modulus

(which depends on the Young's modulus and Poisson ratio).

Shear stresses tend to deform the material without changing its

volume, and are resisted by the body's shear modulus.

Defining a set of internal datum planes aligned with a Cartesian

coordinate system allows the stress state at an internal point P to

be described relative to x, y, and z coordinate directions.

The subscript notation used for the nine stress components have the

following meaning:

For example, the stress state at point P can be represented by an infinitesimal cube with three

stress components on each of its six sides (one direct and two shear components).

Since each point in the body is under static equilibrium (no net force in the absence of any body

forces), only nine stress components from three planes are needed to describe the stress state at a

point P. These nine components can be organised into the matrix:

where shear stresses across the diagonal are identical

(i.e. xy = yx , yz = zy and zx = xz)

as a result of static equilibrium (no net moment).

This grouping of the nine stress components is known as

the stress tensor (or stress matrix).

7/12/12

Consider the static equilibrium of a solid subjected to the body force vector field b.

Applying Newton's first law of motion results in the following set of differential equations

which govern the stress distribution within the solid,

In the case of two dimensional stress, the above equations reduce to,

Equati ons of

Equi l i bri um

Note: The stress state is a second order tensor since it is a quantity associated with two directions.

As a result, stress components have 2 subscripts.

A surface traction is a first order tensor (i.e. vector) since it is a quantity associated with only one

direction. Vector components therefore require only 1 subscript.

Mass would be an example of a zero-order tensor (i.e. scalars), which have no relationships with

directions (and no subscripts).

7/12/12

PLANE STATE of STRESS

Common engineering problems involving stresses in a thin plate or on the free surface of

a structural element, such as the surfaces of thin-walled pressure vessels under external

or internal pressure, the free surfaces of shafts in torsion and beams under transverse

load, have one principal stress that is much smaller than the other two.

By assuming that this small principal stress is zero, the three-dimensional stress state can

be reduced to two dimensions. Since the remaining two principal stresses lie in a plane,

these simplified 2D problems are called pl ane stress problems.

Assume that the negligible principal stress

is oriented in the z-direction. To reduce the

3D stress matrix to the 2D plane stress matrix,

remove all components with z subscripts to get,

Where xy = yx for static equilibrium.

The sign convention for positive stress components

in plane stress is illustrated in the above figure on the 2D element.

7/12/12

7/12/12

7/12/12

7/12/12

The normal stresses (x' and y') and the shear stress (x'y') vary smoothly with respect

to the rotation angle , in accordance with the coordinate transformation equations. There

exist a couple of particular angles where the stresses take on special values. First, there

exists an angle p where the shear stress x' y' becomes zero. That angle is found by

setting x' y' to zero in the above shear transformation equation and solving for (set

equal to p). The result is,

The angle p defines the principal directions where the only stresses are normal stresses.

These stresses are called principal stresses and are found from the original stresses

(expressed in the x,y,z directions) via,

Pri nci pal Di recti ons, Pri nci pal Stress

7/12/12

Coordinate Transformations

The coordinate directions chosen to analyse a structure are usually based on the shape of

the structure. As a result, the direct and shear stress components are associated with

these directions. For example, to analyse a bar one almost always directs one of the coordinate directions

along the bar's axis.

Stresses in directions that do not line up with the original coordinate set are also

important. For example, the failure plane of a brittle shaft under torsion is often at a 45 angle with respect to

the shaft's axis. Stress transformation formulas are required to analyse these stresses.

The transformation of stresses with respect to the {x,y,z}

coordinates to the stresses with respect to {x',y',z'}

is performed via the equations, where is the rotation

angle between the two coordinate sets

(positive in the counterclockwise direction).

7/12/12

The transformation to the principal directions can be illustrated as:

7/12/12

Maxi mum Shear Stress

Di recti on Another important angle s is where the maximum shear stress occurs. This is found by finding

the maximum of the shear stress transformation equation, and solving for . The result is,

The maximum shear stress is equal to one-half the difference between the two principal stresses,

The transformation to the maximum shear stress direction can be illustrated as:

7/12/12

Mohr's Circle

Introduced by Otto Mohr in 1882, Mohr's Circle illustrates principal stresses and stress

transformations via a graphical format,

The two principal stresses are shown in red, and the maximum shear stress is shown in orange.

Recall that the normal stresses equal the principal stresses when the stress element is aligned with

the principal directions, and the shear stress equals the maximum shear stress when the stress

element is rotated 45 away from the principal directions.

As the stress element is rotated away from the principal (or maximum shear) directions, the normal

and shear stress components will always lie on Mohr's Circle.

7/12/12

Deri vati on of Mohr' s

Ci rcl e

To establish Mohr's Circle, we first recall the stress transformation formulas for plane

stress at a given location,

Using a basic trigonometric relation (cos2 2 + sin2 2 = 1) to combine the two above

equations we have,

This is the equation of a circle, plotted on a graph where the abscissa is the normal stress

and the ordinate is the shear stress. This is easier to see if we interpret x and y as

being the two principal stresses, and xy as being the maximum shear stress. Then we

can define the average stress, avg and a "radius" R (which is just equal to the

maximum shear stress),

7/12/12

The circle equation above now takes on a more familiar form,

The circle is centered at the average stress value, and has a radius R equal to

the maximum shear stress, as shown in the figure below,

7/12/12

Pri nci pal Stresses from Mohr' s Ci rcl e

A chief benefit of Mohr's circle is that the principal stresses 1 and 2 and the maximum

shear stress max are obtained immediately after drawing the circle,

where,

7/12/12

Pri nci pal Di recti ons from Mohr' s Ci rcl e

Mohr's Circle can be used to find the directions of the principal axes. To show this, first

suppose that the normal and shear stresses, x , y and xy are obtained at a given point

O in the body. They are expressed relative to the coordinates XY, as shown in the stress

element at right below.

The Mohr's Circle for this general stress state is shown at left above. Note that it's

centered at avg and has a radius R, and that the two points {x , txy} and {y , -txy} lie

on opposites sides of the circle. The line connecting x and y will be defined as Lxy.

7/12/12

The angl e between the current axes (X and Y) and the pri nci pal axes is defined as p

and is equal to one half the angle between the line Lxy and the -axis as shown in the

schematic below,

Rotati on Angl e on Mohr' s Ci rcl e

Note that the coordinate rotation angle p is defined positive when starting at the XY coordinates

and proceeding to the XpYp coordinates. In contrast, on the Mohr's Circle p is defined positive

starting on the principal stress line (i.e. the -axis) and proceeding to the XY stress line (i.e. line

Lxy). The angle p has the opposite sense between the two figures, because on one it starts on

the XY coordinates, and on the other it starts on the principal coordinates.

7/12/12

The principal axes are counterclockwise

to the current axes (because xy > 0)

and no more than 45 away

(because x > y).

Case 1: xy > 0 and x >

y

Case 2: xy < 0 and x

> y

The principal axes are clockwise to the

current axes (because xy < 0)

and no more than 45 away

(because x > y)

A set of six Mohr's Circles representing most stress state possibilities are presented

7/12/12

Case 3: xy > 0 and x <

y

The principal axes are counterclockwise

to the current axes (because xy > 0)

and between 45 and 90 away.

(because x < y)

Case 4: xy < 0 and x <

y

The principal axes are clockwise to the

current axes (because xy < 0) and

between 45 and 90 away.

(because x < y)

7/12/12

Case 5: xy = 0 and x

> y

The principal axes are aligned with

the current axes.

(because x > y and xy = 0).

Case 6: xy = 0 and x

< y

The principal axes are exactly 90 from

the current axes

(because x < y and xy = 0).

7/12/12

Stress Transform by Mohr' s

Ci rcl e

Mohr's Circle can be used to transform stresses from one coordinate set to another,

similar to that described on the plane stress . Suppose that the normal and shear stresses,

x , y and xy, are obtained at a point O in the body, expressed with respect to the

coordinates XY. We wish to find the stresses expressed in the new coordinate set X'Y',

rotated an angle q from XY, as shown below:

Plane

Stress

7/12/12

To do this we proceed as follows:

Step 1: Draw Mohr's circle for the gi ven stress state ( x , y and xy).

Step 2: Draw the line Lxy across the circle from (x , xy) to (y , - xy).

Step 3: Rotate the line Lxy by 2* (twice as much as the angle between XY and X'Y')

and in the opposite direction of .

Step 4: The stresses i n the new coordi nates (x' , y' and x'y ) are then read

off the circle.

7/12/12

Mohr' s Ci rcl e For PLANE

STRAIN

Strains at a point in the body can be illustrated by Mohr's Circle. The idea and procedures

are exactly the same as for Mohr's Circle for plane stress.

The two principal strains are shown in red, and the maximum shear strain is shown in

orange. Recall that the normal strains are equal to the principal strains when the element

is aligned with the principal directions, and the shear strain is equal to the maximum

shear strain when the element is rotated 45 away from the principal directions.

As the element is rotated away from the principal (or maximum strain) directions, the

normal and shear strain components will always lie on Mohr's Circle.

7/12/12

To establish the Mohr's circle, we first recall the strain transformation formulas for plane

strain,

Deri vati on of Mohr' s

Ci rcl e

Using a basic trigonometric relation (cos22+ sin22 = 1) to combine the above two

formulas we have,

This equation is an equation for a circle. To make this more apparent, we can

rewrite it as,

where,

The circle is centered at the average strain value

Avg and has a radius R equal to the maximum

shear strain, as shown in the figure.

7/12/12

Pri nci pal Strai ns from Mohr' s Ci rcl e

A chief benefit of Mohr's circle is that the principal strains 1 and 2 and the maximum

shear strain xyMax are obtained immediately after drawing the circle,

where,

7/12/12

Mohr's Circle can be used to find the directions of the principal axes. To show this, first

suppose that the normal and shear strains, x , y and xy are obtained at a given point

O in the body. They are expressed relative to the coordinates XY, as shown in the strain

element at right below.

Pri nci pal Di recti ons from Mohr' s Ci rcl e

The Mohr's Circle for this general strain state is shown at left above. Note that it's

centered at Avg and has a radius R, and that the two points (x , xy) and (y , - xy)

lie on opposites sides of the circle. The line connecting x and y will be defined as Lxy.

7/12/12

The angl e between the current axes (X and Y) and the pri nci pal axes is defined as p

and is equal to one half the angle between the line Lxy and the -axis as shown

Note that the coordinate rotation angle p is defined positive when starting at the XY coordinates

and proceeding to the XpYp coordinates. In contrast, on the Mohr's Circle p is defined positive

starting on the principal strain line (i.e. the -axis) and proceeding to the XY strain line (i.e. line

Lxy). The angle p has the opposite sense between the two figures, because on one it starts on

the XY coordinates, and on the other it starts on the principal coordinates.

Rotati on Angl e on Mohr' s

Ci rcl e

7/12/12

Strai n Transform by Mohr' s

Ci rcl e

Mohr's Circle can be used to transform strains from one coordinate set to another, similar

that that described on the plane strain page. Suppose that the normal and shear strains,

x , y and xy are obtained at a point O in the body, expressed with respect to the

coordinates XY. We wish to find the strains expressed in the new coordinate set X'Y',

rotated an angle from XY, as shown below:

7/12/12

To do this we proceed as follows:

Step 1: Draw Mohr's circle for the gi ven strai n state (x , y and xy shown below).

Step 2: Draw the line Lxy across the circle from (x, xy) to (y, - xy).

Step 3: Rotate the line Lxy by 2* (twice as much as the angle between XY and X'Y') and

in the opposite direction of .

Step 4: The strai ns i n the new coordi nates (x' , y' and x'y ) are then read.

7/12/12

Case 1: xy > 0 and x

> y

The principal axes are counterclockwise to the

current axes (because xy > 0) and

no more than 45 away

(because x > y).

Case 2: xy < 0 and x

> y

The principal axes are clockwise to the

current axes (because xy < 0) and

no more than 45 away

(because x > y).

7/12/12

Case 3: xy > 0 and x

< y

The principal axes are counterclockwise to the

current axes (because xy > 0) and between

45 and 90 away (because x < y).

Case 4: xy < 0 and x <

y

The principal axes are clockwise to the

current axes (because xy < 0)

and between 45 and 90 away

(because x < y).

7/12/12

Case 5: xy = 0 and x

> y

The principal axes are aligned with

the current axes

(because x > y and xy = 0).

Case 6: xy = 0 and x

< y

The principal axes are exactly 90

from the current axes

(because x < y and xy = 0).

7/12/12

One-di mensi onal Hooke' s Law : Robert Hooke, who in 1676 stated

General i sed Hooke' s Law (Ani sotropi c Form)

Cauchy generalised Hooke's law to three dimensional elastic bodies and stated that the 6

components of stress are linearly related to the 6 components of strain. The stress-strain

relationship written in matrix form, where the 6 components of stress and strain are organised into

column vectors, is,

ie., = S

The power (sic.) of any springy body is in the same proportion with the extension.

announced the birth of elasticity. Hooke's statement expressed mathematically ,

where F is the applied force (and not the power, as Hooke mistakenly suggested), u is the

deformation of the elastic body subjected to the force F, and k is the spring constant (i.e. the ratio

of previous two parameters).

or

ie., =

C

where, C is the compliance matrix, S is the stiffness matrix and S = C-1.

7/12/12

Orthotropi c

Defi ni ti on

Some engineering materials, including certain piezoelectric materials (e.g. Rochelle salt)

and 2-ply fiber-reinforced composites, are orthotropi c.

By definition, an orthotropic material has at least 2 orthogonal planes of symmetry, where

material properties are independent of direction within each plane. Such materials require

9 independent variables (i.e. elastic constants) in their constitutive matrices.

In contrast, a material without any planes of symmetry is fully anisotropic and requires 21

elastic constants, whereas a material with an infinite number of symmetry planes (i.e.

every plane is a plane of symmetry) is isotropic, and requires only 2 elastic constants.

Hooke' s Law i n Compl i ance

Form

By convention, the 9 elastic constants in orthotropic constitutive equations are comprised

of 3 Young's moduli Ex , Ey , Ez , the 3 Poisson's ratios yz , zx , xy and the 3

shear moduli Gyz , Gzx , Gxy

The shear modulus G is related to E and

7/12/12

A wire strain gage can effectively measure strain in only one direction. To determine the

three independent components of plane strain, three linearly independent strain measures

are needed, i.e., three strain gages positioned in a rosette-like layout.

Consider a strain rosette attached on the surface with an angle from the x-axis. The

rosette itself contains three strain gages with the internal angles and , as illustrated.

Suppose that the strain measured from these

three strain gages are a , b and c respectively.

The following coordinate transformation equation

is used to convert the longitudinal strain from each

strain gage into strain expressed in the x-y coordinates,

Applying this equation to each of the three strain gages

results in the following system of equations,

Strai n Rosette for Strai n Measurement

These equations are then used to

solve for the three unknowns, x, y,

and xy.

7/12/12

Note: 1. The above formulas use the strain measure xy as opposed to the engineering shear

strain xy . .To use xy, the above equations should be adjusted

accordingly.

2. The free surface on which the strain rosette is attached is actually in a state of plane stress,

while the formulas used above are for plane strain. However, the normal direction of the free

surface is indeed a principal axis for strain. Therefore, the strain transform in the free surface plane

can be applied.

Special Cases of Strain Rosette Layouts

Case 1: 45 strain rosette aligned with

the x-y axes, i.e., = 0, = = 45.

Case 2: 60 strain rosette, the middle

of which is aligned with the y-axis,

i.e., = 30, = = 60.

7/12/12

The strain gage is one of the most widely used strain measurement sensors. It is a

resistive elastic unit whose change in resistance is a function of applied strain.

where R is the resistance, is the strain, and S is the strain sensitivity factor of the gage

material (also called as gage factor).

Among strain gages, an electric resistance wire strain gage has the

advantages of lower cost and being an established product.

Thus it is the most commonly used type of device.

Other types of strain gages are acoustic, capacitive, inductive, mechanical, optical, piezo-resistive, and semi-

conductive.

A wire strain gage is made by a resistor, usually in metal foil form, bonded on an elastic

backing.

Its principle is based on fact that the resistance of a wire increases with increasing strain and decreases with

decreasing strain, as first reported by Lord Kelvin in 1856.

Consider a wire strain gage, as illustrated above. The wire is composed of a uniform

conductor of electric resistivity r with length l and cross-section area A. Its resistance R is

a function of the geometry given by

Electric Resistance Strain Gages

7/12/12

The resistance change rate is a combination effect of changes in length, cross-section

area, and resistivity.

When the strain gage is attached and bonded well to the surface of an object, the two are

considered to deform together.

The strai n of the strai n gage wi re al ong the l ongi tudi nal di recti on i s the

same as the strai n on the surface i n the same di recti on.

However, its cross-sectional area will also change due to the Poisson's ratio. Suppose that

the wire is cylindrical with initial radius r, the normal strain along the radial direction is

The change rate of cross-section area is twice as the radial strain, when the strain is

small.

7/12/12

The resistance change rate becomes

For a given material, the sensitivity of resistance versus strain can be calibrated by the

following equation.

When the sensitivity factor S is given, (usually provided by strain gage vendors) the

average strain at the point of attachment of the strain gage can be obtained by measuring

the change in electric resistance of the strain gage.

Since most metal materials have the Poisson's ratio around 0.25 to 0.35, the (1 + 2 ) term in the

strain sensitivity factor S is expected to be 1.5 to 1.7.

However, the strain sensitivity factor S itself ranges from -12.1 in Nickel up to 6.1 in Platinum.

This wide variation indicates that the change in electric resistivity r , the so called piezo-resistance

effect, can be quite large in some materials.

Click to edit Master subtitle style

7/12/12

UNIT 3

Distribution of Bending Stress and

Shear Stress in a cross section of Beams

SFD and BMD for propped cantilever,

built-in beams, continuous beams.

Prof. Dr. R. Chandra Sekaran Ph.D (C.Engg)

7/12/12

Beams:

Consider first the simple case of a beam which is fixed rigidly at one end B and is quite free at

its remote end D, Figure 1 ; such a beam is called a canti l ever. Imagine that the cantilever is

horizontal, with one end B embedded in a wall, and that a lateral force W is applied at the free end

D. Suppose the cantilever is divided into two lengths by an imaginary section C; the lengths BC

and CD must individually be in a state of stati cal equi l i bri um. If we neglect the mass of the

cantilever itself, the loading actions over the section C of CD balance the actions of the force W at

C. The length CD of the cantilever is in equilibrium if we apply an upwards vertical force F and an

anti-clockwise couple M at C; F is equal in magnitude to W, and M is equal to W(L - z), where z

is measured from B. The force F at C is called a sheari ng force, and the couple M is a bendi ng

moment. But at the imaginary section C of the cantilever, the actions F and M on CD are

provided by the length BC of the cantilever. In fact, equal and opposite actions F and M are

applied by CD to BC. For the length BC, the actions at C are a downwards shearing force F, and a

clockwise couple M.

7/12/12

When the cantilever carries external loads which are not applied

normally to the axis of the beam, Figure 2, axial forces are set up in

the beam. If W is inclined at an angle to the axis of the beam the

axial thrust in the beam at any section is

The bending moment and shearing force at a section a distance z

from the built-in end are

Rel ati on between the i ntensi ty of l oadi ng, SF and BM:

Consider a straight beam under any system of lateral loads and

external couples, Figure 3; an element length z of the beam at a

distance z from one end is acted upon by an external lateral load,

and internal bending moments and shearing forces.

Suppose external lateral loads are distributed so that the intensity

of loading on the elemental length z is w.

7/12/12

Then the external vertical force on the element is w z ; this is reacted by an internal bending

moment M and shearing force F on one face of the element, and M + M and F + F on

the other face of the element.

For vertical equilibrium of the element we have,

If z is infinitesimally small,

Suppose this relation is integrated between the limits z1 and z2 then

If F1 and F2 are the shearing forces at z = z1 and z = z2 respectively, then

Furthermore, for rotational equilibrium of

the elemental length z,

neglecting higher orders Then, in the limit as z approaches

zero,

On integrating between the limits z = z1 and z2 we have

Thus

The shearing force F at a section distance z from one end of the beam is

On substituting this value of F into equation,

From equations & we have that the bending moment M has a stationary

value when the shearing force F is zero. Thus, we get

All the relations developed in this section are merely statements of statical equilibrium,

and are therefore true independently of the state of the material of the beam.

7/12/12

7/12/12

Basi c Cal cul us Concepts

This is a very basic review of introductory Calculus concepts. We first look at a quadratic function:

y = 9 x2 - 50 x + 50, which is graphed in Diagram 2.

This function has a slope at every point. If we take the "derivative" of our quadratic function, we

obtain a new function (y' = 18 x - 50), which is graphed in Diagram 1.

The 'derivative' function gives us the value of the slope of our quadratic function at every

point. (Thus at x = 2, the slope of the quadratic function is 18 * 2 - 50 = -14)

7/12/12

If on the other hand we "integrate" our quadratic function, we obtain a new function

(y* = 3 x3 - 25 x2 + 50 x), which is graphed in Diagram 3 directly below Diagram 1.

The 'integrated' function tells us the net area under the quadratic function curve (between

the function curve and the x axis). It actually tells us the area between some beginning x-

value and ending x-value (when we do what is called a definite integral).

For the integrated function above, the initial x value is zero and the ending x-value is what ever

value we choose. That is for x = 2, the area under the quadratic function curve between zero

and 2 is: A = 3 (2)3 -25 (2)2 + 50 (2) = 24.

Thus every y value on the curve

in Diagram 3 is equal to the

sum of the area under the curve

in Diagram 2 up to that point.

7/12/12

We can also do an "indefinite" integral which results in 'integrated' function involving a

constant - which is evaluated by applying a boundary condition.

Let us review some basic derivatives

d/dx (any constant) = 0 , d/dx (x) = 1, d/dx (x2) = 2x , d/dx (x3) = 3x2 , d/dx (xn) = n xn-1

A second way to think of derivatives and integrals is as inverse functions of each other. That

is, the integral asks the question - what function must we take the derivative of to obtain what

is inside the integral sign.

Look at the indefinite integral . This integral asks the question - what function

must we take the derivative of to obtain 'x' (what is inside the integral sign).

Some basic integrals,

that is, the integral of a sum (or difference) is the sum (or difference) of the integrals.

, where A is any constant

7/12/12

Shearing Force

The shearing force (SF) at any section of a beam represents the tendency for the portion of

the beam on one side of the section to slide or shear laterally relative to the other portion.

The diagram shows a beam carrying loads of W1, W2 and W3 and is simply supported at two points

where the reactions are R1 and R2.

Assume that the beam is divided into two parts by a section XX .

The resultant of the loads and reaction acting on the left of AA is F vertically upwards and

since the whole beam is in equilibrium, the resultant force to the right of AA must be F

downwards.

F is called the Shearing Force at the section AA. It may be defined as follows:-

The shearing force at any section of a beam is the algebraic sum of the lateral components of

the forces acting on either side of the section.

Where forces are neither in the lateral or axial direction they must be resolved in the usual

way and only the lateral components used to calculate the shear force.

7/12/12

In a similar manner if the Bending moments (BM) of the forces to the left of AA are

clockwise then the bending moment of the forces to the right of AA must be anticlockwise.

Bending Moment at AA is defined as the algebraic sum of the moments about the section

of all forces acting on either side of the section

Bending moments are considered positive when the moment on the left portion is clockwise

and on the right anticlockwise.

This is referred to as a sagging bending moment as it tends to make the beam concave

upwards at AA.

A negative bending moment is termed hogging.

Bending Moments

7/12/12

Shear Force - Moment Relationship

Consider a short length of a beam under a distributed load separated by a distance x.

The bending moment at section AD is M and

the shear force is S.

The bending moment at BC = M + M and

The shear force is S + S.

The equations for equilibrium in 2 dimensions

results in the equations.. Forces.

S - w.x = S + S

Therefore making x infinitely small, dS /dx = - w

Moments.. Taking moments about C

M + Sx - M - M - w(x)2 /2 = 0

Therefore making x infinitely small then dM /dx = S

and putting the relationship into integral form.

The integral (Area) of the shear diagram

between any limits results in the change of

the shearing force between these limits

and

the integral of the Shear Force diagram

between limits results in the change in

bending moment...

7/12/12

To understand the shear forces and bending moments in a beam, we will look at a simple example.

In Diagram 1, we have shown a simply supported 20 m beam with a load of 10,000 N . acting

downward right at the center of the beam. Due to symmetry the two support forces will be equal,

with a value of 5000 each. This is the static equilibrium condition for the whole beam.

Next examine a section of the beam.

We will cut the beam at an arbitrary distance (x) between 0

and 10 feet, and apply static equilibrium conditions to the

left end section as shown in Diagram 2..

We can do this since as the entire beam is in static

equilibrium, then a section of the beam must also be in

equilibrium.

Note: M is a moment or torque - not a force. It does not

appear in the sum of forces equation when we apply

static equilibrium to the section

7/12/12

Equilibrium Conditions:

Sum of Forces in y-direction: + 5000 - V = 0 , solving V = 5000.

Sum of Toque about left end: -V * x + M = 0 , or - 5000 * x + M = 0 ,

M = 5000 x.

These are the equations for the shear force and bending moments for the section of the beam from

0 to 10 feet.

Notice that the internal shear force is a constant value of 5000 for the section, but the value of

the internal torque (bending moment) varies from 0 at x = 0, to a value of 50,000 at x = 10.

We cut the beam at distance x from the left end, where x is now greater than 10 and less then 20

and then look at entire section to the left of where we cut the beam (See Diagram 3).

Where the beam was cut, we have an internal shear force and bending moment - which now

become external. These are shown in Diagram 3 as V2 and M2.

(We add the '2', to indicate we are looking at section two of the beam.)

7/12/12

Equilibrium Conditions:

Sum of Forces in y-direction: + 5000 - 10,000 - V = 0 , solving V2 = -5000

Sum of Toque about left end: -10,000 * 10 -V * x + M = 0 , or

-10,000 * 10 - (-5000 ) * x + M = 0 , then solving

M2 = -[5000x - 100,000]

The two expressions above give the value of the internal shear force and bending moment in the

beam, between the distances of the 10 and 20.

A useful way to visualise this information is to make Shear Force and Bending Moment

Diagrams - which are really the graphs of the shear force and bending moment expressions

over the length of the beam. (See Diagram 4.)

7/12/12

SIGN CONVENTION

The signs associated with the shear force and bending moment are defined in a different

manner than the signs associated with forces and moments in static equilibrium.

The Shear Force is positive if it tends to rotate the beam section clockwise with respect to a

point inside the beam section.

The Bending Moment is positive if it tends to bend the beam section concave facing upward.

(Or if it tends to put the top of the beam into compression and the bottom of the beam into tension.)

Diagram 1, Shear Force V and Bending

Moment M acting in positive directions.

Diagram 2, V is not shown but the horizontal force Fx is shown.

7/12/12

A loaded, simply supported beam is shown. For this beam we would like to determine expressions

for the internal shear forces and bending moments in each section of the beam, and to make shear

force and bending moment diagrams for the beam.

Part A.

We first find the support forces acting

on the structure. We do this in the

normal way, by applying static

equilibrium conditions for the beam.

STEP 1: Draw a free body diagram showing and labeling

all load forces and support (reaction) forces, as well as

any needed angles and dimensions.

STEP 2: Break any forces not already in x and y direction

into their x and y components.

STEP 3: Apply the equilibrium conditions.

Sum Fy = -4,000 - (1,000 )(8) - 6,000 + By + Dy = 0

Sum TB = (Dy)(8) - (6,000)(4) + (1,000)(8)(4) + (4,000)(8) = 0

Solving for the unknowns: By =23,000; Dy = -5,000

(The negative sign indicates that Dy acts the opposite

of the initial direction we chose.)

7/12/12

Part B: Now we will determine the Shear Force and Bending Moment expressions for each

section of the loaded beam.

For this process we will cut the beam into sections, and then use the translational equilibrium

condition for the beam section (Sum of Forces = zero) to determine the Shear Force expressions in

each section.

Determining the Bending Moment expression for each section of the beam may be done in two

ways.

1) By applying the rotational equilibrium condition for the beam section (Sum of Torque =

zero), and solving for the bending moment.

2) By Integration. The value of the bending moment in the beam may be found from . That

is, the bending moment expression is the integral of the shear force expression

for the beam section.

We begin by starting at the left end of the beam, and cutting the beam a distance "x" from the left

end - where x is a distance greater than zero and less the position where the loading of the beam

changes in some way. In this problem we see that from zero to eight feet there is a uniformly

distributed load of 1000 lb./ft. However this ends at eight feet (the loading changes). Thus for

section 1, we will cut the beam at distance x from the left end, where x is greater than zero and less

then eight feet.

7/12/12

Section 1: Cut the beam at x, where 0 < x < 8 ft., and

analyse left hand section.

1. Draw a FBD of the beam section shown and labeling all

forces and toque acting - including the shear force and

bending moment (which act as an external force and torque

at the point where we cut the beam.) (See Diagram - Section

1)

Notice we have drawn the shear force and bending

moment in their positive directions according to the

defined sign convention and have labeled them as V1 and

M1, as this is section 1 of the beam.

2. We check that we have all forces in x & y components

3. Apply translational equilibrium conditions to determine

the shear force expression.

Sum Fx = 0 (no net external x- forces)

Sum Fy = -4,000 - 1,000 *(x) - V1 = 0 ; and

solving: V1 = [-4,000 - 1,000x]

This expression gives us the values of the internal shear force in the beam between 0 and 8. Notice

as x nears zero, the shear force value in the beam goes to 4000 , and as x approaches 8 the

shear force value becomes -12,000 , and that is negative everywhere between 0 and 8

7/12/12

Referring to the free body diagram for beam section 1,

Sum Torque left end = -1000 * (x) * (x/2) - V1 (x) + M1 = 0

Substitute the expression for V1 (V1 = [-4,000 - 1,000x])

Sum Torque left end = -1000 * (x) * (x/2) -[-4,000 - 1,000x] (x)

+ M1 = 0 ;

and solving for M1 = [-500x2 - 4,000x].

Obtain the expression for the bending moment by integration of

the shear force expression.

- 1000(1/2 x2) - 4000 (x) + C1; so M1 = -500x2 - 4,000x + C1

To determine the correct value for C1 for our

problem we must apply a boundary condition: That

is, we must know the value of the bending moment

at some point on our interval into, to find the

constant.

For simply supported beams (with no external torque

applied to the beam) the value of the bending moment

will be zero at the ends of the beam. So we have for